Disassembly or dismantling of the foundation is a complex technological process using special equipment and human resources. Concrete structures perform the function of ensuring load-bearing, reliability and durability of the structure. Therefore, dismantling and removing the foundation is not easy. Over the years, concrete elements can deteriorate, become compacted, and break and crumble when removed.

When dismantled, a slab foundation has its own characteristics. It is not always possible to completely remove the slab due to its large mass and size, then you have to destroy it first.

Depending on the type of structure, the territory on which it is erected, and the depth of the foundation, special equipment for dismantling is selected. In some cases, the destruction of the foundation occurs manually, using sledgehammers, crowbars, hammer drills, and cutting machines. This method is certainly cheaper, but takes a lot of time and effort. Sometimes explosives are used. To do this, the company must have the necessary permits.

When dismantling the foundation, it is necessary to remove all components, especially if it is planned to build a new facility at the site of dismantling.

Engineers and machinists of the construction company "Northern House" will determine the optimal method of dismantling and perform high-quality work with a guaranteed successful result.

Dismantling the foundation. Methods and mechanisms

Our company has at its disposal many types of special tools and equipment, with the help of which work on dismantling the old foundation of a house or cottage is carried out in a matter of days

- It is often possible to dismantle an old brick foundation using high-power manual jackhammers and without the need to involve heavy special equipment. In this case, the cost of dismantling the foundation will be significantly lower.

- We can demolish a strip concrete foundation using an excavator. The destruction of the foundation is carried out with a bucket, and the reinforced base is cut with a grinder. In special cases, the use of a hydraulic hammer is required - a special attachment on the excavator boom.

- It is impossible to remove a foundation made of concrete piles, and even with a concrete tape around the perimeter, without using a “hydraulic hammer”. In the same way, a buried foundation is dismantled. We load all the broken concrete into dump trucks and remove construction waste from the site. At the request of the customer, the hole formed after dismantling the foundation is filled with leveling soil, and the surface is leveled. Filling the area with soil is an additional service and is calculated separately.

Prices for dismantling brickwork in the estimate

Prices for dismantling brick walls or prices in estimates for dismantling brick partitions are most often used when drawing up estimates in Form 4, local resource estimates or local estimates for repair or reconstruction work. Therefore, most often the price for dismantling brick walls in the estimate can be selected either from collections of the regulatory framework for the repair and construction part, or from collection 46 for reconstruction. The same applies to the prices in the estimate for the dismantling of brick partitions.

Thus, the GESN46-04-001-04 standard, which is shown as an example in Figure 2, can be used as a price for the dismantling of brick walls. As you can see, table GESN46-04-001 can also be used when drawing up estimate forms for dismantling foundations of various types, as well as for dismantling small-block walls.

Figure 2. Price for dismantling brick walls

In addition, the price in the estimate for dismantling a brick wall can be applied using special coefficients for dismantling. However, this is possible if the GESN46-04-001-04 standard is not suitable for the technology of work as a price in the estimate for dismantling brickwork.

In addition to the price in the estimate for dismantling the brickwork of walls, the price in the estimate for dismantling the brick partition can also be applied. In this case, it is best to refer to the repair collection GESNr55. The specified collection under the code GESNr55-5-1 contains a price for the dismantling of brick partitions. This price in the estimate for the dismantling of brick partitions takes into account, in addition to the dismantling work itself, the price in the estimate for cleaning the brickwork, or rather, individual bricks suitable for further use. Also, this price in the estimate for the dismantling of partition bricks provides for storing the dismantled bricks in a specially designated area in stacks. However, it should be borne in mind that the price for carrying bricks manually as part of the work of the GESNr55-5-1 standard is not provided, at least for a greater distance than indicated in the technical part. Therefore, if necessary, this type of work should be considered a separate item.

Methods for dismantling strip foundations

The strip foundation can be dismantled in several different ways. A number of professional tools are used for this work - it can be a hydraulic hammer or a jackhammer. It all depends on the strength of the foundation.

Parsing methods:

- Dismantling with a hydraulic hammer - this tool is an attachment to the excavator boom. It works on a similar principle to a jackhammer. It is used for grinding bricks and concrete. After this procedure, concrete fragments are loaded into the back of a dump truck and removed from the territory;

- Dismantling with an excavator bucket - this method for dismantling a strip foundation is rarely used;

- Dismantling with jackhammers - this method is used if it is impossible to use equipment (access to the site is difficult, limited space around the foundation). Using jackhammers, the foundation is crushed into small fragments. Such work requires time and the use of physical force, so it is more expensive than using heavy equipment.

Dismantling a strip foundation can take from one to three days, depending on the complexity. In addition to the listed tools, hydraulic shears (the most modern method), diamond cutters, sledgehammers and crowbars can be used.

A strip foundation is much easier to dismantle than other types of similar structures. The thickness of the product in rare cases exceeds 50 cm. The work may become more complicated if the structure contains reinforcement or channels.

How much does it cost to dismantle a strip foundation?

Dismantling a strip foundation is a labor-intensive job that requires high competence and experience from the workers performing this task. Many activities will require special equipment.

Prices

Type of work performed Cost, rub

| Foundation demolition no more than 6x6 meters | from 35,000 rub. |

| Dismantling the foundation no more than 8x8 meters | from 45,000 rub. |

| Removing the foundation no more than 10x10 meters | from 55,000 rub. |

| Demolition of foundations larger than 10x10 meters | Calculated individually |

| Garbage removal with a 10 cubic meter dump truck. | From 8000 rub. per flight |

| Garbage removal with a 20 cubic meter dump truck. | From 14,000 rub. per flight |

A preliminary calculation of the cost of dismantling is carried out according to the data provided by the client. After the engineer visits the site, the final price is determined. It includes the complexity of the work, the area of the foundation, its strength, and the use of special equipment. The price may be influenced by the distance of the object from the city, the complexity of the entrance, the presence of other houses nearby (building density), the method and the chosen method.

What do we offer?

Professional dismantling of strip foundations is an important component in the work of the Geocomfort company. Regular clients already entrust us with clearing their objects of old slab monoliths and sections of basement made of brick or artificial stone. Take advantage of our help right now and get rid of anything that interferes with landscaping, construction or planting of lawn coverage. An excellent ratio of cost and quality of services is what we are really ready to guarantee you. In addition, the company always carefully fulfills its obligations, ensures the arrival of equipment on time and makes it possible to quickly carry out dismantling work in any conditions.

We are not afraid of complex tasks, we have our own team of professionals and can easily cope with any work. You won't have to spend a lot of time struggling with the foundation when demolishing a house, shed or garage. Just order the services of specialists in advance, and we will definitely cope with the problem that prevents you from using all the capabilities of the site to the fullest. The company's own fleet of equipment: from dump trucks for waste removal to backhoe loaders, is always at your service.

Order a cost estimate

Pile foundation

Dismantling a pile foundation

The pile foundation is dismantled as a last resort, for example, when laying new underground communications. Piles help strengthen soils with weak bearing capacity and there is usually no need for their dismantling.

Use a grinder to cut off the top of the pile foundation and you’re done.

How is a country house dismantled and garbage removed?

Next, the dismantling of the dacha on the summer cottage occurs logically:

- The roof is being dismantled.

- Then we disassemble the walls, door and window openings.

- We saw and disassemble the floors.

- Finally, we dismantle the stove.

- We load all construction waste into a container and transport it to the landfill. Or, at the customer’s request, we store it in the garden for further use.

Reinforced concrete foundation

The old concrete base is considered the most difficult to work with. Even a foundation that has stood for decades is very difficult to break. This is due to the structure of the concrete itself, consisting of a mixture of cement, sand and natural stones of the middle fraction - crushed stone, and the presence of steel reinforcing rods with a diameter of 10-12 mm in the frozen mass.

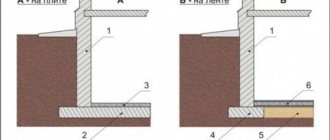

There are several main types of monolithic foundations. In construction you can find strip concrete foundations of one or another depth and slab foundations. The technology for dismantling them is the same.

Reinforced concrete foundation: scheme and implementation

Before breaking a concrete foundation, it is necessary to study all possible methods of dismantling it. They are divided into mechanical, manual power and physical, using the laws of physics. Some of them are more expensive, but allow you to remove the old foundation in a matter of hours, others do not require finance, but their implementation will take from several days to several weeks.

Mechanical methods for dismantling concrete

In order to make it possible to break a concrete structure, the following types of mechanical assistants are used:

- Excavator with a set of hydraulic attachments (scissors, drill, jackhammer, hydraulic hammer). With one machine, you can remove the soil around the foundation, break the foundation into pieces, load them into trucks and fill the resulting trenches with soil.

- A hydraulic wedge is specialized equipment used to break rocks and break concrete foundations. The device uses the ability of a liquid to transmit pressure applied to it in all directions evenly.

- An ultrasonic emitter allows you to break concrete foundations by exposing them to high-frequency sound waves reaching 100 MHz.

- Diamond cutting with disk or cable cutters allows not only to break the foundation into separate parts, but to obtain them of the correct geometric shape for further use in construction.

Manual dismantling of a concrete base

If you don’t want to spend your own money on work that you can do yourself, we’ll tell you how to break a concrete foundation on your own. For work, prepare:

- shovel;

- construction chisel (differs from a metalworking chisel by a much larger length);

- sledgehammer;

- perforator;

- grinder;

- wheelbarrow

We begin the work by digging in the concrete base so that it can be easily accessed along the entire perimeter. We remove the soil and put it in a dump nearby, since it will later be useful for backfilling the trench.

Carefully inspect the surface of the foundation for cracks. It is more convenient to start work from them. If you have a hammer drill, you can drill many holes arranged in rows in the transverse direction. After this, installing a pointed bit to make it easier to break the concrete, we break off the foundation in pieces.

It will not be possible to break steel reinforcement with a hammer drill. For this purpose, we cut the previously released rods with a grinder, observing safety precautions. Be patient, as it will not be possible to quickly remove the old foundation from the site manually. Small pieces of concrete base can subsequently be used as rubble stone when making a new foundation, installing a fence, etc.

How to dismantle the foundation?

To do this, ultrasound waves are sent into pre-made cavities, under the influence of which the unnecessary structure is destroyed. The prices for such foundation dismantling are high, since in this case expensive special equipment is used. In addition to all of the above, there is a method in which special compounds are used. They, after being introduced into the base through specially made holes, provoke its significant destruction after forty-eight to fifty hours.

This method is usually called non-explosive. The technology for this method of dismantling the foundation is not very simple, so carrying out the work yourself would be a mistake. In the case where it is necessary to dismantle the pile foundation, any of the above methods are used. If the piles are screw, after removing the grillage they are unscrewed.

The foundation of a house, if it is laid according to all rules and standards, is the strongest part of any building. Therefore, in order to break the foundation and remove construction waste from the site, you need to spend a lot of time and effort, and it is unlikely to be possible to do this without the involvement of specialists and special equipment.

The joints between the panels are freed from the mortar, the details of the connection between the wall panels and the columns are cut off. The panels are dismantled and transferred to the warehouse. When laying the walls of ancient buildings using lime mortar, dismantling is carried out along the planes of individual bricks.

When dismantling, brick walls of buildings built on cement-sand mortar are cut into separate blocks or broken into blocks. The dimensions of the blocks, depending on the strength of the masonry and the load-carrying capacity of the mechanisms, are assigned in the PPR. Slinging of brick blocks is carried out using grab grips, as well as using pins inserted into drilled holes and grips.

Dismantling is carried out using hand-held machines and a variety of hand tools: jackhammers, disc milling machines, crowbars, sledgehammers, etc.

To build a new house, it is sometimes necessary to get rid of old buildings on the site. This work also includes dismantling the foundation. It may also be necessary to dismantle the old foundation if it is damaged and needs to be replaced. Is it possible to do this with your own hands and what do you need to know?

With strong masonry, to improve the conditions for disassembly, cuts and hems are made to the walls. Dismantling of brick walls is carried out from scaffolding or inventory scaffolding.

What tool is needed?

Dismantling is carried out in the following sequence: - the joints of the crossbar with the column are freed from concrete; - the connecting steel parts and welds on the column console are cut off - after slinging the crossbar and loosely tensioning the slings; — using a hydrocline, the crossbar is separated from the horizontal platform of the column console.

The crossbar is dismantled and transferred to the storage area. After dismantling the crossbar, the column is dismantled, the work is performed in the following sequence: - the columns are slinged; — if the tension of the slings is weak, the temporary fastenings of the columns and struts are removed; — the joint of two columns is freed from embedment concrete; — steel connecting elements are cut; — using a hydrocline, the column is raised and shifted slightly; — the upper column is torn off; — the dismantled column moves to the storage location.

The trusses are dismantled in the following sequence: - the truss is slinged; the slinging location is indicated in the PPR; — when the sling tension is weak, the bolts and welds on the columns are cut off; — the trusses are raised 0.5 m above the installation site; — the farm is transferred to the vehicle.

Transportation of farms is carried out in accordance with the requirements for transportation of new products. Columns should be stacked with wooden spacers - according to the rules for storing new columns. Dismantling of steel crane beams 12 m long is carried out in enlarged sections, including crane rails, braking devices and stops.

The sequence of dismantling the stairs is as follows: - dismantling the railings within one flight; — release from fastenings of flights and steps during slinging and weak sling tension; — dismantling of flights of stairs; — release from stringer fastenings during slinging; — dismantling stringers; — dismantling staircases and beams. The built-up steps are dismantled from top to bottom using a crowbar. The disassembled steps are lowered along guides to the underlying landing, bundled and removed by crane to the temporary storage area.

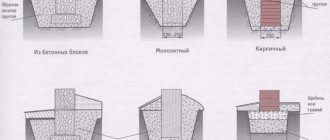

Possible foundation designs for dismantling residential and public buildings: - from rubble stone of ancient buildings; — concrete monolithic; — reinforced concrete from prefabricated blocks. The foundations for the external walls are excavated along the perimeter of the walls using an excavator. The foundations for the internal walls are dug out manually. It is recommended to dismantle foundations using mobile jib cranes.

Dismantling of such structures must be carried out using one of the collapse methods given in Section 7. Dismantling is carried out in order from top to bottom horizontally from the end of the building or expansion joint in the direction of the bond block.

When the racks are hingedly supported on the foundations for the period of dismantling, they are decoupled with temporary connections in two planes. The tower is equipped with the necessary equipment that allows the structures of half-frames and half-arches to be secured during dismantling. Before dismantling begins, the structure must be unfastened from the plane.

Dismantling is carried out in the following sequence: - the ridge assembly is secured to the tower against vertical movements; — when slinging one half-frame of the half-arch, the ridge assembly and the supporting lower assembly are disassembled and loosened; — the dismantled half-frame (half-arch) rises 0.5 m from the design position and is transferred to the vehicle; — the second half of the structure is dismantled.

Before dismantling begins, the structures are unfastened from the plane. After dismantling the joints and supporting fastenings, parts of the structures are dismantled. A justified choice of demolition method must be specified in the customer’s assignment, agreed with the regulatory authorities. When working on demolition, especially of emergency buildings, it is necessary to comply with safety requirements: - installation of temporary fastenings; — fencing the territory; — installation of scaffolding along the facades of the building with a stretched mesh as a protective fence.

Mechanical ones include: - excavators with replaceable attachments: a hammer wedge, a hammer ball, hydraulic shears, etc. For the demolition of one- or two-story buildings, hydraulic excavators are used, which provide the ability to control and control the direction of fall of destroyed structures and elements.

For the demolition of panel buildings up to five floors, excavators with universal hydraulic grips are used. To demolish panel and monolithic buildings up to 25 m high, excavators with hydraulic or mechanical shears should be used. To demolish buildings and structures up to 60 m high, special demolition excavators weighing from tons, equipped with hydraulic shears, are used. To open asphalt concrete pavements and quickly destroy concrete and reinforced concrete structures, a hydraulic hammer is used as a working replacement element for a backhoe loader; — machines with diamond cutting discs are used for cutting concrete and reinforced concrete up to mm thick; — diamond wire — a steel cable with diamond bushings located on it.

The work is performed by means of a rope machine with a motor and a system of rollers that control the movement of the rope. Used for dismantling structures made of concrete, reinforced concrete, brick and thick natural stone; — wedge splitters driven by a hydraulic cylinder. The structure collapses silently and without scattering fragments.

The method is used to destroy monolithic and brick structures in cramped conditions. High-performance thermal methods for the destruction of monolithic reinforced concrete structures are based on the use of a heat source in the form of a high-temperature gas flow or an electric arc.

These methods are used to burn holes in concrete with a diameter of mm and a depth of up to 4 m and to cut concrete and reinforced concrete with a thickness of mm. Protection against gas evolution, scattering of sparks and hot particles should be provided. The explosive demolition method using explosives is usually used on vacant sites. In cramped building conditions, this method requires a device to protect against flying fragments. The advantage of the method compared to mechanical means is the absence of noise, dust and gases.

The method is safer compared to explosives, since the area of scattering of fragments is reduced. The implementation and procedure for conducting construction control is regulated [7, Chapter 6, Article 51]. The subject of state construction supervision is checking the compliance of work performed during the demolition process with the requirements of technical regulations and design documentation.

Contents of the article What tool do you need? Dismantling methods Cost of work. When construction is carried out on an empty site that has not been subject to pre-development, no additional difficulties arise. Things are different if there is an old building that needs to be demolished. Dismantling walls is usually quite simple, but dismantling the foundation can be difficult.

The implementation and procedure for state construction supervision are regulated in [7, Chapter 6, Article 54]. The selection of a crane from those available is carried out according to operational characteristics and technical and economic indicators in the PPR. Slings are among the simplest lifting devices in design and are flexible elements with end fastenings and gripping elements of various designs.

As a rule, steel wire ropes, less often chains and tapes, are used as a flexible load-bearing element. Simple slings SK and STs are used for lifting loads with special devices such as loops, hooks, bolts, etc. Multi-leg slings are used for lifting and moving building parts and structures with two, three or four attachment points. They are widely used for slinging building elements, panels, blocks, trusses, etc.

When using a multi-leg sling, the load must be transferred to all branches evenly, which is ensured by auxiliary connections.

Universal slings are used when lifting loads that cannot be tied with ordinary slings: pipes, boards, rolled metal, apparatus, etc.

Traverses are used for lifting and moving long or large structures or equipment, columns, trusses, beams, etc. Traverses are equipped with various grips, which include rope or chain slings with hooks, carabiners or grips.

In Table A. The main requirement that contributes to the safety of work is the installation of temporary fastenings and compliance with the sequence of dismantling building structures.

If the secondary use of slabs is not relevant, then the most optimal tool for dismantling them is a grinder or a high-power hammer drill. Using a grinder, the wall is sawn into several fragments. A sledgehammer will help knock out the structure. In order to easily transport material from the premises, break it up into small sections. When reusing the material, the dismantling process will take much longer.

In this case, you will need a regular wood saw for the job. In order to learn how to dismantle a plasterboard partition, you must first determine the principle of its installation. Initially, drywall is fixed on a frame made of metal or wooden profile.

These walls do not require additional documentation for their demolition. Dismantling a plasterboard wall is the easiest to perform compared to other types of partitions. In order to dismantle a plasterboard wall, you must first remove the finishing material from it in the form of wallpaper, ceramic tiles, putty or plastic. Next, you should get rid of the fasteners that secure the drywall to the frame. To do this, use a screwdriver or drill to remove the screws.

If there are no cracks or other deformation defects on the surface of the drywall, it can be reused. Next, you should dismantle the frame part of the plasterboard structure. At the same time, the self-tapping screws that connect the metal profile to each other are also initially dismantled.

A pry bar is used to dismantle wooden partitions. To fix the vertical posts on the ceiling, special canopies are used, which also need to be dismantled. A plasterboard wall can be installed in another place, with the correct installation technology.

Before starting dismantling, determine the location where sheets and other construction debris will be installed. If the drywall will not be used a second time, cut it into several pieces and remove it from the room. The article was written by a complete amateur. What does it cost to at least have the thickness of the walls cm and dismantle the bricks starting from the bottom. Articles about repair, construction, building materials.

How is the old foundation dismantled?

Copying information from the site is possible only with the permission of the editors or with a direct link to the source.

Legal justification. Main menu.

Site search. Forgot your password? DIY copper roofing. Do-it-yourself roof insulation with polystyrene foam. Any person understands well that air rises when heated.

Safety precautions during dismantling

Before starting to demolish a structure, you need to fence off the demolition area and prevent strangers, especially children, from being near it.

The work is carried out from 9 am to 10 pm, and it is worth remembering that in some regions it is prohibited to make noise on weekends (Saturday, Sunday).

People who will do the dismantling must wear the following protective clothing:

- protective overalls or suit made of thick fabric;

- closed shoes;

- a headdress in the form of a helmet (when it comes to demolishing a high brick or concrete fence);

- work gloves;

- safety glasses or mask (if you need to work with a welding machine);

- respirator (needed in rare cases when dismantling brick sections).

Each stage of work is carried out with increased care to avoid causing injury to yourself or others.

It is worth doing everything carefully, especially if you need to keep the material from the old fence intact.

Additional description of some dismantling methods

To make it easier, foundation dismantling is usually carried out using large, heavy construction equipment. This method allows you to complete the work in the shortest possible time and does not involve physical exertion. If there is no equipment, you can use the manual method, which is ideal for dismantling the pile foundation.

Hydraulic equipment can help with the work, but its operation is accompanied by the consumption of a large amount of electricity. The use of this technique will not cause harm to other buildings. Using a hydraulic hammer, you can break any reinforced concrete structure.

Dismantling the old foundation can be done using the most modern technology, which involves the use of hydraulic shears. Their working surface has a diamond coating. If desired, the instrument can be rented by contacting specialists from stores with the appropriate products. This approach is convenient if the work is one-time. When several permanent buildings or commercial structures are to be dismantled, the optimal solution would be to purchase special equipment.

Recommendations for working with strip foundations

Dismantling a strip foundation is easier. This is due to the fact that the thickness of the base in rare cases exceeds 50 cm. For disassembly it is recommended to use:

- diamond cutter;

- perforator;

- sledgehammer;

- scrap;

- jackhammer.

Additionally, the use of special equipment for strip foundations will only be necessary if the structure was built using thick reinforcement, the diameter of which exceeds 30 mm. This also applies to cases where there are channels inside the structure.

Features of dismantling work

Professional removal of the top layer of turf can be fraught with difficulties associated with the presence of old concrete or reinforced concrete slabs at the site, which are often completely embedded in the ground. If the monolith is buried, working with it can also be significantly difficult. Please note that the cost of work set for dismantling a strip foundation is always determined based on exactly what difficulties the specialists have to overcome. If you need removal of the waste that remains after crushing artificial stone, you should order complex services from the very beginning.

During the initial visit, the specialist will be able to discuss all the issues with the client, examine the situation and provide information about the availability of access roads or other possible issues that are important. To order the dismantling of concrete slabs , you don’t even have to leave your own home. A specialist will arrive upon an individual request, personally examine and measure all the parameters of the objects to be dismantled, and give an opinion on the final cost. It is worth adding that we will complete all the work even in cases where there is no normal access for equipment and heavy transport.