Many people want to have a separate bathhouse or utility block on their property or country cottage. As a rule, these small buildings are made of timber. The foundations for such buildings are laid in different ways, and a reasonable question arises: how to lay timber on a foundation?

Tying a pile foundation with timber: a competent start to building a house

Kinds

There are several types of foundations that can be used in the construction of a frame structure. When choosing a foundation, you need to take into account the weight of the building, the type of soil, and other loads that will be exerted on a particular foundation.

So, let's look at the most common types of foundations that are built for frame baths. The types of foundations suitable for mobile frame and frame-panel baths are presented in separate articles.

On stilts

This is one of the types of columnar foundations in which the role of supports is played by piles that are driven or screwed into the ground. They are often used on weak, mobile heaving soils. Pile elements are driven into a dense layer of soil; they serve as support for the lower frame. This is an excellent option if the soil at the construction site is problematic, but to build such a foundation you need special construction equipment, so this foundation is used very rarely in private construction. However, the following two types are quite suitable for low-rise construction.

On screw piles

This type of foundation for buildings, despite the fact that it appeared just a few years ago, has already gained enormous popularity among both private developers and professionals. The piles are screwed into the soil until the tip reaches dense soil layers. The elements are arranged according to a pattern that allows you to evenly distribute the load on the soil and foundation.

Screw piles can be installed on any soil – rocky, heaving, on slopes. The advantage of this type of base is the fact that they can be screwed in manually, independently. It is worth noting that construction on such a foundation will not be difficult, since the piles are tied with a channel on both sides, which serves as the basis for the walls.

On bored piles

A type of pile foundation in which prefabricated columnar elements are not used. In this case, a well is drilled or dug, which is subject to reinforcement and then pouring concrete. The arrangement method is very labor-intensive. At the same time, not every private developer has access to this method for independent construction, since it requires the presence of heavy construction equipment, proper arrangement of the drainage system, and reinforcement directly on the construction site. It is also worth noting that finished pile elements are much stronger than those poured independently - they can quickly collapse if the pouring technology is not followed. And yet, many craftsmen make homemade poured piles, which you can read more about in the article about pile foundations for bathhouses.

Video

Tape

Perhaps the most common and popular type of foundation, especially among private developers. The strip base is a time-tested and reliable reinforced concrete continuous strip that completely follows the building plan. It is carried out under all load-bearing walls and under partitions if the weight of the structure requires it. More details about it here.

This is a fairly simple and economical base to build, which can be done with your own hands, without the involvement of builders and special equipment. The only disadvantage of this foundation is that it is very demanding on the nature of the soil - it is impossible to build on wet and heaving soils. There are several options for strip base:

- Monolithic strip is a durable reinforced concrete structure that is installed directly on the construction site. Formwork is installed, in which reinforcement is made, and only after that concrete is poured. The strength of the monolithic tape is quite high, capable of withstanding heavy loads. But there is a significant drawback - it cannot withstand soil movement, since the fracture resistance of the strip base is very low.

- Prefabricated strip base - this base is assembled from ready-made reinforced concrete elements. They are used very rarely in private construction, since special trucks are needed to deliver elements to the construction site. In addition, a crane is required to install the slabs into the trench. And the strength of such a foundation directly depends on the professionalism and experience of the construction team.

- Rubble concrete - instead of reinforced concrete, natural rubble stone is used, combined with mortar. The result is a tape with greater strength than classic tape and is less affected by moisture. The low price of the material used and the likelihood of working with your own hands make this kind of method extremely tempting, but this stone cannot be found everywhere, and delivery to distant regions is an expensive pleasure. This fact limits the use of this type.

Columnar

Despite the advantages of a strip base, it is preferable to equip it for brick, block and light monolithic buildings. For lighter buildings, such as wooden, timber and frame baths, it is better to use a columnar base, as it is much more economical. And everyone decides to choose a beam or frame independently.

There is a limitation in the use of columnar foundations - if the walls of the bathhouse are constructed from heavy material, and the soil at the construction site is weak-bearing. Before deciding on arranging a columnar base, it is worth considering the options for the material from which the pillars can be made:

- Made from a monolith , the pillars are installed directly on the construction site. The option is very good if you need to equip pillars of a certain size, but it requires a large amount of mortar, in addition, you will have to reinforce each element. For high-quality execution, you need to use a vibration machine or the bayonet method to remove voids, which can subsequently lead to destruction.

- Brick is an excellent option if the terrain at the construction site is uneven. Due to the small thickness of the brick, each element of the foundation can be adjusted individually.

From blocks

In this case, it is worth considering two options for block foundations:

- block strip – during construction, FBS blocks (foundation building blocks) are used as a strip. There are several advantages to assembling the bases this way:

- There is no need to wait for the concrete to harden.

- There is no need to construct a reinforcing frame.

- It is possible to provide a high-quality waterproofing layer.

- block columnar - they are made from small blocks that are stacked crosswise on top of each other to the desired height. Such pillars are very durable, since factory-dried concrete has increased quality and strength characteristics.

From tires

Old tires are excellent building materials from which you can build a foundation for a frame bathhouse. Several types of foundations can be made:

- columnar - lay tires in the form of columns;

- tape - in this case they are laid in the form of a continuous tape;

- slab - masonry is carried out across the entire site in two rows.

The advantage of constructing from old tires is:

- efficiency;

- long service life;

- no additional waterproofing required;

- resistance to temperature changes.

The only disadvantage can be considered that when exposed to direct sunlight, old tires emit substances harmful to health. There is more information about this type in this article.

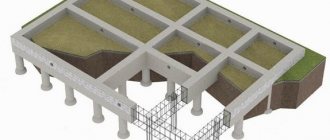

Slab

This is a solid monolithic slab that is poured under different buildings. The strength of such a foundation is very high, so slab foundations are used on unstable, heaving soils prone to movement. If you install a structure on such a foundation, then it will not be afraid of deformation and destruction.

The disadvantage of slab foundations is; high material consumption, high cost and labor-intensive process. For a frame bath it is better not to use a slab foundation - this is often unreasonably expensive.

What to use for tying, depending on the type of foundation

There are three common types of foundation. Each of them has its own priority methods of installation and fastening of strapping materials.

For any method of work, all parameters are first checked. Only after this is the structure secured. This eliminates possible shortcomings.

Tape base

In this case, anchor bolts and dowels are used for fastening. A hole is drilled in the beams and places where the base is attached using a Pobedit drill. After this, a dowel is driven into it.

The situation is similar with fastening timber to the walls.

The slab base requires the use of anchor bolts and liquid concrete.

When using metal strapping, the fastenings will be L-shaped or overlapping. All joints are welded or secured with clamps.

For a strip foundation, a metal bond is preferable, which will give strength to the base.

Pile foundation

Various materials are used to strengthen the pile foundation, but a metallic grillage is considered the best.

For the timber you will need to create U-shaped holes for fastening.

Fasteners include bolts, screws, and welding, which will be required for the metal part of the head and pile.

The use of metal reinforcement is considered a simpler method. It is enough to release the reinforcement and tie it.

The pile base allows the use of any materials for the bond. The choice depends on the type of structure and its mass.

For massive objects, the preferred option would be tying with a channel or I-beam with rigid fastening at the joints.

What does the choice depend on?

The choice of a certain type of foundation directly depends on the specific gravity of the structure and the type of soil on the site.

For example:

- Rocky ground

Rocky and stony soils are particles of different fractions, between which there are no soil elements. This type of soil is considered ideal for arranging any type of foundation, since the lack of moisture in the composition does not allow the soil to change its condition.

- Sandy soil - consists of coarse sand, which allows moisture to pass through it, while being well compacted during construction. The freezing depth of sandy soil is 1 meter.

- Clay soil is unstable, prone to heaving and soaking. Freezes to 1.5-2 meters. It is worth noting that if you do not equip a good drainage system and a gravel-sand cushion, then any foundation will collapse very quickly.

- Sandy loam and loam , which consist of clay and sand. Sufficiently stable soil if it contains more sand than clay. It freezes to 1.5-2 meters and is considered a good basis for arranging any foundations.

- Peat bogs are water-saturated, unstable soils with shallow bottom waters. Peat bogs are usually found in drained swamps and can very easily drag on foundations, especially if they are heavy.

For your information! On swampy and peaty soils, only pile or pile-screw type foundations can be used.

As for other types of soils, the main attention is paid to the specific gravity of the structure. But since we are considering the construction of a frame bathhouse, its weight is not very large, so any type can be used depending on financial capabilities and experience .

General information

First of all, you need to understand what strapping is and what materials are used for this for different types of bases. Screw foundations consist of special screw piles. This is a relatively new construction method that has earned widespread popularity in Western countries and the post-Soviet space. It allows you to build a strong and reliable foundation for any building in a matter of hours, regardless of the type of soil and landscape features. Screw piles are very convenient where there are significant differences in height, for example, if you need to build a house on a hillside.

A screw pile is a metal pole with threaded blades at the bottom that is screwed into the ground. Thanks to the welded blades, the pile not only “sits” firmly in the ground, but also evenly distributes the mass of the building over the entire area.

Classic columnar foundations are constructed from concrete, rubble concrete, asbestos-cement pipes, brick or wood. To do this, markings are made on the site in accordance with a pre-developed plan, after which strictly vertical holes are dug at the points of intersection of walls and heavy loads. The distance between the pillars should not exceed 2.4 m. If the distance is greater, additional support is installed between the two elements. The choice of material for the construction of pillars depends on the load on the foundation, soil characteristics and financial capabilities. The most short-lived is considered to be a wooden base (lasts 15-30 years) made of pine or oak, but rubble concrete or high-quality brick pillars will last 70-150 years.

What is a harness

To better understand the term strapping and its purpose, it is good to consider the features of a pile foundation. As a rule, it is equipped for small and relatively light buildings: guest houses, sheds, verandas, terraces, gazebos, etc. Unlike a strip and monolithic foundation, where contact with the ground occurs over the entire area of the house, a columnar foundation only acts on the soil pointwise, thereby reducing the impact of heaving forces and protecting the lower part of the floor from destruction. The only drawback is that with such a foundation it will not be possible to make a cellar or basement. Despite this, many people prefer this type of foundation, since it saves a lot of money, time and effort.

Pillars or piles are deepened into the ground to a certain level, depending on the degree of soil freezing and the location of groundwater. The lower part of the column must be below the freezing point, otherwise in the spring the heaving will simply push out or distort the supports. But even if the pillars are dug in according to all the rules, this does not guarantee maximum stability and strength of the building, especially if we are talking about a residential building. A harness was invented especially for such cases. It is a wooden or metal frame - beams or rand beams that connect all the pillars with each other. At the same time, the strapping is a good help for fastening walls, ceilings and floors.

Timber for strapping

A frame made using timber is called a grillage. This is the most common type because it does not require complex professional skills and the participation of heavy construction equipment. A beam is a tree trunk, cut on 4 sides in such a way as to produce a square or rectangular cross-section equal along its entire length. Most often it is used for tying foundations for bathhouses, log houses and wooden verandas.

Basically, coniferous species are chosen for grillage construction because they have natural antiseptic properties and are not as susceptible to rotting as deciduous ones. Another compelling argument is that the cost of pine timber is much lower than that of deciduous or oak timber. To obtain a durable and high-quality harness, the cross-section of the timber must be at least 150x150 mm. It is very important to choose the right material - it must be sufficiently dry (humidity level no more than 18%), otherwise after drying the grillage may warp, there should be no cracks in it and there should be as few knots as possible.

Helpful advice: When purchasing material, add 10-15% to the total quantity for reserve. This rule applies to the purchase of consumables for all large-scale work, be it creating a grillage or laying tiles on the roof.

After purchasing the timber, it is necessary to treat it - soak it with a wood antiseptic so that insect pests and mold do not appear inside, coat it with a fire retardant to protect against fire. In the case of conifers, this is a very important step, since they contain a large percentage of flammable resins.

Glued laminated timber deserves special attention - a material obtained by gluing together several beams of small cross-section. First, all components are dried, the defects are selected, and then glued together with a special compound under a press. The result is a high-strength beam of excellent quality, which has all the advantages of natural material and is practically devoid of the main disadvantages of wood. Another important point is that laminated veneer lumber always has exact dimensions, since it is manufactured in a factory. Some types of material have pre-made grooves and tabs for quick and easy joining. But the main advantage of any laminated timber lies in its high hydrophobicity and thermal protection. Since the wood passes through a powerful press, it becomes much denser, which means it almost does not allow moisture to pass through and does not support combustion. And if you additionally treat the material with fire retardants, you can be completely confident in the safety of your future home. Naturally, the price of tying the foundation with timber is much higher than with ordinary “monolithic” wooden beams, but the advantages are obvious.

Harness

A grillage is a structure that connects pillars installed in the ground along the entire perimeter of the base.

You don’t need to think that it’s enough to install piles, weld special heels on them, and you can install a house on them. It is worth understanding that in a columnar and pile foundation, each element lives its own separate life, especially if the soil is heaving and unstable.

In addition, it is worth understanding that each pile will be subject to a different load. The piles can simply be driven separately.

Advice ! If you want to save money, you can tie it with timber, which is perfect for a frame bathhouse. But the strongest and most reliable grillage is a reinforced concrete strip.

This photo does not show a frame bathhouse, but you can see the piping of the screw foundation with a profile pipe

There are four types of pile foundation lining:

- timber;

- channel;

- I-beam;

- monolithic tape.

Only by arranging a grillage on pile, columnar and screw foundations can you be sure that the structure will stand for a long time and will not require repairs in the next few years.

Bottom harness on pile

At first glance, it seems that tying a pile foundation with a corner or channel seems simple; this work requires certain skills:

- it is necessary to be able to carry out welding work, and the level of training must be appropriate;

- you need to understand exactly how to connect the channel; without experience, the work will be of poor quality;

- The channel is a fairly heavy material, so you will have to attract help.

But nevertheless, the algorithm of actions is quite simple:

- the piles need to be leveled;

- cut the channel into elements of the required size;

- connect the channel to the piles using bolts or welding;

- Apply a special anti-corrosion primer.

When using welding to arrange the strapping, you need to remember that the thermal effect on the steel changes its structure - weakening the material. Therefore, incorrect or insecure proficiency in welding work can result from weakening of the points at which the channel is attached to the supports.

Particular attention should be paid to corner joints, since it is in these places that there is a high probability of weakening of the entire structure.

Bottom trim on columnar

It is best to use wood on a columnar base: firstly, it is not expensive, and secondly, it is easy to arrange and process. It is better to use coniferous wood. Advantages:

- increased strength;

- durability;

- low price;

- resinous properties help resist moisture.

Before using wood for strapping, it should be very well prepared:

- treat with antiseptic compounds to prevent rotting;

- impregnate with fire retardants to reduce flammability.

The most suitable material for a grillage would be laminated veneer lumber, since this material is produced using special technology and glued under high pressure.

Methods for attaching the strapping to the foundation

For each foundation option, certain technologies for fastening materials are used. According to the basic installation diagrams, the fastening can be rigid or overhead.

The overhead method is used only in foundations of small mass. In all other cases, a rigid fastening is used, which is created using fasteners or welding.

Which one is better to bet on?

There are many opinions about what kind of foundation to build for a frame-type bathhouse. Some experts believe that since the structure has a low specific gravity, it is possible to get by with a columnar base without a grillage, others give preference to piles, and advise making the frame from laminated veneer lumber.

There is an opinion that it is better to play it safe and install a shallow strip foundation, considering it the most reliable.

But if you don’t have the money to build a concrete foundation, a foundation made from old car tires is perfect. The main thing here is to correctly calculate the load in order to understand how many rows of tires to lay under the building and to correctly calculate the sand cushion for them.

Strip foundation

The most common type of foundation, suitable for private construction and the construction of both light frame houses and permanent buildings made of brick and concrete.

It consists of interconnected concrete blocks along the perimeter of the load-bearing walls of the future building. According to the method of construction, such a base is divided into two main types:

- Made

- Monolithic

The first option can be used in the construction of light houses; in this case, ready-made concrete structures are connected to each other. If we are talking about a capital foundation, then it is better to give preference to the second. In order to begin work on pouring a strip foundation, you will need reinforcement and concrete mortar. If we are talking about a large house, then it is better to order the delivery of concrete to the site using special equipment. This way it will be possible to fill the base in one stage, which will affect its exceptional quality.

[ot-video type=”youtube” url=”https://www.youtube.com/watch?v=Gc2Zxwj3bOQ&feature”]

How to make it yourself

Despite the apparent complexity, almost all types of foundations for a frame bath can be built with your own hands, for this:

- prepare the construction site;

- mark the territory;

- build a pit, trench or holes (depending on the type of foundation). When using a pile-screw foundation, this step can be omitted;

- construct formwork and reinforcement;

- pour concrete.

If you need details, then on our website there is a lot of information on installing any types of foundations with your own hands (how to do it correctly, how to do it yourself, how to pour it).

Jib brackets for attaching vertical frame posts

The jibs serve to add rigidity to the frame of the house. In other words, the jibs prevent the house from collapsing during the wind. The jibs are attached to the vertical profiles below - at the points of attachment to the foundation and for fastening at ceiling level.

Sections from profiles can be used as jibs.

Let's say you need a profile 2.2 cm long. After cutting, you get a piece 80 cm long (Manufacturers sell 3m profiles, that's why). This is exactly the profile that can be used for jib.

Important!

The jibs can significantly reduce labor costs when installing the frame, especially if it is occupied by one person.

The installation procedure is as follows:

- Place a vertical stand. Screw it to the lower frame.

- Check the vertical position of the stand with a magnetic level

- Strengthen the jib.

- Jib braces must be installed in all corners of the frame

Tools for attaching the frame:

- metal saw

- screwdriver or drill

- screwdriver attachment

- screws

Video of installing jib beams in a frame house with your own hands

When is it easier to order than to make?

It is not always advisable to fill the foundation with your own hands; for example, if you do not have experience and you have only heard how to pour the foundation yourself, then it is better not to take on the arrangement. You must clearly understand that even a small mistake in calculations and installation can be fraught with negative consequences - the bathhouse will very quickly fail and you will lose both time and money.

If you plan to order a frame bathhouse from a construction company on a turnkey basis, then you should entrust the pouring of the foundation to the same team that will assemble the building.

Advice from experts

Finally, we invite you to read useful tips from professional builders and self-taught craftsmen. Tying a columnar foundation with timber is no less important work than laying the foundation itself, so before starting practice it is better to study all the available theory.

Helpful Tips:

- All piles must certainly be the same height, which must be ensured before creating the piping. Otherwise, you will not be able to connect all its elements, and if you do, the walls of a house built on a crooked foundation will be of different heights.

- In the process of fixing the beams to the piles, it is necessary to monitor the location of the screw fastenings - it should be strictly in the center. Not only the uniform distribution of the load and strength depend on this, but also the integrity of the wooden beam - if the fasteners are shifted to one side, the wood may crack.

- Before purchasing a beam, keep in mind that its width should be twice the width of the pile or foundation pillar.

We invite you to watch several videos on tying a foundation with timber, in which you will find not only a clear application of the technology, but also resourceful solutions from the master that allow you to reduce costs and labor to a minimum:

In fact, it is important to follow only two rules - buy high-quality timber and strictly adhere to installation technology. The construction of a foundation, even one as simple as a columnar foundation, cannot be rushed, so first create the most detailed project, and then gradually implement it. We hope this article will help you build a high-quality and durable foundation with a grillage.