Basic requirements for insulation coating

Cars do not tolerate prolonged exposure to moisture well.

Because of this, the metal (mainly the body) becomes corroded. If the car is stored in an unheated garage, insulation under the roof will be required to prevent condensation. Insulation materials used for these purposes must meet the following requirements:

- increased resistance to flame;

- should not absorb vapors emitted by chemicals (car oils, gasoline, etc.);

- are not able to accumulate moisture;

- light weight;

- long service life;

- resistant to mold and fungi.

The roofing material should provide comfortable conditions inside the garage throughout the year, regardless of the temperature and humidity level of the environment.

The thermal insulation layer should not attract rodents. These requirements are met by several materials that can be used to insulate the roof in a garage.

Requirements for thermal insulation materials

But how can you insulate the garage roof to ensure that condensation does not occur? A garage is a specific structure, and standard thermal insulation technologies may not work here, since the main enemy of a metal car body is not low temperature, but high humidity, which causes corrosion. Humidity is a consequence of condensation, which will certainly appear if the difference between the outside and inside temperatures is large. This means that it is necessary to create a thermal layer - protection that would neutralize this terminator band and serve as a transition layer.

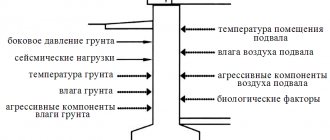

Excerpt from STO NOSTROY 2.12.69-2012

There is only one way to deal with waterlogged air - dry it. And, if there is no heating in the garage (this often happens), then the room should simply be effectively insulated. The requirements for garage insulation are as follows:

- Any garage roof insulation on the interior or exterior must be non-combustible or fire-resistant;

- Garage thermal insulation must be chemically and biologically passive, since oils, gasoline, diesel fuel, antifreeze, etc. are toxins that destroy most thermal insulation coatings. And if the insulation is damaged by rodents or pests, then it will not be able to last long;

- Internal or external insulation must be dense enough so that moisture does not accumulate in it;

- Low weight of insulation is one of the main requirements - a large mass should not put pressure on the garage roof, deforming it and increasing the load on the foundation;

- The service life of the insulating coating should be equal to the service life of the entire garage.

Important: the insulation of the garage roof outside and inside must also be suitable for performing all other insulation functions - the layer of material must work all year round, maintaining optimal humidity and temperature in the room.

To make high-quality insulation of a garage roof, use the following materials:

Fiberglass is the result of processing waste glass products: broken or defective glass, after treatment at high temperature, is drawn into threads, cut to size and cooled. Fiberglass is produced in slabs and mats. The properties of this heat-insulating material are the same as those of glass - it does not interact with aggressive substances, does not burn or rot when moistened, and does not absorb water. Thermal conductivity of glass fiber is 0.036 W/m•K.

Among the disadvantages, high fragility is noted - it is not recommended to subject the material to strong mechanical stress, since the fiber breaks, reducing the thermal conductivity of the material. You need to work with fiberglass only with the use of personal protective equipment - gloves, goggles, a respirator, and thick clothing. When purchasing this insulation, make sure that the packaging is not damaged - moisture entering the damaged structure of the product will reduce its performance characteristics.

Installing fiberglass mat on garage ceiling

Mineral fiber insulation is similar in appearance to the previous material, but is made from basalt rocks by melting. The plasticity, elasticity and flexibility of the material increases its mechanical strength, the thermal conductivity coefficient is 0.045-0.055 W/m•K, which allows the material to be used as a sound-absorbing coating.

Insulating a garage roof with mineral wool

Polymer heat insulators are produced in slabs of different sizes. Such synthetic insulation will work excellently in a metal shell garage, since, having low weight and low thermal conductivity (0.02-0.05 W/m•K) at high density, it protects metal surfaces well from moisture. High moisture resistance makes it possible not to create additional protective layers in the form of vapor barrier films, as required when working with mineral insulation, but sun protection is mandatory, since polymers quickly deteriorate when directly exposed to ultraviolet radiation and high temperature. And, if fire protection can be increased by adding additives, fire retardants, then only direct mechanical protection will save you from sunlight.

Polymer boards

Many car owners have an idea of how to insulate a garage roof with natural insulation materials, since natural materials include cotton wool, felt, felt, and fire-resistant cotton fabric. The advantages of such materials are durability and non-toxicity, but they should be protected from high temperatures and humidity under a layer of vapor or waterproofing.

Ceiling insulation with felt

Choosing the best option

There are several solutions to the question of how to insulate a garage roof. For these purposes, you can use various thermal insulation materials that differ in cost, performance and a number of other characteristics. The correct and inexpensive solution is to lay sheets of polystyrene foam under the roof of the garage. But, if you wish and have a sufficient budget, you can purchase other insulation materials.

Styrofoam

Polystyrene foam is an inexpensive and practical solution to the problem. Expanded polystyrene sheets are inexpensive and help insulate the roof and other structural elements of the garage. Polyfoam has the following features:

- fragile;

- does not absorb moisture;

- does not allow heat to pass out;

- light weight.

Polyfoam is easy to install and prevents the formation of condensation inside the garage. The main disadvantage of such thermal insulation is that insects and rodents often find refuge under the sheets. The latter violate the integrity of the foam, which is why “bridges” of cold appear. The insulation is also susceptible to burning.

Penoplex can eliminate the described disadvantages. The only disadvantage of this insulating coating is that the price of one sheet is higher than that of polystyrene foam.

Glass wool

This insulating coating is made of fiberglass, which undergoes heat treatment. Glass wool is practically not used for laying a thermal insulation layer along the roof of a garage. However, insulation has several advantages:

- withstands moisture;

- does not attract rodents;

- not susceptible to fungus formation;

- provides good thermal insulation.

The low popularity of glass wool is explained by the fact that the insulation, under the influence of minor loads, loses its original properties. In addition, when working with insulating coating, it is necessary to take precautions (wear a respirator, gloves and protective clothing).

Penoizol

Liquid insulation is easy to use, therefore, provided you have enough budget, it is suitable for laying along the roof of the garage. Penoizol is sprayed along the inside of the roof and closes any small holes. The disadvantages of penoizol include high cost and the need to use additional equipment.

Minvata

In appearance it resembles glass wool, but the mineral composition (basalt) provides better characteristics. Mineral wool is produced in the form of rolls, does not attract rodents and does not burn. The operational life of the heat insulator is 50 years. The main disadvantage of mineral wool is the need to lay a vapor barrier layer, since the insulation absorbs moisture in small quantities.

Polymers

Polymers are produced in the form of plates and have the following advantages:

- relatively low price;

- low thermal conductivity;

- simple installation;

- light weight;

- resistance to open flame (typical of new polymers).

Polymers do not require laying a vapor barrier layer, but do not tolerate exposure to direct sunlight.

A few words about insulation

Choosing a material for insulation is not an easy task. The market today is replete with offers, but choosing a safe, durable, economical and aesthetic insulation is very difficult. Let's look at the top 3 among thermal insulators.

Related article: Garage with utility unit under one roof projects

Foam insulation

The most popular and, perhaps, the best option. Among the advantages are:

- lightness;

- versatility (suitable for all types of work - interior, exterior, heat and sound insulation);

- does not absorb moisture, which allows you to do without a vapor barrier;

- strength;

- retains heat;

- resistance to fungus, mold and temperature changes;

- inexpensive;

- convenient for independent work.

Of course, not everything is so rosy. There are also disadvantages:

- flammable;

- exposed to sunlight, which causes it to deteriorate and turn yellow;

- often becomes a haven for rodents.

When using, you should remember the following features of the material:

- installation is carried out using glue;

- Usually they don’t cover it with anything, they just putty and plaster;

- the absence of sheathing will maintain tightness, which, in turn, will save heat.

Insulation with penoizol

A new, young material from the category of liquid insulation. Has the following advantages:

- fire resistant;

- waterproof;

- safe for humans;

- as easy as possible to use - after spraying it turns into a solid layer that completely penetrates all hard-to-reach places;

- does not require protection;

- the need for additional vapor barrier disappears;

- expected to last 50-70 years.

- high price;

- requires special equipment for spraying.

Insulation with glass wool (fiberglass)

A remedy proven by time and the experience of our ancestors. They represent thin glass threads rolled into rolls or pressed into slabs. Advantages:

- in price;

- retains heat well;

- It is resistant to rodents, insects, rot, mold, and mildew.

- voluminous and bulky material;

- sensitive to moisture and mechanical stress;

- difficult to install on your own;

- unsafe: it is strongly recommended to work with it in a uniform, gloves and a mask.

Material selection

To insulate a garage roof, you can use various insulation materials, each of which has certain advantages.

Fiberglass

Glass fiber is made from waste from glass factories: the cullet is melted and drawn into long threads, then trimmed and cooled. The output is the finest fiber threads. This insulation is sold in rolls and in the form of slabs.

The properties are similar to those of ordinary glass: it does not collapse under the influence of an aggressive environment, it is resistant to fire and moisture. The structure of the smallest fibers provides the material with low thermal conductivity.

However, glass fibers are fragile, they are not subjected to mechanical stress - otherwise they will break. When laying the material, you should make sure that the smallest particles do not get on the skin, especially in the eyes or respiratory organs, and if this happens, you should consult a doctor.

When purchasing fiberglass, you need to make sure the integrity of the packaging - if it is damaged, the insulation may spill out and moisture will penetrate into it, which will reduce its high performance qualities.

Mineral

Mineral fiber resembles fiberglass, but is made from a different material. Basalt rocks are used as raw materials for mineral wool: basalt is melted and formed into thin fibers.

Mineral fiber is more plastic and flexible than fiberglass insulation and is less destroyed as a result of mechanical stress. Mineral wool has low thermal conductivity and is used as a sound insulation material. With proper installation and protection from moisture, the insulating structure made of mineral wool will last a long time.

Polymeric

This material is obtained by extrusion of polymers and is available in the form of slabs of various sizes and thicknesses. Polymer insulation is very popular when insulating a metal garage. Their advantages include reasonable cost, low thermal conductivity, ease of installation, and low weight.

It is important that the use of polymer materials does not require a mandatory vapor barrier, since, unlike fibrous materials, polymers do not accumulate moisture. However, slabs of such insulation should be protected from sunlight and fire - the polymer burns out very quickly.

If we talk about fire resistance, then recently new types of polymer fibers have appeared, to which a substance is added that prevents combustion.

Natural materials

This class of materials is not often used in garages - felt, cotton wool, cotton insulation, treated with special fire-resistant impregnations. Natural insulation materials do not deteriorate and have a long service life. Sheet felt can be used to insulate ventilation in a garage, but it is inconvenient to cover the roof with it.

Thermal insulation methods

It is recommended to select methods for laying a thermal insulation layer under the roof before installing the rafter structure. This will save time and select the appropriate insulation. There are two ways to install thermal insulation on a garage roof: from the outside and from the inside. Each of these approaches has advantages and disadvantages.

From the inside

Insulation from the inside is carried out in cases where the roof is made of beam structures or reinforced concrete slabs. This option involves laying three layers in the room: steam, heat and waterproofing. If the roof has a beam structure, before installing the specified materials, the roof is sheathed with sheets of insulation. In cases where the roof is made of reinforced concrete slabs, a frame for thermal insulation is first installed on the latter.

Outside

External insulation is carried out after installing the rafter structure, but before laying the roof. The installation process is not much different from the previous one. The only difference is that reinforced concrete slabs cannot be insulated from the outside.

Types of insulation

Thermal insulation of garages can be external and internal. It is also distinguished by the scope of the work to be done and the material used.

Where to insulate?

Each type of insulation has its own advantages and disadvantages. Internal insulation is more expensive than external insulation, but it reduces the working area of the building. When garage owners are ready to sacrifice free space and can shell out a tidy sum for the purchase of materials, they use a combined option. They are insulated both outside and inside to retain maximum heat in a detached garage.

Advantages of outdoor work:

- the service life of the walls increases due to slight freezing of the concrete box;

- the likelihood of condensation is reduced;

- the risk of fungus, mold, dampness and musty air is reduced;

- usable area remains unchanged;

- the work goes faster because it does not require dismantling internal structures or removing stored items and tools;

- there is no direct contact with fumes from the insulating material.

The cost of such thermal insulation is lower, the work is faster and easier. Finishing work constitutes a separate expense item. Any insulation is covered with plaster, the color of which should match the neighboring objects. This applies to garden plots near the house.

Internal insulation is not inferior to external insulation in terms of reducing heat loss. It is suitable for buildings that are located in garage blocks or in close proximity to the house. It is used in a combined version or in situations where outdoor work is impossible.

The main disadvantage of this type is the reduction in working area. In order not to lose precious footage, sprayed thermal insulation materials are used. Due to them, a thin but heat-efficient layer is obtained. It preserves useful area, prevents the formation of condensation due to excellent adhesion, but is more expensive than its analogues.

It's worth knowing

! In internal insulation, the freezing point of the room shifts, so the walls are destroyed faster than during external work.

Insulation from the outside

External insulation of the garage roof can be carried out during the construction of the building. Necessary steps in the procedure for how to insulate a garage roof from the outside:

- a vapor barrier layer is laid - it is important that capillary moisture does not enter the insulation, and that steam escapes outside. If steam accumulates and condenses on the ceiling and on the insulation, it will shorten the service life and damage the car with rust;

- a layer of thermal insulation materials is attached - sheets of expanded polystyrene, mineral wool;

- installation of waterproofing in the form of a film, the joints of which are sealed with construction tape;

- roofing materials are laid.

Installation using polymer materials

Installation of polystyrene foam is carried out using plastic dowels, and the edges are additionally glued. The remaining cracks are filled with polyurethane foam. To insulate a metal garage with polystyrene foam, you need slabs 20-100 mm thick. and density 25 kg/cm2. Penoplex comes in the form of sheets with a chamfer for laying on top of each other and is preferably with a density of 35-45 kg/cm2.

To insulate with polystyrene foam and penoplex, the layers are simply glued to the ceiling with glue, and on top they can not be covered with anything or can be puttied and plastered. Polymer materials can be in liquid form - for example, polyurethane foam, which is applied by spraying and does not require a vapor barrier.

Installation with wool or fiber

In the case of mineral wool or fiberglass, a mesh frame is constructed from wood or metal material for the flooring. Installation using fiberglass and mineral wool consists of the following steps:

- a vapor barrier film is laid on the rafters, secured with staples, and the joints are taped with construction tape;

- Fiber or cotton wool is laid between the rafters in a layer of 15 cm, and the edges should be in contact with the boards that are nailed between the rafters (the mesh mentioned above).

The entire insulation system is sheathed with chipboards or other decorative coatings. It is worth remembering that working with fiberglass requires more care than with mineral wool.

Natural materials are almost never used to insulate garage roofs; they work best on wooden surfaces. For garages, expanded clay is often used, made from clay in the form of pebbles with a diameter of 10-20 mm. It is laid on the inside of a pitched roof and requires ideal vapor barrier and protection from moisture - you will need film and foil.

Glass wool insulation

This is the most popular material for insulating ceilings from the inside. The raw material for this thermal insulation is glass recycling waste. The material is produced both in rolls and in slabs. Although the first one is cheaper, the second one is preferable because it has high resistance to compression and bending.

Glass wool has the following characteristics:

- density: 11-25 kg/cub.m.;

- flammability: NG, G1;

- moisture absorption: up to 0.8 kg/sq.m.;

- vapor permeability: up to 0.6 mg/mh*Pa.

The procedure for insulating a garage roof from the inside using glass wool involves the following steps:

- installation of sheathing;

- laying a waterproofing layer to protect against moisture penetration;

- laying insulation;

- installation of a vapor barrier;

- installation of the second level of sheathing;

- installation of finishing material.

These steps are detailed below:

Installation of sheathing

For these purposes, metal or wood is used. The second option is often preferred due to its low cost, however, all wooden structures must be pre-treated with an antiseptic to prevent damage. Metal is characterized by durability and higher strength, but its cost is much higher.

When installing the sheathing, it is necessary to provide a ventilated gap; for this, the height of this structure must exceed the thickness of the heat-insulating material. As for the pitch of the sheathing, it must coincide with the width of the slab so that it fits tightly into the prepared space and is securely fixed there.

If wood is chosen as the material for the sheathing, the elements are installed using self-tapping screws, and the metal structure is secured with anchors.

Laying waterproofing

Penetration of moisture into the under-roof space is unacceptable, as it threatens damage to the sheathing and insulation. The hydrobarrier prevents leaks. To protect the roof of the garage, special membranes are preferred, which are pierced with microscopic holes for the passage of steam, but drops of water do not penetrate through them.

The membrane sheets are laid in such a way that the edge of one overlaps the other by 10 cm. The joints are glued with construction tape to ensure increased tightness. The sheets are fastened along the joists with a stapler or staples.

Laying insulation

If the sheathing is installed taking into account the parameters of the slabs of heat-insulating material, then they can easily be placed out of the way, tightly adjacent to the frame.

Installation of vapor barrier

The vapor barrier is laid along the sheathing, directly on top of the insulation. To protect the garage roof, a standard polyethylene film is preferred, which is laid overlapping with a ventilation gap to remove condensation if it ends up on the insulation.

Installation of the second tier of sheathing

This design reliably secures the vapor barrier and other layers of the roofing pie.

Installation of finishing material

This is the final stage of internal insulation of the ceiling in the garage. The finishing finish is attached to the second level of the sheathing. Instead of glass wool, you can use mineral wool. All steps to install it are the same.

Insulation with penoizol

Liquid foam is used to insulate garage ceilings for the following reasons:

- this material is resistant to deformation;

- its weight is light, so it does not create a significant load on the floor;

- its bending strength is high (0.06-0.25 MPa);

- its moisture absorption coefficient is low (from 25% to 4% per 1 cubic meter);

- it can withstand a temperature range from -600C to +800C.

Foam insulation can be done both outside and inside the garage.

Internal insulation

If the garage is constructed on the basis of metal, brick or foam blocks, then polystyrene foam and its liquid version penoizol are suitable for insulating the ceiling from the inside.

This work is carried out in the following stages:

- Installation of wooden or metal sheathing. Fastening with self-tapping screws (wood) or anchors (metal).

- Laying a waterproofing layer. It is recommended to provide a slight sagging of the film to create a ventilation gap.

- Installation of foam plastic between the slats, securing the slabs using construction glue and anchors. Sometimes you may need auxiliary slats that are attached to the sheathing and support the insulation.

- Laying a vapor barrier film over the insulation.

- Clean finish.

External insulation

- To insulate the garage roof from the outside, you must perform the following steps:

- Prepare the outer surface of the roof. Remove old roofing material, protruding nails, and debris.

- Installation of sheathing made of wooden blocks treated with an antiseptic. The pitch of this structure should be equivalent to the width of the foam boards.

- Laying a vapor barrier over the sheathing. This stage is necessary in order to prevent steam from penetrating from the inside onto the surface of the insulation. The film is installed overlapping, and the joints are secured with construction tape to ensure reliable sealing.

- Laying foam boards. Its slabs must be laid spaced between the lathing slats, and dowels with wide heads are used for fastening.

- Installing waterproofing over insulation. You can choose both roofing felt and geotextiles.

- Installation of the second level of sheathing.

- Final roofing work.

What tools and materials will be needed?

The type of tools used to insulate the garage roof is selected taking into account the purchased materials. Together with mineral wool you need to prepare:

- slats or metal profiles for attaching mineral wool;

- vapor barrier;

- scotch;

- polyurethane foam and gun;

- hacksaw for metal;

- construction stapler.

In the case of foam plastic you will need:

- polyurethane foam with a gun;

- stationery knife;

- self-tapping screws;

- screwdriver

If polymers are used, a special sprayer will be required. Also, regardless of the type of materials, it is recommended to take a level.

How to insulate a concrete roof of a garage or house

Externally, you can use polystyrene foam and mineral wool slabs of increased rigidity, for example, Tekhnoruf from the well-known company TechnoNIKOL. External insulation of a concrete roof is preferable when the ceiling has been finished inside the room and additional costs will be required for dismantling and installing the finishing. In addition, high-quality waterproofing of the insulation will be required, since it will be exposed to moisture all year round.

Photo. Scheme for laying mineral wool slabs on a flat roof

If waterproofing is properly installed on the outside, then work can be done from the inside. In this case, you can use cheaper mineral wool with a lower density, as well as foam boards. Please note that carrying out work inside is accompanied by a loss of some ceiling height in the room. And mineral wool needs to be additionally protected with a vapor barrier membrane from moisture contained in the air.

Garage roof insulation technology

The algorithm for carrying out construction work with your own hands depends on the type of garage roof and the materials used. It must be remembered that in some cases installation of vapor and waterproofing will be required.

Wooden

You can begin laying insulation on a wooden garage roof immediately after completing the installation of the rafter structure. At the first stage, it is necessary to sew up the beams with sheet material, after which you can begin the rest of the work.

Installation of foam plastic and mineral wool takes place in several stages:

- a waterproofing layer is fixed between the rafters of the garage roof with a slight sag;

- sheets of thermal insulation are laid between the rafters and fixed with strips or lathing;

- the joints are filled with sealant (spray foam);

- A vapor barrier membrane is laid along the foam (mineral wool), which is fixed with adhesive tape.

Upon completion of the work, the thermal insulation boards are covered with chipboard, plasterboard or other “rough” material. After this, you can begin finishing the interior of the garage roof.

If the insulation is installed outside, the order of work is as follows:

- a vapor barrier membrane is fixed between the rafters using brackets so that the material sag;

- the sheathing is installed and mineral wool is laid;

- joints are sealed;

- The waterproofing film is laid and the roofing material is installed.

In cases where penoizol is used, it is enough to spray the material between the beams using the appropriate tool. There is no need to lay additional insulating layers.

Concrete

Laying thermal insulation on a concrete surface is carried out according to a similar algorithm as described above. The only exception is that in this case, a frame (metal is recommended) is first installed, intended for attaching the insulation.

Laying thermal insulation into the sheathing

If a sheathing can be attached to the roof, then to insulate the car box, in addition to polystyrene foam, you can use other materials, including mineral wool, basalt slabs, and glass wool.

Related article: Do-it-yourself roof gable lining

The sheathing is constructed in such a way that the foam boards fit tightly into it. Additionally, glue can be applied at several points to the side of the polystyrene foam facing the roof. If mineral wool, glass wool or basalt slabs will serve as a heat insulator, the distance between the bars should be slightly smaller than the width of the insulation. The thickness of the thermal insulation must correspond to the width of the beam. Sometimes the roof is insulated with several layers of thermal insulation. In this case, the material is placed so that its joints in adjacent layers do not coincide.

Wooden sheathing elements must be treated with a fire retardant and a composition that prevents them from rotting.

After laying soft thermal insulation, a waterproofing membrane is sewn to the grid, since fibrous materials are prone to moisture accumulation. As a result, it becomes more thermally conductive. In addition, the insulation becomes heavier.

The joints of the waterproofing membrane must be airtight, so adjacent waterproofing sheets are overlapped and their edges are sealed.

A counter-lattice is attached under the waterproofing. It will prevent the insulation from falling and provide a ventilated space between the ceiling cladding and the insulation. The ceiling is hemmed to the counter-lattice.

If the garage roof lies on the rafters, then thermal insulation is laid between them. It is better to place fibrous thermal insulation materials between the rafters. Then waterproofing, counter-lattice and cladding are attached to the timber.

Features of the work

When laying insulation on the roof of a garage, it is necessary to take into account the design features. There are two roofing options: single- and gable. The requirements for the type of material and the procedure for installing the heat-insulating layer are the same in both cases. However, due to the design features of the roof, some problems may arise during the work.

Shed roof

This type of roof has a simple design, which is why it is often used in the construction of a garage. If the latter is adjacent to a house or other building, when laying insulation, it is important to eliminate the gaps between the material and the neighboring building. Otherwise, “bridges” of cold will form in this zone.

If a garage with a pitched roof stands separately from other structures, then the installation of thermal insulation is carried out according to the described algorithm. It is important to ensure that the materials on both sides of the roof are tightly covered with a canopy.

Gable

When installing a vapor barrier on single- and gable roofs, it is necessary to leave a ventilation gap. To do this, it is enough to place bars in several places between the material and the sheets with which the beams are sheathed.

When working on a gable roof, problems may arise when insulating the junction of the beams at the top point. This point requires special attention. To avoid the formation of cold bridges, it is important to foam all the cracks on the ridge.

Insulating the roof of a steel garage

The option using foam plastic, which is laid along the internal planes of the roof slopes, is the simplest. The garage structure includes lintels that hold the longitudinal walls of the building together. Sometimes these lintels are used to form a ceiling. They are hemmed with sheet materials: plywood, chipboard, OSB or iron sheets, which are laid on wooden slats. The latter are attached to the jumpers either with self-tapping screws, or bolts, or with binding wire.

It is the insulation of the ceiling that will solve the problem with the roof. To do this, you will have to lay sheet material from the above mentioned on top of the lintels, and these are the same steel corners 50x50 mm. The sheets are attached to the jumpers with ordinary knitting wire in increments of 50 cm. That is, you need to:

- drill holes in the flooring on each side of the lintels;

- insert the wire into them so that the ends hang down on different sides of the frame element;

- twist the wire along the bottom edge, pulling the sheets to the jumpers.

Now foam plastic is glued to the laid sheets, and then the entire ceiling structure is hemmed with sheets of plywood, OSB, fiberboard or chipboard. Although there are a huge number of finishing options here.

Ceiling insulation with foam plastic

Garage roof insulation

The roof of the garage must also be insulated. Unfortunately, many car enthusiasts forget about this. They prefer to make a kind of box out of thermal insulation material, and leave the roof without attention. As a result, the required temperature regime can no longer be achieved.

Here are some useful tips.

- If you are insulating the ceiling in a garage using foam plastic, you should not drill holes for the bars. It's better to use glue.

- When the roof consists of reinforced concrete slabs, it is advisable to take care of external and internal insulation.

- If you apply foam plastic from the outside, you will have to additionally make a plaster screed. The optimal solution is to lay a waterproofing layer between the insulation and the plaster. You can use roofing felt or film.

- Is the sheathing loose? Then fix the layers of insulation between the rafters. After this, you can use a waterproofing film.

- Do you have a continuous sheathing or a good rafter system? In this case, waterproofing is laid on top, and the insulation is fixed under the sheathing.

- Waterproofing film requires careful attention. Make sure that it does not come into direct contact with the insulating layer if it has reduced vapor permeability.

The best scheme for insulating a garage roof is: waterproofing - thermal insulation - vapor barrier.

How to properly insulate a garage roof from the inside

Insulation methods may vary depending on the insulating material, its placement, and the design features of the roof. The main rule is to provide 3 layers of insulating structure: steam, hydro, and thermal insulation.

The latter is carried out in the presence of the first two.

Materials for roof insulation.

Stages of internal roof insulation:

- Clean from dirt and dust.

- Cover all seams, joints and cracks, treat with plaster.

- Installation of sheathing parts with dowels and screws.

- Creating a water barrier using a waterproofing film.

- Filling the sheathing with insulation. Sealing joints

- Creating a vapor barrier from polyethylene film.

- Covering with decorative material (chipboard, MDF, wood, plasterboard).

Don't forget about safety - select fire-resistant materials and ensure proper ventilation.

Why foam plastic? Material advantages

What is the reason for the high popularity of this material? Why do many forward-thinking car enthusiasts choose to insulate their garage with polystyrene foam? Let's consider the key advantages of the material.

- Polystyrene foam is a fairly economical insulation material. In terms of price-quality ratio, it is superior to many other materials. For example, it outperformed mineral wool by 50%.

- It is quite convenient during the installation process. Even a person without builder skills will be able to cope with sheathing a garage with foam sheets.

- In terms of its properties, the material in many ways not only resembles the popular mineral wool, but also surpasses it.

- The water resistance of this type of insulation plays an important role, since it is in the garage that there is a high probability of increased humidity, but this must be dealt with. After all, condensation is very dangerous for the machine and its metal parts. Just with polystyrene foam you can prevent corrosion.

Some people are confused by the fact that polystyrene foam is still a flammable material. And the garage almost always contains fuel and lubricants. But here the solution is very simple. Now they produce special brands of this insulation, which already contain fire retardants. Such additives provide attenuation and allow achieving the required level of fire safety.