Reinforcement is the skeleton of any foundation; it is also the basis of all reinforced concrete structures.

The durability, safety and reliability of the building depend on how correctly it is selected by type (brand, diameter) and quantity. Failure to comply with basic standards can lead to disastrous results, which is why professional builders always pay a lot of attention to reinforcing the foundations of buildings.

Reinforcement of strip foundation.

Many owners of private plots, planning to build their own house, encounter problems at a certain stage. A house plan has been drawn up, a construction site has been selected, a soil analysis has been carried out and a foundation pit has even been dug. It's time to start the foundation. In the construction of a private house, the most justified is the use of a strip foundation, but not everyone knows what kind of reinforcement is best to use for a foundation of this type and whether it actually needs to be reinforced. As a result, buildings erected by hand are not always safe for use.

How to knit reinforcement for a foundation?

As noted above, the entire theoretical basis and numerical data must be calculated and prepared in advance so that construction can proceed directly from them.

Parameters such as the amount of concrete, the location of the foundation and the type of materials used must be fully specified in the technical specifications and checked before the start of the construction process.

Selecting the type of reinforcement

What kind of reinforcement is used for strip foundations? Today the most popular types of rods are:

- Steel, with a diameter of at least 5 mm for transverse bars and 10 for longitudinal ones. The strength of the entire strip structure will depend on what brand of reinforcement is needed for the strip foundation. Class A steel rods with a yield strength of 400 are used. Visually, the following differences between the grades can be determined: A 240 has a smooth surface, A 300 has a ring pattern, A 400 has a herringbone pattern. The use of lower quality rods is impractical.

- Fiberglass rods are resistant to corrosion and lack electrical conductivity. Often this material is used for buildings where it is important to avoid radio interference. The strength of high-quality rods is not inferior to metal ones.

For laying the main longitudinal reinforcement elements, exclusively rods with a ribbed surface are used, as this guarantees better adhesion to the concrete. Smooth rods are used to create side lintels.

It is strictly prohibited to use the following materials as reinforcement:

- metal pipes;

- chain-link mesh;

- metal profile;

- iron cables.

Failure to comply with the requirements for reinforcement for a strip foundation can lead to subsidence of the base and further destruction of the entire structure.

Reinforcement scheme

In a cross-section of a reinforced concrete structure, you can see the reinforcement in the form of a rectangle. This is due to certain geometric laws.

During operation, two physical forces act on the foundation. One is directed upward and occurs due to the effect of heaving in cold weather, and the second force is the pressure of the mass of the house, which is constantly active and is directed downward.

Read here - Types of foundations - tips on choosing suitable types, necessary materials and installing a foundation (100 photos)

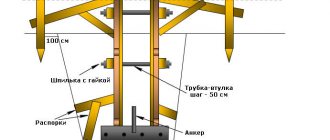

To fully compensate for these forces and balance them, reinforcement is installed in two layers, top and bottom at an equal distance from each other. For deeper foundations with a thickness exceeding 100 cm, 2 layers of metal can be used.

What reinforcement is suitable for the foundation? When using a strip foundation, two types of reinforcement are distinguished. For those that are load-bearing, that is, perform the main strength function, class AII or AIII rods are used. For non-load-bearing secondary structures, a more budget-friendly material is used in the form of AI, the thickness of which does not exceed 8 mm.

The properties of fiberglass in combination with concrete and fiberglass reinforcement for foundations have not been studied. You can experiment and use a hand-made composite, or simply trust the manufacturer when purchasing iron.

Determine the required amount of materials

Above, we found out what types of foundation reinforcement there are and examined the features of using each of them. Before moving on to a description of calculating the amount of materials required for a reinforcing frame, let us dwell in more detail on its structure.

We clarified why reinforcement is needed in the foundation. It forms internal elements of rigidity that prevent the destruction of the foundation of buildings. In order for it to perform its task with maximum efficiency, it is necessary to properly manufacture the reinforcing frame.

Reinforcement calculation

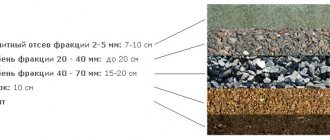

It consists of rods laid in two rows. In this case, the strip foundation frame consists of two parallel rows of rods connected by transverse and vertical pieces of reinforcement. At the base of the slab base, the rods form two grids located one above the other. A prerequisite is to deepen the rods inside the concrete pour.

Calculation of strip base

As an example, we will determine the required amount of strip foundation reinforcement for a 6x6 meter house with one partition. Based on the building parameters, the total perimeter of the walls will be 6x4+6=30 meters. We lay the rods in four strips, therefore, we multiply the length of the walls by 4, getting 120 meters.

To maintain the high strength of the reinforcing frame, individual rods in the corners of the house must overlap each other by at least 1 meter. Based on this, the total footage of the rods should be increased by 16 meters and, with subsequent rounding, we will ultimately obtain a quantity of reinforcement of 140 meters.

Scheme for calculating reinforcement for a strip base

Transverse horizontal and vertical inserts with a tape section size of 1.5x0.5 meters are equal to 1.4 and 0.4 meters, respectively. We install them in 1 meter increments in pairs. Therefore, the length of such rods will be 60x1.4+60x0.4=80.4+24=105 meters. Due to the lack of load on them, the diameter can be reduced to 6-8 mm by using smooth wire.

To connect the frame elements, soft knitting wire is used. Each connection requires 0.3 - 0.5 meters, depending on the diameter of the reinforcement. Our version will require 30x4=120 connection points. Having calculated the amount of knitting wire, we obtain the required length of 120x0.3 = 36 meters. By adding a few meters for connections at the corners, we round the footage to 50.

Calculation of slab base

Above we gave recommendations on what reinforcement to make the foundation from. The calculation of its quantity depends on the specific type. So, a slab foundation of the same size 6x6 will require much more reinforcement. The standard size of mesh cells is 25 cm. Therefore, the number of rods is determined by the formula: 6/0.25x4=96, and the total length is 96x6=576 meters.

Vertical posts with a slab thickness of 25 cm will be equal to 0.15 meters. And their total length is determined as 24x24x0.15 = 86.4 meters. Rounding up, we get an additional 90 meters of reinforcement for the racks, which will give a total of 666 meters.

The number of connections of the upper and lower mesh rods to the posts will be determined as the product of the tie points by 4, since each reinforcement is attached to vertical spacers: 24x24x4=2304, and the total required length is 2304x0.15=345.6 meters.

The above calculations clearly show that the slab base of the house is significantly higher than the strip base in terms of material consumption. Before choosing reinforcement for the foundation, it is necessary to calculate the financial costs of the entire structure.

Calculation of strip foundation reinforcement

We make the correct reinforcement for the foundation. Like any other technical task, the laying of the foundation is controlled and regulated by various GOSTs and applications. They regulate the quality of the material used for construction, the geometric features of the process, and even the safety precautions of working personnel.

The minimum amount of reinforcement, for example, should be at least 0.1% of the entire transverse area of the foundation. The calculation of reinforcement for the foundation is also carried out according to other parameters.

What is it made from?

First, let's talk about the materials used in the manufacture of fittings. Today there are metal and plastic analogues on sale. The latter, due to their novelty, attract great attention, and not always justified. We list the advantages of both options so that the reader can decide which reinforcement to use for the foundation. Let's start with the advantages of metal:

- Even with a significant load, the metal rod does not bend, which ensures high reliability of the structure - the plastic analogue can be deformed under such a load;

- can be bent directly on the construction site with a special tool. The plastic analogue cannot be bent - you can only pre-order products of the desired shape at the factory;

- The price, although a little, is lower than that of plastic.

Related article: Do-it-yourself foundation formwork from boards

Now let's talk about the advantages of plastic:

- It has less weight, which greatly simplifies the process of transporting and assembling the frame;

- not subject to corrosion, which is the scourge of all metal products;

- works well in tensile strength, in some cases withstanding loads twice as high as those for a metal material.

As you can see, it is quite difficult to answer unequivocally what kind of reinforcement is needed for the foundation - each option has its own advantages that should be taken into account in order to make the right choice.

Corner reinforcement

One of the most vulnerable places in the foundation to mechanical damage and splitting is the corners and junctions of heterogeneous media. Such areas are subject to increased load because they are not solid and heterogeneous material.

In order for the load to be distributed evenly, reinforcement or tying of reinforcement under the foundation is necessary. Moreover, simply trying to connect sections in this way will not be a completely reliable way.

This must be done using strict technology, otherwise such a fastening system will only last for a very short period of time. The bottom line is that for reinforcement it is necessary to use L-shaped clamps.

Fiberglass or metal (steel) reinforcement - comparative characteristics

Fiberglass reinforcement rods are a bundle of fiberglass, each 15 microns thick, impregnated with epoxy or other resins and having a corrugated surface for better adhesion to concrete. A properly constructed rod should have a central core of fibers that is spirally braided with a second layer of fiberglass.

The type of fiber material determines the properties and name of the reinforcement. In addition to fiberglass, there are carbon fiber and basalt products.

The diameter of the reinforcement bar is in the range of 4-18 mm, and the maximum length is limited only by the settings of the production equipment. The density of fiberglass is only 1.9 t/m3, and 1 cubic meter of steel reinforcement weighs at least 7 tons. Due to this property, composites have been used in the production of lightweight concrete since the 60s of the last century. The average service life is at least 80 years.

The corrugated surface of the reinforcement facilitates its adhesion to concrete.

The production of fiberglass rods for reinforcing concrete is possible only in factory conditions, which reduces the likelihood of buying a low-quality product that does not meet regulatory requirements. Composite reinforcement does not rust, does not conduct electricity and is environmentally friendly.

There are no materials that are ideal in everything, and composite reinforcement has a number of features that impose restrictions on its widespread use. Disadvantages of non-metallic elements of a concrete structure:

- the modulus of elasticity of steel is 4 times higher than that of fiberglass, so floor slabs and load-bearing structural elements are made from iron reinforcement;

- plastic cannot be welded, only knitting together or using reinforcement with metal tips;

- any composite rods cannot be bent at right angles; special corners are taken for connection or tied end-to-end with an overlap;

- mechanical properties deteriorate with heating, and at a temperature of 600 degrees, complete destruction of the structure occurs;

- construction teams have little experience working with composites and lack of certification for most of the objects being built (metal reinforcement is set by default).

Composite reinforcement does not bend in corners.

The combination of metal units and plastic rods of various diameters in the design will help to reduce disadvantages to a minimum. This mutual combination is considered optimal and reliable.

To choose which reinforcement is best to use for the foundation, you need to take into account all the above factors. The most common types of foundation on which composite material can be used are shallow strip, grillage and monolithic slab.

Composite reinforcement is well suited for strip foundations of small buildings

For them, reinforcement is taken with a thickness of 8-12 mm and with special notches for reliable adhesion to the mortar. Smooth rods of type A1 can be used for light outbuildings and as beacons when pouring the foundation.

An example of the use of plastic reinforcement in a slab foundation

Features of the reinforcement of the foundation of a house:

- the number of rods is calculated based on the method of laying and the depth of the reinforcing layers;

- for a strip foundation, 2 such layers are needed, for a slab foundation, one and a sand cushion under the base are enough;

- the cell pitch for fiberglass should not exceed 500 mm;

- the corners of the foundation are covered with special corner elements, because butt joints in the corners are not allowed;

- tying of reinforcement at the joints is carried out with wire, staples and a special gun or plastic clamps;

- to evenly distribute the frame in the thickness of the concrete, reinforcement clamps will be required, the distance to the surface is 1-2 centimeters;

- The columnar foundation is placed below the freezing depth (usually from 0.7 to 1.5 meters depending on the region), which eliminates its movement and ruptures.

We suggest you familiarize yourself with Which vapor barrier to choose for the walls of a frame house

Composite reinforcement can be used in the construction of a pile foundation for a small building.

Important! When pouring the solution into the formwork, check that all parts of the frame are hidden by concrete. Where the reinforcement reaches the surface, cracks will form and further destruction of the foundation will occur.

The number of vertical power bars of a periodic profile in a pile is 2-4 or more. Diameter - 10 mm, more is usually not used. The exact number of rods depends on the diameter of the pile, determined by the formwork. Its functions can be performed by an asbestos cement pipe:

- with a diameter of up to 200 mm, use 2-3 rods;

- 200-250 mm – 4 pieces;

- more than 250 mm – more than 4 pieces.

In bored piles, the same rule is observed as in strip foundations - a small distance must be maintained between the reinforcement and the surface of the concrete element.

For horizontal jumpers, smooth profile rods with a diameter of 6 mm are used, their installation pitch is approximately 50 cm.

The properties of this type of reinforcement are regulated by GOST 31938-2012, according to which it is divided according to the type of reinforcing filler into glass (ASK), carbon (AUK), aramid (AAK), basalt composite (ABK), combined (AKK). The range of nominal diameters is 4-32 mm.

The characteristics of these types of fittings differ quite significantly:

- tensile strength for SK products is 800 MPa or more, for UK products - at least 1400 MPa;

- the tensile modulus of elasticity of glass-composite reinforcement is 2.5 times less than that of carbon-composite reinforcement;

- the ultimate transverse shear strength – for SK reinforcement is at least 150 MPa, for UK reinforcement – more than 350 MPa;

- The compressive strength of all types of polymer reinforcement is 300 MPa or more.

Attention! GOST 31938-2012 regulates only product characteristics, and manufacturers determine the recipe independently.

Comparing the properties of polymer composite and steel reinforcement will allow you to determine which one is better in a particular case.

- The conductivity of steel is not always a disadvantage; for example, it can be used to construct a grounding loop. Polymer materials are dielectrics. Complete inertness to magnetic fields and the ability to transmit radio waves in a wide frequency range without loss ensure the use of these products in the construction of laboratories and similar structures.

- The specific gravity of polymer reinforcement is 4-5 times less than that of steel. But this property plays a role only during transportation. For the building structure itself, such a difference in mass does not matter.

- If steel rods are bent directly at the work site, then polymer products can be given a certain shape only in production conditions.

- A big advantage of polymers is corrosion resistance. One of the applications of these products is the creation of meshes from polymer rods for additional external strengthening of the foundation located in an aggressive environment. If there is a distance between the reinforcement and the concrete surface, the steel rods also do not collapse.

- The disadvantage of polymer products is a much higher elongation coefficient compared to steel products. This property can cause sagging strip or slab foundations.

- The lower thermal conductivity of polymers compared to steel is a plus in cold regions, since such reinforcement does not create cold bridges. However, these materials cannot withstand temperatures below -15°C - the process of embrittlement begins. The upper limit is 120°C, at which temperature the thermoset resin begins to melt, causing the rod to lose its shape.

Conclusion! Composite reinforcement can be used to reinforce foundations, but only if the accompanying documentation for the product indicates this possibility.

Concrete is used to pour the foundation. But this material, although characterized by high strength and durability, is quite fragile. Therefore, it is additionally strengthened with reinforcement. Previously, only metal rods were mainly used, but modern technology has expanded the choice.

Today, 2 main types of reinforcement are used to strengthen the foundation:

- Metal. It consists of steel rods. The most commonly used rods are those with a round cross-section. To improve the strength characteristics, the rods have a ribbed helical surface.

- Fiberglass. Composite rods were invented back in the late 70s. XX century, however, they began to be used in the construction of foundations relatively recently. Gradually they began to supplant the metal type. They are made of durable fiberglass. The main advantage of such rods is their resistance to corrosion, which cannot be said about steel rods.

Foundation reinforcement

Which reinforcement is better: metal or fiberglass? Each option has its advantages and disadvantages. In addition, the second option has appeared recently, and its durability and strength have not yet been proven in practice.

We suggest you familiarize yourself with How to insulate the foundation of a house from the outside with your own hands

The main parameter of reinforcement is its cross-section (diameter). Metal rods are produced with a diameter from 5 to 32 mm, fiberglass – from 4 to 20 mm. Thanks to this, you can choose the best option for the construction of any building or structure, while ensuring the necessary strength of the foundation.

When constructing private houses, steel rods with a diameter of 8-16 mm are used. What reinforcement to use when pouring the foundation also depends on its type. For strip, slab, and pile foundations, steel rods are selected separately.

The use of steel rods in the construction of houses

In addition, metal fittings are divided into 2 types: with a ribbed or smooth surface. The first option is used in areas subject to tensile loads. Smooth rods are used, as a rule, as connecting jumpers. And they are not affected by the main loads.

The reinforcement for the foundation differs depending on the grade of steel. Carbon and low-alloy steel can be used to make rods. The brand of material is chosen by the consumer or indicated directly by the manufacturer.

What kind of reinforcement is needed for the foundation depends on many factors. It is necessary to take into account the type of soil, seasonal deformations, the power of the building under construction and all loads. No less important in choosing the type of rods is the type of base (tape, slab, bored).

Reinforcing mesh in the foundation - connecting element