Aerated concrete is a modern building material that is used in both private and industrial construction. Experts prefer aerated concrete for qualities such as durability, thermal insulation and strength.

So what is aerated concrete and what is it used for? Let's take a closer look at this building material and find out the reasons why it has gained popularity among developers.

a brief description of

Aerated concrete is a type of cellular concrete and belongs to lightweight concrete. The material has a pronounced porous structure, which provides such qualities of aerated concrete as lightness and thermal insulation.

Aerated concrete is made by mixing the main components of concrete, such as binders in the form of Portland cement, sand and water, with a special foaming agent. Aluminum powder or paste plays the role of a foaming agent for aerated concrete.

Lime and aluminum react, as a result of which many air bubbles appear in the aerated concrete solution, which, when the concrete hardens, form closed cells and make the blocks light.

There are two ways to produce aerated concrete: autoclave and non-autoclave. Manufacturers most often use the first option, so aerated concrete gets better strength indicators.

Below we will look at the main properties of aerated concrete, the process of its manufacture, find out what load aerated concrete can withstand and in what area of construction it is best to use it.

Compound

The following materials are used in the production of aerated concrete:

- Portland cement – M400 or M500;

- Quartz sand – thoroughly cleaned of dirt, debris and foreign impurities, fine fractions;

- Lime;

- Water;

- Aluminum paste or powder.

The components specified in the composition of the material are available in any hardware store, so anyone can make aerated concrete with their own hands, the main thing is to strictly follow the recipe and maintain the correct proportions of the ingredients.

Technical characteristics of aerated concrete

Aerated concrete is a fairly popular material, but what explains its popularity? Let's study the key properties of the material and find out why developers and specialists prefer it.

| specific gravity | 300 – 1,200 kg/cub.m. |

| density grade | D350 – D1200 |

| water absorption | 20% — 25% |

| strength | 1.5 – 3.5 kg/cm2 |

| Compressive strength class for D500 | B2.5 |

| thermal conductivity | 0.1 – 0.4 W/m*K |

| frost resistance | F35 – F50 |

| vapor permeability | 0.2 mg/mhPa |

| shrinkage | 0.3mm/m |

| compressive strength | 0.5 – 25 MPa |

Aerated concrete is an excellent solution for the construction of small residential buildings (maximum height of three floors), it retains heat in the room and protects the building from overheating.

The vapor permeability of the material allows you to maintain an optimal microclimate for life, providing natural air exchange and humidity.

Due to its structure, aerated concrete can be classified as a soundproofing material. Air bubbles in gas blocks not only retain heat, but also absorb noise.

Aerated concrete is not a flammable material, it belongs to the first class of fire resistance, does not melt, does not burn. Aerated concrete blocks can withstand up to 7 hours of exposure to open fire.

In the production of aerated concrete, only safe materials are used; the radiation background of the material is significantly lower than the standards established by the state guest. Aerated concrete is not susceptible to biological influences; mold and mildew do not form on its surface.

About aerated concrete

Aerated concrete is a type of autoclaved cellular concrete; it is an artificial stone with spherical closed pores with a diameter of 1 to 3 mm evenly distributed throughout the volume. Pores make up about 85% of the volume; this structure determines a number of high physical and chemical properties of aerated concrete and makes it a very effective building material, in the production of which only natural minerals are used without the addition of chemical additives. The geography of application of aerated concrete covers all climatic zones and all continents. Factories for its production are located both in frosty Canada and Siberia, and in hot Australia and Africa. Autoclaved cellular concrete is used in the arid Arabian Desert and monsoon Southeast Asia, in seismically active Japan, Turkey and California - in a word - everywhere.

History of aerated concrete

Humanity has been trying to use lightweight aggregates and foaming agents to lighten masonry wall materials since Roman times. Aerated concrete, in contrast to wall materials made from light aggregate mixtures or foamed materials, is produced by the reaction of an alkaline binder (lime and cement) with an oxidizing agent, as a result of which gases are released, the bubbles of which solidify in the material. The first patent for the production of aerated concrete was received by E. Hoffman in the Czech Republic in 1889. In 1914 in the USA, Islesworth and Dyer first used aluminum powder and calcium hydroxide as aerating agents in the production of cellular concrete. In 1917, a Dutch patent was registered for the use of yeast as a leavening agent for cellular concrete. Later patents for the production of cellular concrete used reactions between zinc dust and alkali in the cement mixture, hydrogen peroxide, sodium or calcium hypochlorite. The use of metal powders as hydrogen-forming agents was developed in 1919 in Berlin. The Groza company used aluminum powder for controlled aeration of concrete to form hydrogen bubbles of a certain size.

Despite the fact that almost all inventors managed to obtain a lightweight cellular structure of cement stone, most of the resulting materials were characterized by low compressive strength, increased fragility and, as a rule, turned out to be unsuitable for use as a structural material.

The first autoclaved aerated concrete was produced as a result of experiments in 1924 by the Swedish architect Johan Axel Eriksson, working together with Professor Henrik Kruger at the Department of Civil Engineering of the Royal Institute of Technology in Stockholm. The discovery of new material was made almost by accident. Associate Professor Eriksson worked on various samples of cellular concrete. Due to lack of time, he decided to speed up the curing process of the porous mass of slate limestone, water and aluminum powder by placing the sample in a laboratory autoclave. When Associate Professor Ericsson took a sample of cellular concrete from the autoclave the next morning and subjected it to examination, it turned out that the resulting material was highly durable and had a crystalline structure different from non-autoclaved aerated concrete. When exposed to high temperature and high steam pressure, the silicon and lime components formed calcium silicohydrate, similar in structure to the volcanic rock called tobermorite. This mineral was named after the town of Tobermory on the Scottish island of Mull, where it was first discovered.

Further research showed that it is the tobermorite structure that determines all the high physical characteristics of autoclaved aerated concrete. Ericsson patented aerated concrete and by 1929, having found an investor for the construction of a plant in the person of Karl August Karlen, he established its industrial production in the Swedish city of Hällabrottet. Also, autoclaved aerated concrete began to be called “warm stones” due to the material’s good resistance to heat transfer.

Back in the early 1930s, a project was prepared to use a mixture of cement and sand as a starting material for the production of aerated concrete. In the post-war years, the composition of the mixture was improved in Germany. The Germans used a mixture of lime and crushed quartz with aluminum powder to produce calcium silicate autoclaved aerated concrete. In the UK and Eastern European countries, ash began to be introduced into the mixture for the production of autoclaved aerated concrete, which made it possible to achieve even greater strength of the resulting tobermorite crystalline structure of the material.

In 1939, commercial production of autoclaved aerated concrete was established in continental Europe. In the same year, aerated concrete houses were built in Riga from high-density blocks, which have survived without any finishing to this day. In Germany in 1943, at the height of World War II, Joseph Hebel acquired the technology for the production of autoclaved aerated concrete, which he began to produce in a former sand-lime brick plant near Munich, already equipped with large autoclaves. Joseph Hebel was the first to use wire cutting to produce high-precision aerated concrete blocks. In 1945, Hebel's head office in Munich was completely destroyed in one of the last Allied air raids. Josef Hebel managed to resume the production of aerated concrete only in 1948. After World War II, much of post-war Germany was rebuilt using autoclaved aerated concrete blocks.

In the 1950s, about 80 plants producing autoclaved aerated concrete were built in the USSR. In the 1960s, Polish-made aerated concrete plants were deployed in the USSR. Since 1959, aerated concrete began to be used in Leningrad for mass housing construction.

In the 1960s, aerated concrete appeared in Asia, and in the 1970s in North America. Today in the European Union, up to 40% of all building structures are built from autoclaved aerated concrete. In Germany, up to 60% of new structures are built from aerated concrete. In Japan, up to 80% of buildings are built from autoclaved aerated concrete. Autoclaved aerated concrete is widely used in Canada and Mexico. In the USA, autoclaved aerated concrete is not widely used.

Types of aerated concrete

The main indicators of any building material are density and strength; it is on them that the purpose for which the material is used depends. Density indicators must be indicated in the marking of building blocks; for this purpose, the letter “D” with a digital indicator is used.

Manufacturers produce aerated concrete with strength grades from D300 to D1200, the most popular type for construction is D500 or D600.

Based on strength grade, aerated concrete is divided into:

- Structural - used by specialists for the installation of load-bearing structures, block density from 1000 - 1,200 kg/m3, grade from D1000 to D1200;

- Structural and thermal insulation - used in the construction of one-story structures (utility room, garage) and for the installation of interior partitions. The density of the blocks ranges from 500 to 900 kg/meter per cube, respectively, the strength grade D500 is 900;

- Thermal insulation - used by specialists in the form of an additional thermal insulation layer, the density is 300 - 500 kg/meter per cubic meter.

Let's compare the popular types of aerated concrete according to key parameters:

| strength grade | strength/ MPa | Thermal conductivity/W/(M2*C) |

| D350 | 0,7 – 1,0 | 0,08 – 0,09 |

| D400 | 1,0 – 1,5 | 0,1 – 0,11 |

| D500 | 2,0 – 3,0 | 0,12 – 0,13 |

| D600 | 2,5 – 4,5 | 0,14 – 0,15 |

In addition, aerated concrete blocks according to GOST 31360 2007 are divided into two types depending on the presence of defects. Blocks of category I may have slight deviations of up to 2-3 mm, category II blocks have deviations of up to 10 mm, chips and cracks.

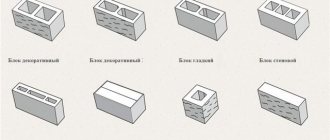

Manufacturers, focusing on the needs of consumers, produce gas blocks of various shapes, purposes and configurations. The range of blocks is quite extensive, here are:

- Wall panels made of aerated concrete;

- Aerated blocks with smooth surfaces;

- Tongue-and-groove blocks;

- Elements with recesses for hands;

- Partition panels;

- Monolithic aerated concrete;

- U-shaped blocks;

- Semicircular elements and lintels.

Wall blocks and panels have standard sizes and are used for the construction of structures that carry heavy loads. The partition elements are different - they are lighter and narrower.

Tongue-and-groove blocks allow you to increase the speed of work; the blocks are folded like a construction set, as a result of which strength increases, costs for laying solutions are reduced, and cold bridges are eliminated.

When laying reinforcement and forming monolithic belts, specialists use U-shaped blocks.

Blocks for installing wall structures of the “Ytong” brand

Itong aerated concrete wall blocks are available in various sizes and shapes.

Rectangular flat wall aerated concrete block "Ytong"

The cellular system of the blocks gives them high thermal insulation performance, this is the main difference between Itong blocks and other wall materials.

Various brands of Itong wall products and their scope of application

With a high load-bearing capacity, wall structures made of aerated concrete blocks have a fairly low weight.

Line of wall aerated concrete blocks "Ytong"

The ease of installation and processing of the products allows you to arrange walls of various configurations.

Ytong U-shaped blocks

Ytong U-shaped aerated concrete blocks have a wide range of applications.

"Ytong" aerated concrete U-block

Having a complex configuration, these blocks have all the advantages of conventional wall blocks. U-blocks also have identical dimensions, which makes it possible to simply and easily install them into the overall wall structure. The elements are laid using special glue.

Identical sizes of different blocks

Scope of application of U-shaped elements:

- Jumper arrangement;

- Making stiffeners;

- As external permanent formwork to create a reinforcing belt.

When installing lintels and stiffening ribs, U-blocks act as an insulating formwork element, inside which the reinforcement frame is laid. It is also possible to lay an additional thermal insulation layer. Next, the concrete mixture is poured into the block.

Installation of lintels over openings from U-shaped elements

The multilayer structure obtained in this way has great strength and thermal insulation ability. The appearance of “cold bridges” is eliminated, and this significantly reduces heat loss.

Aerated concrete lintels "Itong" with factory reinforcement

Reinforced lintels made from Itong aerated concrete have a great advantage over conventional reinforced concrete elements.

Reinforced aerated concrete lintel

When constructing energy-efficient buildings, an essential factor is the absence of heat loss through jumper blocks. Therefore, it simultaneously performs two functions: a load-bearing beam and an insulating element.

Installation of reinforced aerated concrete lintel

Types of jumpers "Ytong":

- For load-bearing external and internal wall structures - height 249 mm (model PN250);

- For non-load-bearing internal walls - height 249 mm (model PP250);

- For load-bearing external and internal wall structures - height 124 mm (model PN125).

Jumpers PN250 have great strength, PN125 are lighter in weight. Installation of any of them is done by hand, without the use of lifting equipment.

Prefabricated monolithic floors from Ytong elements

The Xella company is also engaged in the production of complex systems for the installation of interfloor ceilings of prefabricated monolithic type.

System of prefabricated monolithic flooring of buildings and structures made of beams and aerated concrete blocks

This system consists of several constituent structural elements:

- Reinforced concrete or steel beams;

- Free reinforcement frame made of steel;

- T-shaped blocks made of aerated concrete.

Based on the size of the span to be covered, the required size of beams is selected. They are available in lengths up to 9 meters.

Prefabricated monolithic type ceiling made of aerated concrete blocks on reinforced concrete beams

Floors on reinforced concrete beams are perfect for the construction of new buildings or reconstruction of old buildings. The length of the overlapped span is up to 7 meters.

Prefabricated monolithic type ceiling made of aerated concrete blocks on light steel beams

This option has a higher load-bearing capacity - up to 500 kg/m3, the span length can be up to 9 meters.

T-shaped block made of aerated concrete "Itong" for prefabricated-monolithic type slabs

T-shaped aerated concrete elements measuring 600*250*200 mm are laid along the beams.

Advantages of using a prefabricated monolithic floor using Ytong aerated concrete blocks

Floors using elements made of lightweight cellular concrete are a fairly innovative approach.

The design of prefabricated monolithic systems has a lot of advantages:

- Significant reduction in the weight of the entire floor structure due to the use of lightweight blocks;

- The high load-bearing capacity of the entire system is ensured by the joint work of beams and blocks;

- Reducing concrete consumption for work – up to 30%;

- The stages of installing temporary formwork and installing auxiliary structures are excluded from the technological process;

- Installation of all components can be done without the use of special equipment;

- Reducing overall construction costs by saving materials and labor;

- Significant reduction in construction time.

Many related work on finishing structural elements can be done at the construction site: cutting to the required dimensions, giving the required shape..

Laying T-shaped blocks on load-bearing beams

Wall structures with complex architectural forms, for example, bay windows, are much easier to cover using prefabricated monolithic systems.

Arc-shaped blocks "Itong"

Manufacturing arc-shaped blocks is an innovative approach to original design solutions in building layout..

Arc-shaped aerated concrete block "Ytong"

The production of such elements allows you to create non-standard external and internal wall structures.

Dimensions of arc-shaped aerated concrete blocks "Ytong"

These can be semicircular bay windows, interior partitions, round shower stalls and much more.

Dimensions of arc-shaped Ytong aerated concrete blocks

The arc-shaped blocks are laid using thin-seam adhesive - a variety of coatings can be applied to the resulting surface without prior treatment with putty and plaster.

Blocks for partitions “Itong”

The main advantages of partition elements made of aerated concrete are their low weight and ease of laying.

Partition aerated concrete block "Ytong"

The variety of sizes of partition blocks makes it possible to widely use them for various purposes.

Dimensions of partition blocks:

- 5 cm;

- 7.5 cm;

- 10 cm;

- 15 cm.

It could be:

- Creation of simple internal partitions between rooms;

- Construction of spatial objects - podiums, bar counters;

- Decoration of loggias and bathrooms.

They are very easy to process; you can give them various shapes and make any dimensional elements.

Aerated concrete blocks “Ytong” for the installation of internal partitions

Thanks to the perfectly smooth surface of the partition blocks, their finishing is not difficult: any finishing is done at minimal cost. Sufficient moisture resistance of the material allows it to be used in rooms not only with normal humidity conditions, but also with high ones.

In areas such as:

- Bathrooms;

- Shower cabins;

- Kitchens;

- Drying rooms.

Wall finishing in such rooms can be done without additional treatment of the surface of the blocks.

Finishing aerated concrete partitions in the bathroom with tile materials

Hanging furniture and plumbing fixtures can be attached directly to the blocks themselves. The use of embedded structures is not required, since the material has a sufficient margin of safety.

Advice! Lightweight interior items, such as paintings, can be mounted using ordinary construction nails. They are hammered from top to bottom at an angle of 45 degrees.

Dimensions of aerated concrete blocks "Ytong" for installing partitions

Installation of partition elements is carried out using a thin-seam adhesive solution.

Stair blocks and slabs "Ytong"

produces several types of Itong staircase blocks: reinforced steps (LS model) or reinforced slabs (LSP model).

Stair aerated concrete block "Ytong"

The ease and simplicity of processing of Itong aerated concrete materials allows you to create flights of stairs of any size and configuration.

Complex spiral staircase made from Ytong blocks

Instructions: to construct a staircase structure, first a retaining wall is constructed from gas blocks with a thickness of more than 250 mm.

Advice! A waterproofing layer must be laid under the supporting structures on which the stairs will rest.

The depth of support of aerated concrete elements on the retaining wall is more than 150 mm. All the components of the stairs can be easily assembled using Itong glue. The main direction in solving the housing issue in Russia is active low-rise construction.

Project of a low-rise building made of aerated blocks "Ytong" - photo

The use of cellular concrete in individual construction is still gaining momentum. Aerated concrete blocks "Ytong", in addition to all the above advantages, also have a low cost and can be installed in a fairly short time.

The prospects for their wider use look very favorable. You can get more information about Itong products and aerated concrete blocks by watching the video in this article.

Aerated concrete production technology

The process of making aerated concrete begins with the preparation and combination of the ingredients that make up the aerated concrete mixture - Portland cement, water, sand, lime and foaming agent.

In a separate container, the dry ingredients are mixed until smooth, then the resulting mixture is poured into molds and sent to the autoclave. When exposed to high temperature and pressure, the aerated concrete mixture swells and the mass acquires a porous structure.

The finished aerated concrete is cut into blocks of the required configuration. In the factory, cutting is done using an automated machine, which allows you to obtain products with perfectly even geometry.

There are two types of aerated concrete production:

- Autoclaved - aerated concrete is exposed to hot steam and high pressure and dried in special chambers;

- Non-autoclaved - drying occurs naturally.

Aerated concrete produced by the autoclave method is strong and durable; the blocks can withstand heavy loads. Non-autoclave blocks are much inferior in quality, their density indicators are much lower. It can only be used for insulation; it is not suitable for construction, as it is too fragile.

Domestic producers of aerated concrete

After studying customer reviews, the best aerated concrete manufacturers were identified, trusted by both consumers and specialists:

- Betokam is the largest manufacturer of gas blocks and reinforced concrete structures in the Urals;

- “Gazobet” is a famous aerated concrete plant in Ternopil;

- “Silex” (Sayan aerated concrete) - production is located in the Irkutsk region, the plant produces autoclaved aerated concrete wall blocks;

- Plant 211 KZHBN (reinforced concrete products plant) - the main product is autoclaved aerated concrete, located in the Leningrad region, Sertolovo;

- PZSP is the largest manufacturer of aerated concrete products in Perm and the Perm region.

- EuroAeroBeton is a manufacturer of aerated concrete products in the city of Slantsy;

- "Rostovsky GazoBeton" - produces aerated concrete elements and delivers the material;

- “Baikal aerated concrete” is a plant for the production of concrete and aerated concrete blocks and building structures, the branch is located in Ulan-Ude;

- ROSBK (Russian concrete structures);

- "UDK" - the company produces autoclaved aerated concrete, the main production is located in Dnepropetrovsk;

- — produces non-autoclave aerated concrete, the plant is located in Novosibirsk, the production uses an automated line;

- — production is carried out in the Republic of Crimea, Simferopol, the company produces autoclaved aerated concrete of any configuration.

When choosing aerated concrete from the manufacturer, you can count on the quality and reliability of the material. Only the latest technologies and specialized equipment are used in production, which allows us to produce high-class materials.

Features of UDK aerated concrete: characteristics and advantages

Specialists produce such building materials using the autoclave hardening method.

UDC concrete blocks appeared in 2007. To produce them, a cement mixture is mixed, to which sand, gypsum and lime are added. To produce cellular aerated concrete, aluminum powder or paste is added to the resulting solution. Then the forming process takes place, thanks to which UDK slabs are made into any shape. The blanks are sent to an autoclave, where after firing a finished product with a smooth surface is obtained.

The production method determines the characteristics of the building material. Due to their physical properties, UDK concrete blocks have the following properties:

The material is of fairly high quality and has a lot of positive characteristics.

- thermal insulation ability;

- ease;

- low density;

- significant strength;

- standard size;

- fire resistance.

Manufacturers of UDK aerated concrete produce foam blocks of standard correct sizes, which allows them to be positioned with maximum accuracy. Concrete blocks have frost resistance within 35 cycles. Density ranges from 400 to 600 kg/m3 (dry). The class of this concrete varies depending on the brand and ranges from B2.0-B3.5.

Advantages of building materials

YuDC aerated concrete appeared recently, but has already conquered the market thanks to the advantages presented in the table:

| pros | Characteristic |

| Strength | Reliability is achieved by the autoclaving method, which, under the influence of temperature and pressure, gives the original mixture natural mineral properties |

| Thermal insulation | Firing in a kiln causes a low ability of the material to conduct heat |

| Yudk aerated concrete is not additionally insulated | |

| Economical | The price of foam concrete is determined by the low cost and simplicity of the initial mixture required for its production |

| Environmental friendliness | Manufacturers do not use aggressive chemical components during production |

| The properties of the blocks are determined by physical methods of influencing the composition | |

| Frost resistance | You can build a house from UDK aerated concrete at any time of the year |

| Low density | Aluminum foaming agent ensures low density of the building material, which reduces its weight |

| Depending on the brand, the density of the product varies | |

| Fire resistance | UDC concrete slabs do not burn and can withstand high temperatures for a long time |

| Soundproofing | Building material does not transmit sound |

| Standard size | The correct shape of UDK aerated concrete elements reduces the time for installation of the structure |

| Smooth surface | This property reduces the cost of plaster and primer when building a house |

| Grip pockets | Guarantees ease of laying |

This type of concrete is suitable for low-rise buildings. Its lightness ensures a low load on the foundation, but is a disadvantage if it is necessary to build a multi-story building.

Areas of use

Aerated concrete is used by specialists in various fields of construction; it is used for the construction of industrial and public buildings, for example, warehouses or one-story general purpose buildings.

But more often it is customary to use aerated concrete in private construction. From it are cocked:

- Cottages are low-rise buildings up to three floors;

- Dachas;

- Utility rooms;

- Garages;

- Fences, you can build a gazebo or summer kitchen from aerated concrete.

People who want to build or reconstruct a country house can contact special companies - design bureaus. Here you can learn more about the use of aerated concrete and see projects of construction projects, for example, the Gleba Grinfeld bureau provides design and construction services for any projects .

Our employees will tell you in detail about the advantages of the material, for what purposes it is suitable, and will create an individual project, taking into account all your wishes.