Features of various materials for ebb tides

The cost and effectiveness of the elements depends on the material from which they are made. For example, duralumin products can withstand severe frosts and are resistant to high humidity levels. Zinc-coated ones have good decorative and technical characteristics, practicality and cost-effectiveness. Copper casting is durable and wear-resistant. Concrete products are the most durable and practical compared to competitors. They withstand loads and act as protection for walls. The only caveat is that the concrete mixture must be of high quality, this will guarantee resistance to frost.

Steel castings

Elements made of galvanized metal and coated with polymer coating. They have high strength indicators and a reasonable price. Steel products can be purchased ready-made or ordered individually, according to the required dimensions. The material is resistant to aggressive environmental influences.

Aluminum ebbs

Aluminum products are durable, resistant to temperature changes, durable and reliable. The material is not prone to corrosion. Thanks to its pliability, it is easy to work with. The surface layer does not need additional protection, but since it is soft, there is a risk of scratches. Paint and other coatings are applied for decorative purposes and prevent darkening of the building material. This type of ebb is expensive and of high quality.

Types of basement ebbs

Also check out these articles

- Quality and reliability of the lock - use of specialized lubricant

- Features of daily apartment rental

- Dantex conditioners: advantages

- Advantages of modern gas fire extinguishing

The modern market offers flashings for the foundation plinth of the following types:

- Plastic.

- Concrete.

- Clinker.

- Steel galvanized or coated with polymers.

- Copper and aluminum.

Fasteners for installing ebb tides

Before starting installation work, you should check the horizontalness of the surface. If there are deviations or distortions, the surface must be leveled with cement mortar. To ensure that the mixture adheres well, the surface layer is shaped like a slope. At the corner of the walls, a painting cord is attached in a horizontal position, which will serve as a guide for constructing the slope. Proportions of working solution: 1 part cement to 3 parts sand. Water is added in such proportions that the finished mixture does not drain from the painting tool. In order for the moisture to evaporate properly and the solution to consolidate, it should be kept for two days. The ebb tides are attached to the plinth to the wall surface or to the guide elements.

Materials for basement flashings

Such an insignificant and simple element at first glance, like the ebb for the base, has a number of its own characteristics. The shape of the drains is almost universal, with minimal differences in the size and configuration of the drain. The tilt angle is left within 10-20 degrees. The fastening area is not formed by a wide, flat collar. A drip pan is a curved drain, sometimes in a zigzag shape. The working part, the shelf, is calculated according to the width of the thickening of the base in such a way that the ebb does not extend excessively beyond its limits, but fits as tightly as possible.

It is made from the following materials:

- Steel (galvanized) – for such purposes, it is most rational to use galvanized steel, with one or two sides coated. One of the most budget-friendly options, with proper care it can last about 50 years! Steel castings are produced in various lengths, usually up to 6m. They are not difficult to cut to size, and also to bend at turns along the inner or outer corner. Very often they are offered to be made to order by companies dealing with roofing materials;

- Steel with a polymer paint coating is a common material for the manufacture of various additional roofing elements, including base flashings. Its advantage is that more and more shades of color are offered, which means the number of decorative solutions is increasing. In addition to its decorative advantages, this coating of galvanized steel is corrosion resistant to atmospheric conditions, and in the absence of damage, can last for decades;

- Aluminum - this refers to standard ebbs for metal-plastic windows, which can also be used for finishing the basement area. Aluminum does not rust and has higher mechanical rigidity than galvanized steel. However, its adjustment to curved shapes is difficult, and such ebbs are not bent to order;

- Plastics (PVC, polypropylene) - exist in the form of standardized window sills, or as additional elements for vinyl siding. Despite its low cost, this material is not reliable and durable, requiring its complete replacement over time. Therefore, when installing plastic ebbs, it is necessary to take into account its replaceability in the future;

- Copper and stainless steel are among the most expensive materials, but they are also used for these purposes. Shades made from these materials represent an exclusive solution, and their use is justified only to maintain the high decorative style of the house's architecture.

Features and technology for installing ebb tides

Product installation technology includes:

- measuring the perimeter of the house;

- determining the required width of the structure;

- installation of elements in the corner part of the house;

- fastening the sills to the wall using sealants and self-tapping bolts;

- checking the system for functionality and leak detection.

Installation of foundation protection on the base of a wooden house is mandatory. Wood absorbs moisture, and this feature has a detrimental effect on the façade of the building. Logs need enhanced protection, for this reason it is better to choose the installation of a log or metal ebb. Main features and installation technology: wooden parts must be treated with water-repellent agents.

What is a basement ebb

Flashings for plinths are made of plastic or metal with a protective coating. As a rule, these are strips 20-25 cm wide, which are installed at the junction of the external walls of the house and the beginning of the basement level. In fact, the basement ebb is a small canopy that protects the connection of the house with the foundation, since this is the place that is weakest in the face of various negative environmental factors.

In addition to direct protection, low tide can improve the appearance of the structure . Often the basement level is slightly wider compared to the walls of the house. This is due to the fact that the basement level has to withstand maximum loads both from the weight of the structure itself and from the interior, people and even the snow that lies on the roof in the winter season. The low tide covers the resulting ledge , and its angle of inclination prevents sediment from accumulating on the base.

Return to content

Useful tips

- Tighten the fasteners correctly!

- You should not knock on the ebb of metal coated with plastic; the coating may be knocked off. Place a felt or rubber pad under the impact area.

- Low tides do not go more than 5 meters.

- Install flashings after completion of construction work to prevent heavy objects (such as bricks) from falling and damaging the flashing.

- Make holes for fastening the ebb on the wall in place, while simultaneously marking them on the ebb, placing it on the foundation.

- At low tide, pre-drill holes for fasteners.

- In a wooden house, a groove is cut into the log into which the straight adjacent edge of the ebb fits. In this case, there is no need to bend it. At low tide, a board is laid for rigidity.

- To install flashings under any finishing façade material, measurements are taken after installing the sheathing for it.

- The areas where the ebb tide meets the wall can be sealed with sealant. You can put strips of polystyrene foam on the foundation (below the tide, before installation) or seal it with polyurethane foam, then cutting off the excess before starting work.

Simple but reliable design to protect the base

The plinth ebb is a profile strip that is installed at a certain angle of inclination to the upper edge of the plinth and is attached with an overlap or cut into the outer wall of the building. The edges of the slope are usually bent in a special way to give an aesthetic appearance to the structure, as well as to form a stiffening rib that effectively resists various mechanical influences.

Attention!

The ebbs are installed on the base of a wooden house in a special groove in the outer wall in order to ensure a tight connection. This fact must be taken into account when calculating the width of the slope.

What should you pay attention to?

- Carefully tighten the fasteners, avoiding distortions and pinch.

- When bending a polymer-coated metal workpiece, do not knock on an unprotected surface. Place a rubber or felt “shock absorber” under the hammer to soften the impact. Otherwise, you will easily damage the protective polymer layer.

- Low tide should not be longer than 5 m

- Proceed with the installation of ebb tides only after all other construction and installation work has been completed, in order to avoid accidental damage to the structure.

- When preparing holes for fasteners in the wall, simultaneously mark their location on the drip blank.

- When arranging solid wood buildings, cut grooves into which the non-curved side of the ebb, in contact with the wall, will fit. A board placed under the ebb will provide additional rigidity to the structure.

- Start taking measurements after installing the façade sheathing.

- Seal the gap between the ebb and flow with sealant.

- To enhance the waterproofing effect, lay foam plates between the ebb and the foundation, or blow out the resulting gap with installation foam, removing its excess.

Remember that all measures for the manufacture and installation of flashings are aimed at enhancing the moisture insulation of the foundation and the building as a whole. Flashings should be designed to drain storm water away from the building as efficiently as possible.

Installation technology

When installing basement ebbs, you should not have any difficulties. You can easily cope with this task yourself. All you need to do is follow the instructions below. It doesn’t matter whether you purchased metal ebbs or your choice fell on plastic, in any case, the installation will consist of the following steps:

- Fastening of ebbs is carried out after finishing the base and before finishing the walls. Check the top layer of the plinth with a building level. It must be horizontal. The surface of the wall must also be absolutely flat so that the ebbs fit snugly against it and water does not flow down the wall to the base.

- In order for the tides to come into better contact with the wall, you need to make slopes. To do this, stretch a thread from one corner to another. Prepare a solution of cement and sand in a ratio of 1:3. At an angle of 150C from the thread, lay out the slope with a trowel.

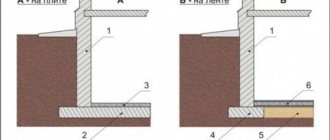

- The base ebbs can be attached to the guides or directly to the wall. The first option is convenient in that after installing the drip tides, the cladding of the building's facade will be attached to the guides.

- When attaching the sills to the wall, dowel-nails are used, and self-tapping screws are used for the guides.

- The overlap of the plank on the plank should be 3 cm, the place of which is then treated with sealant. They are also used to treat the joints between the tides and the wall.

- All corners are made from the remnants of the plank and mounted in the same way.

- To install wide ebbs, brackets are used that will ensure strong fastening of the structure.

Base flashings are an ideal option for protecting the foundation and base from water. With them you will save not only money, but also time on major repairs of the building’s foundation.

Video instructions for installation and cutting of ebbs:

The flashings for the foundation plinth act as protective structures that serve to drain excess rain moisture. Thus, basement flashings are one of the elements of the moisture protection system of the building foundation.

Other components of the structure include waterproofing of the underground and above-ground foundation walls, a concrete walkway poured around the perimeter of the house, and a drainage system located along the basement walls.

Types of tides and their functions

Before looking at the installation technology, let's try to figure out why ebb sills are installed in the first place. Due to the large loads on the base, the lower part of the wall, which lies on the base of the building, is made slightly wider than the rest. When it rains or when snow melts, water accumulates on the formed ledge, which has a detrimental effect on the base itself and the entire lower part of the structure (foundation, plaster). Penetrating inside the walls, water can wash away the connecting elements of materials. In addition, the liquid in the pores of the foundation expands when it freezes and creates pressure, forming cracks. For these reasons, no construction can be completed without protecting the upper part of the plinth.

Almost any material is suitable for making castings. Various types of plastic, non-ferrous metal (aluminum, copper) and steel are used as it, but it must be stainless or galvanized. Purchased steel castings have an additional coating of zinc or dye, which serves as protection against corrosion.

- Possessing high performance indicators, metal plinth ebbs are the most popular today. The polymer layer makes them resistant to any weather conditions, and they are also affordable. When ordering metal castings, you can also indicate your measurements. After installation, metal castings are painted or left unpainted.

- Plastic ebbs are easy to install and light in weight, which makes them most preferable for self-installation. It is durable, not afraid of the sun, durable and silent.

Installation of ebb and flow for the foundation

Before installing the flashing, inspect the walls of the house for cracks, chips and other flaws. Places where such phenomena are detected should be sealed with sealant or putty for facade work. If it is planned to insulate the foundation, then the ebbs must be installed after completion of this type of work.

When installing ebbs on the foundation yourself, it is important to accurately measure the dimensions of the depth and width of the foundation so that the ebb can fulfill its main purpose as much as possible: to protect the house from precipitation. In addition, you need to install it correctly on the foundation, tightening the screws technologically correctly and maintaining the required slope for low tide along the entire perimeter of the house.