How to insulate concrete walls: the most effective ways

Hello!

We live in a two-flat panel house. The house is one-story. Despite the fact that we covered all the walls inside with plasterboard and laid mineral wool underneath, it is still cold in the house in winter. The neighbors also complain. At the same time, our floors are quite warm; there is no cold coming from below. So it's the walls?

Tell me, maybe there are other ways to insulate concrete walls. Tired of freezing and paying large sums for heating. It's better to spend this money on repairs.

I will be very grateful for the answer. Irina.

Your problem is quite clear and can be explained simply: you did almost everything wrong. Namely: they insulated from the wrong side, choosing the wrong thermal insulation material. Let me explain.

Basic methods

Modern manufacturers delight customers with a wide range of various thermal insulation materials that meet the basic quality parameters of these products.

However, experts with sufficient experience in the construction industry give advice on how to insulate a concrete wall in an apartment using only three main methods, which are considered the best:

- Insulation using foam plastic,

- Insulation using a warm plaster solution.

Mistakes when insulating concrete walls

See what happens when walls built from concrete are insulated from the inside:

- External walls are completely cut off from the heat coming from the room . That's why they freeze in cold weather.

- Concrete, despite its density, absorbs moisture . Thawing and freezing, it gradually destroys it.

- The dew point for internal insulation is at the junction of the walls with thermal insulation . This is where warm air meets cold air and condensation forms.

- Mineral wool absorbs the resulting moisture , thereby losing its thermal insulation properties.

Conclusion: it is better to insulate any walls from the outside, and even better - from both sides. When choosing how to insulate concrete walls from the inside, preference should be given to moisture-resistant materials.

These conditions are not met in your case, so the heat in the house does not remain. What to do?

Errors during insulation

When independently insulating the facade or interior of a house, you must take into account a number of rules:

- Insulation boards must cover at least 60% of the facade.

- You can start thermal insulation work only in dry weather at a temperature of +5…+25°C.

- Do not allow the adhesive base to get into the joints.

- Particular attention should be paid to the finishing of the facade after insulation.

- Insulation of only one part of the facade of the house. Proper insulation requires covering the entire concrete house.

- Using the services of climbers. When working on slings, they will not be able to properly secure the slab and apply plaster.

- Application of extruded foam. The material allows moisture to pass through and causes the formation of condensation, mildew and mold. It is allowed to be used only when insulating foundations and basements.

- The use of insulation up to 10 cm thick. Such products are not capable of providing a heat-saving effect, and they also quickly deform under the influence of aggressive factors.

- Insulation of only the inside of the house. This approach leads to the accumulation of condensation on the walls.

If you do not allow the listed deviations from the rules, you will be able to protect your apartment from heat loss in winter and ensure good thermal insulation.

Insulation methods

Before listing these methods, we would like to give a couple of tips:

- All walls around the perimeter of the house need to be insulated. In your case, this is possible, but you need to convince your neighbors of this need. In apartment buildings, such an operation is much more difficult to perform. Partial thermal insulation of the walls of one apartment, if it gives any effect, is minimal, since the cold still penetrates them from uninsulated areas.

- Insulation from the inside and outside should begin with sealing all seams and cracks and treating it with antiseptics so that fungus does not appear in the apartment.

Method 1 – insulation with polystyrene foam

If the financial issue is acute, you can use ordinary polystyrene foam for insulation. The price of the material is cheap, and the thermal insulation properties are very good.

Advice. If quality and efficiency are more important, buy extruded polystyrene foam. It is not so fragile, is not at all afraid of water, and rodents avoid it, which can be important for a private home.

You can do the work yourself, which will also reduce the cost of repairs. The algorithm is like this:

- We apply adhesive to the back side of the insulating boards at several points along the perimeter and in the middle;

- Glue the sheet to the wall, starting from any lower corner;

- Additionally, we secure it with plastic umbrella dowels in the corners and in the center;

- We mount the remaining slabs close to each other. We blow out the seams between them with foam;

- After the glue has dried, we attach a fiberglass reinforcing mesh over the insulation;

- We use the same composition as for gluing the slabs, applying it evenly to the surface and pressing the mesh into the fresh solution with a spatula;

- When this layer has dried, we plaster the surface;

- The last stage is priming and painting. Or installation of a suspended ventilated facade. For example, siding.

Method 2 – insulation with polyurethane foam

This is the most effective modern heat-insulating material that is not afraid of moisture. But it is quite expensive, since it is performed by spraying using special equipment. That is, you will not install it yourself.

But: all the work will take a little time, and the hardened foam forms a continuous thermal insulation layer on the surface without seams or cold bridges.

Polyurethane foam can also be used for internal insulation. Moreover, for a good effect you will need a very thin layer of this material, which will save the usable area of the house.

Note. The material is destroyed by sunlight, so insulated walls must be finished immediately. It is best to use ventilated facades.

Method 3 – heat-insulating plaster

This method is the fastest and cheapest, but its effectiveness is lower than the previous ones. To achieve high-quality insulation, the plaster must be applied in a thick layer in several passes.

Nowadays there are many dry mixtures with heat-insulating additives on sale. Each type is accompanied by instructions on the method of preparation and use. There is also information about the maximum thickness of one layer. As well as recommendations for subsequent finishing.

This plaster can be used both inside and outside. But in your case, it’s easier to keep the existing frame and replace the non-moisture-resistant insulation with expanded polystyrene or polyurethane foam. And then put the drywall back in place.

Internal and external insulation of concrete walls - what you need to know about the thermal insulation of an apartment

Monolithic reinforced concrete is the simplest and most convenient building material for the rapid construction of residential buildings and other permanent structures. The advantages of monolithic concrete include such qualities as high strength, reliability, durability, relatively low price, as well as the ability to manufacture load-bearing elements and architectural forms of any degree of complexity. Despite all its positive qualities, due to its monolithic structure and high density, this material has good thermal conductivity, therefore, to ensure a comfortable temperature inside a concrete building, additional insulation of concrete walls is required.

Thermal insulation of concrete walls in apartments

Special requirements

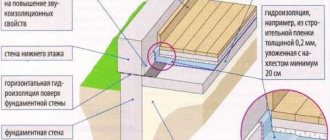

Thermal insulation of a concrete wall requires compliance with all technological conditions, the violation of which can affect the efficiency of the work performed, as well as the service life of the structure and the entire house. Before you begin installing thermal insulation on the facade of a building, you need to consider the following factors:

- The surface of the walls must be treated with an antiseptic solution. This will prevent the formation of mold and the appearance of insects that can disrupt the integrity of the structure;

- It is necessary to insulate the entire surface of the external walls of the house, and not just individual elements. This will serve as an additional guarantee that there will be no “cold bridges” in the facade;

The term “cold bridge” refers to a section of the wall that is colder in winter compared to the rest of the façade surface. These mainly include cement seams, through metal elements (gas pipeline pipes), metal ceilings in window or door openings.

- Installation should begin only after completion of all communications necessary for human life, so that it does not happen that, after the insulation is fixed to the wall, drilling or gouging out an additional hole from the outside is required.

It is the simplest and most convenient building material for the rapid construction of residential buildings and other permanent structures.

The advantages of monolithic concrete include the following qualities:

- high strength;

- reliability;

- durability;

- relatively low price;

- as well as the ability to manufacture load-bearing elements and architectural forms of any degree of complexity.

Despite all its positive qualities, due to its monolithic structure and high density, this material has good thermal conductivity, therefore, to ensure a comfortable indoor temperature, concrete buildings require additional thermal insulation.

Thermal insulation of external concrete walls

In order to help the reader understand this issue, this article will discuss the main aspects of thermal insulation of external walls of buildings made of monolithic reinforced concrete.

In addition, detailed instructions will be presented here, which describe the main methods of insulating walls using the most common building materials.

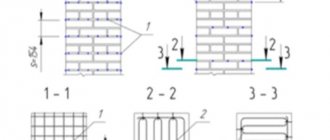

Layout of insulation panels

Features of insulation of a residential building

When considering the technology for performing work, it should be borne in mind that thermal insulation of the walls of a residential building can be done in two ways: from the outside and from the inside. Each of them has its own advantages and disadvantages, therefore, if possible, to achieve the best result, it is most effective to use a combination of interior and exterior decoration.

Regardless of the chosen method, as well as the type of materials used, there are certain rules that must be followed when performing such work.

- To achieve the maximum effect, you need to insulate the entire outer surface of the building's facade , not forgetting the thermal insulation of the floor, ceiling, as well as window and door openings.

- When installing internal insulation, you should leave a small air gap between the decorative wall and the heat-insulating material.

- Before carrying out installation work, the walls on both sides must be treated with an antiseptic compound to prevent the formation of mold.

- All insulation work should be carried out after the final installation of electrical networks and laying of utilities . For through penetration of walls, you can use diamond drilling of holes in concrete using a special drill bit.

- Installation of external panels is carried out using special glue, so it is recommended to carry out all work outdoors at an ambient temperature of at least +5°C.

What is the best way to insulate a house?

Many modern technologies are used for thermal insulation. At the same time, when choosing a method, the materials from which the building is constructed are of great importance. Before buying them, you should find out how much money will be needed to insulate the room inside and out. What prices do sellers offer? If you want to save money and at the same time efficiently insulate your home. The best solution would be to use modern blowing technology. They are suitable for buildings built from different building materials.

Brick house

To insulate a house made of brick or concrete, they resort to “wet facade” technology. It is based on the use of building mixtures and solutions previously diluted in water. Glue for installing thermal insulation sheets and a plaster coating with reinforcing stack are applied to the walls. This makes it possible to obtain a multilayer structure in which there is no air at all. The adhesive layer serves as a retainer for the structure, and the insulation layers serve as insulation. For the installation of a “wet facade”, polystyrene foam and its varieties are most often used.

EPS is most often used for thermal insulation. Expanded polystyrene is characterized by low thermal conductivity, reliability and durability. It does not absorb moisture and protects against the spread of mold, as well as destruction due to the negative influence of the external environment. Mineral wool is often used to insulate brick buildings. It is suitable for thermal insulation using the “wet facade” method. There are several ways to insulate a house. Each of them has its own distinctive properties and disadvantages, so you need to carefully study the issue and choose the best option.

Wooden house

Many people are often interested in how to insulate a wooden house. They are usually insulated from the outside. To do this, use the most suitable methods. A protective layer is installed on the façade. The standards imply the use of another method of insulation - a non-ventilated air gap, but experts do not recommend resorting to it due to the characteristics of solid wood.

Often cottage owners are interested in which materials are cheaper, but at the same time are highly effective. The amount of costs is determined by several parameters - the cost of the selected insulation and the area of the room. Mineral wool in this case will be the most economical option. Moreover, the blow-in insulation method fully meets the parameters of “complete drying of the partition,” which is important when working in a wooden structure.

House made of foam blocks

Houses made of foam blocks are most often insulated using lightweight panels. They consist of several layers - insulating, vapor barrier and decorative. For thermal insulation of walls and facades of buildings made of foam blocks, lightweight materials are used that do not require the construction of a heavy load-bearing frame. As a rule, polystyrene foam insulation and mineral wool are used for this.

If we are talking about thermal insulation of the attic, then in this case it is worth using the blow-in method. Insulation of a cottage from the inside, the price of which is not inflated and is acceptable for everyone, is carried out in a short time. At the same time, there is no waste left after the work.

Frame house

To insulate a house with frame walls, pay attention to materials that are environmentally friendly, have no shrinkage, and have low water absorption. Experts do not recommend using polystyrene foam and its derivatives as insulation. The best performance in thermal insulation is achieved by mineral wool insulation, namely different types of wool with fiber from basalt, mineral substances, and stone.

Moreover, to quickly and efficiently insulate a building, it is recommended to use the modern blow-in method. Cotton wool is fed automatically through a hose. The resulting layer is environmentally friendly, light weight, has optimal vapor permeability parameters, and is not susceptible to pests.

How to insulate a concrete wall for the best result?

Walls that do not have good insulation from the cold tend to freeze during the cold season. This unpleasant phenomenon affects not only insufficient heat in the room, but also on your finances, since heating devices transfer most of the heat to cold walls. As a result, you end up paying for heating that doesn't heat the room properly. This problem can be solved with additional insulation. This article will discuss how to insulate a concrete wall .

How to properly insulate concrete walls

Concrete is the main building material. It is found everywhere and has many positive characteristics. But its thermal conductivity coefficient is high, so the material is cold. Heat escapes through the walls, so a lot of money is spent on heating. The only option is to insulate concrete walls. There are many materials for this purpose, and the work itself can be done with your own hands.

How to insulate a concrete wall: from the outside or from the inside?

Having decided to insulate, you can do it in two ways: insulate the wall from the outside or from the inside. Experts recommend choosing the first option, as it is more reliable. It seems that it is easier to do insulation from the inside, but not everything is as simple as it seems at first glance, so this method should be resorted to only if it is impossible to carry out work from the outside.

Note! Internal insulation often becomes a breeding ground for mold and mildew.

By insulating a concrete wall from the inside, you will protect it from the heat source with material, and this will lead to its cooling. In severe frosts, it can cool so much that its dew point will be on the border with the insulation layer. This in turn will cause condensation and dampness to form. At the same time, the larger the vapor barrier layer, the more moisture will accumulate. The method of external insulation does not have these problems, which is why it is recommended as the main one by experts.

External wall treatment

Insulation of concrete walls from the outside with any materials should be carried out at a temperature not lower than +5 degrees Celsius. If there is a need to carry out work at a colder temperature, then special anti-frost additives will have to be added to the adhesive compositions. External insulation work is carried out in the following order:

- The foundation is being prepared. If there are places on the wall with an old layer of plaster, then they need to be cleaned. The maximum level differences on the surface should be no more than 15 millimeters. If the differences are greater depth, then they will have to be leveled with putty. After this, to increase the adhesion of concrete, it needs to be primed;

- Fastening the base profile. The profile width is selected in accordance with the width of the insulation;

- Applying glue to slabs of material. The glue is not applied evenly over the entire area of the slab, but in the corners and in the center. At the same time, the fastening is quite strong and the adhesive solution is saved;

- Fastening with dowels. Experts recommend calculating the number of dowels based on the fact that there should be four fasteners per square meter. The length of the dowel should be 50 millimeters longer than the thickness of the insulation;

- Installation of the reinforcement layer. This layer is necessary to increase the strength of the entire structure. For reinforcement, a mesh with a cell of 4x4 or 5x5 millimeters is used. It is glued from top to bottom with an overlap of 10 centimeters. After this, the entire mesh is covered with plaster;

Important! The reinforcement mesh must be coated with a solution that will protect it from the influence of alkalis.

- Applying a decorative layer. After the insulation of the concrete wall is completed, the entire wall should be treated with a decorative layer to give the appearance of the house or apartment an aesthetic appearance.

Facade insulation

Insulation of a concrete house from the outside should be done at above-zero temperatures. If it is colder, then it is necessary to add an anti-frost compound to the glue.

Insulation of a concrete facade with mineral wool

1. Preparing the base: cleaning old plaster, paint, dirt.

2. Alignment. The permissible level difference is no more than one and a half centimeters. Large irregularities are sealed with putty or plaster (depending on the thickness of the layer). Sometimes plaster with reinforcing mesh is necessary. For better adhesion, the surface is primed before leveling.

3. When insulating concrete walls, the first profile strip is attached to the base, and the strips are placed along the entire wall. The pitch between the profiles should be equal to the width of the insulation slab, the width of the profile should not be less than the thickness of the slab.

4. Glue is applied to the insulation blank (in the corners and in the center). The plate is placed on the wall and fixed with dowels at the rate of four pieces per square meter. The dowels are chosen to be five centimeters longer than the thickness of the slabs.

5. Installation of reinforcing mesh with a square cell, the length of the cell side is half a centimeter. Adjacent sections are laid with an overlap of ten centimeters. After this, the structure is covered with plaster mortar.

Insulation of a house made of concrete with cladding

6. As a finishing touch, you can paint the surface or cover it with textured plaster.

Internal insulation

Insulating concrete walls from the inside differs from working on the outside. The main difference is that there is a need to make a layer of waterproofing and vapor barrier, as well as sheathing. The beginning of the work is the same: you need to prepare the wall. To do this, the old coating is removed from it and cleaned. Differences should be no more than 5 millimeters. All large irregularities are filled with putty.

Important! It should be borne in mind that the lathing takes up a certain space, so the usable area in the room is reduced.

Next, guides are mounted on the wall (sheathing) from wooden blocks with a cross-section of 10x10 centimeters. After this, a layer of waterproofing is laid. If the waterproofing material has a foil layer, then it must be placed with the foil facing you, this will create an additional heat shield. The next step is to install the selected insulation. To do this, it is tightly inserted into the inter-batten space of the sheathing. When all the material is laid, a vapor barrier is made on top.

Features of internal wall insulation

Usually, major insulation of walls from the inside is carried out out of urgent need, because external insulation is impossible. Internal insulation has a number of specific disadvantages that must be taken into account when choosing an insulation method. First of all, applying wall coatings changes the overall indoor climate. Creating an insulating layer does not allow the wall to “breathe,” which increases moisture condensation and requires additional ventilation of the room. Inside the wall, due to changes in heat exchange conditions and moisture transfer, moisture accumulates, which can lead to the formation of fungi and mold. These phenomena can reduce the load-bearing capacity of the wall.

Additional thermal insulation enhances the effect of internal drafts in the room. Finally, internal wall cladding reduces the usable area of the room. In addition, changes in wall design must be taken into account when creating the overall design of the room. The specific conditions that arise when insulating a concrete wall from the inside dictate the basic technical requirements. The internal coating of the wall should be a good heat insulator and create a reliable vapor barrier, provided that the room is well ventilated.

Return to contents

Internal and external insulation of concrete walls of a residential building

- 1 Thermal insulation of external concrete walls 1.1 Features of insulation of a residential building

- 1.2 Internal thermal insulation

- 1.3 External wall insulation

- 1.4 Construction materials

Monolithic reinforced concrete is the simplest and most convenient building material for the rapid construction of residential buildings and other permanent structures.

The advantages of monolithic concrete include the following qualities:

- high strength;

- reliability;

- durability;

- relatively low price;

- as well as the ability to manufacture load-bearing elements and architectural forms of any degree of complexity.

Insulation of an apartment in a multi-storey residential building using industrial climbers.

Despite all its positive qualities, due to its monolithic structure and high density, this material has good thermal conductivity, therefore, to ensure a comfortable indoor temperature, concrete buildings require additional thermal insulation.

Thermal insulation of external concrete walls

In order to help the reader understand this issue, this article will discuss the main aspects of thermal insulation of external walls of buildings made of monolithic reinforced concrete. In addition, detailed instructions will be presented here, which describe the main methods of insulating walls using the most common building materials.

Layout of expanded polystyrene panels on the external wall of the building.

Features of insulation of a residential building

When considering the technology for performing work, it should be borne in mind that insulation of a concrete wall of a residential building can be done in two ways:

Each of them has its own advantages and disadvantages, therefore, if possible, to achieve the best result, it is most effective to use a combination of interior and exterior decoration.

Regardless of the chosen method, as well as the type of materials used, there are certain rules that must be followed when performing such work.

- To achieve maximum effect, it is necessary to insulate the entire outer surface of the building's facade, not forgetting the thermal insulation of the floor, ceiling, as well as window and door openings.

- When installing internal insulation, a small air gap should be left between the decorative wall and the heat-insulating material.

- Before carrying out installation work, the walls on both sides must be treated with an antiseptic compound to prevent the formation of mold.

- All work should be carried out after the final installation of electrical networks and laying of utilities. For through penetration of walls, you can use diamond drilling of holes in concrete using a special drill bit.

- Installation of external panels is carried out using special glue, so it is recommended to carry out all work outdoors at an ambient temperature of at least +5°C.

The photo shows dowels with wide washers for fastening polystyrene foam panels.

Note! When choosing the option of internal insulation, you should keep in mind that in this case the dew point in the wall will be close to the inner surface, which under certain conditions can lead to the formation of condensation. In addition, due to the thickness of the air gap and heat-insulating material, the internal usable volume of the room will decrease.

Internal thermal insulation

This method is the most inexpensive and simple, therefore it is often used by residents of multi-storey buildings whose apartments are located above the second floor. It does not require special equipment and can be done by any homeowner himself without outside help.

There are several options for energy-saving systems, which differ from each other in the complexity of installation and the type of materials used.

- The simplest, but at the same time effective way of thermal insulation is the usual plastering of the walls from the inside of the room. To ensure the durability of the coating, before insulating a concrete wall from the inside using plaster mortar, it is necessary to attach a metal reinforcing mesh to it and cover it with one layer of penetrating primer.

- In the second case, the problem can be solved using sheet material with low thermal conductivity, such as polystyrene foam. It needs to be fixed to the wall from inside the building, covered with fiberglass mesh and covered with a layer of finishing putty. After this, the wall can be painted, wallpapered, or finished with other materials for interior work.

- The third method is to install an additional partition made of plasterboard sheets. It is necessary to mount a supporting frame made of metal profiles on the inside of a concrete wall, and lay a layer of mineral wool in the space between them. After this, install sheets of drywall, fill the cracks and visible fasteners, and then finish the room.

Installation of a metal frame and mineral wool panels for a plasterboard partition.

Advice! To achieve maximum energy-saving effect, it is recommended to use mineral wool, the front side of which is covered with aluminum foil. In this case, an air gap of 20 mm wide must be left between the foil and the drywall.

External wall insulation

This method is the most effective because it allows you to remove the dew point outside the room as much as possible, thereby preventing the formation of condensation and preventing the wall from freezing. However, its implementation requires the use of more expensive materials, and in the case of insulation of an apartment in a multi-storey building, the use of special equipment or the services of industrial climbers will be required.

Expanded polystyrene sheets are used as a heat-insulating material, which is attached to the facade, then puttied and painted with facade paint in the required color.

Applying an adhesive solution to a polystyrene foam board.

- Before insulating a concrete wall from the outside, it is necessary to remove the old coating and peeling plaster, and clean the surface of construction debris and dust, and then coat it with a penetrating primer.

- At the level of the foundation base (for a private house) or the lower edge of the interfloor ceiling (for an apartment in a multi-storey building), install a base profile, the width of which must correspond to the thickness of the polystyrene foam used.

- Apply special glue to the expanded polystyrene board around the perimeter and at several points, then press it to the wall in the right place, and then fix it in the corners and in the middle using dowels with wide plastic washers.

- Mount all the panels in this way, making sure that the glue does not get between them and does not come out at the joints.

- Using a special glue, attach a reinforcing mesh to the surface of the expanded polystyrene, which will tie all the panels into one, give them additional strength and serve as the basis for applying plaster.

- To finish everything off, the facade needs to be covered with a thin layer of light plaster, which will provide protection from atmospheric factors, and painted with facade paint in the required color.

Sectional diagram of insulation of the external wall of a building.

Advice! For high-quality gluing of foam panels, a flat surface is necessary, so before installation, all cracks and depressions on the facade must be filled with putty, and sagging and protrusions must be removed. For this purpose, cutting reinforced concrete with diamond wheels using a special cutting machine can be used.

Construction Materials

Table 1 shows the comparative characteristics of density and thermal conductivity of the most common thermal insulation and building materials (the lower the value, the better the thermal insulation).

Material Density kg/m3 Thermal conductivity W/(m?С°) Thermal insulation materials Mineral wool - slabs 200 0.08 - slabs 125 0.07 Expanded polystyrene - Polystyrene foam PSB-S 15 Up to 15 0.043 - Foam plastic PSB-S 25 15.1 - 25 0.041 — PSB-S foam plastic 35 25.1 — 35 0.038 — PSB-S foam plastic 50 35.1 — 50 0.041 Construction materials Reinforced concrete 2500 2.04 Concrete 2500 1.30 Solid brick 1800 0.81 Wood 500 0.18

Which insulation to choose for concrete walls

Method of applying liquid polyurethane foam insulation.

The best insulation materials for the walls of a concrete house are those that best protect the room from constant heat loss. They must have a minimum thermal conductivity coefficient. All other criteria are of secondary importance. Important aspects:

- price;

- installation features;

- moisture absorption;

- vapor permeability.

The factors are presented in descending order: from more important to less important. Therefore, you need to choose the best insulation for concrete walls according to the specified algorithm. If we consider popular materials, the most effective insulation with a thermal conductivity coefficient of 0.023 W/m*K is two-component polyurethane foam (PPU). Its installation is carried out only by specialists and only with the help of special equipment. It does not allow steam to pass through and does not absorb moisture, and also does not support combustion, that is, without exposure to an open flame, it immediately goes out.

The cheapest option is to insulate with mineral wool both inside and outside.

This thermal insulation belongs to the group of non-combustible materials, allows steam and moisture to pass through and is laid both over lathing and without it under plaster. But there is one serious drawback - it is highly hygroscopic; mineral wool strongly absorbs moisture and does not remove it well. This leads to a violation of the characteristics, up to a complete loss of the ability to retain heat, as well as to the formation of mold.

Polystyrene foam is also often used to insulate concrete houses, but it cannot be called the best option. Before choosing insulation for concrete walls among foam plastics, compare it with mineral wool. It costs twice as much as mineral wool, but does not provide any advantages except a lower thermal conductivity coefficient (the difference is maximum 0.005 W/m*C).

Features of internal insulation

Before you begin insulation work, you should know several features:

- Insulation of the inside creates conditions for condensation accumulation.

- Almost all materials that are used for insulation emit chemicals harmful to humans, although within normal limits.

- Many materials are flammable.

- If there is a choice between insulating the inside and outside of the room, then it will be cheaper to do it inside, although this will reduce the living area.

The room temperature will change much faster.

Insulation instructions

Regardless of the type of insulation, there are a number of basic rules that anyone who wants to insulate concrete walls on their own should know:

- Carry out work only in the warm season, when there is no high humidity.

- Dry the surface. At this stage, you can use a heater.

- Perform a complete clean. Pay special attention to areas where there has been moisture or mildew.

- Treat the surface with an antiseptic, then prime. The wall must dry out after each stage.

- The second wall is mounted only after the surface has completely dried. Do the final work on it: glue wallpaper, paint, etc.

Expanded polystyrene

This material is popular, it is easy to get in the store, and the gluing procedure is quite simple:

For better reliability, in addition to glue, use disc dowels. The reinforcing mesh should have cells of 3–5 mm and an overlap of about 10–12 cm.

If housing is built according to old technical standards, the recommended layer thickness is at least 8 cm.

Mineral wool

The technology for installing such slabs is distinguished by the presence of a special frame, which is made of wood or metal. Below we have selected the main recommendations:

- Fastening in two stages - filling the space between the surface and the frame and in the gaps of the frame.

- The insulation boards for filling should be about 50 mm, density - at least 75 kg/m³.

- After insulation, a vapor barrier film is attached to the frame using a stapler. If the frame is made of metal, use double-sided tape or glue.

- The film is attached with an overlap on the lower and upper edges.

- The places with which the film comes into contact are covered with a liquid sealant, which is applied to the junction. The film is fastened in the same way as described above. It’s better not to use just adhesive tape and be on the safe side.

- The final work is attaching drywall and finishing the surface.

Plastering

Most often, plaster is used at the final stages. It is usually applied using indicators to ensure uniform coverage. The final touch is primer.

The plaster is applied in three layers:

- Spray. Layer thickness – 10 mm. This is a liquid solution that is used to cover all cracks and roughness.

- Padding. Thickness – 45–60 mm. The basis of thermal insulation.

- Covering. Thickness – 5 mm. This is a solution of chalk powder and water, designed to completely hide flaws.

Other materials for insulation

In addition to the above, there are other insulation options. They are less popular, but are also used.

Thermal panels

When purchased, insulation is already applied to the plasterboard slabs. Quite easy to install: glue is applied to the sheet and attached to the surface.

Foam glass with fiberglass coating

Foam glass slabs, mainly with a density of 100–150 kg/m³, are glued and, if necessary, additionally fixed with dowels. In addition to glue, dowels are used during installation. Plasterboard is also placed on the slabs or simply plastered. It is convenient because it is steam and waterproof, environmentally friendly, not afraid of fire and rodents, and also cuts well.

The surface of the slabs is also additionally secured with glass mesh and metal corners.

The main disadvantage of fiberglass is that the material is more expensive than other offerings on the market.

It is characterized by high vapor permeability. Insulation with penofol 10 mm thick will have a heat-saving effect equal to insulation with mineral wool with a layer thickness of 3 cm. But often this thickness is not enough for effective insulation.

More often they are used as an auxiliary material, as an additional insulation material and as a vapor barrier. Attaches to the sheathing.

If you are offered to insulate your home with penofol alone, securing it in several layers with gaps, then this method will be extremely unprofitable - the process will be expensive and labor-intensive.