A reliable and economical option for arranging the foundation for buildings for various purposes is a columnar foundation made of plastic pipes. It is usually erected in places where there is a high level of groundwater, which means it is impossible to dig a pit or trench there.

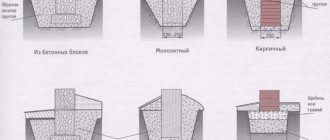

Today, there are several types of foundations and each of them has its own characteristics associated with the installation method, manufacturing materials and the use of special equipment during the work process.

Severe demands are placed on the quality of foundations for buildings. They must be durable and at the same time constructed in the shortest possible time. It is also desirable that the cost of the materials used be affordable.

Structural features of the construction of a columnar foundation

The design of this type of foundation for construction is characterized by its simplicity and this is its advantage over other options. Such a foundation can be built on any soil, since it will preserve the integrity of the structure even on difficult soils, for example, sandy.

Its main part consists of pipes that are buried in the ground through a previously prepared hole. To ensure the reliability of the foundation, the pillars should be located at a depth of 150 centimeters, taking into account the freezing point of the soil.

When erecting a building, all loads on the base act in all directions and this prevents the pipes from loosening and sinking. When arranging the foundation, it is carried out to such a depth that will prevent the building from sinking under the influence of all possible factors, and the pillars will not fall to the ground.

Despite the fact that building foundations made of plastic pipes have many advantages, they also have disadvantages:

- They are suitable exclusively for the construction of small buildings, since they cannot withstand significant loads. Such a foundation made of PVC pipes is one of the best options for the construction of commercial buildings, small houses, and garages.

- The service life of such foundations does not exceed 70 - 80 years, which is enough for a garage building, but not for a full-fledged home ownership.

- Due to its structural features, a columnar foundation does not make it possible to build a basement.

- When constructing such foundations on highly mobile soils and on soils with elevation changes, many problems arise, so it is advisable to abandon such ideas - it is better to choose another option or, if possible, move the construction of the house to another location.

Types of columnar bases

- Such a foundation cannot withstand large load-bearing loads. This factor limits the use of such foundations for construction.

- The service life of the foundation is relatively short, no more than eighty years.

- It is not recommended to build a basement in such buildings due to the nature of the foundation.

- Impossibility of construction on moving soils and when there is a difference in ground heights.

Depending on the complexity of the terrain, the depth of soil freezing and the load on the foundation, point support structures and piles are calculated and installed. They can be made from various materials. Installation methods are selected during design.

The foundation can be made of various pipes:

- metal;

- asbestos-cement;

- plastic.

A foundation made of pipes is called a columnar foundation.

Design advantages

Advantages of a columnar foundation made of PVC pipes:

- Affordable construction cost. Materials and the use of equipment for its arrangement will cost approximately 2 times less compared to pouring a monolithic base. This circumstance is most often the reason for choosing a pipe foundation, especially if you plan to build an outbuilding, a small frame house, a garage, etc.

- Excavation work is kept to a minimum; you only need to dig holes for the pipes.

- You can build a columnar foundation from pipes with your own hands in 6–8 days. For comparison, it will take at least a month to arrange a strip base. Thus, the speed of construction plays an important role.

- Thanks to the design features - after completion of construction, the building is raised above the ground by about 20-30 centimeters - protection is provided from flooding, which can occur as a result of melting snow or heavy rains.

- The presence of free space facilitates the work of laying utilities, including sewer and water supply systems. Their performance in this case can be checked immediately after installation is completed. If there is a need for repair work, there is no need to dismantle elements of the building or dig holes.

Thus, a self-made foundation made from PVC pipes, even taking into account its shortcomings, is more advantageous compared to other options for constructing a foundation. This is explained by the simplicity of its arrangement and the availability of affordable building materials.

Conditions for the construction of a pipe foundation made of plastic pipes

There are no particular difficulties in independently constructing a columnar base from pipes. But you should adhere to some rules. First of all, you need to decide on the site for the construction of the building - it must be level and not have significant differences in height.

The soil is cleaned - debris and unnecessary elements are removed, after which they begin to mark the pile field using pegs and a cord. To determine the number of supports (piles), you need to take into account the area of the building, soil characteristics and expected loads. It is advisable to have an expert opinion regarding the geological features of the area where construction is planned.

Using a hand drill, or better yet a motorized drill, holes (wells) are made for pipe pillars, which must be placed at a distance of 1.5 to 2.5 meters from one another. At the same time, in places where additional load will be placed, additional reinforcement should be provided - this means the installation of load-bearing walls, stoves, fireplaces, etc.

When building a foundation, support pillars should be immersed in the ground approximately 30 centimeters below the freezing point of the soil. As a rule, the depth of the pits is from 1.4 to 1.7 meters. This parameter depends on the type of soil and the presence/absence of groundwater. The diameter of the well for pipes depends on their diameter, but usually it is 150–250 millimeters.

The supports should rise above the ground by about 40–50 centimeters. This distance cannot be less than 20 centimeters.

Appendix B (mandatory). Determination of adhesion by the “fungus” detachment method

This standard uses terms according to GOST R 57512, GOST 2601, GOST 16504, GOST 28548, GOST 9.008.

Appendix B (mandatory)

B.1 Tests are carried out on pipes with a seal or in laboratory conditions on witness samples cut from pipes with a seal. The recommended dimensions of the witness samples are 15080 mm.

B.2 For testing, the following are used: - adhesion meters to determine adhesion by the normal peel method; - a tensile testing machine (for testing in laboratory conditions) with a meter scale division of no more than 0.1 kN, providing a given speed of movement of the gripper; - a device for fastening sample in the grips of the tensile testing machine;

– test “fungi” made of aluminum or stainless steel, with a diameter of 10 to 20 mm; - cutting tool (annular cutter with an internal diameter of the cutting element corresponding to the outer diameter of the “fungus”); - two-component epoxy or acrylate glue (solvent-free) ;- ethyl alcohol according to GOST 17299.

B.3 Tests on pipes with a seal are carried out 24 hours after its application on three sections of the pipe spaced at least 100 mm apart. Before testing, the thickness of the seal is checked at the place where the “fungi” are glued. The working surface of the “fungi” is cleaned of glue residues and traces of peeled grout.

The areas of the seal in the place where the “fungus” is glued and the working surface of the “fungi” are treated with sandpaper to give roughness, and degreased using a rag soaked in ethyl alcohol. A thin layer of glue is applied to the surface of the “fungus” and the coating and the “fungus” is pressed tightly to the coating. Tests are carried out no earlier than 24 hours after gluing the “fungi”.

Using a cutting tool (annular cutter), the coating around the “fungus” is cut through its entire thickness to the metal, and the cutting width must be at least 1 mm. Tests are carried out using a mechanical adhesive meter. The “fungus” is placed in a special clamp of the adhesive meter. After this, by rotating the handle of the adhesive meter through the spring, a normal tearing force is applied to the “fungus”. The tests are completed after the “fungus” is separated from the surface of the coating. Adhesion A, MPa, is recorded on the measuring scale of the device.

B.4 Tests in laboratory conditions are carried out using a tensile testing machine. Preparatory work is carried out similarly to tests on pipes. The sample with the “fungus” glued to it is placed in a special clamp fixed in the lower fixed grip of the machine. The upper part of the “fungus” is fixed in the movable grip of the machine, after which the coating is peeled off at a constant specified stretching speed of no more than 2.5 mm/min.

The permissible error in the stretching speed is 10%. At the moment the “fungus” is torn off from the coating, the tearing force F, kN is recorded. After the “fungus” is torn off, the seal is inspected at the place where it was torn off. The test report records the peeling force and the nature of peeling of the coating (“adhesive”, “cohesive”, “mixed adhesive-cohesive”).

B.5 When determining adhesion using a mechanical adhesion meter, the result of one test is taken to be the value recorded at the moment the “fungus” comes off on the instrument scale. When testing on a tensile testing machine, coating adhesion A, MPa, on each test sample is determined by the formula

, (IN 1)

where i is the sample number;

F – peeling force, kN;

S – surface area of the “fungus”, mm.

Materials for creating a columnar foundation

A tubular foundation is a type of pile structure. Materials for poles, in addition to plastic, can be asbestos cement or metal (more details: » «). But the best choice now is considered to be piles made of plastic pipes.

The installation technology is simple:

- Pipes with a diameter of 200 millimeters are placed into the prepared well. They are immersed to a depth of about 150 centimeters. A piece of product 30–40 centimeters long is left above the soil surface.

- Metal rods are inserted inside the pipe and the free cavity is filled with concrete. This design of a columnar foundation is characterized by increased strength and resistance to the most unfavorable operating conditions.

The foundation for the building, built from metal pipe products, is more reliable, but such a design is expensive. When constructing a foundation, high precision must be observed when installing metal supports and treated with anti-corrosion agents. If this is not done, in just two decades the foundation will become unusable.

When installing metal supports, the following methods of pouring concrete can be used:

- a sand and gravel cushion is placed at the bottom of the pit and a pipe is driven into it, inside which metal rods or pipes of smaller diameter are placed, and then the filling begins;

- metal pillars are immersed to a depth of 50–100 centimeters, for which products with a diameter of 15 to 20 centimeters are used, and finally the structure is filled with concrete mixture.

For strength, a grillage is installed.

Making a foundation from PVC pipes with your own hands

The easiest to construct and inexpensive is considered to be a columnar foundation, which is made using plastic pipe products. PVC sewer pipes with a length of 200 centimeters and an internal diameter of 20 centimeters are suitable for this purpose. If you don't know how to cut pipe straight, it's worth reading for more information.

You will also need metal reinforcement - for each of the supports you need 4 two-meter sections with a diameter of 8-10 millimeters.

Sequence of installation work:

- First you need to drill the required number of wells with a widened bottom with a diameter of about 21 centimeters.

- Then a bed of gravel and sand is placed in the holes.

- The pipe supports are capped on one side with a plug to prevent groundwater from penetrating inside. The pipe is then fixed to the pad.

- 4 reinforcing bars are placed inside the supports and poured with concrete.

A pile foundation made of plastic pipes is safe and reliable, it is not subject to corrosive processes and is environmentally friendly, it is not affected by groundwater and the cost of its construction is low.

When building a house, sometimes interesting ideas are realized. For example, many ways have been invented to build a foundation. The columnar foundation alone has so many solutions! Pillars are wooden, concrete, metal (from pipes), brick. Here we will describe how to build a columnar foundation from plastic pipes with your own hands. A good idea implemented by smart, competent people.

Preparation for construction

Before building, you need to prepare the materials. Fittings. So that you have something to reinforce the concrete that you will pour into the plastic pillars. The fittings can be found in specialized construction stores. Ingredients for concrete: sand, cement, crushed stone of medium fractions. Everything - better quality must be purchased. So that the foundation is strong.

Prepare wooden beams in advance for grillages that will connect the pillars. Why wooden? So, the diameter of the pillars made of plastic pipes will not be too large. Although there will be concrete with reinforcement inside the plastic pillars, you still need to think about lightening the load on them. In this case, wood is better than concrete or metal grillages. You can buy plastic sewer pipes at any plumbing store. PVC pipes are 200 cm long and 20 cm in diameter.

Foundation marking

To make a foundation from plastic pipes with your own hands, you need to make the correct marking of the work area. Using a tape measure, a triangular object with a right angle (to set a right angle from one peg to another), pegs, clotheslines (to mark the area, the places of pillars on the site), a level, which determines the height of the pillars throughout the area, the horizontal component.

Before installing poles made of plastic pipes

It will be necessary to decide how long the pillars will be. Optional 2 meters. You can make it shorter. It is necessary to calculate everything so that the lower part of the column (in the soil) is larger than the upper part, protruding above the soil. It is necessary to decide how to insert the pipe into the soil. Most people prefer to simply drill a well. They customize a Belarus tractor with attachments. A tractor digs into the soil with a drill. A sand cushion is poured in there, just a little bit. 30–40 centimeters. The pipe is placed in the hole. Vertical. Of course, this is easier than the other method, pitting.

But there is one caveat. If you just drill, then over time the pillars may, for some reason, settle and go down. And this can compromise the structural safety of the house. Therefore, the pit method is preferable. Here is a foundation pit for a house, already covered with sand. The sand cushion for the pillars is ready.

If possible, it is better to make a pit with an excavator. It will take less work, and less time will be spent on work.

Why make a pit

It is needed so that there is a rigid base under the pillars that prevents the pillar from going down. There will be no shrinkage. How? Place small concrete slabs (they are sold in specialized construction stores) on the sand cushion in the pit in the places where the pillars made of plastic pipes are installed. Install the pipes on the slabs, gradually digging them in from all sides so that they stand firmly vertically in the soil.

Thorough installation of plastic pipes for the foundation

Here you can also think about the soil in advance. Use the services of an excavator again. One excavator shovel of soil between the concrete slabs under the plastic pillars will be enough to place all the pillars firmly on the slabs. Earth next to the pipe, you can always install the pipe, sprinkle and compact the earth near the pipe. The installation of pipes should be done in accordance with the level readings, so that the tops of the pipes are in the same plane above the surface of the pit. Here, stretched ropes according to the level readings can help. They will accurately indicate whether the pillars are positioned correctly or whether there is a horizontal difference. When all the pipes are firmly installed in their places, remove the ropes.

Pipe concreting

We continue to build a foundation from plastic pipes with our own hands. We cover the top of the pipes with film to prevent soil from getting in there. Then we adjust the excavator. Soil is generously poured between the pillars. The pit is covered with soil. Carefully. We manually level the soil between the pillars. Remove the film from the tops of the plastic pipes.

We insert a reinforcement structure into the pipes. It looks like this: 4 fittings the length of the pipe are connected with knitting wire into a square frame that will fit inside the pipe. Vertically, all the way to the top. And one more thing: insert a metal rod into the center of the pipe. It rests on a concrete slab under the pipe, and at the top it looks out of the pipe about 20 centimeters. All pipes should be equipped with reinforcement cages inside, with metal rods in the middle.

And only then do we begin concrete construction. Before we start preparing the concrete, we prepare water in large containers not far from the construction site. After all, while working, carrying water from afar is not entirely convenient. Let's start making concrete. Using a mini concrete mixer, which you can always buy in any supermarket. Sand, water, cement, crushed stone - in the proportions of the brand of concrete you want. We pour concrete inside plastic pipes. Not forgetting the central position of the rod, which is needed to connect the grillages.

Completion of pipe foundation construction

The concrete is poured. Let's give it time to harden. 2–3 weeks is enough. Then we place the grillages.

The wooden beams at the corners of the house are overlapped. And they were planted on rods sticking out of the pillars. In the same way, the grillages hold the rods from all the other pillars. By the way, coat the bottom of the beams that lie on the pipes with bitumen mastic. The bars are fixed rigidly. You will get a strong, durable foundation. All that remains is to waterproof the grillages and cover them with waterproof impregnation. That's it, the foundation is ready. A house built on such a foundation will stand for a very long time.

The cost of constructing a foundation for any building is at least a quarter of the total estimated cost, and in cases of construction on difficult soils and flooded areas, even more - more than one third of the total costs are due on the foundation. Over the past ten years, low-rise individual construction has experienced a boom, and that is why modern, economical foundation options are so in demand. The foundation made of plastic pipes - an ingenious option to construct the foundation for a house from a new inexpensive and durable polyvinyl chloride as a formwork for a bored pile, has many supporters.

Metal supports

Metal pillars can be represented by steel piles and casing pipes driven into the ground, which are subsequently filled with concrete mixture.

Screw piles are most often used. They are hollow pipes with a conical point at the bottom and a spiral guide blade for screwing into the ground. Screw piles

Such a pile can be installed manually by three people, with one constantly monitoring the verticality of the immersed rod. Making your own foundation using screw piles is easy and financially profitable. Such a foundation is used for the construction of a wooden house, bathhouse or fence.

It should be especially emphasized that the work on making such a foundation for a house is all-season, the building is raised above the ground, is not subject to spring flooding and can be quickly erected with your own hands.

The next stage will be the installation of a grillage on piles, which can be a concrete strip or a wooden frame. For light structures, a pile structure made of pipes serves as support pillars for fastening above-ground profiles.

Foundations for heavy loads can be made using metal piles installed in pre-dug holes.

In this case, installation of pipes with your own hands takes place using a special technology.

- According to the plan, foundation points are marked on site and pegs are driven in.

- The foundation boundary is marked with a retreat of 2 meters around the perimeter.

- Pits for pillars up to one and a half meters deep are being prepared. You can drill holes.

- A sand cushion is poured onto the bottom, a pipe is installed and secured with sand around the circumference.

- The reinforcement is driven into the sand inside the pipe with a distance between the rods of 7 cm.

- The concrete mixture is poured, compacted, and the alignment and verticality of the supports are controlled during the hardening process.

- A grillage is installed on top of the pipes.

When doing the work yourself, you must use metal pipes with a diameter greater than 250 mm. When installing pipes, the sand cushion must be sufficient to support the heavy structure. There should be at least 30 cm left at the edges of it in order to fill this cavity with clean river sand.

Even before pouring, a binding unit should be mounted on the pipe. Concrete should be poured only using M500 cement. When pouring, constantly compact the mixture using available methods to remove air from the glass. A columnar foundation of this design will withstand heavy loads and can be used to install a house on a slope with a large slope. Such supports are not afraid of quicksand.

The grillage is installed after the concrete has hardened to connect the pipes. The columnar foundation acquires an additional bond, which is made of metal or heavy concrete.

The disadvantage of such structures made from large-diameter pipes is the impossibility of using an underground horse for a warm circuit.

Bored pile foundation made of asbestos-cement pipes

- The cost of work is much less than when constructing other types of foundations.

- There is no need to create a pit and level the soil.

- High construction speed and the ability to start construction immediately.

- The building is located at a certain height (25-30 cm) above the ground, so there is no flooding during heavy rainfall or flood water.

- This also makes it easier to make all the necessary communication connections to the house.

The popularity of pipes made of materials such as asbestos in the construction of foundations is explained by their resistance to frost and aggressive environments. But you will have to spend money on the purchase of reinforcing bars, which will be needed in order to strengthen the pipes for the piles.

Columnar foundation made of metal pipes

This type of foundation requires the most waste, but is the most reliable among analogues of pile foundations.

The most difficult thing when constructing a foundation made of metal pipes is the correctly determined accuracy of their height relative to each other. To level the pipes, they must be filed down.

These pipes also need anti-corrosion treatment with special substances, otherwise the structure will not last more than twenty years.

And such processing also costs money.

Advantages of foundations made of PVC plastic pipes:

- All installation work with PVC pipes is possible on your own; there is no need to involve heavy special equipment, equipment and crews. To install the most common type of foundation for frame and lightweight houses - columnar - there is no need to perform large volumes of excavation work.

- According to the technology, bored foundations are considered one of the simplest, and are used for any foundation soil, including problematic ones - heaving, weak, waterlogged, bulk. When constructing on a site with complex terrain, slopes, changes, pile foundations are also successfully used.

- The technology does not require large-scale excavation work; all actions can be performed in the immediate area of the building. If there are buildings nearby, the area is saturated with underground utilities, and the root system of nearby green spaces must not be damaged, then a pile foundation made of pipes will also be a practical solution.

- A foundation made of pipes allows you to vary the height of the building above ground level with a minimum of additional financial investments, as needed. For areas flooded by floods or high water in the spring, this is an important advantage.

- It is possible to lay the necessary pipelines and utilities under the building.

- In terms of construction time, this foundation is one of the fastest. It is possible to cut pipes to the required length using ordinary household tools, without additional equipment.

- In terms of cost, this foundation provides a reduction of more than two times. The advantages of polyvinyl chloride over other building materials are absolute neutrality to the aggression of the natural environment, to chemicals contained in soils, to water - no waterproofing is required. Plastic also does not need thermal insulation, since PVC does not experience temperature deformations under operating conditions in the ground. Thus, there is no need to purchase insulating materials for the foundation, and in addition, transportation of lightweight plastic pipes is significantly cheaper.

Disadvantages of using PVC pipes for pile foundations:

- Arrangement of a basement or basement is possible only with considerable additional costs for wall insulation; in addition, in this case, a grillage will be required, working in conjunction with a pile foundation.

- The service life of this foundation is often shorter than for other types of foundations, but this is due to the weight of the structure. Frame houses are much less massive than brick and block houses. With high-quality installation, a columnar foundation using plastic pipes will last more than 30 years.

- There is a limitation on the weight of the building, and as a result, all materials are selected on the basis of the least weight: load-bearing blocks for walls, roofing, floors, finishing and cladding.

Scope of application of plastic pipe foundations

- Country house.

- Outbuildings - garage, summer kitchen, bathhouse, gazebo or terrace, small architectural forms and others.

- Prefabricated houses made of large lightweight blocks. Bored piles in pipe formwork can be loaded earlier than a columnar foundation, since the concrete in the pile formwork gains strength faster (up to 70% on the 14th day from the day of concreting under normal hardening conditions).

- Light frame houses.

- Stoves, massive boilers and fireplaces

Sequence of work on constructing a foundation made of PVC pipes

The first step is to prepare the site: no leveling is required, only cutting off the fertile soil is performed. Pre-clean the area of stones, debris and vegetation - trees, bushes, roots.

The second stage is marking the piles. The base of plastic pipes is installed so that all pile supports are located along the perimeter of the walls and internal partitions; in the corners and junctions of external and internal load-bearing walls, the piles must be precisely centered. The greatest distance between the centers of pile supports is 250 cm.

The third stage is drilling wells. For this type of foundation, a PVC sewer pipe of small diameter is usually used (200 or 250 mm, much less often 400 or 500 mm), so it is possible to use a hand drill. When drilling manually, it may be difficult to maintain the verticality of the holes, so they are made with a larger diameter than the cross-section of the pipe - for subsequent straightening and unfastening of the pile support in the vertical design position. Along the bottom of the wells, a crushed stone (sand, sand and gravel) cushion and waterproofing are made to protect the concrete of the pile base.

The fourth stage is to install plastic pipes into the wells, level them to the mark and ensure that the plane of the upper edges of the piles is horizontal. Then the piles in the wells are strengthened with external sprinkling with careful layer-by-layer compaction. The filling is made from fine crushed stone or gravel, pouring cement mortar on each layer, and filling the top of the holes with soil.

The fifth stage is to reinforce and concrete the piles in plastic formwork. The number of longitudinal rods and the diameters of the working reinforcement depend on the weight of the future building; usually, periodic profile reinforcement with a cross-section of 8-10 mm is used. There are options for installing a vertical reinforced frame into a pipe before concreting, or installing one to three reinforcement bars into a PVC pipe immediately after the pipe is concreted and the concrete is compacted by bayonet. The outlets of the working rods from the pipes must be left - for connection with the grillage piping or directly with the ceiling of the first floor.

The concrete mixture for filling plastic formwork is usually prepared on site, since the need for the mixture is small. Portland cement M400 and fine aggregate are used, since the cross-section of the pipes is small, and the pipe should be filled tightly and air should be removed from the concrete.

A few nuances regarding the construction of a foundation made of plastic pipes:

One of the main requirements for foundations is to ensure maximum service life by reducing the destructive influence of the external environment. The difficulty lies in the difficulty of monitoring their condition, especially reinforced concrete structures, which are sensitive to the presence of moisture and sudden temperature changes. Therefore, the optimal solution would be to lay a foundation with permanent formwork made of plastic pipes.

Laying a sewer pipe under the foundation of a house

Let's consider laying sewerage under the main types of foundations.

Strip foundation

The sewer outlet device depends on the depth of the strip foundation and the thickness of the freezing layer of soil.

For example, with a shallow monolith of 1.2 meters, the pipe passage can be located under the foundation. To do this, a vertical pit with a diameter larger than the sewer riser is dug under the house to the bottom of the foundation. They dig trenches from the outside and lay pipes from the septic tank (cesspool) to the reinforced concrete base of the house.

Sewer liner

An entrenching tool is used to make a hole under the foundation. A metal, polymer or asbestos pipe (sleeve) with a diameter larger than the sewer pipe by 50 mm is inserted into the resulting hole. This is done in order to avoid the effects of various deformations on the pipeline. The sleeve acts as a gasket between the pipeline and the body of the tape monolith.

The external inlet is connected to the internal outlet by a knee section. The knee joint is performed at an angle greater than 90 degrees. This will prevent blockages in the pipeline.

When laying a deep foundation, the sewerage outlet is made through a passage in the body of the monolithic foundation of the house. To pass the sewerage system through the foundation monolith, an inclined drilling method is used.

If the structure of the foundation is rubble concrete, that is, it does not have internal reinforcement, drilling the body of the monolith will not cause any particular difficulties. Drilling reinforced concrete can be complicated by the collision of the drill bit with the reinforcement cage, which will inevitably cause damage to the reinforcement ties.

Drilling of monolithic reinforced concrete should be trusted to experienced specialists so as not to break the reinforcement frame in critical places. This can significantly weaken the bearing capacity of the foundation and cause destructive deformations in the building structures.

In the resulting well, it is imperative to install a gasket in the form of a sleeve, which is wider than the waste pipe. The sewerage system laid in this way will protect the sewer pipe from deformation and damage.

In case of any complications associated with soil freezing, the pipe inside the sleeve is insulated (wrapped with mineral wool).

Foundation design made of plastic pipes

Plastic pipes are made of reinforced concrete pillars, which are poured when laying the foundation into a specially installed permanent formwork made of polyvinyl chloride (PVC) pipes. In the lower part of the base, a widening of the base is provided on the basis of a sand-crushed stone cushion, ensuring the immobility of the structure in the vertical direction.

A grillage is formed in the upper part of the foundation, which evenly distributes the load between the pillars. It is made of reinforced concrete, metal or wooden beams. The specific option is selected individually, based on the design features of the building being constructed.

Using PVC pipes as formwork allows you to obtain the following advantages:

- The columns have the same cross-section along the length with minimal deviations from the calculated value. The design has the necessary strength and load-bearing characteristics.

- Concrete is protected from contact with the external environment due to complete waterproofing. Freezing of the soil in conditions close to the surface of groundwater will not cause destruction of the foundation.

- The resistance of plastic to acidic and alkaline environments will prevent their contact with concrete with the subsequent formation of cracks and the appearance of corrosion on the reinforcing layer.

- The simplicity of the technology for laying the foundation with your own hands due to the minimization of excavation work and the absence of the need to manufacture formwork of specified dimensions.

Pipe columnar foundation - recommendations for arrangement

Foundations made of plastic and metal pipes are laid to a strictly defined depth. Its specific value depends on:

- The mass of the building that will be installed on a columnar foundation. This figure can be taken approximately. At the same time, we should not forget about the pressure that the foundation itself will exert on the ground. It is especially important to consider the weight of metal pipes. It can be quite significant.

- Soil features. If the soil water on the site is located close to the surface, you will need to take care of high-quality waterproofing of the structure and the construction of an effective drainage system. It is impossible to build a columnar foundation on peat and silty soils. But it can be built on sandstones without the slightest difficulty.

The most important advice! A columnar pipe foundation is always laid below the freezing point of the ground. Do not neglect this recommendation if you want a self-made structure to provide reliable support for your house or other structure.

Pipe column foundation

A foundation made of plastic products is usually made using supports with a cross-section of 200 mm and a length of 2 m. Sewer pipes are ideal. They are characterized by sufficient rigidity and good reliability, long service life, resistance to sub-zero temperatures, and ease of DIY installation due to their low weight.

When using metal pipes, they must be treated with anti-corrosion compounds (for example, bitumen mastic) and wrapped with roofing felt in several layers.

If you do not do this, the supports will rust very quickly, which will reduce the service life of the foundation by 3-4 times.

Pipe columns are installed at the corners of the future building, on the lines where its load-bearing walls intersect. In addition, supports must be installed every 1.5–2 m along the perimeter of the facility under construction.

It is recommended to make holes for installing pipes using a hand drill. In this case, the diameter of the hole should be slightly larger than the geometric parameters of the permanent formwork.

The technology for creating a tubular base with your own hands is not difficult!

The foundation of plastic and metal products is laid in the same way. The order of work is as follows:

- You are preparing the site for laying the foundation. Level the ground, mark the territory according to a pre-drawn plan, and mark points for installation of pipe products.

- Drill holes of the required depth and section.

- Create a cushion of gravel and sand (the layer should be about 20 cm thick after carefully compacting the filled materials).

- Install the pipes in the prepared holes. At this stage, you should carefully monitor the vertical installation of the supports. Keep a building level handy and use it at all times.

- Fill the supporting elements with 30–35 centimeters of sand and compact it.

- Fill the holes with a concrete liquid composition (water, 3 parts sand and part cement). The solution should thoroughly saturate the compacted sand.

- You make and install formwork from boards. Now you need to wait for the concrete mixture to harden.

- Place reinforcing bars into the cavity of the tubular products. The distance between the individual rods is maintained at 7 cm. Press another rod into the middle of the pipe. It must go all the way to the concrete base. This element is necessary to increase the strength of the entire structure.

Then you need to fill the supporting elements by a third with concrete (inside and outside), wait a day, pour earth onto the hardened surface, compact it and add concrete mixture into the pipe to its upper end. The last step is to fill the outside of the pipe with a mixture of earth and sand and compact this layer.

The work is completed! You have created a reliable column-type pipe foundation for unloaded buildings.

Source https://remoskop.ru/fundament-iz-metallicheskih-trub-svoimi-rukami.html

(Visited 355 times, 1 visits today)

Preparatory work

The main stage of preparation is to calculate the expected load on the foundation and study the bearing capacity of the soil. The first problem is solved by carrying out engineering calculations based on the building design and the building materials used. The second task requires a thorough analysis of the soil composition on the site and determination of the occurrence of groundwater.

Soil analysis requires the involvement of specialists who can reliably determine its composition and location of dense rocks. The depth of laying the foundation pipes and the reliability of the object being built will depend on the result.

There are three types of columnar bases:

- Not buried. They are used for the construction of auxiliary or ancillary facilities. The laying depth is up to 0.5 m.

- Shallow. The laying depth is up to 1 m, which is half the soil freezing level in the middle zone. They are used for the construction of frame houses on dense soils.

- Recessed. They are laid to a depth below the freezing level (from 1.5 m). They are used for the construction of low-rise buildings on weak or floodable soils.

After choosing the type of foundation, they proceed to preparing the site for construction with their own hands. Wooden or steel pegs are driven into the corners of the building being erected and a rope is pulled around the perimeter on them. From the corners of the markings, they retreat 0.5 m along the lines, drive in pegs and pull ropes on them to form the perimeter of the building being erected. The pegs driven into the corners are removed. This solution will allow you to accurately drill holes for pillars without disturbing the markings.

Using a tape measure, mark the places for the pillars, remove the fertile soil layer to a depth of 30 cm and drill wells along the diameter of the pipes. It is important to provide a margin of 10 cm in diameter to allow alignment of the pillars. It is allowed not to remove the surface layer on the building site if the area is flat. The interval between pillars should be 1-2.5 m, depending on the load of the building and the type of soil.

At the bottom of the wells, special equipment is used to drill expansions for the base of the piles. The diameter of the PVC pipes used is from 150 to 250 mm. Consequently, the diameter of the drilled wells will be from 160 to 260 mm.

Where to begin?

Marking the foundation for piles

First, the future foundation is marked.

We suggest you read: How to press the upper corner of a plastic window

Then they cut off the top layer of soil from the place where the construction will be. And then the required number of wells is drilled. Wells are made at a distance of 1.5-2 m from one another.

It is imperative to determine the number of supports under the foundation of the house where the greatest load will be. In this place, you will need to drive a larger number of pipe piles into the ground

The size of foundation wells depends on the "caliber" of pipes expected to be used. The height of the piles above the ground does not exceed 0.5 m.

Formation of sand and crushed stone cushion

A columnar foundation made of plastic pipes must be installed on special drainage pads, which are formed as follows:

- A layer of purified sand 25-30 cm thick is poured into the bottom of the wells.

- The layer is compacted by pouring copious amounts of water and tamping.

- A 15-20 cm layer of medium-grain crushed stone is poured on top of the sand, leveled and compacted.

- To reduce the consumption of cement mortar, an additional 5-10 cm layer of fine-grained crushed stone is poured.

Laying PVC pipes

After laying the pillow with your own hands, proceed to installing PVC pipes. They are pre-cut to a given length. The height of the outer part is 40-50 cm.

The lower part of the pipe must be waterproofed. To do this, it is wrapped with a dense layer of waterproofing film or roofing felt and secured with a plastic ring or clamp. However, the layer is not made tensioned, but with a margin, since it should take the shape of a cushion at the bottom of the well. Be sure to check the tightness of the connections, since the presence of microcracks will shorten the service life of the columnar base.

After preparing the PVC pipes, they are carefully inserted into the wells without damaging them. Using a plumb line or level, set them in a vertical position, and fix them on the ground surface with wooden blocks. Deviations from verticality can cause improper load distribution and cause premature wear of adjacent posts.

First, you should insert PVC pipes into the corners of the building being constructed with your own hands in order to determine the zero level of the pillars for installing the grillage, if necessary, trim their upper part, and only then proceed with the installation of auxiliary ones. If the intermediate pipe is not of sufficient height, then the zero level is reduced.

Columnar foundation manufacturing technology

Further work will be divided into two stages, each of which requires responsible and step-by-step implementation.

Drilling wells and installing piles

- According to the markings, wells are made using a drill. The depth of the well should be 25 cm deeper than the soil freezing level, and the width should be 7 cm greater than the diameter of the PVC pipes. Due to possible collapses, you should not drill all the wells at once, it is better to make them sequentially;

- Using a shovel or a special drill attachment, an expansion is made at the bottom of the well with a height of 25 cm and a diameter of 12 cm;

- A cushion is made at the bottom of the well from a mixture of sand and gravel 20 cm thick;

- The pipe is inserted so that its surface practically coincides with the lower plane of the grillage.

- Using a level, mark the location of the lower part of the grillage on the pillars and, if necessary, cut the piles according to the markings;

The verticality of each pipe must be checked with a level and then secured.

Pipe concreting

- For convenience, pour the prepared concrete solution into a container and pour 20 liters into the cavity of the pipe; it is necessary to raise it by 20 cm. The concrete, spreading along the expansion, forms a heel. Cover the remaining space around the support with soil and compact it thoroughly;

- Insert a pre-welded frame of three reinforcement bars into the pipe so that their edge is 25 cm higher than the plastic pipe if you plan to install a reinforced concrete foundation. If the connection will be made with wood, then the reinforcement should be installed below the edge of the plastic pipes by 5-7 cm.

- Concrete should be poured in portions, with each layer carefully compacted using a vibrator or metal rod. In the latter case, it is necessary to act with the utmost caution so as not to damage the integrity of the plastic poles;

- Pour concrete solution until it reaches the level of the pipe;

- Fill the pipes completely with the solution, compact them, install a pin with a diameter of 10-12 mm (for a wooden grillage) into the pile and leave until completely hardened.

Formation of the reinforcing layer

Installation of a reinforcing layer is mandatory for the foundation, as it distributes the load along the column, and in the presence of heaving or loose soils, it eliminates deformation or damage to the structure. Structurally, it consists of four reinforcing bars with a diameter of 8-12 mm, located in cross-section at the corners of a square, with thick wire ligation along the length of the column at intervals of 1-1.2 m.

The length of the side of the square of the piping is determined taking into account the diameter of the pipe: the reinforcement should not touch its walls and be at a distance of 20-30 mm. When pouring concrete, the reinforcing structure must be completely immersed in the solution and not come into contact with the surface of the PVC pipe.

The reinforcement cage at the level of the sole should have an extension in the form of ends bent at right angles, and its length should be equal to the height of the pipe. It is formed on a flat surface, and then carefully lowered into a PVC pipe and centered.

How to correctly introduce water into a private house from a water supply system

It would seem that it could be easier to install a water pipe into a private house. But, as practice shows, this seemingly simple process is associated with some requirements relating not only to the laying of pipes with the installation of a water meter, but also to their insulation and insulation. In addition, the water supply to the house from the water supply system, or rather the point of entry, can be located very low. This means that you will have to lay pipework through the foundation into the basement, and maybe even under it. Therefore, even at the stage of laying the foundation, a pipe with a larger diameter than the diameter of the pipe of the future water supply is laid into its structure.

Laying pipes through the foundation

Let's start with the fact that the water supply system of a private house can be connected to a central water supply or can be organized as an autonomous local network in which water will be drawn from a well or well. Therefore, the installation process of a water pipe (home) will be carried out differently in different cases.

Pouring concrete

To fill the columnar base, concrete grade M400 or higher is used to ensure the strength and reliability of the structure. The main feature of pouring is the need to perform this procedure at a time to obtain a monolithic structure. Preparation of the solution is required in large volumes, which cannot be done in construction concrete mixers. Therefore, it is recommended to order it from a concrete plant.

When pouring concrete with your own hands, you need to ensure that air bubbles are removed from the volume inside the pipe. For this purpose, it is advisable to use vibration installations. The surface of the pillars should be leveled with a rule or trowel, and then an anchor pin should be inserted to secure the grillage. When the solution shrinks, it is necessary to add it to the upper level before it begins to harden. The concrete hardening time is 28 days.

Final part

Laying a columnar foundation with your own hands using PVC pipes is a simple technology for obtaining a reliable and durable foundation at minimal financial cost.

Today there is a wide variety of types of foundations created. Each type uses different materials and installation methods. Since this is a load-bearing structure, the most stringent requirements are always placed on it; it is the basis of any structure. The main property that it should have is strength. The speed of foundation construction and its cost are also important. One of the common types today is a columnar foundation made of PVC pipes, which is reliable and has many advantages.

How to fix the error?

When constructing a foundation from piles yourself, if the load is calculated incorrectly, violations appear that lead to the building being skewed, its subsidence in problem areas, or cracks in the load-bearing walls.

If the place where the mistake was made is discovered immediately, there is no need to panic. If metal pipes that protrude above the soil were used for the foundation, then this is the simplest correction option.

You can weld profiles to them and thus connect them to each other. For other types of pipes, you will have to dig trenches in places where the foundation subsides and pour a monolithic foundation base.

Well preparation

Screws or anchors are screwed into these holes, and reinforced rods are welded to them, thereby ensuring a rigid connection between all supports.

As a last resort, it is possible to use special equipment to lift the corner of the building from the sagging side and dig a trench.

And in the trench, build part of a strip or monolithic foundation.

Design features

The design of a columnar foundation made of polypropylene pipes is quite simple, which distinguishes this type from other types. It can be installed on any soil, including sandy soil. The supports are installed in the ground, in a pre-drilled hole. They must be installed 1.5 meters below the point at which the soil freezes. This technology will ensure reliability and durability of the future load-bearing structure.

Subsequently, the loads of the house act on the pipes in all directions. This will prevent them from becoming loose and will prevent them from sinking. When installing the foundation, one of the main points will be the correctly calculated depth and location of the supports. The resulting value must be such that, under the influence of any factors, the building remains stable and does not sink into depth.

Making the foundation with your own hands

Let us dwell on the main points of the question of how to make a columnar foundation from PVC pipes yourself. It is possible to make such a foundation without the use of professional labor, but for this a number of conditions must be met:

- In order to have good adhesion to the grillage, steel rods are left on each pipe support in its upper part.

- The grillage is installed and connected to other elements in accordance with the chosen design.

- To prevent groundwater from entering the pipes, they must be closed with a plug on one side and secured to the previously poured sand and gravel.

- They must be located at every corner of the future building and in places where the main structures intersect and adjoin.

- The supports must be placed 25-30 cm below the point at which soil freezing is recorded, approximately from 1.4 to 1.7 m.

- The pipes should rise above the ground by at least 20 cm, and on average 40-50 cm.

And in conclusion, I would like to say that if, when laying a foundation from PVC pipes, you use high-quality basic and consumable materials, be sure to adhere to the basic recommendations and follow construction technology, then such a building will become durable and reliable. It will delight owners with its efficiency, and in addition, it will last a very long time.