Cladding with plasterboard sheets: advantages

Facing with HA sheets is carried out in the following cases:

- surface leveling;

- improved heat and sound insulation;

- hide wires and pipes;

- surface decoration - creating niches, shelves, design with figured elements.

The plasterboard sheet has a flat surface; when mounted on a wall, it does not deform, but remains flat. This is convenient for subsequent painting, laying tiles, and wallpapering.

In various rooms with high humidity and high temperatures, the following types of gypsum boards are used:

- An ordinary room with moderate temperature changes is a gray gypsum board sheet.

- Wet room: bathroom, corridor in a private house, balcony, attic, kitchen - green sheet of plasterboard.

- A room with a working fireplace, a Russian stove, with a rough stove - pink gypsum board.

There are methods for attaching sheets to the surface - frame and without frame. In the first case, profiles are applicable. For the second method, you need to choose the right adhesive composition.

Advantages of gluing gypsum board to the surface:

- installation is easy and quick;

- less expensive method compared to frame;

- this method does not take away extra centimeters.

The negative side is the inability to hide wires and communications behind the casing.

Types of glue

It is known that the most reliable fixation of plasterboard sheets is carried out using a metal profile. But the adhesive for drywall can be different. Installation of drywall with glue will be quick if the solution was chosen correctly, and the quality of such fastening will be in no way inferior to a metal frame.

The advantages of this installation include:

- saving space;

- saving time and money that would have been spent on installing the frame;

- simple and quick installation.

Today, gypsum board sheets can be attached to the following compounds:

- Knauf Perlfix;

- polyurethane elastic adhesive Polymin;

- Volma gypsum mixture;

- Fugenfüller putty;

- silicone sealant (for example, Bolars).

Let's consider each type separately.

Knauf Perlfix is an ideal solution for installing plasterboard sheets on various surfaces. Features of Knauf Perlfix include its high moisture resistance. Therefore, this glue is used for finishing bathrooms, kitchens, balconies and loggias. In addition, the Knauf Perlfix mixture contains special additives - synthetic fibers. During operation, the solution is consumed sparingly. Knauf Perlfix takes about a week to dry, but if the right conditions are created, its drying time can be reduced to 5 days. At the same time, Knauf Perlfix glue is not elastic.

Polyurethane glue is sold in stores in bottles. It is ideal for installing gypsum board sheets, as well as gluing seams on uneven walls. You can also use it to glue ceramic tiles or level the ceiling. To use such glue, a special gun is required, which ensures economical consumption of the solution.

Volma gypsum mixture is the most plastic composition. Glue is used in situations where it is necessary to install individual elements that contain gypsum. In addition, using Volma gypsum mortar, you can fix not only sheets of drywall, but also polystyrene foam as a sound insulator or wall insulation. The Volma composition makes it possible to easily process the ceiling with your own hands, since it is able to take the shape of any irregularities. Please note that Volma glue does not shrink after drying, while maintaining high resistance to various pathogenic microorganisms. Volma adhesive products can be used for finishing bathrooms and other residential premises with high humidity. The material consumption here is 5 kg per 1 mm layer when applying the solution to the entire wall area.

Fugenfüller putties are used if, after installing drywall, further installation of tiles is required on its surface. The putty itself is applied pointwise, which minimizes its consumption. This type of putty allows you to attach sheets of material to wood, shell rock, stone and foam blocks. The solution increases the protection of walls from the harmful effects of fungi and mold, as well as high humidity.

Silicone (tile) adhesive for drywall is similar in its characteristics to the polyurethane composition, but differs from it in consistency. It is used to treat cracks, corners and joints. The solution promotes their impermeability. Using this mixture, not only the installation of gypsum boards is carried out, but also wallpapering, installation of plastic and tiles, as well as any finishing materials that are light in weight.

Detailed instructions included with each mixture will tell you how to glue drywall to each of the above solutions.

Is it possible to glue on uneven walls?

One simple way to level a “falling” wall is to cover it with plasterboard on a pre-made frame.

If the difference in wall unevenness is small, the method of gluing sheets is used. To use this technology, you need to familiarize yourself with the nuances and rules.

- The type of plaster and adhesive composition must be selected in accordance with the humidity and temperature conditions in the room.

- The frameless method is applicable if the wall has an unevenness of maximum 5 cm.

- When carrying out installation, you must follow the step-by-step instructions in compliance with all the rules.

- To select glue, you need to pay attention to the material of the rough wall.

If you follow all the rules, installing gypsum boards with glue will be easy and will last a long time.

How to choose the right gypsum board adhesive for gluing plaster

Wall covering with plasterboard is carried out by choosing the right adhesive composition. The mixture is selected according to environmental factors. Stroy market offers mixtures:

- Gypsum glue "Perlfix".

- Plaster based on gypsum: “Start”, “Finish”.

- Gypsum-based putty “Knauf-fugen”.

- Tile adhesive "Ceresit -SM 11". This is a cement composition with fillers.

- Silicone sealant made of acrylic and polyurethane, “liquid nails”, assembly adhesive mixture. These mixtures are used for smooth surfaces or for gluing sheet to sheet.

- Polyurethane foam. Select a composition with a “min” coefficient.

Sealants are mainly used on brick, concrete walls, and foam blocks.

Is it possible to glue it to polyurethane foam?

There are 2 ways to glue a sheet of material to the wall on foam:

- First, the gypsum board is attached to the wall with dowel nails, then holes are made and the void under the plaster is filled through them.

- Apply foam to the sheet and stick it to the wall.

The material is placed on a flat horizontal surface. 9-12 holes are drilled in it. After the gypsum board with holes is applied to the wall, all drilled holes are marked with a pencil. The holes for the dowels are brightened on the rough coating.

The GC sheet is secured with dowel nails. There is no need to screw in the screw all the way. It is necessary to achieve evenness of the vertically placed material, so when screwing in, use a level. When the sheet is exposed, foam is injected into the holes.

If the wall is flat, then the foam is applied to a horizontally lying plasterboard. After this, the sheet is applied to the wall, leveled and pressed to force the foam to adhere to the surface.

Is it possible to glue gypsum boards to tile adhesive?

GKL is glued with tile adhesive, but if the wall has unevenness up to 1 cm. If the unevenness is more than 1 cm, the adhesive will eventually fall off along with the sheet of drywall.

For greater strength, plasterboard sheets are additionally fixed with self-tapping screws or dowel nails.

If you need to make a double covering of gypsum plasterboard, then when gluing the first layer, apply glue with a thickness of 0.3-0.5 mm, after complete drying, the same amount of glue is applied for the second gypsum board. A prerequisite is additional fixation with self-tapping screws.

Adhesive for foam block walls

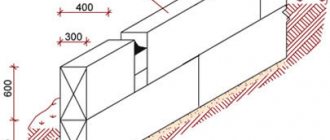

The best option for choosing adhesive for a foam block wall is Perlfix. Holes are made in the HA sheet at a distance of 40 cm with a diameter of 2-2.5 cm. The glue is applied to the wall. After which, the gypsum board is immediately glued. Excess glue will come out through the holes made. It is removed with a spatula. In this way, additional reinforcement is achieved.

Made from polystyrene concrete

Polystyrene concrete - made from cement, foam balls, quartz sand and additives. On a wall made of this composition, it is necessary to use cement-based adhesive mixtures with fillers. There is a negative point at the base - it freezes. Therefore, to ensure that the wall finish is held firmly in place, it must be additionally secured with dowel nails.

For wooden walls

The cladding of wooden walls is done in this way:

- Treating wood with an antiseptic agent.

- Setting beacons for the evenness of the applied sheet.

- Holes are made 30 cm from the beacons and a plastic sleeve from the dowel-nail is inserted.

- GK sheets are glued to the adhesive mixture. Additionally fixed with dowel nails.

Attention. Before using glue, you need to coat the rough surface with a primer.

For walls made of brick, concrete

GCRs are attached to brick and concrete walls in 4 ways:

- Fixation with glue.

- Cladding with polyurethane foam.

- Using self-tapping screws.

- Fixing the dowel-nails.

The choice of method depends on the curvature of the wall and humidity.

Concrete wall. Basically it is smooth - cement-based glue is used. For better adhesion, notches are made on the wall, covered with a primer, and then the gypsum board is fixed.

Brick wall. The facing material is fixed using polyurethane foam. Applying foam to the sheet with a snake allows you to control the amount of product applied. After applying the foam to the sheet, wait 2-3 minutes. When the foam begins to expand, the sheet is applied to the wall and leveled.

How can I glue drywall?

Experienced builders know that the speed of work and the quality of the final result depend on three factors: the skills of the craftsman, the quality of building materials and the correct choice of materials in accordance with the characteristics of the room. The last two points are directly related to the choice of adhesive for installing gypsum boards.

The choice of adhesive mixtures from various manufacturers on the construction market is quite wide, and it is difficult for an inexperienced person to navigate.

Therefore, in anticipation of the repair, this issue needs to be dealt with. We will not consider all possible options.

Here are only the most popular and in-demand materials:

- Perlfix plaster mounting adhesive from ;

- dry mixture “Volma-Montazh”;

- silicone glue;

- polyurethane glue;

- Fugenfüller putty;

- polyurethane foam;

- tile adhesive.

" Perlfix Knauf " - gypsum assembly adhesive. Designed for gluing gypsum boards and insulating materials on concrete, brick and plastered surfaces. It is also used when installing tongue-and-groove slabs. Material consumption when gluing is 5 kg/sq.m. m. The cost varies from 350 to 400 rubles per bag weighing 30 kg.

“ Volma-Montazh ” is produced on the basis of gypsum binder with chemical and mineral additives. Provides excellent adhesion, has high water-holding capacity, and has high ductility. Used when working with brick, concrete, plastered, gas and foam concrete bases.

The big advantages of this mixture:

- it does not shrink when dried;

- has high resistance to fungal growth and microorganism development.

Material consumption is 3.5 – 5 kg/sq.m. m. The cost of a bag weighing 30 kg is about 300 rubles. The mixture is packaged in 5, 15 and 30 kg.

Silicone glue - firmly attaches sheets to any base, but it is better to use on relatively flat surfaces.

Polyurethane glue - can be used not only for gluing gypsum boards, but also for leveling walls. They can also glue fiber cement panels, decorative parts made of wood, tin, and plastic to any base. To work with it you will need a construction gun.

“ Fugenfüller ” is a putty based on gypsum and additives that increase the plasticity of the mixture. Can be used for gluing gypsum boards. Also a product of the Knauf company.

The putty has:

- high elasticity;

- attaches well to a wide variety of substrates;

- resists mold growth;

- not afraid of moisture.

Polyurethane foam - for attaching gypsum boards to walls, it is better to use foam with a minimum expansion coefficient when setting.

Tile adhesive is a cement mixture with fine aggregate and high mobility. It allows even a less skilled person to fit the joints of adjacent sheets well, since it does not set too quickly.

Also, for installing drywall, starting and finishing putties, gypsum plasters, and liquid nails are used.

Such a wide selection of adhesive compositions is possible thanks to the excellent adhesion of kraft paper, which is used to decorate the surfaces of drywall.

Preparing a plasterboard wall: what is needed?

To fix the gypsum board to the wall, you need materials and tools:

- The selected type of drywall is moisture-resistant, ordinary.

- Dowel-nails, self-tapping screws.

- Selected adhesive for fixing sheets.

- Hammer, construction mixer.

- A plumb line, usually a sharp knife, a level.

- Container for preparing glue, spatula.

- Primer, roller, brush.

After collecting the necessary tools, as well as purchasing all the materials, you need to prepare the rough surface.

- Clean the wall of old cladding, wallpaper, paint.

- Existing cracks must be reinforced and puttied. Seal all holes with cement or gypsum based mortar.

- The surface is coated with a primer.

DIY gluing plaster to the wall: step-by-step guide

Having prepared the rough walls and mortar for fixing the gypsum boards, you can begin installation. There are 3 methods for gluing sheets:

- Apply a continuous layer of glue using a notched trowel. Used for concrete walls.

- Applying glue in small piles.

- Using beacons and lining foam (gypsum pieces). For very uneven walls.

Each method is applicable according to the evenness of the rough wall.

Sticking the first sheets

A sheet of drywall is placed on long wooden slats opposite the place where it will be fixed. An adhesive composition is applied to the sheet in a continuous layer or in piles.

After this, the gypsum board with glue is carefully lifted to the wall. Wires are threaded through the holes. The sheet is raised above the floor by 10mm - for this you can put a piece of drywall. Place it close to the wall and level it. Evenness is measured by level, diagonally, vertically and horizontally. After installation, the plasterboard is pressed against the wall and checked again for evenness. The glued drywall must be secured with supports.

The second sheet is glued only after the glue under the first sheet has set. Equalization follows it.

Plasterboarding corners

Pasting the wall with finishing material begins from the inner corner. Drywall is glued onto the adjacent wall with an overlap.

To paste the outer corner, you need to measure the distance from the corner to the glued sheet and carefully cut off the measured distance from the whole gypsum board. This cut out part with glue is applied to the corner and aligned with a level and plumb line.

The next cut piece is placed on the corner so that it covers the end of the drywall glued to the 900 corner.

Grouting joints

After covering the wall and the glue has completely dried, it is necessary to carry out a series of work to reinforce the joints. For this:

- Cover the entire surface with primer. All joints are primed with a brush.

- After the primer mixture has dried, joint putty is applied to the joints. Reinforcing tape is glued onto it and covered with the same putty on top. If self-tapping screws or dowel-nails were used, then all fasteners are covered with the same solution.

- When the putty has dried, grout with sandpaper to remove all small excess putty particles and smooth out the seams.

The last stage is filling the entire surface and priming before finishing.

Useful video

Leveling the walls with plasterboard greatly facilitates interior finishing. Simple technology, a minimum of “wet” work, a perfectly flat surface - these advantages alone are enough to abandon classic plaster. But not all materials from which walls are made are the same. Even within the same room, they can differ in strength and ability to hold fasteners. If everything is relatively simple with brick or wood, then walls made of cellular concrete have their own characteristics. And in order to know how to attach drywall to a foam block, you need to take them into account.

Profile mounting

Covering walls with plasterboard over sheathing, in addition to leveling the surface, solves different problems in each room:

- in living rooms, acoustic mineral wool mats are used to improve sound insulation;

- in the kitchen, bathroom - used for hidden pipe installation;

- in the bathroom behind it, an installation is installed for a wall-hung or attached toilet.

The frame for covering can be provided with niches and shelves. For example, for TV and decorative accessories.

The easiest way is to lay electrical power and low-current cables in a foam concrete wall. But even in this case, you can not groove the channel, but lay the wiring behind the drywall - a corrugated pipe with a diameter of 25 mm is placed in the gap, which provides the height of the side of the standard profile.

Materials

To arrange the lathing for attaching plasterboard to the wall, use ceiling profiles CD (according to the Knauf standard) or PP (according to the Gyproc standard). They are absolutely identical in size - 60 mm shelf width, 27 mm wall height. They are supplied with UD or PPN guide profiles, which are attached to the floor and ceiling. They are the same in shelf width 28 mm, but differ in wall height. If the CD profile has both walls of the same height of 27 mm, then the PPN side for fastening drywall is slightly higher than the inner one - 33 mm versus 27 mm.

The profile thickness may vary. For branded products it is 0.6 mm. There are domestic analogues made of thinner sheet steel - 0.4-0.55 mm. These profiles are not as durable as branded ones. But for lathing fixed to the wall, the strength of such a profile is sufficient provided that the spacing of the attachment points is reduced by 20%.

To fix the profiles to the wall and level the plane of the sheathing, direct hangers are used. And the most difficult thing when interior finishing walls made of foam blocks with plasterboard is to attach the hangers to the wall.

The usual plastic dowel-nail, which is available from the Knauf company, is not suitable for cellular concrete. You need special plastic dowels with enlarged external ribs. There are also screw and drive-in anchors, but they are more expensive and are used if you need to secure a heavy object to the wall.

To attach the suspension you need a 6x52 dowel for a screw with a diameter of 3.5-5.0 mm. Its wholesale price starts from 1.15, retail - about 1.5 rubles. For one suspension you need 3 dowels: one in . For a branded profile, the height of the mounting points is 80-100 cm (plus fixation in the guide profiles on the floor and ceiling). For a room with a standard ceiling height, 3 hangers are needed. For a profile made of “thin” metal - 4 hangers.

The type of drywall depends on the humidity conditions of the premises:

- in living rooms they use ordinary gypsum board with a light gray or gray-blue tint of cardboard;

- in the bathroom, toilet, hallway - moisture-resistant green plasterboard.

The standard sheet has a size of 250x120 cm, a thickness of 12.5 mm and a thin semicircular edge (PLUC).

Which dowels are suitable for interior decoration?

For foam concrete you need to use special metal dowels.

Selecting the necessary dowels is a crucial moment for interior finishing. Without them, all the fasteners on the wall will not hold and all the trim will fall off. Two types of this fastener are common. They can be made of metal or plastic. One type of dowels for foam blocks requires a pre-prepared hole in the wall, the other is screwed in without drilling. Fasteners made of plastic are suitable for most construction and installation work. They are not subject to aging and wear, and are most often used for attaching lightweight household items to foam block walls. Their size is selected depending on the type of product and load. Recommended diameter is from 4 to 12 mm. Metal dowels are used for increased fire safety requirements. It is equipped with 4 spacer segments, and external teeth increase its load-bearing capacity, and is used for fastening various building structures.

After the frame is ready, sheets of plasterboard are attached to it and the walls are puttied as usual. You can glue wallpaper onto finished walls; they will look great on this material.

Technology for plastering foam concrete walls

Another option for interior decoration of walls made of foam blocks is traditional plastering. Before starting work, the walls are coated with a water-repellent primer. Then, using special dowels, a reinforcing mesh is attached and, based on it, the wall surface is plastered. The work is carried out with a gypsum plaster mixture, which allows the application of a thick layer.

After complete drying, the wall is puttied, leveled and covered with finishing materials. This can be tiles or paints based on silicate or silicone. They have higher vapor permeability and will stay on the wall for a long time after application.

Preparation and marking

First, the surface is prepared for work. For new construction, you just need to clean the wall from any remaining mortar and dust. During repairs, the list of activities is wider:

- clean the old finish;

- having de-energized the network, remove wall lamps, sockets and switches;

- insulate exposed wires (when replacing wiring, it is dismantled to the junction box);

- perform markings.

Although the markings for the frame are done individually in each case, the algorithm for carrying out the work is general:

- Using a level, find the most protruding point on the surface. It is “projected” onto the floor using a plumb line or laser level, and then transferred to the ceiling. This will be the “zero” level.

- From this point, two lines are drawn on the floor and ceiling parallel to the plane of the wall. Check with a level (plumb line) in the corners to ensure that the edges of these lines lie in the same plane. With conventional cladding (without installing installations and laying large-diameter pipes), UD guide profiles are subsequently attached along these lines.

- The same markings are made for adjacent walls. Determine the points of angular intersections. Departing from these points a little more than 30 mm, beat off a vertical on the wall for the central fastening of the suspensions of the corner posts from the CD profile.

- Having chosen one of the corners as the “start”, marking the lines for attaching the suspensions of the remaining CD profile racks on the wall with a step of 600 mm.

How to properly attach drywall to foam block

Leveling the walls with plasterboard greatly facilitates interior finishing. Simple technology, a minimum of “wet” work, a perfectly flat surface - these advantages alone are enough to abandon classic plaster.

But not all materials from which walls are made are the same. Even within the same room, they can differ in strength and ability to hold fasteners. If everything is relatively simple with brick or wood, then walls made of cellular concrete have their own characteristics.

And in order to know how to attach drywall to a foam block, you need to take them into account.

Profile mounting

Covering walls with plasterboard over sheathing, in addition to leveling the surface, solves different problems in each room:

- in living rooms, acoustic mineral wool mats are used to improve sound insulation;

- in the kitchen, bathroom - used for hidden pipe installation;

- in the bathroom behind it, an installation is installed for a wall-hung or attached toilet.

The frame for covering can be provided with niches and shelves. For example, for TV and decorative accessories.

The easiest way is to lay electrical power and low-current cables in a foam concrete wall. But even in this case, you can not groove the channel, but lay the wiring behind the drywall - a corrugated pipe with a diameter of 25 mm is placed in the gap, which provides the height of the side of the standard profile.

Materials

To arrange the lathing for attaching plasterboard to the wall, use ceiling profiles CD (according to the Knauf standard) or PP (according to the Gyproc standard). They are absolutely identical in size - 60 mm shelf width, 27 mm wall height. They are supplied with UD or PPN guide profiles, which are attached to the floor and ceiling. They are the same in shelf width 28 mm, but differ in wall height. If the CD profile has both walls of the same height of 27 mm, then the PPN side for fastening drywall is slightly higher than the inner one - 33 mm versus 27 mm.

The profile thickness may vary. For branded products it is 0.6 mm. There are domestic analogues made of thinner sheet steel - 0.4-0.55 mm. These profiles are not as durable as branded ones. But for lathing fixed to the wall, the strength of such a profile is sufficient provided that the spacing of the attachment points is reduced by 20%.

To fix the profiles to the wall and level the plane of the sheathing, direct hangers are used. And the most difficult thing when interior finishing walls made of foam blocks with plasterboard is to attach the hangers to the wall.

?

The usual plastic dowel-nail, which is available from the Knauf company, is not suitable for cellular concrete. You need special plastic dowels with enlarged external ribs. There are also screw and drive-in anchors, but they are more expensive and are used if you need to secure a heavy object to the wall.

To attach the suspension you need a 6x52 dowel for a screw with a diameter of 3.5-5.0 mm. Its wholesale price starts from 1.15, retail - about 1.5 rubles. For one suspension you need 3 dowels: one in . For a branded profile, the height of the mounting points is 80-100 cm (plus fixation in the guide profiles on the floor and ceiling). For a room with a standard ceiling height, 3 hangers are needed. For a profile made of “thin” metal - 4 hangers.

The type of drywall depends on the humidity conditions of the premises:

- in living rooms they use ordinary gypsum board with a light gray or gray-blue tint of cardboard;

- in the bathroom, toilet, hallway - moisture-resistant green plasterboard.

The standard sheet has a size of 250x120 cm, a thickness of 12.5 mm and a thin semicircular edge (PLUC).

The final list of materials for attaching drywall to a foam block looks like this:

- ceiling profiles CD and UD;

- straight hangers;

- single-level connectors;

- plasterboard 12.5 mm thick;

- dowels for foam concrete;

- dowels for floor slabs and floors;

- fasteners for profiles, hangers, drywall.

Tools

In total you need three sets of tools.

For marking you need: tape measure, laser level (or plumb line and bubble level), construction angle, ruler, pencil, marking cord.

To install the frame, work with the profile and fasten the gypsum boards, use:

- drill for foam block;

- perforator for ceilings and floor screeds;

- rubber mallet;

- hammer;

- metal scissors;

- screwdriver (screwdrivers).

?

To work with drywall you need:

- hacksaw;

- knife;

- edge plane.

Execution of work

For installation, you need a drawing (sketch) of the frame with dimensions and details for each node.

Drawing and detailing are also necessary to calculate the amount of materials

Preparation and marking

First, the surface is prepared for work. For new construction, you just need to clean the wall from any remaining mortar and dust. During repairs, the list of activities is wider:

- clean the old finish;

- having de-energized the network, remove wall lamps, sockets and switches;

- insulate exposed wires (when replacing wiring, it is dismantled to the junction box);

- perform markings.

Although the markings for the frame are done individually in each case, the algorithm for carrying out the work is general:

- Using a level, find the most protruding point on the surface. It is “projected” onto the floor using a plumb line or laser level, and then transferred to the ceiling. This will be the “zero” level.

- From this point, two lines are drawn on the floor and ceiling parallel to the plane of the wall. Check with a level (plumb line) in the corners to ensure that the edges of these lines lie in the same plane. With conventional cladding (without installing installations and laying large-diameter pipes), UD guide profiles are subsequently attached along these lines.

- The same markings are made for adjacent walls. Determine the points of angular intersections. Departing from these points a little more than 30 mm, beat off a vertical on the wall for the central fastening of the suspensions of the corner posts from the CD profile.

- Having chosen one of the corners as the “start”, marking the lines for attaching the suspensions of the remaining CD profile racks on the wall with a step of 600 mm.

Installation

Installation of the frame and fastening of drywall is carried out in the following sequence:

- UD and CD profiles are cut to size in the drawing.

- UD guide profiles are attached to the floor and ceiling. The fastening step is 40-60 cm. To reduce the level of structural noise, an elastic tape is laid between the profile and the surface of the floor/ceiling.

- Direct hangers are attached to the walls.

- Insert the CD profile into the guides, check the position in the plane of the skin, and attach it to direct hangers. Check the vertical level and finally fix it to the walls of the guide profiles.

- To cover the height of the wall, a standard sheet may not be enough. In this case, additional jumpers are installed between the racks. They are secured using a single-level connector. In adjacent areas, the jumpers should be located alternately at the top and bottom, and the joints of the sheets should lie in the middle of the profile.

- A chamfer is made at the ends of the additional pieces along the joint line.

- The frame is sheathed with plasterboard - the fastening step is no more than 20 cm, the head of the screw is slightly “recessed” into the sheet.

To hang something heavy on the sheathing, the frame in this place must be reinforced with an embedded element that is attached to the frame. It redistributes the load onto the supporting structure.

Installation without frame

If the walls do not have large irregularities, and the thickness is sufficient to lay wiring in the grooves and install mounting boxes, then you can fix the drywall to the foam block without a profile. For this purpose, adhesive solutions with mineral fillers are used.

There is even a technology for fixing drywall to mounting foam. But any of them (even with a small expansion coefficient) requires additional tightening of the sheet to the wall with self-tapping screws at several points. The method is labor-intensive, it is difficult to level several sheets, so it is used in small areas - for example, when arranging window slopes from plasterboard. It is not suitable for walls.

Installation

Installation of the frame and fastening of drywall is carried out in the following sequence:

- UD and CD profiles are cut to size in the drawing.

- UD guide profiles are attached to the floor and ceiling. The fastening step is 40-60 cm. To reduce the level of structural noise, an elastic tape is laid between the profile and the surface of the floor/ceiling.

- Direct hangers are attached to the walls.

- Insert the CD profile into the guides, check the position in the plane of the skin, and attach it to direct hangers. Check the vertical level and finally fix it to the walls of the guide profiles.

- To cover the height of the wall, a standard sheet may not be enough. In this case, additional jumpers are installed between the racks. They are secured using a single-level connector. In adjacent areas, the jumpers should be located alternately at the top and bottom, and the joints of the sheets should lie in the middle of the profile.

- A chamfer is made at the ends of the additional pieces along the joint line.

- The frame is sheathed with plasterboard - the fastening step is no more than 20 cm, the head of the screw is slightly “recessed” into the sheet.

To hang something heavy on the sheathing, the frame in this place must be reinforced with an embedded element that is attached to the frame. It redistributes the load onto the supporting structure.

Installation without frame

If the walls do not have large irregularities, and the thickness is sufficient to lay wiring in the grooves and install mounting boxes, then you can fix the drywall to the foam block without a profile. For this purpose, adhesive solutions with mineral fillers are used.

There is even a technology for fixing drywall to mounting foam. But any of them (even with a small expansion coefficient) requires additional tightening of the sheet to the wall with self-tapping screws at several points. The method is labor-intensive, it is difficult to level several sheets, so it is used in small areas - for example, when arranging window slopes from plasterboard. It is not suitable for walls.

Materials

In addition to drywall, installation requires a mineral-based adhesive mixture and a Betonkontakt type primer.

The advantage of mixtures over ready-made contact adhesive is that, due to the increased layer thickness, they can compensate for minor surface unevenness (up to 20 mm).

There are two large classes of adhesive mortars: cement and gypsum.

Cement compositions are universal - for external and internal work. They can also be used for fastening sheets of drywall, but their main purpose is tiling the surface.

For interior work with drywall, dry adhesive mixtures based on gypsum are produced. The most famous is KNAUF-Perlfix. To improve adhesion, it contains polymer additives. And the manufacturer indicates concrete surfaces as one of the base materials.

Why come up with some ways to glue drywall to a foam block? For example, use putty or finishing gypsum plaster as glue. There is a proven technology for this, which is recommended by the Knauf company, a manufacturer of drywall and dry mixes.

Tools

To work with drywall, you need a standard set of tools: a hacksaw, a knife, and an edge plane.

To prepare the glue you need:

- capacity of at least 50 liters (for 1 bag of dry mixture weighing 30 kg you need 15-16 liters of water);

- mixer;

- trowel.

To prepare the surface you need a vacuum cleaner (preferably a construction one) and a primer brush.

Execution of work

Before gluing drywall to a foam block wall, to improve the adhesion of the glue to the surface, the following preparatory stage is carried out:

- Clean the wall from the old finish.

- Remove construction debris and dust from the surface.

- Deep chips and potholes on foam concrete blocks are repaired with gypsum mortar.

- Apply primer in two layers.

- Check the level of the floor surface near the wall. Find the most protruding area and mark a horizontal line on the wall relative to it. A starting profile or block is attached to it, on which the sheets of drywall will rest.

If the surface of the ceiling was leveled with a screed, then the bottom row of sheets is supported on the subfloor.

Fastening drywall is carried out in the following sequence:

- Prepare the adhesive mixture. Standard consumption is 1.5 kg/m2. For one sheet of 2500x1200 mm you need 4.5 kg of dry mixture. Taking into account losses per sheet, it is better to measure 5 kg. Working time with one portion of the prepared solution is 30 minutes.

- Apply glue to the surface of the sheet in portions. One trowel - one serving. Along the perimeter they do this as “tightly” as possible. In the center of the sheet - in a line every 35 cm.

- Place the sheet against the wall and press it.

- Correct the position of the sheet by lightly tapping the surface through a wooden strip. After applying the solution, no more than 10 minutes should pass.

If the solution has not been used within 30 minutes, then the container must be cleaned and a new portion prepared. Do not add water to unused solution.

In the process of aligning the sheets in the plane of the sheathing, the glue protruding beyond the edge is immediately removed. If time permits, it is returned back to the container or the joints are sealed with it.

Advantages of installing drywall without a profile

The frameless method of attaching gypsum boards to walls is justified under certain circumstances. The most compelling and mandatory use of a frameless fastening method is the curvature of the walls. The maximum permissible value of curvature is 5 cm over the entire plane of the wall, otherwise it is unlikely that you will be able to level it using adhesives and save money.

So, three reasons why installing drywall without profiles is beneficial:

- This method will allow you to save significantly. Thus, by purchasing all the necessary elements for a metal frame, you can spend five times more than on purchasing adhesive compositions. However, it is worth remembering that the greater the unevenness, the more glue will be required to level the walls.

- Gluing drywall will not reduce the total area of the room as much as installing gypsum board on the frame. For comparison: when installing lathing (depending on the unevenness), the length of each wall will take about 5–10 cm, while with the adhesive installation method it will be 2–3 times less, often no more than 1 cm.

- You can attach drywall directly to the wall in different ways and on different bases. It doesn’t matter whether they are permanent or partitions, brick, shell rock, foam concrete or aerated concrete, concrete panels or clay blocks. It also does not matter whether it is a wooden base made of boards, timber or shingles, covered with plaster or not.

Leveling walls with plasterboard without a profile is possible regardless of the technical condition of the base. This could be old brick or clay walls, old plaster, wallpaper or paint, partially crumbling plaster, etc. Naturally, there are certain restrictions:

- large rubble of walls;

- high room humidity or direct contact of plasterboard with water (even moisture-resistant drywall will collapse under constant exposure to moisture).

How to glue drywall to a foam block wall

Leveling walls with plasterboard without a profile is possible regardless of the technical condition of the base. These could be old brick, clay walls, old plaster, wallpaper or paint, partially crumbled plaster, etc. Naturally, there are certain limitations: Before you begin installing drywall without using a frame, you need to carefully check the surface of the walls for irregularities and differences level. Using a building level, rules, plumb lines or a professional laser level, the necessary parameters are determined.

If for the adhesive method of installing gypsum boards the curvature is not critical (differences are no more than 5 cm), you can proceed to the next stages of work. 1 . Working with relatively flat surfaces. These are concrete ones. The drywall will be applied to a thin layer of adhesive.

Therefore, increased demands are placed on the foundation. It will not be possible to lay electrical infrastructure (cables, wires) directly under the gypsum board. It should be hidden in grooves.

And in the wall covering you will need to cut holes for switches and sockets. In the final version, the entire coating is treated with final putty. It is applied in a thin layer, sanded and rubbed 2-4 times with a sponge grater. First time with a dry and then with a moistened instrument.

In the case of a painted surface, if the coating adheres tightly and securely to the base, it does not need to be removed. For the primer, special mixtures of the betacontact variant are used. They are more expensive than their analogues, but finishing the walls with plasterboard will not have negative consequences.

Strength qualities of adhesion belong to the highest category.

Features of fastening gypsum boards without a profile to different bases

Carrying out repairs on their own, many home craftsmen wonder whether it is possible to attach drywall directly to the wall and how exactly to do this.

There are several ways in which you can attach sheets of drywall directly to the base and still correct the plane. The main parameter when choosing methods is the material of the base wall.

Wooden base

Whether it is a wooden partition in an old “Stalin” building or a wall made of timber in a new house, plasterboard is attached to the wall without a profile using wood screws. It is better to use self-tapping screws of at least 35 mm, but you should pay attention to the curvature of the walls. Perhaps in some places the fastenings will need longer ones, for example in old houses on wooden walls, where a thick layer of plaster is applied, which should not be removed. In this case, you need to choose a self-tapping screw of such a length that it reaches the tree.

Self-tapping screws can only be screwed in with a screwdriver; doing this with a screwdriver is extremely inconvenient. In this case, you need to ensure that the fastener fits strictly perpendicular to the gypsum board sheet.

After installing drywall on a wooden structure, the seams must be reinforced, because fluctuations in humidity and temperature may change the geometry of the sheets. For reinforcement, a narrow sickle mesh is used, which is applied to the seam and puttied.

Capital base (brick, foam concrete, etc.)

To attach drywall without profiles to a solid brick base or to a foam block wall, it is optimal to use the following methods:

- fastening with gypsum glue;

- fixing gypsum board sheets with mounting foam;

- with a perfectly flat surface with differences across the entire plane of no more than 5 millimeters, gluing gypsum boards to assembly adhesive (for example, liquid nails) is allowed.

Gluing a sheet of drywall using any of the above methods is not enough to securely fix it. How to properly attach drywall to a wall without a profile using each of the above methods, we will consider in more detail.

How to finish with plasterboard

One of the most common methods is to decorate the interior of a house made of foam blocks with plasterboard.

Interior decoration of a house made of foam blocks with plasterboard is very popular

The main advantage of this method is the possibility of applying any heat, hydro and vapor barrier, as well as forming a ventilation gap between the foam block wall and the outer covering. The most commonly used technology is covering walls with plasterboard and installing sheathing. In this case, a wooden beam (slat) or aluminum profile is attached to the surface of the plastered wall. The lathing is made in the form of vertical posts with an installation step of 50-60 cm.

Drywall installation diagram

The stages of interior finishing of a house made of foam blocks using plasterboard are as follows:

- Applying primer and plaster in one layer without finishing leveling.

- Fastening the vertical posts of the sheathing from a wooden lath or beam 2x4 or 4x4 cm. The best option is an aluminum U-shaped profile.

- Laying waterproofing in the cells of the sheathing from a layer of roofing felt or polyethylene film.

Stages of gluing drywall to a wall

- Applying a heat-insulating layer over the waterproofing. As a rule, mineral wool is used, which has a breathable effect. In order not to install additional vapor barrier, it is recommended to use rolled or sheet mineral wool with a layer of aluminum foil. When laid, this layer faces outward. Protective films are secured using dowels or by gluing. Particular attention should be paid to the tightness of their fit to the sheathing beams - gaps are not permissible.

Mineral wool is used for the thermal insulation layer

- Sheets of plasterboard are attached to the sheathing using screws. Holes are pre-drilled at the fastening points to prevent damage to the material. The screw heads should be recessed.

- External finishing of drywall is carried out in accordance with the selected interior (painting, wallpaper, etc.).

Scheme of puttying seams of plasterboard panels