Irregularities during block production

Aerated concrete blocks consist of cement and sand, with the use of additives that change the characteristics and composition of the mixture. The density of the product is regulated by proportions, and the brand of aerated concrete is determined by it. One of the features of this material is its fragility, compared, for example, with “traditional” brick. However, this is precisely due to the fact that when the material is compacted, its thermal insulation properties will deteriorate.

Some manufacturers, especially small ones, may change the composition to reduce the cost of the production process. In the worst cases, this leads to the destruction of masonry, deformation of walls and the risk of structural collapse if this is combined with other factors - for example, problems with the foundation. We will not open America if we say that it is safer to buy an aerated block from the manufacturer directly than to rely on luck. In most cases, prices will be the most favorable.

Quality of aerated block

Now there are many different manufacturers, including private owners, who make it in garages. As a rule, such a gas block has different densities, structures and even sizes. If you buy a gas block from a decent factory that monitors quality, then you will not face these troubles.

Technologists say that gas block with a density of D400 is suitable for building a house of up to 4 floors. But I want to share my experience with you. Almost everyone who told me that cracks were appearing in the walls built their house from D400 gas block.

I decided that I would not take risks and therefore used a gas block with a density of D600.

Incorrect selection of material

According to GOST, grades of aerated concrete differ in average density from D200 to D1200. The fragility of the material decreases with increasing numbers in the designation. For example, D250 is absolutely not suitable for the construction of load-bearing walls, and D1000 is not able to provide sufficient thermal insulation.

Table of types of aerated concrete blocks by grade, according to GOST

Depending on the brand, the following types of blocks are distinguished:

- D200 (d200)–D350, thermal insulation blocks

- D400–D600 (d600), structural and thermal insulation

- D700–D1200, structural gas blocks

When choosing aerated blocks for construction, do not hesitate to ask questions to specialists who will be able to advise what type of material will be required for the construction of walls and partitions. Incorrectly made independent decisions, or the results of the work of non-professionals, can later result in very serious expenses, or even lead to accidents.

How to choose the right aerated concrete block

Compliance with documents and acts, as well as timely work and support from highly qualified specialists - these are all the necessary conditions that must be met for aerated concrete production.

What blocks are used and where?

Attention: Consumers need to select products only from trusted and competent suppliers who have proven themselves not only in the domestic but also in the international market for construction materials. In the process of choosing the right blocks, you should familiarize yourself with the characteristics.

- First of all, you need to select a foam block according to the type of structure. After all, they eat differently and each one is suitable exclusively for its own job. The photo above shows a table on this matter.

- The main indicators in this process are strength, density, size and, of course, frost resistance. These indicators are basic, therefore they are all indicated in the passport data on checking the quality of an aerated concrete product.

- Also, the certificate or passport must have a specialized blue seal, which must be supplied by the manufacturer. In some cases, quite frequent, an additional mark from the organization that conducts the tests is required. Quality indicators must be fully suitable and consistent with the requirements of the project.

Attention: If the project involves the construction of a building with more than one floor, it is necessary to select aerated concrete products above grade 500 in density.

- Separately, you should pay attention to the fact that a good quality block is distinguished by a light color shade, smooth corners and edges, as well as a uniform structure. Therefore, if there are stains, stains or oily films on the surface of the block, you must refuse to purchase it.

- If all the rules of the technological operation have been followed, then the pores of the block will always be only closed, round and even. They will be distributed evenly over the block area.

- Also, when purchasing, you should pay special attention to the cut of each block. If there are pores that differ greatly in size and are not round in shape, this indicates that the rules and parameters of thermal conductivity were not followed. This may also be a sign that the block has poor sound insulation properties.

- If a monolithic aerated concrete block is used, special attention should be paid to the surface level of the mixture. If there are watery compartments, this indicates that the required recipe was not followed when creating the block.

Aerated concrete monolith is subject to shrinkage deformations more than others. Therefore, to prevent the walls from cracking, it is necessary to comply with all preparatory work, including work on holes and possible microcracks. There should also only be clean formwork. It would be useful to take sufficient care of concrete products during the hardening process.

Reasons for and ways to remove cracks in structures

Aerated concrete wall blocks are today considered one of the most advantageous materials for private construction, the construction of apartment buildings and commercial buildings. However, despite all its advantages, it is important not to forget about the need to protect aerated concrete from negative external influences: wind and moisture, ultraviolet radiation, snow and mechanical damage.

The porous material absorbs water well, and it, increasing in volume when freezing, causes cracks to appear. At the same time, you should not only insulate the surface of the blocks, but also avoid making mistakes in waterproofing the foundation. In addition, improper installation of the thermal insulation layer can also lead to the appearance of moisture at the junction of materials and its further penetration into the aerated concrete.

Violation of the geometry of the building frame

If you are building according to an individual project, then all calculations related to the terrain: geology, climate, load from snow and wind, etc., must be made specifically for your conditions. In the case when they turn out to be incorrect, or are not taken into account at all in the project, the erected building may experience additional loads, leading to a change in its geometry. The consequence of this, of course, will be the occurrence of cracks and related problems.

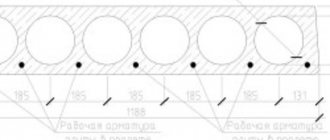

Reinforcement of aerated concrete walls to avoid deformation

Errors when constructing a roof

It is quite common to hire workers from seasonal crews for roofing work. They are not always professionals and may not take into account the choice of rafter system as applied to a given wall material. This can further lead to deformation and damage to the blocks.

When choosing hanging rafters, there will be no tension beam in their lower part, which would help remove the forces pushing the gables apart and acting on the upper rows of gas blocks. To avoid the appearance of cracks, tie downs are used to hold the rafters and neutralize horizontal forces. If cracks do appear, they are filled with the same glue that was used for the seams in the main masonry.

Methods for sealing cracks in foam block walls

Initially, you should find out the circumstances that led to the violation of the integrity of the wall, which you should then try to eliminate. After this, you can begin to seal the cracks using one of the appropriate methods.

Repair of shrinkage cracks

Their elimination must be done as follows:

- The first step is to remove the plaster from the area with the crack, then clean it of dust using water and cover it with a primer.

- Next, you should expand the width of the seams, for which you need to use a metal spatula. In addition, a forced increase in the seam must also be carried out along the length.

- At the next stage, you can begin to seal the crack with glue or a solution intended for foam blocks, which contains foam concrete chips, cement and water. During its implementation, for greater reliability, it is also advisable to glue the serpyanka.

After treating the damaged areas, you should wait until the applied mixture dries completely.

Repairing large mechanical cracks

To eliminate major damage, it is necessary to reinforce them and treat the seams with one of the following materials:

- glue intended for laying foam concrete;

- cement mortar with silicate crumbs;

- polyurethane foam;

- epoxy adhesive composition.

Reinforcement must be carried out on the entire surface where cracks have formed, keeping a distance of at least 40 cm from them on the sides. This work can be done in several ways:

- The plaster must be removed from the area where the reinforcement is being carried out. At the same distance on the sides of the crack, anchor bolts should be driven in, between which wire, construction mesh or Chainlink is pulled. Next, regardless of the chosen material, you need to plaster it. The thickness of the applied coating of plaster mixture should reach about 2-3 cm.

- The entire layer of plaster must be removed from the area with the crack. Following this, a reinforcing mesh made of fiberglass must be glued to the damaged area. For this purpose, adhesive mixtures intended for laying foam blocks are used. The reinforcing mesh fixed on the surface should be plastered with a similar composition. After it hardens, the wall is treated with putty and plaster.

Having figured out how to repair a crack in a wall made of foam blocks, you will be able to carry out repair work with your own hands properly and reduce to a minimum the likelihood of such damage occurring in the future if you follow the recommendations given.

Video:

Wall installation and the influence of the foundation on it

The foundation differs from other parts of the building in that it has an influence on all the structures of the future building. The reliability and service life will depend on its design.

Attention: If suddenly the aerated concrete walls begin to crack, you must first of all turn your attention to the condition of the foundation. A “weak foundation” will not do without irreversible mechanical deformations.

- In other words, it will float. If so, then deep cracks may appear on the walls, running from bottom to top. They may vary in location, but in most cases they appear in the middle of the wall. These are critical cracks that weaken the strength of the walls. They also pose a threat to the strength of the entire building.

- If the foundation is weak, repairs or work related to it cannot be started. In half the cases, it is necessary to strengthen the foundation in order to eliminate the appearance of cracks in the walls.

- In rare cases, a building needs to be dismantled.

- You should not use ordinary plaster on aerated concrete walls, as they will crack. It is better to take plaster with a specialized composition (see. Let's look at how to plaster walls made of foam blocks).

Methods for sealing cracks on foam concrete walls

First of all, you need to determine the reason why the wall is bursting. Then try to eliminate this reason. After this, you can begin to seal the cracks. Several methods are proposed for this.

Small cracks (shrinkage)

- The place where the crack appears is cleaned of plaster, removed dust with water and primed.

- The seams are being unstitched. They are expanded with a metal spatula to the required width. The length of the seam is also forced to increase.

- We seal the seam with adhesive for foam concrete or a mixture consisting of foam concrete chips, water and cement.

- A certain amount of time is allowed for the sealing mortar to harden.

Causes and characteristics of cracks in aerated concrete

The causes of this type of damage are divided into two main categories:

- Exceeding the maximum permitted mechanical load on the masonry. The load itself can be either constant or variable.

- Various violations of the technological process in the production of aerated concrete blocks.

Specialist masons can indicate the reason for the formation of such damage based on one type, place and time of occurrence.

Classification of cracks in foam concrete walls

In total, there are 2 categories of cracks that can appear on walls made of foam blocks: mechanical and shrinkage:

- Mechanical cracks. They differ from shrinkage cracks in their greater width and length. In the vast majority of cases, they arise as a result of movement or destruction of the foundation. Less commonly, they can occur due to subsidence of the entire structure on shifting soils. To eliminate the cause of the crack, it is necessary to examine the foundation under the crack. To do this, it is advisable to expose it. If there are problems, the foundation is strengthened with a concrete pad.

- Shrinkage cracks. They are less dangerous. They are small in width. They are often horizontal. Sealing such cracks is not difficult.

Why do they crack?

There are several reasons why cracks may appear in foam block walls, usually due to subsidence of the foundation or due to a violation of the block production technology.

There is another reason that arises when creating a ventilated facade, when the wind load is transferred through the frame to the walls of the house.

Violation of manufacturing technology

Some manufacturers, when creating blocks, may experiment with the composition of the mixture and violate their manufacturing technology.

This may be the use of inappropriate additives, when they begin to set earlier and the gas-forming processes do not have time to complete; there may be no hardening accelerators or additives that ensure uniformity of the structure.

In this case, cracks usually appear almost immediately or 1-2 weeks after the walls are erected. It will not be possible to correct this drawback , since the structure of the building material has been changed, so the way out of the situation is to dismantle the walls and use normal foam blocks.

It is imperative to carry out high-quality waterproofing, since foam concrete absorbs moisture well and this can cause cracks.

If you plan to install a ventilated facade with additional insulation , then you must use blocks of grade D600 and higher, otherwise they may not withstand the wind load that is transmitted from the cladding to the walls.

If the rafter system is created incorrectly , the load is unevenly distributed, which can cause damage to the walls made of foam blocks.

To compensate for the forces created by the rafter system, it is necessary to install tie rods (a beam connecting the rafters at the level of the mauerlat) and use an installation scheme with inclined legs.

Errors during construction

Often, the cause of cracks is associated with a violation of the technology for creating both the foundation and the walls of the building:

- during the installation of the foundation , the characteristics of the soil were not taken into account and as a result of heaving forces, soil layers shift, which destroy the concrete foundation of the house;

- the masonry was not reinforced , this must be done every 3-4 rows, as a result of which the rigidity of the wall decreases and cracks may appear on it;

- a homemade solution is used , which does not comply with the recommended proportions or contains impurities that reduce the strength of the seams.