Cement mortar for screeding the surface before laying tiles

It is made from fine and medium sand, Portland cement and other ingredients (lime, retarders or accelerators,

etc.). Pre-mixed mixtures are available for sale, packaged in bags, and are used for both floors and walls. You only need to mix them with water or liquid polymer before use.

This solution is used to level surfaces during repairs and new construction. Should not be used as tile adhesive.

Technology for laying cement-sand mortar on the roof

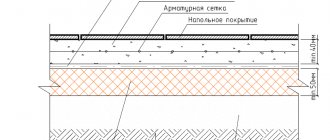

A strip of cement-sand mortar is laid by two workers, leveling the laid mortar with a shovel, after which they smooth the surface of the mortar using rule (vibrating screed) 3 or a trowel, making zigzag movements. If after one pass of the rule there are still unsmoothed areas, the smoothing is repeated. The strips are made up to 2 m wide and are performed alternately, after the cement-sand mortar has set in the previously laid strips, and the edges of the finished strips are used as beacons (Fig. 10.1).

Rice. 10.1 Installation of screed on lighthouse slats a - leveling the cement-sand mortar; b-grater for leveling; 1 – lighthouse strip; 2 – fresh strip of screed; 3 – rule; 4 – box for solution; 5 – finished screed; 6 – intermediate strips are filled after removing the slats

When performing work, one should take into account the installation of temperature-expansion joints (temperature-shrinkage joint) in the following cases: - if the building’s length or width is more than 60 m; — at the junction of roofing bases with different coefficients of linear expansion (concrete floor slabs adjacent to a base made of galvanized corrugated sheeting); - the roof is adjacent to the wall of the neighboring building; — in places where the direction of laying the building frame elements, purlins, beams and roof base elements changes; — in places where the indoor temperature changes.

To reduce the likelihood of roof leakage through an expansion joint, it is necessary to form slopes on the roof in such a way that water flows in different directions from the expansion joint. When installing expansion joints, it is best to tear the roofing carpet (Fig. 10.2). Rolled rubber can be used as a vapor barrier membrane in the construction of an expansion joint.

Fig. 10.2 Expansion joint

To ensure a high-quality connection of the roof to a vertical surface, it is necessary to install a transition edge or a smooth transition (fillet or Tekhnoruf B60 fillet) (Fig. 10.3) from cement-sand mortar. According to SNiP II-26-76 “Roofing”, clause 2.21, “the transition side must be made at an angle of 45° with a height of at least 100 mm. The fillet must be made along a radius of R=100mm.”

A fillet or transition edge allows for high-quality gluing of seams and layers of material at the transition to a vertical surface. Another purpose of a fillet or transition edge can be considered to equalize temperature fields at the intersection of two surfaces. Therefore, from this point of view, it is necessary to arrange a transition side of at least 150 mm, and a fillet along the radius of at least 150 mm.

Rice. 10.3 Transition (circle).

Additional materials:

Types of built-up roofing material bases

Roofing material from TechnoNIKOL company Linokrom

Mechanical fastening of roofing carpet on a vertical surface

Violation! Laying the roof on an unprimed base

Technology of waterproofing foundation structures of buildings, structures, private houses during construction and repair

Waterproofing materials for waterproofing foundations, basements of buildings, structures, private houses

Thin-layer cement mortar (cement mortar for laying in a thin layer)

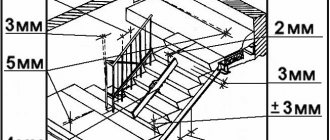

Where did the term thin layer come from? The fact is that for a cement screed, a thick layer of cement is placed on the surface (for example, the floor), which is then leveled and turns into a smooth, even surface suitable for further work. The thickness of this layer varies depending on the situation, but is usually quite significant. Adhesive compositions, on the contrary, are quite thin - the optimal thickness is about 2-3 mm. That is why the term thin-layer cement mortar (adhesive mortar) appeared.

This solution is prepared from fine sand, Portland cement and other ingredients, has a paste-like appearance and is used for gluing ceramic tiles or natural stone tiles to various substrates. The maximum force is achieved with an adhesive layer thickness of about 2.5 mm. There are 4 types of such solutions:

Conventional thin-layer cement mortar - no polymer additives (miscible only with water);

Polymer cement thin-layer mortar - made with the addition of dry polymer or mixed on site with liquid latex or acrylic. Polymer additives add various special properties to the solution: less porosity, water resistance, elasticity, higher strength, better adhesion, etc.

Thin-layer, medium-thick cementitious mortar - designed to facilitate installation of uneven tiles (such as homemade tiles);

Dry epoxy adhesive (100% solids) - a dry ingredient (colored silica), sometimes in the form of a commercially prepared mixture with one of the liquid components (resin or hardener); when mixed with resin or hardener, it begins to harden; used as an adhesive or grout.

Laying mortar for brickwork

The quality of masonry in general, and its strength in particular, directly depend on the uniform distribution of the mortar, ensuring the same compression and density of the mortar in the masonry.

Properties of the solution.

Lime, cement-clay or cement-lime mortars have greater plasticity. They are easy to spread and level over the masonry. In addition, when laying bricks, they are compacted evenly.

Cement mortars are not so plastic, so they are more difficult to spread and level. To increase their plasticity, it is necessary to introduce plasticizing additives. After the introduction of plasticizers, cement mortars delaminate more slowly and release water weakly, which allows the binder in the solution to harden in normal times.

Regardless of the composition of the solution, it must be mixed before applying to the wall to prevent delamination.

Mortar mobility required for brickwork:

- from ordinary clay brick - mobility by 9-13 cm;

- from hollow or porous-hollow - mobility of no more than 7-8 cm, which will not only prevent loss of mortar when it flows into voids and holes in the brick, but also avoid a decrease in the thermal characteristics of the entire brickwork;

- in hot weather, for dry brick masonry, the mobility of the mortar is increased by introducing plasticizers until the cone is immersed by 12-14 cm.

Tools for working with the solution.

The supply and spreading of the solution is carried out using:

- shovels;

- scoop designed by Maksimenko - its volume is enough to supply mortar for laying 8-10 bricks in one go;

- tray - for laying half-brick partitions, as well as lightweight walls:

The final leveling of the solution is done with a trowel.

Laying the solution.

The solution is spread:

- for a spoon verst row - in the form of a bed 80-100 mm wide;

- for tychkovy – 200-220 mm wide;

- when laying hollow (when the seams are left empty to a depth of 10-15 mm from the outer surface of the wall) - with an indentation of 20-30 mm from the face of the mile;

- when laying with full filling of joints - with an indentation of 10-15mm;

- the thickness of the mortar bed should be 20-25 mm - in this case, when laying bricks, a seam thickness of 10-12 mm will be ensured;

- under the tray rows of wall masonry - through the side edge of the shovel, under the butt rows - through the front edge of the shovel;

- leveling the beds is done with the back of a shovel;

- for laying individual pillars with a cross-section of up to 3x4 bricks - apply the mortar to the middle of the pillar and spread it, leveling it with a trowel.

Tweet

Share

{lang: 'ru'}

We recommend:

Mortar for laying shell rock: proportions

In the classic version, the solution for shell rock is prepared according to the following proportions:

- One bucket of cement.

- Four buckets of tyrsa or sand.

Experts must add a plasticizer, which makes the solution more plastic. Its consumption: 0.5 plasticizer is required per 1 m3 of solution. On tyrsa you can make a more economical solution by adding it in a ratio of 6 to 1.

The fewer auxiliary components such as sand or sand, the stronger the solution. All components are mixed dry, after which water is gradually added to them to obtain the desired consistency. Sand and tyrsa absorb moisture differently, and therefore the required amount of water is determined by eye. If the same proportions are observed, the solution from tyrsa is stronger.

When mixing the mortar manually without a concrete mixer, builders use one trick. A bath is formed from the dry mixed material, which is filled with a small amount of water. The water is absorbed by percolation, after which the solution-forming mounds are removed from the center and stirred into the liquid until it runs out. If necessary, water is added. The solution should be viscous and not very liquid. One way to check the quality is to apply it to a trowel. It shouldn't drain.

Composition of the solution

Regardless of the type of masonry that will be used during construction, the composition of the mortar includes:

- Water and cement.

- Sand or tyrsa.

- Moura or clay.

- Other materials.

Crimean shell rock is mainly laid on a solution of sand or tyrsa. It is best to give preference to tyrsa if construction is taking place near a quarry, where you can buy it cheaply. In other cases, it is more profitable to take sand. The solution into which the clay will be added will give the house additional heat resistance. It is advantageous to take Mura during construction in the Sevastopol region, since it is mined there.

If you have to work in cold conditions, add a little “anti-freeze” to the solution, which slows down the process of its hardening. Plasticizers are added to improve viscosity.