Asphalt has unique qualities that allow it to be used as a road surface. This choice is practical and effective, in addition, it is suitable for any roads, regardless of their purpose. In addition to GOSTs, the asphalt laying technology must comply with SNIP (SNiP 2.05.02-85 and SNiP 3.06.03-85), and other regulatory documentation.

Laying asphalt on old asphalt

General information

The rules for laying asphalt allow you to clearly divide all the work into several most important stages:

- preparation of the work site;

- formation of a bearing layer (sand-crushed stone mixture);

- applying a coating layer (coarse-grained asphalt KZ-7 or KZ-10);

- processing with a compacting roller.

Defects during asphalt paving and immediately after it appear in the road surface quite often. To quickly eliminate them, you can use cold asphalt, which differs from the usual one in its changed composition, high frost resistance and plasticity. This is a functional and wear-resistant material that is perfect for carrying out spot repair work, forming a coating in areas adjacent to the railway, carrying out preventive road repair operations, etc.

Necessary equipment:

- Mixing device;

- Containers that will contain bitumen compounds;

- Devices providing temperature control;

- Mixing mechanisms for preparing asphalt mortar.

“Before laying, cold asphalt of fine-grained (0.5 cm) or sandy (1-1.5 cm) fraction is mixed with bitumen thickeners.”

No special surface preparation is required for laying cold asphalt; you just need to remove excess debris and get rid of excess moisture. Cover the hole in the road surface with the prepared mixture and leave to harden. There is no need to specially compact it; it will happen naturally due to natural compaction on the site.

Advantages of the approach

Many people don’t know whether it’s possible to lay paving slabs on asphalt, but it’s really possible. This approach significantly saves time, allows you to strengthen the old surface and improve its visual qualities. There is no need to remove the coating if there are cracks, bumps and other defects; everything can actually be leveled by laying the second layer in a similar manner. This is not a very expensive and high-quality repair that transforms any sidewalk in a short time, without dusty, noisy work and a long wait until the surface is prepared for walking on it.

Types of stackers used

The technology of laying asphalt on old asphalt with an asphalt paver involves the use of the following types of mechanisms:

- road milling machines - devices that allow you to remove the top layer of road surfaces;

- asphalt pavers - devices used at the main stage of laying;

- rollers are mechanisms that ensure compaction and compaction of soil.

Asphalt pavers, in turn, are also divided into several groups.

According to the type of chassis they can be:

- tracked (used primarily for the construction and reconstruction of road surfaces);

Crawler Paver

- wheeled (more suitable for repairs by laying a top thin layer).

Wheeled Paver

There is also a division of these mechanisms by standard sizes:

- Laying width 1-3 m: used for processing widening strips, pedestrian paths, sidewalks;

- Laying width 2-4.5 m: covers one lane of the road;

- Laying width 2.5-7.5 m: covers two lanes of the road at once;

- Laying width 3-9 m: used for work on roads of the 1st and 2nd technical categories with a two-lane carriageway.

- Laying width 3-12 m: used for work on roads of the 1st and 2nd technical categories with a three-lane roadway.

What is the minimum layer that needs to be laid on old asphalt?

The minimum layer of asphalt when laying should have a thickness of 80 mm. It must be applied at a uniform speed, without stopping. The structure of the road surface may include two layers at once, then each of them individually may not correspond to the specified value, but their total thickness must be at least 8 cm.

Technology of laying new asphalt on old

The technology for laying asphalt over old asphalt will differ depending on the nature of the damage and the degree of wear of the previous coating. For example, individual potholes can be repaired with cold asphalt. If the damage is non-local, then it is possible to use the hot or cold milling method, which involves removing the top layer of old asphalt, texturing the base and applying a new coating.

Finally, you can apply the asphalt restoration method. In this case you will need:

- carry out a thorough cleaning of the old asphalt (this will require a sprinkler);

- lay a crushed stone layer (this work is performed by a grader);

- clean the edges of the road surface and warm it up;

- Using rollers, lay a layer of reclaimed asphalt concrete.

When the procedure is completed, all seams and all joints are impregnated with bitumen. If the asphalt concrete sheet has worn out evenly and is generally in good condition, then it can be “increased.” It is enough to lay a new one on top of a thoroughly cleaned old layer.

Paved road with old asphalt

The correct technology for laying asphalt on old asphalt (GOST R 54401-2011, 9128) implies carrying out any type of road work only in dry weather and acceptable temperatures .”

An asphalt layer laid in the rain can immediately be considered defective.

How much does it cost to lay new asphalt on old asphalt per 1 m2?

To accurately calculate how much it costs to lay 1 m2 of asphalt, you need to take into account the costs of consumables and the work itself. Specific figures may vary depending on the region or the specific technology chosen. However, the average cost per square meter of asphalt with installation ranges from 400 to 1000 rubles.

What documents are needed to carry out repair work?

Like any other type of construction activity, repair work is accompanied by appropriate documentation.

Installation contract (sample):

Sample installation contract

Contract for paving the territory (sample):

Sample contract for asphalt paving

Technology for laying asphalt in winter.

It is clear that not everything is good with the climate in Russia, even in Moscow there can be snow for 7 months a year, but roads must always be repaired... Nevertheless, there are requirements - lay asphalt only in dry weather at a temperature of +5 degrees.

However, there is a technology for laying cast asphalt, which can be used to lay asphalt in winter in rainy weather and at sub-zero temperatures. By the way, this honey method has been used in Europe for a long time. Cast asphalt is a mixture of sand, ground limestone, gravel and natural bitumen. At operating temperature (180°C), cast asphalt is a hot, plastic black mass. The production technology of such a coating allows the use of a number of additives, such as rubber and cellulose, thereby increasing the quality characteristics of the material. The coating is based on cast asphalt and has a rough surface.

One of the disadvantages of cast asphalt technology is that it is expensive. Well, our potential customers in Russia always want to save money. Therefore, if you contact some more or less decent company, for example https://asfalto.ru/ for asphalt laying with Russian teams, its own fleet of equipment and normal prices, they will definitely tell you “let's wait for the dry period.” And they will be right.

At what temperature can asphalt pavement be laid?

The Road Administration of the city of Yakutsk informs that according to the Methodological Recommendations for the construction of asphalt concrete pavement in adverse weather conditions ODM 218.3.102-2017, issued by order of the Federal Road Agency dated September 6, 2020, it is prohibited to carry out road work with precipitation of more than 5 mm . Currently, in the city of Yakutsk the precipitation level is in the range of 0.1-2 mm.

According to the recommendations of the Federal Road Agency, at ambient temperatures ranging from +5 to –10 degrees Celsius, before laying asphalt concrete mixtures, the contractor is required to prepare the base of the roadway. Preparation includes clearing snow and ice, drying the base with compressors and additional heating with specialized road equipment - thermal heaters. Such thermal heaters are designed to heat the structural layers of road pavement to above-zero temperatures in conditions of low ambient temperatures.

“It is allowed to lay asphalt concrete pavement during precipitation, the level of which does not exceed 5 mm. Until the end of October, according to preliminary data, we will not exceed this indicator. We monitor precipitation levels daily and check with several sources before laying asphalt concrete mixtures,” said Konstantin Popov, head of the road department.

It should be noted that this year in the city of Yakutsk, for the first time in the construction of roads, laboratory tests of the composition of asphalt are used for compliance with standards with the participation of JSC YakutPNIIS.

“After completion of the coating laying work, JSC YakutPNIIS goes directly to the site and takes samples (cores). Tests are carried out in the laboratory, after which we receive a conclusion about the quality of the road surface. Core samples will also be taken from areas where work is currently being completed,” commented Konstantin Popov.

The contractor for the major repairs of roads in the Avtodorozhny, Guba, and Saysar districts is Sakhatrastroy LLC. In the Gagarinsky and Construction districts, repair work is carried out by PJSC SU - 5 Doriss. In the Industrial District, the completion of transitional work is carried out by Alliance-2005 LLC.

The contractor for the major renovation of the streets of the Markha microdistrict is MontazhServis LLC. The construction of the bridge over the Markhinka and Severny rivers is being carried out by KSK Bridges of the North LLC. In the village of Prigorodny, the bridge over the Shestakovka River is being built by the Ilin insurance company.

Until October 31, 2020, as part of the national project “Safe and High-Quality Highways”, roads with a total length of 25.8 km are being repaired in the city of Yakutsk.

Cutting maps when using cold asphalt concrete mixtures

This article describes how to repair damaged asphalt overlays using cold mix asphalt.

What is the peculiarity of this technology, what are the advantages and disadvantages of cold asphalt concrete mixtures, what is worth paying attention to.

What are cold mixtures?

The main difference between cold asphalt concrete mixtures (CABC) and hot ones is that in cold mixtures the liquefaction of bitumen is ensured by various solvents and water-bitumen emulsions (WBE), in contrast to heating in hot mixtures. Therefore, working with HABS is safer than working with hot ones.

Some HABS compositions are mixed with the addition of water, which allows the compositions to be stored for a long time and mixed directly at the work site. To prepare HABS, only crushed stone of small fractions is used. HABS are not applicable for creating a complete layer of road surface or for repairing damage to more than one layer of asphalt concrete.

HABS is used only for pothole repairs, installation on pedestrian paths, stadiums, and parking lots near small shops.

Cold asphalt concrete mixtures

In terms of compression resistance, HABS is somewhat inferior to cast or compacted asphalt concrete mixtures, despite the fact that they consist of the same materials - bitumen, crushed stone, sand and mineral powders. Different proportions and methods of liquefying bitumen greatly affect the performance properties of the finished asphalt concrete.

- Pros of HABS. The advantages include the preparation of mixtures at the work site, less hazardous work, ease of use, lower cost of work, this is achieved by reducing the number of operations. HABS can be laid at temperatures down to minus five degrees and the laid mixture does not require strong compaction.

- Cons of HABS. Equipment for preparing VBE is quite expensive. Without it, using purchased emulsions, it will not be possible to achieve a cost reduction. The cost of the HABS itself is noticeably higher than the hot one. It cannot be used for laying the lower layers of asphalt concrete pavement, because it requires a more compression-resistant asphalt concrete mixture, which is compacted with heavy rollers.

Preparation of cold mixtures on site

Composition of cold mixtures

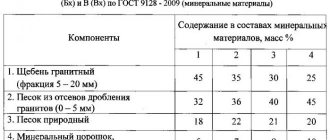

The composition of HABS directly depends on the operating conditions of the repaired road section and the bitumen used for its production. The exact composition of HABS must be determined taking into account GOST, SNiP and regulatory documents.

All materials used must comply with GOST and SNiP. In this case, the repaired coating will serve for many years.

Security

Safety rules do not differ from the rules for any other type of repair of asphalt concrete pavements. The work and detour routes for vehicles must be agreed upon with the OATI and the traffic police. Fences and temporary road signs must be posted. Workers should be provided with orange clothing with white or yellow reflective stripes.

The work site must be equipped with a change house with drawers for clean and work clothes, a first aid kit and clean drinking water. All workers and operators must undergo daily medical examination. All equipment must be inspected and tested before going to work.

Transportation of ready-made cold mixtures

Ready-made HABS are transported in conventional dump trucks. They do not require any special transportation conditions. The lifetime of the mixture directly depends on the amount and type of polymers added to its composition.

Preparation of maps for repairs with cold asphalt concrete mixtures

Preparing maps

Maps are marked according to the general rules for pothole repair. The optimal shape is a rectangular map, located parallel or perpendicular to the direction of movement. You can cut cards of any shape, but from the point of view of ease of repair, it is better to make them rectangular.

This will help smooth and compact the asphalt concrete better.

The card must be cut to the full depth of the damaged asphalt concrete layer. Maps are cut using both milling mechanisms and using soil cutters and jackhammers.