One of the problems that has to be solved when arranging a staircase is related to the correct choice of the type of covering for the steps. Parquet, wood, are convenient, but expensive, and besides, the wear and tear is very strong. Plastic looks beautiful, but somehow too unnatural. Many master tilers used laminate for concrete stairs even before the advent of porcelain stoneware. And even today, during a period of general enthusiasm for ceramics, the technology of finishing staircase steps with laminate remains just as popular and in demand.

Such a staircase can be found in any home

Features of finishing staircase steps with laminate

The popularity of laminar flooring does not mean that the method of cladding a flight of stairs will be simple. In essence, this is painstaking work comparable to the work of a cabinetmaker. It is not just necessary to lay a board or tile, it is necessary to correctly adjust the lamella so that the design of the steps looks like a single whole.

In addition, it is necessary to take into account some specific requirements for planning finishing work using laminate:

- To cover steps with laminate, you need to choose lamellas 1-2 cm wider than the transverse size of the step. There should be no joints or cracks in the laid covering. Otherwise, the locks will open under load, moisture and dirt will get inside the joint, and accordingly, the cladding will quickly lose its appearance. Not to mention the fact that the lock may simply not withstand the load;

- The laminate itself must be strong and wear-resistant enough to withstand a load much higher than that to which the flooring is exposed when laid on the floor of an apartment or house;

- If you plan to climb stairs in street shoes, then the front edge or overhang of the laminate-lined step support will need to be protected with an additional metal trim. Otherwise, the end of the tread will quickly wear down to the chip base.

Of course, covering the stairs with a laminate based on pressed cellulose fiber makes sense only for structures located indoors and reliably protected from rain and snow. For external flights of stairs, you can use vinyl laminate, in which case it will have to be glued with waterproof glue.

For your information! Unlike the classic method of laying laminate flooring, an adhesive fit is used to finish the stairs.

If you choose the option of cladding the stairs using wood-look slats, you will need to think about how to decorate the side parts and risers. It is important that the sides and bottom are also made of laminate. Only then will you get a single composition of a flight of stairs made of wood. If you use a laminate with imitation stone, you can limit yourself to laying vinyl covering on the treads of the stairs.

The perfect combination of white and chestnut shades

What do we know about laminate

Laminate for finishing stairs is a modern, practical option

Laminate can be safely called one of the most profitable options for finishing stairs, and this is facilitated not only by the price that is acceptable to many. The benefit also lies in the fact that this material is very practical.

A staircase finished with laminate practically does not differ in appearance from a wooden one, but at the same time it is less noisy and does not require pre-treatment with impregnations and paints.

Installation of laminate flooring for stairs does not require special preparation, and it can be done with your own hands. Such structures can be restored just as easily - worn parts are removed and replaced with new ones. But before you run to the store for this wonderful material, you still need to get to know it better.

The essence of laminate and its properties

Laminate is a multilayer material, and depending on the class, it is used in areas with varying traffic. The staircase experiences constant loads, so a laminate of at least class 31 is used for its finishing.

Structure of a standard laminate floor board

The main elements of any laminated board are:

- The protective layer – it is its thickness and strength that determine the class of the floor covering.

Advice! When choosing a laminate, you should not look at the thickness of the product, thinking that the better it will last longer, since the degree of abrasion of the coating depends only on the thickness of the upper protective film. Always inquire about the abrasion class from the seller first, and only then evaluate the other parameters.

- Decorative layer – creates the texture of the material and determines its shade. Laminate can imitate not only wooden surfaces, but also others, such as stone, tile, wood, leather, textiles, etc. If the protective surface wears off, the decorative layer will still serve for some time, but we wouldn’t count on much.

- The fiberboard panel is the basis of the material, giving it strength and elasticity at the same time. It is made from small wood chips, which are compressed under high pressure and bonded with adhesives.

On a note! It would be hard to call laminate an environmentally friendly material, but in terms of this parameter it also has classes, which we will discuss later.

- Stabilizing moisture-resistant layer - protects the board from moisture that can be transferred from the base on which it lies, for example, concrete.

In addition, the laminate is protected from moisture by the substrate underneath it, so it is covered quite well from below. Such a coating is much more difficult to withstand contact with water spilled on top of it - it penetrates between the seams and is absorbed into the fiberboard, despite the fact that the locks are usually covered with wax. As a result, the board swells, the locks come apart, and sometimes it happens that the coating becomes like a “house.”

This leads to a simple conclusion that for a laminate to have a good long service life, it is not enough to be treated from the factory. Correct, careful use of the coating is very important.

If water gets on a seam, it must be wiped off immediately

One small drop on the seam and your coating can look like the one shown in the photo below.

Swollen laminate that has absorbed a lot of liquid

To prevent this from happening to you, always remember one simple rule. Wet cleaning should only be done with a well-wrung out cloth so that any moisture remaining on the surface quickly evaporates into the air. If it happens that water is spilled, then wipe it off immediately, and the sooner the better.

If you are used to washing your floors like this, then laminate is not for you.

So let's get back to the main point. What should you pay attention to when buying laminated boards?

Classification of laminate according to the degree of abrasion

- The abrasion class is the main parameter that will determine the service life of the coating. Choose higher options. More details in the table presented above. Remember that the higher the class, the more expensive the finishing.

- Product thickness – there are options of 6,7,8,9,10 and even 12 mm. The larger this parameter, the stronger the board. It is easier to work with and will creak less during operation.

- Width is a particularly important parameter when finishing the stairs in a house with laminate. The fact is that both the height and depth of the steps are fixed values, and it will be much more convenient to carry out the cladding if the board is selected correctly and does not need to be constantly trimmed longitudinally. In addition, it is desirable that the treads of the stairs do not have a locking connection, which can come apart over time.

- Now about health. The coating should not in any way harm the people using the stairs. For this purpose, the formaldehydes used in the composition of the board were divided into environmental classes. For interior coatings of residential buildings, it is best to use E1 class laminate, which complies with European EN standards

Eco-friendly laminate labeling

- The guaranteed service life specified by the manufacturer - on the packaging you can find figures from 2 to 6 years - naturally, these are greatly underestimated figures. In practice, such coatings last at least 10 years, but with the condition that all requirements for the operation of the product are met. But, nevertheless, a situation where a plant is confident that its products will last longer than analogues from competitors puts it in a more advantageous position.

- Manufacturer - here you can safely separate the rest of the world from China. We don’t want to offend our friends from the Middle Kingdom, since there are companies whose products are not inferior in quality to the world’s best brands, but most often they buy low-quality products at a lower price. Separately, we note that perhaps the world leader in the production of floor coverings is Swedish, whose products are always distinguished by their excellent design and quality.

Factory manufacturer of floor coverings

When choosing a laminate, also pay attention to the surface texture. It should not be slippery, since moving up stairs, especially for older people and small children, always involves some risk. Therefore, it is better to immediately abandon polished options and choose something matte or semi-glossy.

Accessories for laminate

Laminate flooring is a prefabricated product that can be cut to fit the intended location if necessary. There are also external and internal corners on the flight of stairs.

All this must not only be firmly installed, but also beautifully designed - the cut points are covered with decorative overlays, and moldings are installed on the corners, which, in addition to beauty, may have anti-slip properties.

Corner moldings are attached with self-tapping screws or glue, making the skin almost monolithic and more durable. Installing them yourself will not be difficult.

For cladding external corners, L-shaped stair corners are most often used, which are:

| Corner type | Description |

Metal corners | Metal - made of aluminum, steel or brass. Such corners are very durable - wear resistance depends only on how long the paint on the product lasts. Colors like gold, polished steel and wood are very popular, but it is better to choose the texture and shades to match the main coating and the surrounding interior so that everything looks harmonious. |

Corner made of plastic | Plastic ones can also be made to match any material, so choosing the exact shade to match the laminate will not be difficult. Such a part will not only serve for a long time, but will also hide all minor irregularities, as it has some elasticity. Separately, it is worth noting the low price compared to other analogues. Such corners are attached with glue, so for a strong connection, purchase especially strong compounds. |

Wooden corners | Wooden - this is the most expensive option. Thanks to it, the corners of the steps can be rounded by purchasing options, as shown in the photo. Such steps are less dangerous because they do not have sharp protrusions that can be hit when falling. They go well with laminate in appearance, and are suitable for restoration: the wood can be sanded, cracks and gouges filled with putty, and re-opened with varnish. |

In addition to the simplest standard options discussed above, special laminated profiles are sold for laying laminate on steps.

Laminate finishing of stairs: laminated profile at the corner

Such profiles are fastened with the help of special metal plates containing counter protrusions and grooves, due to which the strip is firmly held in place. Particularly popular are products from the Belgian company Quick Step under the Incizo brand, which are produced to all quality standards.

Metal strips come in several sizes, and their shape can vary significantly from model to model.

Laminated end cap

To install this structure, a metal rail is attached to the steps using self-tapping screws. Next, the overlay is coated with glue along its entire length and installed on top. The resulting connection has no visible fastening areas, therefore it is more aesthetically pleasing.

Self-adhesive tape

To hide the steps from the sides, adhesive tape is used, which has the same pattern as the decorative molding.

Laminated plinth

In order to cover where the steps meet the wall, you can also purchase a rectangular plinth made of laminated boards. With its help, you can carefully repeat the shape of the steps, hiding all visible flaws.

Inside such a plinth there is a cable channel through which you can run an Internet cable or any other wires to the top.

Plastic skirting board

A standard plastic baseboard will also work, but this solution will lack the elegance of the previous option, and the finish will look more budget-friendly. Among the advantages I would like to note is the ease of installation and the presence of a cable channel.

The underlay under the laminate is used only on large, flat areas where the laminate lies like a large shield under its own weight. On treads, its presence is not necessary, and sometimes it is not necessary at all, but if it is necessary to create a heat, sound or waterproofing layer, a preliminary laying of this coating is carried out. To protect against water, it is enough to lay a thin plastic film.

Types of underlays for laminate

Among other things, the substrate will increase the resistance of the coating to loads - it cushions the board when walking on it, although over time any substrate will be pressed and pressed, losing these properties.

Pros and cons of covering stairs with laminate

When choosing a material, the question always arises about the advisability of using lamellas for finishing work. How profitable is it to decorate the stairs in a private house with laminate? At first glance, using an expensive laminate where you can lay a regular board looks like an unjustified waste of money.

If we take into account the service life of a high-quality laminate flooring, it turns out that the costs will pay off at least twice as much as a wooden staircase:

- Finishing a staircase opening with laminate will provide a cladding life of 10-15 years, while wooden steps lose their appearance already in the second year of service. After which you will need to sand the surface, additionally open it with varnish or paint;

- In order to replace a damaged lamella, it is enough to cut off the covering with the adhesive base and install a new piece of material; in this case, a wooden or metal staircase would have to be disassembled down to the stringer.

If we consider the positive aspects of the technology, then the use of laminate is completely justified. The coating made of melamine film is more resistant to abrasion and practically does not lose its appearance even in conditions of heavy traffic. In addition, the slats do not generate dust, like concrete or brick, and the coating does not rub off until polished spots appear, as on the steps of a metal staircase.

Laminate flooring laid on the treads of the stairs provides more comfortable walking conditions. Thanks to the artificial roughness, climbing laminate flooring is much more pleasant than if it were wooden steps. The surface of the slats is never slippery, even if for certain reasons there is water on the stairs.

Cladding the stairs will require the skills of a carpenter

Among the negative aspects, one can note the increased complexity of the work. In order for a laminate staircase, photo, to look quite presentable, you will need to spend a lot of time and effort. But in general, such work is justified, since with high quality installation, the next repair, even cosmetic, will be required no earlier than in 10-15 years.

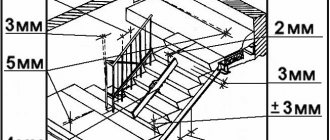

Parquet installation quality

Another disadvantage is associated with the formation of a worn dark path. The steps are designed in such a way that most people, going up or down, step on the same places on the tread. As a result, a dark stripe forms, which will need to be washed and cleaned periodically.

Advantages and disadvantages of laminate

The primary factor that indicates the advantage of laminate over other materials is the low noise level during operation. Laminate steps are able to absorb sounds, which reduces the overall noise level in the house and increases comfort. Among other positive properties, the following should be noted:

- budget price;

- ease of self-installation;

- long service life;

- waterproof;

- resistance to mechanical damage;

- environmental friendliness.

In this video you will learn how to finish a staircase with laminate: In order to make an objective choice of material for cladding the stairs, you need to know both the pros and cons, and correlate them in proportion to your needs. So, laminate flooring for stairs will present you with the following negative aspects:

- When temperatures fluctuate, it tends to change its size, increase or decrease in volume, which creates some difficulties. When installing, a gap should be provided in advance for the upcoming increase in volume;

- During installation, an additional backing will be required, since without it the lower part of the board will rub against the step, creating an unpleasant crack and squeak. Such a substrate requires additional financial investments and time;

- Cheap types of laminate do not differ in durability and quality. Any product purchased at a minimum price will have fairly low properties, so it is better to take the average price.

These points may have greater or lesser force for each person individually, so it is quite difficult to judge how the pros and cons compare.

How to choose laminate for laying on stairs

The process of selecting material for cladding a staircase opening turns out to be no more complicated than a similar choice for arranging a laminated floor. First of all, you need to decide on the color and texture of the laminate.

Traditionally, the color and texture of the surface of the coating is tied to the interior of the room to which the staircase belongs. It can be the rich colors of chestnut, mahogany or the calm dark colors of bog oak.

Staircase in the color of the flooring

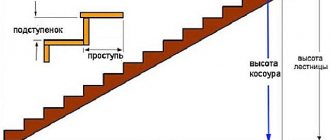

The second step is to select the size of the laminate. Typically, the height and width of the step are 18 cm and 25 cm, respectively. Therefore, at a minimum, you will need to purchase two sets of laminate - for the tread and the riser.

For your information! The amount of laminate can be calculated by measuring the dimensions of the step. For a wooden staircase with turns and intermediate platforms, additional material consumption will be required to arrange the junction of the laminate flooring and the staircase.

Regardless of the size of the span itself and the area of the steps, for cladding it is necessary to buy a class 33 laminate, preferably certified according to EN13329 standards for the content of formaldehyde and toluene.

Criterias of choice

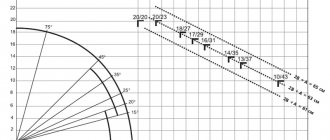

When choosing a material for finishing a flight of stairs in a house, you should pay attention to the technical purpose of the product and its class. At the same time, the class indicator indicates the wear resistance of the material. The second number in the product class marking indicates the thickness of the top laminating layer.

By purpose, laminate is divided into:

- Domestic. Class marking begins with the number 2. They have low impact resistance;

- Commercial. Class markings begin with the number 3. Products marked 32 and 33 have medium and high impact resistance, respectively.

Laminate class 23

Laminated boards marked 21 and 31 have low wear resistance. They can be used to finish stairs that are rarely used. The average service life of the material is 2-3 years. Products with strength classes 22 and 32 have an average level of wear resistance. They are designed for frequent use by a small number of people. This coating will last about 4-5 years. Material with classes 23 and 33 are among the most wear-resistant products. They are able to withstand constant active use of the surface by a large number of people. The service life of such material is 5-6 years.

When choosing a finish for a staircase, you should also pay attention to the appearance of the products and the texture of their surface. The material can have different colors. The color scheme of the laminate should be selected in accordance with the style and colors of the room in which the staircase is installed. It is important that the material does not merge with the flooring and wall decoration.

The slabs can be smooth or textured. Textured products imitate the relief of wood or other material and look very aesthetically pleasing. However, during operation, debris may accumulate in the recesses. Therefore, smooth slabs are more convenient to maintain.

Another important criterion when choosing a laminate is the slipperiness of its surface. To ensure safe use of the stairs, it is advisable to choose products with the lowest slip rates for finishing the steps.

How to prepare a staircase for laying laminate flooring

About half the time is spent on preparatory work. The laminate itself was conceived as a floor covering laid on a soft base made of polystyrene foam, cork or pine cloth. In addition, a perfectly flat, almost smooth surface of the tread is required so that the lamella is completely adjacent to the base of the step with its back side.

Therefore, no matter what material the staircase is made of, each step will need to be checked with a building level, cleaned, sanded and primed with an acrylic mixture.

Algorithm for performing cladding

Following the preparatory stage, the operations of lining concrete stairs with wood are carried out in a certain sequence.

Blanks are cut from ten mm plywood according to the size of each step.

On dry surfaces after puttying and leveling, adhesive mastic is applied with a wide brush, a plywood part is placed (with additional control of its horizontal level) and fixed with dowels.

A waterproofing polyethylene layer is laid. The cladding begins from the bottom with the installation of the first riser, at the end of which three bolts were previously fixed, protruding outward by 6 cm. Having placed the riser in the right place, the contact points of the bolts are marked, the heads of which are cut off.

Holes are drilled at these locations, epoxy resin is added, and bolts are immediately placed. This operation allows you to accurately and reliably strengthen the initial riser.

A groove is cut in the wooden step to align it with the already prepared vertical element. On the other side, the second riser is fixed with self-tapping screws, checking the right angle with a square.

Glue is applied to the plywood, the groove is also coated, after which the first step is put in place. For reliability, its exact horizontal position is checked again, and a load is placed on top.

The entire staircase structure is covered using the same scheme. Having installed the top riser, attach it to the platform with a corner. You can also cut out a wooden blank, in which a groove is also prepared, allowing you to give the entire structure a single harmonious look.

A visual example of how this work is performed:

Wooden plates are fixed on the sides with self-tapping screws. Finally, a protective varnish coating is applied in several layers. Wooden railings and balusters will enhance the beauty and graceful nobility of the updated staircase, allowing it to become one of the dominant accents of the surrounding interior.

How to decorate a staircase with laminate yourself

Cladding a flight of stairs with lamellas is not limited to fixing the material on the surface of the steps, side posts and bowstrings, and risers. First of all, you need to find an acceptable design option so that laminate stairs in the interior, photo, look as organic as possible and at the same time are easy to use.

Unlike wood, laminated coating is practically not subject to abrasion

How to finish a concrete staircase with laminate

Structures made of brick and concrete have long been common in private houses and apartments. You can buy and install a ready-made concrete flight of stairs between floors, or even order its production according to an individual project.

Laminate can be glued or mechanically fixed to concrete

Concrete facing begins with the installation of steel reinforcement, to which railings with fencing and fixing strips that hold the laminate on the surface of the steps will be attached.

For curved surfaces and adjacent areas, you can use vinyl laminate

The simplest cladding option is to stick laminate boards onto the treads, risers and side surfaces of the staircase. It is known from practice that the concrete base turns out to be too rigid, and over time the adhesive fit of the laminate peels off from the surface of the steps. Therefore, it is necessary to use polyurethane adhesives, silicones and other expensive chemicals.

While the glue is setting, the material must be secured with tape.

The second option involves dry laying the laminate, as is done when laying slats on the floor of an apartment. In this case, a cork or coniferous lining is glued to the concrete, and the facing material is laid on top without any bond.

Advice! Use underlayment material for stairs if there are small children in the house. For them, the height of the steps turns out to be too high, so the backing made of pressed pine needles seriously softens and cushions every step.

Fastening with metal profile

To prevent the slats from moving when walking, they are fixed with metal plates in the area of the overhang and riser. After sealing the side parts of the staircase with laminate, the metal fasteners remain hidden.

Adhesive-based finishing of steps

How to finish a metal staircase with laminate

The method of facing metal steps, depending on the design of the span, can be open or closed. The first option is used for stairs in which the steps are already formed from a metal sheet or rod; all that remains is to lay the supporting surface of wood and laminate.

In this case, a lining of two or three layers of plywood glued together is laid on the metal step. You can use a board, but plywood turns out to be more durable and hardy. After installing such a package on the metal frame, the step and riser are glued to the laminate panels, and the overhang is covered with a decorative overlay. To prevent the step from moving off the frame, it is fixed on the back side with self-tapping screws.

Cladding the frame with laminate boards

In the second case, the sheets are simply laid on a metal frame and secured with mechanical fasteners. The joint along the eaves line is closed with a decorative metal corner.

How to finish a wooden staircase with laminate

Unlike concrete and metal, wood is best suited for attaching slats. It is not without reason that the laminate manufacturer strongly recommends using wooden slabs and surfaces as the basis for laminate flooring.

Finishing a wooden staircase with laminate consists of the following operations:

- Initially, the surface of the step is cleaned and adjusted to size so that the laminate sheet does not “flap” under load. If necessary, small strips of geotextile can be placed under the edges;

- A slab cut to size is laid on the base, marks are applied to the lamellas to allow the most correct position of the cladding to be fixed on the wooden frame;

- Polyurethane glue is applied, after which the lamella is laid, aligned to the marks and pressed to the staircase frame using a pad.

Making a joint line with an overhead corner

The risers can be installed a few days after the glue has completely set. This part of the cladding is installed with support on top of the horizontal plane of the step. There should be a gap of 1-2 mm between the riser and the overhang of the lamella; it cannot be sealed or filled with putties.

Preparatory work with the staircase structure

Even before laying the laminate on the stairs, it is imperative to prepare the staircase structure itself and, if necessary, make a complete or partial repair. This is an integral step of the entire complex of work.

Before purchasing panels for cladding stairs with laminate, you should calculate its quantity. First, measurements are taken (length and width) of the largest horizontal surface (tread) in width, and the calculated value of its area is multiplied by the number of steps. The same calculation is made for risers.

After purchasing the laminated material, it is kept indoors in packages for 48 hours to acclimatize.

At this time, we prepare the stairs for cladding.

Checking the reliability of steps, replacing or restoring defective areas

In preparation for covering a wooden staircase

laminate, you need to make sure that its components are securely fastened and strengthen them, if necessary, using self-tapping screws. Gaps and cracks are filled with wood putty.

Worn or defective steps must be replaced, after which they are leveled in height using plywood sheets.

When covering a concrete staircase

With laminate, uneven or defective steps are leveled using leveling mixtures (cement; for large gaps, concrete mixture is used). When the solution dries, sand the surface using sanding paper. To get rid of cement dust, the steps must be vacuumed and then wiped with a damp cloth.

Removing the remains of the former coating

All steps should be thoroughly cleaned of any loose paint, old linoleum, carpet or other trim, this could damage the installation of the laminate panels. Clean off traces of glue and grease. Remove protruding nails and screws.

In case of damage to the wooden covering itself, it is necessary to perform leveling. You can do this in several ways:

- removing the top layer with a polishing tool;

- the use of a leveling substrate that can level out minor differences in height;

- leveling with plywood.

Rules for caring for stairs covered with laminate

In order to prevent deformation of the material and maintain its appearance, the stairs are cleaned at least once a month from dust accumulated at the joints. This can be done with a vacuum cleaner and a stiff brush.

The stairs will have to be polished regularly with mastic

If stains appear on the surface, they are removed by dry cleaning using special products with a minimum amount of water. Immediately after cleaning, the surface is wiped dry and treated with wax mastic used to care for parquet.

Surface preparation

Finishing stairs with laminate is a labor-intensive and multi-step process. It begins in the same way as all other finishing works with surface preparation.

If the staircase is completely new, then there is no special need to prepare it, but the old structure needs to be carefully worked on.

First you need to remove the worn coating from its surface. Next, thoroughly wash and remove dust and dirt from each step.

If there is black mold on any structural element, it must be treated with a special antifungal compound.

If this is not done, then the fungus will definitely spread to the laminate and then the staircase will not only lose its attractiveness, but will also begin to collapse.

Which classes to choose

The specifics of using laminate flooring on stairs do not imply exposure to large amounts of water or the use of heavy furniture on wheels. In this regard, stairs have better conditions than the floors in the rooms they connect.

Therefore, the choice of laminate class can only be determined by the magnitude of the load on the surface.

- If the movement of people is infrequent, episodic, then you can get by with the cheapest class 31, which has poor abrasion resistance compared to other types of material.

- A load of medium size corresponds to strength class 32, the most common among all coating samples. It has the widest selection of color, texture, gloss level and other coating parameters.

- The constant walking up the stairs of people in street shoes, women in heels, high mechanical loads on the coating determine the choice of the highest classes - 33 or 34. This laminate is able to withstand the constant flow of people, its degree of resistance to mechanical stress on the surface is the highest, but also the price is appropriate.

What will you need?

To cover a staircase with laminate, you will need:

- High-strength laminate, the width of the panels is equal to the width of the steps.

- Corner wooden thresholds, metal or plastic profiles covered with laminated film to match the color of your panels.

- Special polyurethane glue.

- Self-tapping screws.

The corner profile, or molding, when facing the stairs with laminate, is used to decorate the outer corners of the steps. It is needed in order to close the unaesthetic joint that is formed by the panels laid on the step and riser. In addition, it additionally fastens the panels together and protects the joint during operation. This profile is placed on top and secured with glue or self-tapping screws.

Stair profiles for laminate can be of several types:

- Metal moldings. They perform an excellent decorative function and also reliably protect the corners of the steps during the operation of the stairs. In addition, such profiles are equipped with a corrugated surface and have anti-slip properties.

- Plastic profiles. They also do a good job of protecting edges and keeping corners neat while covering the joint. Their main advantage is their low price. Manufacturers offer a fairly wide range of various shades of such profiles. They are attached with glue that has good strength characteristics.

- Wooden thresholds. They are a great addition to laminate stairs. Characterized by a long service life. Installed with screws or glue. Such moldings are quite expensive.

- Laminated profiles - ideally combined with laminate flooring. The laminated profile consists of a metal guide and a laminated covering. The metal strip is mounted on self-tapping screws, then a laminated corner is glued on top with glue. This option is considered the most reliable, durable and aesthetic.

Laminate: features and advantages of the material

Laminate is a modern wood-fiber material that is highly resistant to physical and mechanical stress. Its main feature is that in appearance it closely resembles natural wood.

Laminate-covered steps look neat and aesthetically pleasing and are convenient and comfortable to walk on.

Even a beginner can easily do laminate cladding with his own hands, since this finish is easy to install and very versatile.

The advantages of laminate include:

- high strength to various types of impacts;

- economical cost;

- ease of installation;

- practicality and versatility;

- water resistance;

- environmental Safety;

- long service life (up to 6 years or more).

The environmental properties of laminate make it a universal material for use in private country houses and cottages