You need to have certain skills and the right tools. However, there is nothing complicated about it, and you can drill a brick wall yourself, without the help of craftsmen. A brick wall can be drilled in different ways, but when working, you should always keep in mind that brick is a very durable material, and in order for its drilling to be successful, it is necessary to use a cutting drill bit stronger than the brick itself.

There are many tricks in drilling holes in a brick wall; knowing them will help you do all the work in the shortest possible time.

In order to drill a brick wall, you will need:

- drill (powerful, impact action), you can use a hammer drill;

- dowel;

- pobedit glass;

- screwdriver;

- metal detector;

- a container filled with cold water;

- mark;

- face shield or safety glasses.

Preparing tools

Before you begin, you should make sure that all the necessary tools are in working order. The drill must have a power of at least 600 W and an impact function. Revolutions up to 2500 beats per minute, so that there is the possibility of smooth adjustment from zero to maximum. You should give preference to a drill with reverse rotation, with a self-clamping chuck (then you won’t have to waste time clamping drills and looking for a constantly lost key).

It should be taken into account that a material such as brick can withstand statistical loads very well, but sudden impacts will only interfere with the process. If you use a drill without a hammer function, the drill simply presses, it is not easy for the cutting edge to catch on to the material, and therefore the drilling progresses slowly, while the drill quickly heats up.

You can drill the wall with a professional hammer drill. If you can’t buy it, you can rent it; drilling holes with such a tool is not difficult. However, when working with a rotary hammer, you should carefully study all the manufacturer’s recommendations.

It is necessary to purchase several drills, the diameter of which should be 6 and 8 mm. Drilling holes in a brick wall can be effectively carried out only with drills that have Pobedite surfacing (it is an alloy of tungsten and cobalt). The advantage of such a cutting tool is that it does not need to be pre-sharpened; it was specially designed for drilling dense surfaces. It will be easy to drill a brick wall with such a tool. If we are talking about drilling a wall made of dense brick, then you should purchase a dowel at a hardware store according to the size of the drill used. If you need to drill a wall to a greater depth or through it, you should use a drill; its cutting edges are not sharp, but rounded, to increase wear resistance.

How the process is carried out

The hammer drill must be powerful with special devices.

A drill for drilling a hole must have a power of at least 600 W; be sure to choose a tool that has an impact action. It must be assumed that a material such as brick has the ability to withstand static loads very well, but it does not withstand strong impacts well, so they should be avoided when drilling. To drill a hole with maximum precision and accuracy, you need to use a professional hammer drill. It is not cheap, so there is no point in purchasing it for a one-time job; it is easier to rent it. It is not safe to work with such a tool, so you should carefully read the instructions from the manufacturer.

It is necessary to purchase a drill whose diameter is from 6 to 8 mm; you need to take only one that has a surfacing made of pobedit (this material is an alloy of tungsten and cobalt). The tool has cutting properties; no pre-sharpening is required; it can effectively work with hard surfaces. Most hardware stores offer dowels for solid bricks according to the size of the drill used.

Markings for drilling are made with a core.

The location of the hole in the brick wall needs to be thought out in advance.

The surface must be examined in advance. When drilling, you need to exercise maximum caution; under no circumstances should you damage electrical wiring or water pipes, as this can lead to negative consequences. To ensure that drilling into the wall is as safe as possible, you should first check everything with a metal detector. If such a device is not at hand, then all sockets, switches and lamps must be pre-marked.

To maintain safety and in order to detect communications recessed in the wall in time, the first 20 cm of the hole length must be made manually (this way you can drill the wall using a screwdriver). But we must act with the utmost caution.

The future hole for drilling must be marked with a core (this is a special device designed to make marks for drilling). This must be done so that the drill is fixed in the first stages of work. Safety precautions must be strictly observed, which includes wearing safety glasses or a welding shield. With their help you can protect your eyes from dust and hard brick fragments.

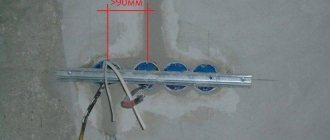

First of all, drilling holes in a brick wall is associated with the improvement of an apartment or country house. This service is in demand in cases where you need to make an internal socket or securely secure a TV mount.

The price for drilling holes in a brick wall depends on the diameter and depth of the opening, as well as on factors that complicate the process. These include work in hard-to-reach places and at high altitudes, the need to use antifreeze, etc.

Preparatory work

Before you begin, you should carefully consider the location of the holes in the wall. The surface where holes are supposed to be drilled must be carefully examined to ensure that there is no possibility of damage to internal electrical wiring, water pipes, etc. To avoid bumping into an obstacle when drilling, you should use a metal detector. After this, we drill the holes safely, nothing will interfere. However, you should remember that even after checking the wall with a metal detector, you need to drill into the wall carefully.

Before you start drilling holes, you need to mark all sockets, switches and lamps. As a rule, electrical wires run from these devices along a vertical line to the distribution box (it must be borne in mind that sometimes they can be run diagonally). For safety reasons, in order to find communications recessed in the plaster in time, we drill the first 10-20 mm by hand (a screwdriver is perfect for these purposes). When doing this, drill very carefully, because... Damage to electrical communications can lead to the most negative consequences.

Drilling holes in a brick wall

The future hole in the wall is marked with a core (this is a special tool for marking holes for drilling). This is done in order to fix the drill at the initial stage of work. At the same time, do not forget safety glasses (you can use a welding shield), which will protect your eyes from dust and hard brick fragments. Drill into a brick wall in such a way that the working tool is held straight, otherwise the drill may break. When drilling into a wall, apply gentle pressure to the drill to ensure even drilling. Drilling holes involves significant loads (even if the most powerful machine is used), and therefore the drill must be regularly cooled. The drill is lowered into a container of cold water, but care must be taken to ensure that the water does not get directly into the electrical mechanism.

If during the work you come across a burnt brick, then you need to take into account that drilling it is more difficult. It can be easily recognized by the color of the dust, which is usually black. You can drill such areas at low speeds when the impact mode is turned on. In this case, you need to press harder on the drill handle and carefully ensure that the drill does not overheat. When drilling holes in a wall, you should take the necessary precautions. Thus, the drill can become heated to a high temperature, so you should not touch it, as you may get a severe burn. You also need to know that a very hot drill will quickly dull its cutting edges, and without sharpening it will be very difficult to drill holes. Drilling holes can be done with diamond drilling, which allows you to get a quick result, while significantly saving time; drilling holes in this way is quite easy. If you need to drill holes with a diameter greater than 30 mm, it is permissible to use a core drilling machine; you can drill holes with it quickly, but you need to have certain skills.

Drilling holes in the wall must be done both during capital construction and in everyday life. And in this matter everything depends on the material of the base plane and the diameter of the hole. Therefore, you need to choose the right drill material. After all, there is a significant difference here.

A drill for making a hole in a brick will not withstand concrete and will simply burn out. Today we will look at how holes are made in different materials. Also in the video in this article and photo you can find out the options for the tool and choose the one you need.

Installation by drilling recesses is quite easy these days. If a person is trained and correctly uses modern electric tools, then there will be no difficulties. To ensure that your home remains clean after work, use a jig that allows you to drill with a minimum of dirt and dust.

The easiest way to make a hole in the wall is with a hammer drill; this is what professionals recommend using. It will cope best with the most durable materials in the wall and nothing better has yet been invented. But such power tools are expensive and not everyone can buy them for home use. An electric drill with an impact effect will help you make holes in the wall.

Cutting holes in walls in most cases is done with a drill. Almost every family has this tool, and experts give their recommendations that will expand the scope of use of the drill.

Attention: When choosing a drill, carefully read the technical descriptions. The power of the electrical appliance must be no less than 600 W, and the revolutions can be no more than 2500 per minute, and this is in the mode of their regulation.

So:

- It is necessary to have a reverse

, which changes the rotation of the drill clockwise and counterclockwise. Choose a model with a quick-release chuck, only then you will not waste extra time looking for a key to replace the drill.

- Do not forget that the device must have a shock function

. It will help cope with any complexity of the wall surface, and drilling holes will be quite easy and simple. And that’s all, because materials such as bricks, cement or concrete are quickly destroyed by dynamic actions, namely impacts. If the electric drill is not equipped with such an impact function, then the simplest drilling process will take a long time. The drill will cling to the compound located in the wall and at the same time become very hot, but this will be of little use. This is how impact drilling occurs in a completely different way. This is something like chiselling.

How to drill a brick wall with a drill

Ways to drill a brick

Brick is a durable material that cannot be drilled without special tools. But besides this, to create holes in brickwork, you need to have some skills. There are several technologies for drilling brick.

Manual drilling method

If you don't have an electric drill or hammer drill at hand, you can make a hole in a brick wall by hand. For this you need a bolt and a hammer. The bolt is a long steel tube. You can buy it at the store or make it yourself.

Hammer as a handy tool for drilling walls

To make a bolt you will need a steel pipe. A piece of 30 cm should be cut from it. It is desirable that the diameter of the pipe be at least 25 mm. At one end of the bolt, teeth are made using a file.

The technology for creating holes using a bolt is quite simple. First you need to designate the drilling location. The bolt side with the teeth is placed at a right angle to the mark. It must be hit with a hammer, getting rid of brick dust every three hits and turning the bolt.

Electromechanical drilling technology

Making holes in brick using power tools is much easier than making holes by hand. An impact drill or hammer drill is suitable for these purposes.

Hammer for drilling a brick wall

The drill must meet special conditions so that it can easily drill through brick:

- It is necessary to use a drill with an impact function only. The impact drill has protection against overheating of the drill, so it will last much longer than a regular one. It also puts more pressure on the material in which the hole is made.

- A drill with a power of 600 W or more is suitable for drilling bricks.

- To make precise holes of the required depth, you should give preference to a drill with a continuously variable speed control function.

A hammer drill costs more than an impact drill, but drilling is much easier with it. A good option would be to rent equipment if you need to make holes larger than 18 cm. In this case, you will need a hammer drill with diamond bits.

It is worth paying special attention to the choice of drills. For small holes you will need drills with a diameter of 6 and 8 mm with pobedit. It is an alloy of tungsten and cobalt, which is capable of piercing durable materials without additional sharpening. Drills are suitable for creating holes with a diameter of no more than 15 mm. Holes of larger diameter can be drilled using a special attachment - a drill. It is suitable for drilling holes with a diameter of 15 to 28 mm.

The drilling technology for an impact drill or a construction hammer is the same:

- First of all, you should take care of protection during the work process, since brick or metal chips can get into the eye. A welding helmet is suitable as protection. If you don't have one, you can use safety glasses.

- It is worth making a mark at the location for the hole for future drilling.

- Then you can start drilling. The impact drill or hammer drill must be held at a right angle. If the tool is tilted, the drill will break. The pressure should be smooth; you cannot apply a lot of force, as you can damage the wall or break the drill.

- Since brick is a dense material that is not easy to process, it is necessary to cool the working tool during work. To do this, you need to lower a little more than half of the drill into a container with cool water. This must be done carefully so as not to get on the electrical mechanism itself.

- The drilling process must be constantly monitored. When drilling into a wall, there is a possibility of touching wiring. It is also worth considering that brick is not uniform in structure. If the dust from the drill turns black, a section of the brick is burned. In this case, you need to drill at low speeds and constantly cool the tool.

For creating small holes in masonry, electromechanical technology is the most convenient. It is also less energy-consuming than manual.

Automatic brick drilling

If you need to make a deep hole, for example 50 or 110 mm, or place the hole at an angle, conventional drilling methods will not work. In this case, special construction tools are used that work autonomously.

Diamond drilling for bricks

Automatic drilling technology has many advantages:

- creating wide and deep holes,

- possibility of drilling at an angle,

- quiet operation of the tool,

- no vibrations,

- speed,

- accuracy,

- creating even and smooth holes of the required shape.

Automatic drilling of bricks is possible using diamond cutting tools. They are a special installation. The diameter of the hole is changed thanks to diamond crowns. Crowns of several sizes are used, usually from 2 to 60 cm. The drilling depth can reach from 0.4 to 4 m. The device operates absolutely silently, spending 30-40 seconds per centimeter of drilling.

To use the diamond drilling rig, a power source and water are required. Water is supplied to the tool itself, which reduces the amount of dust from work to a minimum, and also protects the device from overheating. A standard household outlet is suitable as a power source. Creating a hole in a brick takes place in several stages:

- The center of the future hole is determined, as well as its dimensions.

- The required inclination of the hole is set.

- After carrying out the calculations, a guide is attached to a special plate and placed against the wall.

- Afterwards, the drilling tool is secured to the base with a drill of the required diameter.

- Water is supplied to the device.

- Drilling occurs automatically and does not require any further intervention.

The technology that will be used to create the holes depends entirely on the purpose for which the drilling is being carried out, as well as what diameter of the holes is required. Drilling holes in brick must be done using special equipment that is suitable for working with dense materials.

Features of drilling holes in a brick wall

Drilling brick walls. How to drill a brick wall, what tools to use, what subtleties you need to know when working.

- Criteria for choosing a drill and drill bits,

- Starting the drilling process in the wall,

- How to prevent dust in the room?

- Nuances that arise when drilling.

When moving to a new house, you often have to make a lot of holes in a brick wall. They are necessary for installing sockets and mirrors.

Criteria for choosing a drill and drill bits

To drill holes, you need to purchase an electric drill, which has a speed of 2500 revolutions per minute. It is advisable to look for a device that has the ability to smoothly regulate power. It should be from 600 watts. The ability to quickly clamp will make the job easier.

To remove dust that arises during the drilling process, you will need a specially made jig.

A rotary hammer does this job better. But often an electric drill has a hammer drilling function. It is based on dynamic load. Therefore, it is possible to do without an expensive device.

The tool requires drills made of hard alloy metal. They should have pobedite inserts with a diameter of 0.6–0.8 mm for a hole 15 cm deep.

When through drilling, you cannot do without a drill with rounded edges. They are installed on a hammer drill or drill with the ability to hammer drill.

In order for a hole to pass through a wall 60 cm thick, devices are needed that differ in length, but have the same diameter. This speeds up work and makes it safe. The process begins using a shorter length drill.

Starting the drilling process in the wall

Before you start drilling, carefully check where the wiring is located so that if you touch it you do not get an electric shock. Wires are usually located near sockets and switches. From here they track how they go. Check this by piercing the intended area with a screwdriver.

To detect wiring hidden in the wall, devices are provided that have a special mode. It is used to search for metal. The presence will be indicated by a flashing light diode or an intermittent sound.

Having made the markings, the Pobedit drill is inserted into the tool. To operate, the impact mode is turned on, although at first the number of revolutions should not be made more than 300. To prevent overheating, the drill is cooled in water.

The depth is checked using stops. You can make them from an ordinary pipe. An option would be to wrap polyvinyl chloride tape around the device.

Let's start drilling. How to prevent dust in the room?

During the drilling process, the appearance of dust is caused by the heterogeneous structure of the brick. To avoid the problem, they make a conductor. It is a sheet of plywood. It’s better to simply secure the sandpaper to the wall using tape or glue. This will increase traction where the drill touches the wall.

Holes are drilled where indicated in the markings. They have approximately the same diameter and are applied in advance.

The dust will not scatter throughout the room, but will fall onto the plate if it is attached perpendicular to the emery conductor. This is how the installation holes are made:

- shelves, cabinets,

- mirrors and walls,

- electrical equipment,

- skirting boards,

- for hanging carpets.

Drilling services are not cheap. But if the work is to be done in seam areas, and there is no experience in using the equipment, it is better to hire professionals. Otherwise, there is a risk of damage to the wall.

Nuances that arise when drilling

To apply markings you need a pencil or level. You need to wear a mask and safety glasses when drilling. Before the process, they look for wiring with a metal detector.

Before starting work, check:

- serviceability of the drill or hammer drill,

- presence of dowels and pobedit drills,

- Is the power of the equipment appropriate?

During the process, you must press the device very smoothly, not forgetting that the drill heats up. Therefore, you often need to cool it in water. But it should not get on the surface of the device.

There are walls made of burnt material. Then the process is possible at low speeds when the shock mode is turned on.

During operation, the device is held at right angles to the wall. The hammer drill significantly speeds up drilling. To prevent the tool from breaking, when there is a need for a hole larger than one centimeter in diameter, several drills are used, starting with 2 mm and ending with 10 mm. Thanks to this, the process itself speeds up.

To obtain a shallow hole with a small diameter, use the manual method. Having made the markings, they hit the brick edge with a chipper, then secure the bolt with a hammer.

To install ventilation, air conditioning, and electrical wiring, you need to use an automatic drilling method. Thanks to this, the work gets done quickly. Dust does not fly around the room. The holes can have a diameter of 50 centimeters.

How to choose the right drill bit

Probably everyone has seen a huge assortment of different types of drills in stores and markets. Now we will figure out where it is best to use which. It is not difficult to drill a wooden, plasterboard or foam concrete wall surface with the most ordinary drill.

Now, if the material is brick, stone or concrete, then it is better to choose a drill made of hard alloys. Unlike the previous one, it has pobedite cutting plates. Welded elements are visible on the edge.

If you have at least a couple of such drills in your home with sizes starting from 6 mm. up to 8 mm is already great, rest assured you will still need them. With their help you can make a hole up to 20 cm deep.

When you need to make a large hole, you need to purchase a drill. They drill dense surfaces almost a meter deep, but only with the help of a hammer drill; a conventional drill will not help here.

So:

- The drills have tails with a diameter of 15 mm. and more, there are grooves that serve for fastening. But if the drill works as a hammer drill, then they are clamped quite well in the chuck. The characteristics of the drill are located at the very tail.

- If you need to drill a solid surface, this process is divided into several stages, drilling will be done safely and quickly.

- First, choose a drill up to 20 cm long, intended for a depth of almost 15 cm.

- Next, use a long drill designed for 35 cm.

- Drilling ends with a 50-centimeter drill. To do this, you need a powerful drill, but note earlier that we mentioned that it is not designed for heavy loads, except for certain cases.

- If purchasing a hammer drill is not possible, rent one for a few hours.

Attention: Punching a hole in the wall d=150 mm or more is best done with a drill. They are quite large in length and they are securely fastened to the cartridge.

Drilling holes safely in walls

It is quite possible to drill a hole in the wall with your own hands. But at the same time, everything must be done quickly, efficiently and safely. For different wall materials there are also instructions on how to perform the work. Read about this in detail below.

Attention: Before starting work, carefully examine the surface of the walls, make sure that there are no electrical or other cables in the drilling areas. Through haste and inattention, the wires will be damaged, and even worse, your own health may be at risk. You may ask, how can you avoid getting caught in the cable? Now let's look at everything in detail.

What to do to avoid getting caught in a wire

There are switches or sockets on the walls; carefully inspect their presence. From them, network wires diverge vertically and go straight to the junction box.

If this is the case, then this is ideal, but rare. Typically, electricians do not always follow the rules; in order to save cable, they run it diagonally.

So:

- Most often, devices are used to check the presence of a cable; their price is not high and detection is quite fast.

- If you don’t have a device, then you should know that the wire is located at a depth of up to 10 mm. To check its presence, very carefully, using any blunt instrument, gouge the surface. If you don’t find the presence of a cable there, then you can safely drill. Experts advise making the recess a little larger, let it be 20 mm.

- Do not press the drill too hard against the wall and inspect every few millimeters for wiring. You can also purchase a special device in specialized stores that determines where the electrical network wire is located. When purchasing, be sure to inquire about the quality and choose the best one; your own health depends on its proper operation. Also, during normal and folded operation of the device, you can find the place where the reinforcement passes in concrete surfaces.

- A copper electrical wire can be found quickly if it is recessed to a depth of 10 mm. But the aluminum cable will only be detected if the device has a metal detector function. When searching, constantly look at the indicator, which is equipped with an LED light and also emits a signal, so be careful, your “assistant” will give a sign.

- In metal detector mode, if an electrical wire is located, the diode will light up and you will hear a continuous sound. Every normal device should have a sensitivity regulator. The finder is powered by a Krona battery.

Attention: Not a single builder who installs suspended and tension structures on the ceiling surface can cope without it. The fact is that the systems are attached using self-tapping screws to the ceiling itself, and all the electricity cables are located there.

Drilling holes on reinforced concrete surface or brick

Now let's look at how to make a hole in a concrete and brick wall. Brick can be easily drilled with a Pobedit drill bit.

Attach a jig to the place where drilling will be done and drill a slot; the speed of the power tool should not be too high; the drill should not overheat.

If the surface of the walls or ceiling is made of durable cement, then drilling them is quite difficult. Typically, the material selected is grade 400; work on it can be carried out quickly without any particular difficulties. Perhaps, if the building is still old, then there is strong concrete and the drilling process will be delayed.

- Manufacturers put iron reinforcement into wall panels and blocks for quality - these are rods no more than 20 mm thick. and they can add crushed stone. A drill made from pobedit will not cope with such a task.

- There is always a way out: when it becomes clear that the drill has found the reinforcement, use a regular drill. If it is not there at the right time, you can move the place for the recess up or down diagonally.

- Granite crushed stone crumbles in the wall from the blows of the drill; beware that during such a process the tool sometimes jams; to make it easier, turn the mechanism four turns.

- When the obstruction is removed, continue drilling the surface with a Pobedit drill bit. A hammer drill and a drill will deal with the problem quickly and drilling holes will be much more successful.

Holes in tiles

If you need to make a hole in a tile, use a drill that has welded protrusions and they are made in the form of teeth. This is a crown for drilling tiles.

But sometimes you need to make a small hole and a crown will not fit. Then make a mark in place.

- For this process, select a core; if you can’t find one, use a regular self-tapping screw or a thick nail with a sharp tip. Carefully remove the glaze from the tile where you will drill the hole. Set the tool speed to low, as for a brick surface.

- After the glaze is removed, then we make a hole with a small drill.

- After this, we expand it to the required diameter with a thicker drill.

Large recesses in the wall

When installing ventilation systems, you need to make a wide recess - 20 mm. Sometimes a meter showing electricity indicators is hidden in the wall, then you generally need to make a niche on the surface. In your own home this is done using a carbide drill.

So:

- Carefully mark a place on the wall for the recess with a pencil

. Holes are drilled on the wall from the outside using a drill with a diameter of at least 5 mm. at a distance of 15 mm. - To deepen up to 20 cm, you need to make almost 30 turns with a drill.

Only then remove the materials with a chisel or hammer, making a niche of the required size from the wall. If the diameter of the drills is smaller, the edges will be neat, but for this you will need to make a large number of holes.

It may be that the wall surface is hard enough, and in order to obtain a through recess, the drilling stages are divided into several processes:

- If you can drill the surface on both sides, then do it on one side first, and only then make a full through recess. And repeat the steps until you are satisfied with the hole.

- When it is not possible to drill the surface of the wall on one and the other side, then carry out the processes alternately in several steps. From the previously made mark, draw another line, and as soon as you have chosen the unnecessary material, you can drill deeper into the niche without touching the edges on the wall. To make the job easier, choose a long drill bit at the very beginning.

Drilling a brick wall - Working with Brick

Drilling a brick wall includes the practical implementation of certain skills, as well as preparatory processes regarding the tool used and the surface we process, in fact, the brick wall.

The list presented below is optimal regarding the drilling process, or more precisely, the implementation of the task without interrupting the process itself.

So, the list consists of the following names:

- impact drill;

- dowels;

- drill (pobedit / 4 – 12 mm);

- curly screwdriver;

- metal detector with limited range;

- cold water poured into any convenient container;

- metal core;

- eye protection element.

The tool used in the process of drilling a brick wall is an impact drill. Such a drill must be powerful, which means it must have at least 600 W and 2500 thousand revolutions per minute. A feature worth paying attention to is the ability to smoothly adjust the speed to maximum.

If buying a drill is still an upcoming event, then the emphasis should be on a drill with reverse rotation, as well as a self-clamping chuck. The latter eliminates the need to constantly use a key to clamp drills, although one is included in the kit.

The presence of a shock function is a prerequisite, since its absence will undoubtedly lead to:

- overheating of the drill, and in particular surfacing from pobedite (sudden wear of the cutting part);

- normal drill pressure without engaging the cutting edge, since only the static load increases.

Preparatory work regarding the brick wall itself immediately before drilling is more of an informational nature than a “strategic” - design one. From the point of view of safely performing such work, it is necessary to use the metal detector that was indicated in the list above.

Its practical application immediately before drilling will eliminate the possibility of damage to wiring, internal heating systems, as well as various reinforcing components.

Despite the expected accuracy in choosing the drilling location, the first 10-20 mm deepening must be done with a screwdriver. Using this will allow you to timely identify communications recessed in the plaster, as well as avoid their critical damage.

The answer to the question of how to drill a brick wall with a drill can be obtained solely through independent practical experience. So let's get started!

The drilling process itself, regardless of the finish of the brick wall or its complete absence, begins with making a mark. The hole in the wall is marked with a core. Why do you need a mark? After using the core, a slight depression remains, which reliably fixes the cutting part of the drill at the initial stage of work.

The human factor affecting the drill and the static load on the drill are interrelated quantities. The first, namely “pressure” on the drill, should be smooth and soft, despite the need for significant loads in order to achieve the final result.

The drilling process is monotonous and does not require special skills, but it does require considerable attention. So, for example, the latter will help to identify and, of course, overcome a burnt brick, if, of course, one came across the drilling path. You can identify a burnt brick by the color of the dust. Usually it is black.

Passing such sections must be carried out at low speeds, which, in turn, must be combined with the activation of the shock function. Observing these two conditions, as well as making efforts towards the tool itself, it is necessary to carefully control the heating of the Pobedit drill.

Drilling holes measuring 12 mm requires a slightly different approach, namely the consistent use of all of the above sizes of Pobedit drills. To start drilling a brick wall for a 12 mm hole, you need to start with a 4 or 6 mm drill.

We invite you to familiarize yourself with the construction and installation of water heated floors under tiles

Taking into account this technology to achieve the required hole diameter, namely a diameter of 12 mm, the final result will be achieved much faster, and, at the same time, without unnecessary effort. Regarding how to quickly and efficiently drill any brick wall with a drill in order to obtain a diameter of, for example, 30 mm, you should pay attention to diamond drilling.

The quality of the final result depends on the type of drill used. The latter must have a strength exceeding the strength of the brick used at the time of laying. Typically, pobedit drills with a diameter of 4, 6, 8 and 12 mm are used, respectively.

To make a hole in a brick wall use:

- drill or hammer drill;

- pobedit glass;

- dowel;

- jumper;

- hammer;

- brush for cleaning debris;

- screwdriver and metal detector;

- a bucket or other container for cold water;

- goggles for eye and face protection or shields;

- mark.

It is possible to drill a brick wall of small or large diameter on your own, without resorting to the help of specialists, but simply using the necessary tools.

To complete the work, you will need an impact drill, since a regular one will not be able to handle such a wall.

Initially, you need to check their serviceability and readiness for work. Suitable power for the drill is 600 W. A non-impact tool is not suitable due to the strength of the brick and its ability to withstand static loads.

Punching holes in brick for pipes or deep drilling for other work is carried out not with a hammer drill with a drill, but with a drill.

Preparation stage

Drilling a brick wall begins with the preparatory stage. Before making a hole, you need to clearly determine its location. There should be no wiring or water pipes. To do this, use a metal detector to properly exclude obstacles.

But even after this, all work is carried out carefully. There are sockets and lamps on the wall, as well as switches from which the electrical wiring runs.

For work safety, an initial depth of up to 20 mm is gouged out with a regular screwdriver; a drill is used when there is no risk of damaging communications.

Return

Drilling

You can drill a brick:

- manually;

- using an electromechanical tool;

- automatic unit.

If the diameter of the future hole should be more than 3 cm, then you need to use a core.

Using a core, marks are made for the recess. This way the drill is fixed. The worker must wear protective glasses or a shield against dust and debris. The drill should be held straight so as not to break the tool and to drill through the fireclay brick correctly.

It is necessary to periodically turn off the hammer drill to prevent the drill from overheating. To make the hole even, apply a little pressure on the drill. A hole in a wall becomes more difficult if the building material is burnt. Low speeds and shock mode will help make the task easier.

A core drilling machine is used when drilling a hole with a diameter of more than 30 mm.

Return

If there is no automatic tool, you can drill into the brick manually using a bolt. Using a punch, marks are applied to the wall where the recess should subsequently be. The bolt is placed at a right angle (90 degrees) to the surface and driven in with a hammer. After 3 blows, the tool is rotated, the hole is cleared of residues and the blows are repeated until the desired recess is obtained. This is a time-consuming and labor-intensive method, which leaves a lot of garbage behind.

Return

Electromechanical

For holes with a diameter of more than 2 cm, it is more effective to use diamond core bits.

Use an impact drill or hammer drill with the same application technique. The type of hole and its dimensions are determined. Based on this data, the required drill or drill is selected.

You can make a stencil from plywood or other available material to control distances. He is attached to the wall with tape. Marking is done using a core. The installation is held perpendicular to the surface and with slight pressure.

For diameters greater than 0.2 cm, it is better to use diamond drill bits.

We invite you to familiarize yourself with Repair of AEG refrigerators AEG

Return

Automatic

This is a diamond type of drilling, which minimizes labor costs, but the use of professional equipment is much more expensive. It is better to have qualifications and skills in working with the tool. The maximum depth with this drilling method is 40 cm. It is carried out at any angle almost silently.

In one article it is quite difficult to pay broad attention to such a topic as the construction of an external chimney. Firstly, it has many nuances, and, secondly, such an article will be incredibly large and inconvenient to read.

That is why I will now give only a general overview, and I will address all questions on individual points that you have in separate publications. Although today there is already material on a similar topic. So, the outer pipe can be made of several materials.

- Let's start with the brick output.

Such arrangement of the hood will become as convenient as possible for people who want to organize a fireplace in their home. After all, this design is considered the most optimal for a fireplace. Although, it may be suitable for a bathhouse (it all depends on your capabilities and desires). But it is worth noting that it requires certain skills to install it correctly (which we will talk about in other articles).

- An ordinary stainless steel pipe.

Tips to help you make the most accurate drilling

It turns out that there is nothing difficult in drilling recesses in the surface of the walls:

- On the side of the conductor we glue a sheet of sandpaper with tape or glue. Its size depends on the area where the hole will be. Thus, the adhesion of the device to the wall surface will increase and you will accurately make the ideal hole in the right place. It is also quite possible to use a stationary limiter. Its price is not high and can be purchased at retail chains.

- Sometimes you need to drill a hole for a dowel; they can be of different diameters, but usually it is up to 10 mm. It all depends on what you will hang and its weight and, of course, on the density of the material in the wall.

- To make the jig universal, drill a couple of holes of the required size in it with a regular drill so that the device can be hung.

- You can attach a plate to the conductor, thanks to which such a shelf will protect the finishing of the wall surface from dust and debris. You can use this device when making recesses for attaching skirting boards to the floor and wall.

- Measure the spaces on the jig of the required dimensions at the selected height from the shelf, and drill holes. In order to make recesses, simply place the shelf on the floor, and all the cracks will be exactly the right size and height. Carrying out the installation, gradually adhering to the rules, the plinth will lie tightly on the floor surface.

- If you need to hang some decorative element on the wall - it could be a painting, a photo frame and much more, you cannot do it without an auxiliary conductor. The point is that the holes must be at a clear distance from each other. In general, take into account your own wishes and the uniform style of the room.

- To make your own jig that serves for the most correct drilling of holes, select plywood or a metal sheet. Make markings on it and make the required number of recesses with a regular drill.

Let's consider the option when you need to fasten parts not with one screw, but with several:

- The first hole is drilled on the wall, and the second is made equal in size to the screw. For precise deepening, use a jig. And then a dowel is driven into the hole.

- You can screw the jig to the wall surface using a self-tapping screw and dowel, level it with a water level, so your drilled recesses will be smooth on the same horizontal line.

- Using a simple jig, which, as you already understand, can be made with your own hands within literally half an hour, the recesses drilled with a drill will be located exactly at the required distance from each other.

- Given this technology, it is possible to make holes over a fairly large gap. To do this, first drill holes in the same way as previously discussed, then screw the jig on both sides with self-tapping screws and use a drill to make the remaining recesses.

Attention: If you are thinking of running a cable through a hole in the wall, then make it 20% larger, because it should lie freely and not be pinched.

You now know how to drill a large diameter hole in a wall. Take your time and apply the markings correctly. Using stops, you will make the desired depth and diameter. Making a hole in a brick wall is not a difficult task, but it requires careful execution.

hole in the wall

Sometimes it becomes necessary to drill a large diameter hole in concrete or brick, for example, to organize the inflow or outlet of air in a barn or to exhaust a gas boiler with a closed combustion chamber. If you have diamond bits of the required diameter and a powerful hammer drill, that’s good, but what if you don’t have this? Well, you definitely can’t do it without a hammer drill, but you can do it without an expensive diamond bit (it’s a pity to buy it for a one-time job).

To make a hole with a large diameter, we will need, as noted above, a hammer drill, a drill of the required length with a Pobedit tip and a spatula for gouging out the middle of the hole.

First, let's determine the diameter of the large hole and draw a circle in the right place on the wall. For a hole with a diameter of 10 cm, you need to draw a hole of at least 12 cm, since during operation the drill can move a little to the side, so it is better to immediately make a small reserve.

Secondly, you need to draw dots on the circle every 2-3 cm, where you need to drill a large diameter hole. The more often you drill holes, the easier it will be to knock the brick out of the wall. About 20 holes need to be drilled on a circle with a diameter of 12 cm.

Thirdly, you need to determine the thickness of the wall and select a drill of such length that it drills right through the wall.

How to make a hole for a pipe in a brick wall with your own hands: methods and tools

Before drilling a wall for a pipe, it is worth understanding what standards must be observed during the work process, especially if you are going to drill a load-bearing wall.

When cutting a hole for communications, make sure that such structural elements of the building are not affected, such as:

- barrier and reinforcing bars in the thickness of the wall;

- ventilation ducts, if any, in the building;

- electrical wiring lines.

At the same time, when arranging holes for pipes in the wall, make their diameter slightly larger than the cross-section of the pipeline so that you can install a protective sleeve and, possibly, insulate it with mineral wool or other non-flammable material.

When carrying out repair and construction work in brick houses, it is often necessary to drill holes in the walls for supplying water, heating and sewer pipes. When solving the problem of how to make a hole for a pipe in a brick wall, you can choose the optimal methods and tools that significantly reduce the costs of carrying out this work.

To do this, it is useful to study the used construction technologies for producing through holes of large diameter and outdated methods without the use of modern power tools, which are no less effective.

Rice. 1 Professional wall drilling using special equipment

The main power tool that can be used to drill into a brick wall is a hammer drill or impact drill. A conventional household drill has less power and, according to its technical characteristics, is not designed for long-term operation with high loads that arise when drilling large-diameter holes.

If a construction hammer is not available, the household drill used must have a switch for impact drilling, a power of at least 600 W, the ability to smoothly regulate the speed; a reverse mode may be useful during operation.

The main trouble that may arise during work is damage to the electrical cable. To detect it, if there are supposedly wires running at the work site, special devices are used to search for hidden wiring. If they are absent, using a screwdriver or any sharp tool, you can lightly knock off the outer covering of the material on one and the other side of the wall to locate the cable.

To drill a brick wall, use a special tool designed for working with concrete, which in most cases has a shank for attaching to a hammer drill.

There are several ways to make a hole in a brick wall, but many of them will require significant expenses if you do not do it yourself.

Drill

Special pobedit drills are the simplest and most affordable tool for drilling holes in any building materials. A standard drill with a Pobedit tip for a household drill can make through holes 150 mm deep; the length and diameter of drills for rotary hammers can be significantly higher - such large-section models are called not drills, but auger drills.

We suggest you familiarize yourself with the Types of good kitchen hoods 60 cm and their manufacturers

How to drill a hole

Next we start drilling. We set the rotary hammer switch to the “drilling-chiselling” mode and drill a hole. Here you need to remember about your own safety: if the hole is high from the floor, then the support on which you are standing must be securely fastened.

hammer drill blade

We drill holes at the points that we marked on the circle. Since you need to drill a lot of holes, there will be a lot of dust, so you need to cover all the objects in the room with some material in advance so that they do not become unusable before their use. To strictly horizontally, you can attach a small one to the hammer drill. We drill through so that the drill comes out on the other side. As a result, we get a circle with 20 holes.

After this, remove the drill; it will no longer be needed. We insert a blade into the hammer drill, switch it to jackhammer mode without drilling and knock out the jumpers between the drilled holes. You can place a spatula in the center of the circle and chisel away any excess brick or concrete. If the blade is short and does not penetrate the wall, you can chisel the brick on the other side of the wall. But this can only be done low from the floor; in multi-storey buildings you need to purchase a spatula according to the thickness of the wall. When we hollow out the extra brick, we will have a large diameter hole in the brick wall.

Funny video

A large number of structures are made of concrete slabs. This is not surprising, because such construction takes place much faster than brick construction. But during renovations, apartment residents face certain difficulties. For example, drilling a hole in a concrete wall, especially without dust, is not so easy, since inside you will most often have to deal with reinforcement and stones. Although it is not easy, it is possible. How to drill holes, including large ones and for a socket, will be discussed further.

How to drill a hole in concrete for an outlet or switch

Drilling holes in concrete for sockets is not an easy task, especially in the absence of special equipment. Therefore, you often have to “reinvent the wheel” and use “old-fashioned methods.” But not everyone knows about them, so in our article we decided to look at some of them in more detail.

Drilling holes in concrete using a hammer drill

There are several options for drilling holes in a wall using a hammer drill, and they all depend on the density of the concrete, as well as the availability of the necessary tools. Let's start our story with the simplest methods and end with the most labor-intensive ones.

Drilling holes using a crown for socket boxes

If you don’t know how to drill a hole for a socket in the wall, then just ask the store for a crown for socket boxes. This is a very simple device that greatly facilitates this labor-intensive work.

The crown for socket boxes consists of four elements. The first is the basis. It is a pin for mounting in a hammer drill, with a flange for screwing on the crown. The crown is a piece of pipe with a diameter of 68 to 80 mm.

At its ends, on one side there is a thread for fastening to the base, and on the other end there are carbide cutting elements. In some crowns, these cutting elements are coated with diamond, which increases their service life. The third element is a drill, which is also secured to the base using the fourth element - a screw. Purpose of the drill: centering the crown.

The price of such a crown is within very reasonable limits. Therefore, if you have started a renovation that involves moving electrical points, we highly recommend that you buy one. It will always come in handy on the farm.

First of all, we mark the installation location of our new outlet.

We need to measure the center of the required hole.

The centering drill of the crown protrudes slightly above the edges of the crown itself.

We insert it into the previously drilled hole.

Ideally, the crown will go 2/3 into the wall, and we will get a nice, even hole.

Drilling holes using a crown and drill

Using a crown, you will get the hole you need. But this will not always be so easy to do. The fact is that this crown copes quite well with brick and some types of concrete. But sometimes she is powerless. And then you have to invent another way to properly drill a hole for sockets.

- If the crown does not handle your concrete well or at all, then you will have to use a slightly different method. Let's look at it step by step.

- First of all, as in the first option, we find the center of our future outlet. Then we drill a hole for the centering drill. We take a crown and try to drill a hole with it.

- This didn't work out for us. But there were clear traces of our future hole on the wall. They are what we need. Now, using a regular concrete drill, make several holes along the edges of the future hole with your own hands. The greater their number, the easier it will be for us later, so make about 20 such holes in them.

Now we put our crown on the hammer drill again, and, using it, we again make a hole for the socket box. Things should go much faster.

Note! If you are lazy and make a small number of holes with a drill, then when working with a crown, shocks are quite possible. Therefore, hold the hammer drill tightly.

Drilling holes with a hammer drill without a crown

But sometimes it may turn out that there is no crown, but a hole is needed right now. Therefore, you should know how to drill a rosette hole in concrete without a crown.

In this case, we will use a regular drill and chisel, or an appropriate attachment for the hammer drill if it has a jackhammer function.

- To use this method, we need to outline our future outlet. This can be done by applying a socket box, or using a rope and a pencil.

- Then, along the contour of the future hole, as in the option described above, we make many small holes. In this case, it is desirable that there are more than 20 of these holes.

- Then, using a chisel or the appropriate hammer drill attachment, we begin to knock out the remaining concrete between the holes left by the drill. The process is long and labor-intensive, but there are simply no easier options.

Hole for socket using a grinder

Sometimes it may turn out that you don’t have a hammer drill at hand, but you need to make a hole for the socket. In this case, you can use a grinder. Of course, this is far from the best option, but, in extreme cases, it is quite applicable.

- To use this option, you first need to outline the outline of the future outlet . For this you can use a regular pencil.

- The next step is to prepare for working with a grinder on concrete . The instructions advise wearing glasses, a respirator, or at least a gauze bandage. It is also better to protect your head with a hat.

- After this, using a grinder, with a concrete circle of the appropriate diameter, we make cuts at the extreme points of the future hole. The cuts must be of appropriate depth. The minimum number of cuts to obtain a square is four, but you can also make a figure closer to a circle.

Note! When performing work, under no circumstances should you change the position of the angle grinder relative to the wall. This may cause the disc to break and cause fragments to fly out. This, in turn, can lead to very disastrous injuries.

- After this, using a regular chisel and hammer, we begin to knock out the concrete in the center of the cuts . The work is painstaking, but there are no other options.

Now you know how to properly drill a hole for sockets in a variety of conditions. But it’s better not to reinvent the wheel and use the appropriate tool for this.

Moreover, many of the methods described above are quite dangerous, especially the option using an angle grinder. And not one socket hole is worth your health.

Use of special nozzles

Concrete is, of course, a wonderful building material: strong, durable, reliable, but repair work with it is fraught with some difficulties. First of all, this concerns the creation of holes, for example, for a socket. Before drilling a hole, you need to decide on its diameter and depth, and whether you will have to deal with reinforcement. Depending on this, the tool and attachment are selected. Drills and drills are used to drill holes of small and medium diameter. During operation, you should always remember that they need cooling, which can be provided by cold water.

To drill a large diameter hole in a concrete wall, you need to use special crowns, which are cylinders that are empty inside (see photo). Such parts are made either from hard alloys or with diamond cutting edges. Moreover, the former are used in the case of impact drilling, and the latter – for non-impact drilling. Crowns, no matter what they are made of, are quite strong, but despite this, they require restoration from time to time. To drill large-diameter holes, it is advisable to use special tool mounts to the wall.

Using the Drilling Tool

As for the tool itself, to drill a hole in a concrete wall, you can use an impact drill or a hammer drill (see photo), with the latter being more preferable. The hammer drill is great for drilling holes with a diameter of about 10 centimeters, but you need to take into account that if you have to deal with reinforcement, the attachments may break. An impact drill is only suitable if there is not a lot of drilling work, for example, you need to make one or two holes for a socket. If you need to drill large-diameter holes in the wall, it is better to use the diamond drilling method with a special electric tool.

Basic drilling steps

Both when working with an impact drill and in the case of a hammer drill, a concrete wall is drilled almost the same way. To do this you need:

- determine the location of electrical wiring;

mark the drilling locations and, if possible, make sure that the hole can be drilled without dust, although this is practically impossible;

make the first mark with a drill;

use a special attachment to break the stones in the concrete wall;

Allow the drill to cool slightly;

start drilling in the selected place with the selected nozzle;

from time to time pull the drill out, allowing the concrete dust to fall out;

stop when the required depth and diameter have been reached.

There are several ways to drill a large diameter hole in a concrete wall. The first is to create holes of small diameter next to each other, after which you can refine them with a chisel. It is worth noting that the edges of the recess in this case will most likely not be very neat. It is best to use a special crown, the size of which should match the size of the desired hole. If during operation the nozzle encounters reinforcement or stones, which can be recognized by a characteristic sound, the drill must be removed and a punch or other drill used instead, but for cutting metal. More detailed information on how to properly drill holes in a concrete surface can be found in the video presented.

To make a hole in a brick wall, you can use many methods and tools, but we will talk about the most effective options for implementing the task.

What you need to drill through a brick:

- Dowels;

- Pobedite drill;

- Drill;

- Hammer;

- Screwdrivers of different types;

- Container with water;

- Protective shield and glasses.

How to repair holes in a brick or concrete wall

The extent of repair work to the surface of a brick or concrete wall will depend on the extent of the damage. If these are holes left when old nails, screws or dowels were removed, then it is enough to cover them with putty or a special repair mixture.

Let's take a step-by-step look at how this can be done:

- To do this, take a long nail or screwdriver and widen the hole. This must be done so that the putty penetrates as deeply as possible inside.

- Then use a dry brush or vacuum cleaner to remove any accumulated dust and crumbs.

- Now moisten the resulting hole with water. For this purpose, you can again use a brush or a spray bottle, or a piece of foam rubber. This should be done so that moisture from the repair mixture or putty does not quickly absorb into the wall.

- After a few minutes, putty the damaged area, carefully rubbing the mixture into the hole.

- Once completely dry, sand the surface with fine-grained sandpaper.

- Now the area can be painted over or wallpapered.

If the hole in the wall is large and deep enough, for example, it was left after replacing pipes or dismantling an electrical outlet, then putty alone will not be enough. You will need either cement, gypsum, or a ready-made concrete repair mixture, which can be purchased at a hardware store.

What to do in this case:

- Before you fix a hole in the wall, prepare the hole by clearing away any debris and moistening it with water.

- Then fill the void with pieces of stone or brick mixed with cement mortar. This will save putty and strengthen the area being restored. Cement mortar for this purpose is prepared from one part cement and three parts sand. In such a case, you can also use building gypsum or concrete repair mixture.

- When this cement (or plaster) “patch” has dried, putty it, carefully filling and leveling the remaining voids and cracks that have formed.

- The area treated in this way should dry well. This will take at least 12 hours.

- When everything is fairly dry, smooth the surface with fine-grit sandpaper. To prevent this place from showing off as an ugly bump, it should be leveled with the rest of the wall surface.

- The wall is leveled, and now it can be painted or wallpapered.

If, during the shrinkage of the building in the room, the interpanel seams have come apart or a deep crack has formed, then there is no need to rack your brains about how to repair such a hole in the wall. In this case, use polyurethane foam, which is sold in aerosol cans at any hardware store. It perfectly fills voids, easily penetrating even hard-to-reach places. In this article you can learn how to repair cracks of varying complexity.

Polyurethane foam adheres perfectly to various surfaces and quickly hardens in air. So you are guaranteed a good result in the process of eliminating deep cracks and holes.

- Before you start work, prepare the place - clean it of dirt, dust and other debris. Wet the wall surface.

- Before applying the foam, you need to shake the can well so that its contents turn into a homogeneous mass. This will take you at least a minute.

- During operation, hold the container upside down, since the gas contained in it, which displaces the polyurethane foam, is lighter than it.

- Vertical cracks should be filled from bottom to top.

- If the hole is too deep, apply the contents of the can in layers, applying a new layer after the previous one has dried.

- After filling the hole, do not touch the damp polyurethane foam with your hands, this can change the structure of the material and slow down the process of its hardening. Wait until it dries.

- Remove excess dried foam with a knife and putty the surface.

- When the putty is dry, smooth the area with fine-grit sandpaper.

Now you can see for yourself that it is simple and easy to repair any hole in a concrete or brick surface, no matter what size, without outside help.

The main thing is to correctly assess the scale of the repair work and carry it out in accordance with the rules for using the material that you will use when restoring your wall.

How to drill a brick: preparing tools

To work well with tools, you need to make sure they are in good working order, so check if you have a powerful enough tool:

- Drill. Must have 2500 rpm with reverse rotation and self-pressing chuck. Drilling will be slow, but the drill should heat up quickly.

The brick must withstand static stress.

- Hammer. Perfect for such a complex task.

- Drill. To work, you need to purchase a drill with 5 and 8 mm. Only they can work with pobedit glass - the most durable material that can easily cope with even the most durable tempered brick.

- Dowels. They can be bought at any hardware store in accordance with the drill.

- Boer. If you plan to drill through the wall, then use a drill, as it has rounded but well-cutting tips, which also increase its resistance to all types of impact.

Drill a hole in a brick wall: wall preparation and marking

The preparatory stage in drilling is that you need to determine and mark on the wall the place where you would like to see the hole. This is very important, since there may be electrical wiring in the wall, damaging which will not cause problems. So use a metal detector to locate wires or check out the article “How to Find Hidden Wiring” on our website.

In order not to run into communications in the wall, as part of safety, make a hole of 15-20 mm with your own hands and, if everything is normal, you can also use a drill.