Today, it cannot be concluded that concrete stairs are very popular among owners of houses with several floors. But, on the other hand, those who decide to build such a structure will not regret it, since it always looks very beautiful and lasts much longer than other metal or wooden structures. This effect is achieved thanks to the material itself, which will provide high performance characteristics.

One of the most important stages in construction work is the calculation of the concrete staircase. For this, craftsmen use a special calculator, which is necessary to accurately determine the amount of concrete and reinforcement. You can also use it to indicate the angle of inclination for a specific room.

Features of concrete stairs

When constructing any building, stairs can be considered one of the most complex and serious elements. Each design will be subject to a number of requirements in relation to reliability, comfort, durability and safety. Also, do not forget that the design should fit favorably into the overall interior of the room.

This staircase has some nuances

If desired, the home owner will be able to turn the staircase not just into a functional object, but into a real work of art with complex shapes.

Such a design is likely to be heavy and bulky in appearance, but at the same time it can perfectly highlight even the most insignificant design details. As for the main advantages of concrete, they will be as follows:

- increased reliability. In this situation, the march is attached to the embedded elements of the foundation, which will allow it to be combined with interfloor slabs into one structure. By using high-quality cement and steel reinforced slabs, the strength of the structure can be further influenced;

- when ascending or descending such stairs, unpleasant creaks never occur, which can almost always be heard on a wooden structure;

- all concrete masses are resistant to moisture;

- safety during operation is ensured by a flight of stairs, which is characterized by an increased safety margin;

- in the event of a fire, the concrete structure will not be an additional factor influencing the spread of fire to the upper floors;

- such a ladder always has increased load-carrying characteristics;

- any options for further decoration. Any materials are suitable for cladding - ceramics, metal, wood or marble;

- concrete is not susceptible to temperature changes, even if they are very significant;

- in most cases, each concrete staircase lasts as long as the building itself;

- During operation, there are almost never problems with the need to repair the structure; it also does not require any investments for constant maintenance.

In this video you will learn more about concrete stairs:

Video: how to make a concrete staircase with your own hands

The video below shows the process of making a concrete staircase system with your own hands.

Any staircase, no matter what its design, requires not only physical effort, but also time and nerves. It is much easier and more profitable to purchase a ready-made staircase system made by real professionals in their field.

A beautiful and stylish finished staircase from the “Solo” series with a straight, laconic design can be purchased from us for only

RUB 70,858

The magnificent “Prestige” model will advantageously decorate your country house and emphasize its style, the cost of the product is 44,290 rubles

You can purchase magnificent stylish and modern stairs of any type and shape in our online store “Staircases Master”. At the same time, you will be pleasantly surprised not only by the excellent quality of the products, but also by the low economic price of the products.

A finished staircase structure with steps made of natural oak will cost you only

75,136 rubles

A wonderful wooden structure from the “Duet” model range with forged elements in the fence has a price of 75,000 rubles

Concrete staircase building materials calculator

Before making any calculations, every master must understand that in this case the amount of materials directly depends on the angle of inclination of the stairs. The most optimal and frequently used indicator is set at 30-35 degrees. If you use a calculator, it will allow you to determine as accurately as possible not only the amount of material, but also the amount of funds that will be needed to carry out this work.

Using such a device, the master determines the volume of concrete required, the footage and amount of reinforcement in kilograms, and the angle of inclination that best suits a particular feature of the interior of the room. The calculator will also automatically calculate the depth and height of the steps for the future staircase.

How to use a calculator to calculate material

Using an online calculator to calculate materials is quite simple; to do this, you just need to fill in the fields with certain indicators, namely:

- C – number of steps.

- W is the width of the structure.

- Y – height of the stairs.

- B – pad thickness.

- X – length.

- A is the length of the platform.

After this data is entered, the person will receive results where the dimensions of the steps will be displayed (separate data are entered for this), the volume of concrete, the amount of reinforcement, and the string of the stairs.

Reinforced concrete stairs and their types

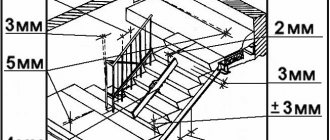

Figure 1. Types of reinforced concrete stairs

According to the shape of reinforced concrete products, stairs have the following types:

- Straight designs with one march. They are built with low ceilings. Such reinforced concrete stairs are easy to install and are inexpensive to manufacture.

- Turning marches. Used with high ceilings to adjust the angle of inclination. It is performed by a turntable device.

- Screw products. They are compact, have original shapes, and fit perfectly into the design of the room. Manufacturing requires constructing complex formwork with your own hands. Each of the steps has a different width along its length. With a small diameter of the entire flight, it is difficult to move large objects.

Reinforced concrete stairs can be prefabricated or monolithic, with standard elements manufactured at the enterprise. The products have different purposes - for home, emergency, fire, service.

What are the disadvantages of concrete stairs?

In addition to the large number of positive aspects of concrete stairs, some disadvantages of the design can also be noted. First of all, we are talking about the following:

- if the owner of the house wants to install the structure himself, he will not be able to do it without professional skills and experience, especially if it is necessary to build a complex, from an architectural point of view, staircase;

- Such a structure can be operated only after the concrete has completely dried. Therefore, you will have to wait some time, which depends on the amount of material used;

- manufacturing formwork will also require some time, which cannot be said about cases with wooden or metal structures;

- in order to protect the surface from chipping and improve external performance, you will have to spend additional funds on facing work;

- Due to the large weight of the structure, it is necessary to strengthen the foundation and provide the surface with sufficient strength so that it can withstand heavy loads.

Don't forget to strengthen the foundation

Classification

Concrete stairs are built based on different technological and design approaches and, depending on this, have a certain configuration.

Screw

This type is considered one of the most spectacular. It should be noted that with further finishing or processing, the costs of such stairs are often higher than those of a standard U-shaped winder design.

Installation of spiral staircases is advisable in case of limited space or if a similar design was chosen by the customer.

Considering the complexity of the configuration, a DIY spiral concrete staircase is not the best option, because... its installation requires certain professional training and skills.

Marching

A concrete staircase can be multi-flight (connected between floors by intermediate platforms) and single-flight or straight, the most popular (directly connecting the floors of a building).

Straight monolithic structures require a large amount of free space. These concrete stairs are considered the simplest and most cost-effective. In addition, they are aesthetically attractive and suitable for any room design.

The cladding of a concrete flight of stairs can be made of granite, wood or forged elements. This product is considered convenient and reliable: it has straight, level steps that guarantee users safe movement.

L-shaped

The construction of such a staircase structure involves rotating elements that can turn the object into a staircase with a special platform or a winder product. As a rule, there are few winder steps, which makes the cladding quite inexpensive. However, it is worth considering that additional costs will be necessary in order to make reliable fences.

In order to save usable space and maintain aesthetic appeal, concrete L-shaped stairs are most often located along the walls of the room.

U-shaped

This type is considered the most popular, especially in the construction of low-rise buildings. Monolithic ergonomics, together with noticeable space savings and affordability (only marching objects are considered cheaper), fully justify their relevance.

Like L-shaped stairs, U-shaped ones can have turns with winder steps or special connecting platforms. The design provides comfort when descending and ascending, it is safe and reliable, and its finishing can be made of any materials.

The U-shaped option is convenient in that the space under it can be used to locate technical and utility units, as well as a recreation area.

Individual design

Concrete individual stairs can have any shape, and their implementation directly depends on the level of professionalism of the craftsmen.

In some cases, it is considered more profitable to purchase reinforced concrete products for staircase structures manufactured in industrial conditions. But they have specific standard dimensions and are not suitable for all special cases.

The principle of making concrete stairs

After the formwork is made, the master begins to form the reinforcement frame. It is he who takes on the greatest load, so this element of the staircase must have maximum strength. As for the reinforcement in the lateral projection, it is performed in increments of at least 250 mm in each direction.

If the calculations are made correctly regarding the load on the stairs, no problems will arise at the initial and subsequent stages. But if the foundation is not designed for heavy weight, this threatens the collapse of the structure. Steel rods must be laid towards the load-bearing edge. Their recommended diameter is 10-13 mm. To connect these elements, cross braces are used.

Every craftsman needs to pay attention to the fact that fixing staircase elements using a welding machine is extremely undesirable, since, most likely, in the future there will be a weakening of strength due to heating of the carbon contained in the reinforcement. In such cases, it is better to resort to the already proven option with knitting wire. You will have to connect the parts using a special hook, which will take quite a lot of time, but this method is the most reliable.

As for the distance between the bottom of the formwork and the frame itself, it should not be less than 3 cm. A plastic clamp is well suited for this purpose. In addition, a concrete staircase, in any case, requires additional attachment of the frame to the walls, in which you will have to drill a hole of the required diameter in order to drive the reinforcement there; such work will provide additional strength and stability.

Useful tips

Experts advise every person who is going to build a concrete staircase to adhere to the following rules:

- First of all, you should prepare to concrete the march in one go.

- Regarding the grade of concrete, it should not be more modest than B15. The M300 solution is considered the most acceptable for almost all cases.

- To rid the solution of unnecessary mobility, it is necessary to use a crushed stone diameter of 15-20 mm for the mixture.

- If you do not pay enough attention to compacting the concrete, this may negatively affect the strength of the entire structure in the future. It is recommended to perform this work using an electric vibrator.

What concrete are reinforced concrete products made from?

To produce concrete steps with or without a metal frame, several types of concrete are used:

- Heavy. This type of concrete is the most common. Depending on the filler, it is divided into brands and areas of application. Heavy concrete can be made from quartz, sand, and gravel. Products made from it are used for above-ground, underground, and underwater work.

Not only individual steps are made from heavy concrete, but also monolithic flights of stairs. - Easy. When cut, such concrete resembles pumice. It is made on the basis of organic and mineral porous aggregates. It can be expanded clay, vermiculite, wood concrete.

It is thanks to its porous structure that lightweight concrete received its name.

The composition of lightweight concrete affects not only its characteristics, but also its appearance.

Despite its “heterogeneity,” this type of concrete is very durable.

- Silicate. This is a modern type of artificial building material. It is made by combining ground quartz sand, ground quicklime and ordinary quartz sand into one mixture. Depending on the filler, silicate concrete can be dense, medium-dense and cellular. It is often used to make load-bearing and supporting floors in buildings.

Silicate concrete blocks

The density and strength of concrete is established by GOST depending on the components for production. For the manufacture of reinforced concrete products, heavy concrete is used, sometimes with an admixture of silicate and light concrete .

This results in a very durable and practically invulnerable product, designed for frost down to minus 40 degrees. Reinforced concrete steps can withstand 300 freezing cycles without noticeable changes in composition and appearance. That is why concrete and building elements made from it are widely used all over the world in various branches of construction and territory design. Production of reinforced concrete steps

What stages are available?

Many people may think that all steps are the same. This opinion is wrong. There are several types of reinforced concrete steps:

- Basic. This type is used throughout the staircase and forms the main part of the structure.

Main steps - Upper frieze step. It serves as a link between the platform and the upper end of the stairs. It differs from the main stage only in that it has a special console, with which it can be attached to the floor slab.

- The lower frieze performs the same functions as the upper one. It is attached to the floor and the first main step of the stairs.

- Platform liner. This is a special stage that is installed after the main stage. The liner is designed for short-term load.

- Step for through march.

Frieze steps

All of the listed types of reinforced concrete products can be used for both internal and external work. Even to descend from a small porch, you need a lower and upper frieze step, main steps and a landing liner. But such a design can withstand any load.

If space is limited

This is the main advantage. Prefabricated stairs can be made of any size, height, width. You can even make a spiral staircase from them or on stringers. It can be L or U-shaped. Staircases can be with spans or turning. If there is very little space, then you can make a spiral staircase from reinforced concrete. One turn should have 15 steps. At the narrowest point of the structure, the width of the step should not be less than 12 cm.

A spiral staircase made of concrete looks very impressive.

The structure on stringers with reinforced concrete steps can be placed both inside and outside the building. A small, neat staircase to the attic or a narrow but strong descent to the basement will not spoil the appearance of the building. Conveniently, you can order steps of any width, length and thickness.

Concrete steps on one stringer with an offset look unusual.

Decorating concrete structures with colored mosaics has become very relevant and often used. This allows you to combine the strength of concrete and modern fashion trends in home decoration. Steps can be with or without railings. For greater safety, it is better not to give up handrails. Although, if they interfere, it will be enough to have a supporting wall on one side.

With the help of mosaics, concrete steps can be turned into real paintings.