A blind area is a strip around a building, which is constructed from materials that do not allow water to pass through. Everyone could see it, just not everyone knows what it is.

The base of the building is subject to serious influences from ground moisture and precipitation. Every winter, the soil freezes and puts increased pressure on the walls of the basement or crawl space. The blind area was created to alleviate the fate of the foundations. The structure is a strip of monolithic or piece materials with a leveled underlying layer, made with a slight slope for unhindered water flow away from the building.

Necessity of design

The blind area removes moisture from the house and additionally insulates the foundation

The construction is necessary for the following reasons:

- Drainage of storm and melt water from the load-bearing structures of the building. Limiting contact of the foundation with aggressive substances in the soil.

- Creation of a heat-insulating layer that prevents freezing and heaving of the ground. Creating comfortable living conditions in the basement.

- Use as a path on which you can walk and push a wheelbarrow. If the concrete blind area around the house is thick enough, it can be used to park a car.

- Giving the building a spectacular, attractive and finished look.

When choosing a concrete blind area, you should give preference to the most durable, reliable and durable options.

Possible mistakes

To ensure strength, beginners tie the blind area to the foundation, drilling the reinforcement to the base. This is a common mistake because cracks will form as the building shrinks.

Arranging a blind area is a guarantee of reliable protection of the house from the influence of negative factors.

Arranging a blind area is a guarantee of reliable protection of the house from the influence of negative factors. Correctly carried out reinforcement will make the structure strong and durable and save on repair work.

Construction of a concrete blind area

The path along the house will effectively fulfill its purpose with proper design and high-quality construction.

The building codes and regulations establish the parameters of this structure:

- Level above ground. Regardless of the thickness of the concrete, it must be at least 50 mm to prevent water from contacting the walls of the building.

- The width of the line. It cannot be less than 120 cm. The size is set to exceed the roof level by 40 cm or more.

- Thickness. Determined by the expected load that will affect the structure. For a pedestrian it is 5 cm, if he is with a heavy wheelbarrow - 7-8 cm, and for a car - 15 cm.

- Slope. Attached to ensure rapid flow of water towards the ground or drainage system. It is 2-3%, you shouldn’t do more, as the risk of slipping increases.

- The gap between the blind area and the wall. Depending on the climate, it is taken within 10-20 mm. It should not be left open. A formwork board is inserted into the gap or it is filled with façade sealant.

- Drainage system. Must be at least 200mm wide and 100mm deep with a perforated pipe installed inside to drain water away from the building.

The blind area manufacturing technology is selected based on the type of soil, the depth of its freezing, the architecture of the building and the prevailing climate.

Necessary materials

The three main components for the construction of this concrete covering are:

Substrate material. This can be medium-sized sand, sand and gravel mixture or crushed stone. The thickness of the pillow is taken to be at least 20 centimeters.

Crushed stone is the best underlying material. The analogue is sand.

Material of the facing layer. Concrete for blind areas can be factory-made or self-prepared. It is important to choose a mixture with additives that increase frost resistance, which will prevent the appearance of cracks at low temperatures. For the blind area, it is better to use concrete of at least grade M200 or class B15. Often, the material used for production is M150 (B12.5), which belongs to the category of “lean” concrete. For such a blind area, reinforcement must be provided.

Concrete grade M-200 – cladding material

Fittings. Use rods with a diameter of 6 or 8 millimeters. The mesh is knitted with square cells with a side of 10 to 15 centimeters. At the intersection points, the rods are welded or connected with knitting wire. Welding is not used at the corners of the building, since it does not provide sufficient reliability. Reinforcement with steel rods laid along the walls is less effective, since it compensates only for longitudinal load, and transverse load can lead to cracks in the future.

Reinforcing mesh for blind areas - a more convenient replacement for reinforcing bars

In addition to the basic materials, you will need wooden boards for arranging expansion joints and assembling formwork. For formwork, boards 22 or 25 millimeters thick are sufficient.

To insulate the structure, extruded polystyrene foam, expanded clay, polystyrene foam, and sprayed polyurethane foam are used. Each of these materials has its own advantages and disadvantages. Most often, polystyrene foam is used for insulation. It is quite easy to install yourself, it has an attractive price, is resistant to temperature changes and is not susceptible to rotting.

Types of blind area

Paving slabs

There are several approaches to arranging a blind area, but in all cases its performance is of paramount importance, and only then issues of price and attractiveness are considered.

During the construction process the following materials can be used:

- Paving slabs. Construction stores can offer stone pavers, cement-based products, rubber, plastic and composite resin products. Considering that the sand-filled seams between the tiles allow water to pass through, a waterproofing gasket is placed under them.

- Concrete. The material is strong, durable, resistant to dampness and temperature changes. During the construction process, a home-made or factory-made solution can be used. To improve the quality of the mixture, dyes and plasticizers are added to it.

- Asphalt. It is extremely difficult to prepare, let alone evenly lay this substance. Renting a truck and compactor would be so expensive that it would not cover the benefits of the coating. One should also take into account the peculiarity of asphalt, which becomes soft in the heat and emits a pungent odor of bitumen.

- Crushed stone. Used as a base for laying natural or artificial turf. A waterproofing fabric is rolled out under the stone to remove water seeping through the coating. This blind area looks interesting and picturesque, but requires special care.

Asphalt

Crushed stone

Concrete

When planning construction, it is possible to combine coatings to achieve a better visual effect.

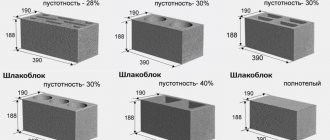

What types of mesh are most often used?

There are several types of reinforcement structures that are used to construct blind areas. Each of them has its own characteristics and features.

Regular

These are wire wires welded onto each other in a perpendicular position. It is lighter than the standard design.

It is supplied in roll form and is used when it is necessary to strengthen brickwork, asphalt concrete in a parking lot or in an industrial building, or a blind area.

Standard

It is characterized by medium sizes with a diameter of rods of 5-7 mm, which are intertwined at right angles.

The standard mesh is used for reinforcing foundation walls, floor slabs, and tightening the surface.

Metal

This is a durable material that is used to strengthen structures and building materials.

Metal fittings are resistant to all kinds of unfavorable operating conditions - atmospheric conditions, temperature changes, high humidity and exposure to chemical reagents.

Often such material is galvanized during manufacture using the galvanic method. It has a number of advantages over its unprocessed counterparts:

- long service life;

- resistance to external influences;

- resistance to mechanical stress;

- aesthetic appearance;

- high strength;

- ease of transportation;

- no special storage conditions are required;

- Corrosion is excluded on galvanized fittings.

Geogrid

This material contains polymers and fabric. A polypropylene product can be covered with rubber, fabric or geotextile materials.

More often, this material is used when it is necessary to strengthen the soil before laying asphalt concrete.

Do-it-yourself concrete blind area manufacturing technology

You need to start by making calculations and preparing the necessary tools.

To work you will need:

- concrete mixer, welding, grinder;

- pliers;

- shovel, hammer, axe;

- tamping;

- putty knife;

- hacksaw;

- tape measure, level, cord.

Step-by-step instructions for installing a concrete blind area:

- Carrying out markings. It is carried out taking into account the space required for the formwork.

- Digging a pit. The depth should be between 30-60 cm, depending on the degree of thermal insulation. The bottom is leveled and compacted well. You should immediately make a slope.

- The sand cushion is filled in. The material is wetted, compacted and leveled.

- Waterproofing is being installed. Roofing felt or several layers of dense polyethylene are suitable. When building in cold climates, foam boards are added.

- Installation of formwork, which will simultaneously serve as guide beacons.

- Reinforcement. Each unit is fastened by welding, wire or plastic ties. The frame is raised 2 cm from the base and firmly fixed.

- Filling the blind area. This is done in stages, by continuously filling each compartment with solution. After pouring, the surface is leveled with a rule and a spatula.

Concrete needs 28 days to fully cure. During this period, the material must be watered and covered with film.

Damage protection and repair

Concrete is prone to destruction under the influence of moisture and soil pressure. You can make its surface stronger and more airtight using deep penetration impregnation, water repellent and liquid glass. The ironing procedure gives a good effect, but for this you need to rent special equipment. To protect the edges of the tape from chipping, it is advisable to install concrete or stone curbs. It is better to immediately replace wooden expansion joints with rubber gaskets, which have better elasticity. Sometimes ceramic tiles are placed on the blind area, which protects it from moisture and abrasion.

Most often, cracks appear on the tape. Minor defects are simply rubbed over with sealants and fillers. Larger cracks are widened, treated with a primer and filled with cement mortar. Large chips and cavities are cleaned of dust and debris and filled with concrete, followed by leveling and priming. Delamination is eliminated with a mixture of water, cement and liquid glass. After strengthening the surface, it is leveled with mortar or finished with tiles.