- Floor insulation: which one is better to choose for a wooden house

- Choosing material for floor insulation

- How to properly insulate the floor in a wooden house with sawdust

- Subtleties of using mineral wool

- Features of using penofol

- Floor insulation with foam plastic

- Ecowool floor insulation

- Floor insulation with penoplex

- Using the "warm floor" system

- Tips for caring for insulated floors

- Floor insulation: which is the best manufacturer and how much does the material cost?

- Video: floor insulation in a frame house

Floor insulation: which one is better to choose for a wooden house

Floor insulation plays a very important role in the overall insulation of the house. It is best to do this at the construction stage, then for insulation you will not have to dismantle the existing floor covering, and the consumption of time, effort and building materials will be kept to a minimum. If you need to insulate the floor in an already inhabited house, then it will be somewhat more difficult. First you need to decide what will be used as floor insulation , which one is better to choose to create high thermal insulation in a wooden house.

Wooden floors in a private house: options for installation and insulation (read more)

Insulation of a wooden floor with glass wool.

A few words about thermal insulation

Drafts in combination with a cool floor do not bring positive emotions, and they also have a bad effect on health. Therefore, there is no point in arguing about the need for thermal insulation in the house. Insulating the floor below is a mandatory and inevitable event, which will pay off all costs over time.

Insulation of a wooden house

The thermal insulation process can be divided into several stages:

- dismantling the floor covering;

- installation of subfloor;

- laying a layer of thermal insulation;

- laying vapor barrier;

- installation of finished floor.

Floor insulation scheme on the first floor

Advantages of a wooden floor

A similar scheme is suitable for cases where a wooden house is being restored during renovation. But if a house is being built from scratch, then all of the above steps are performed during the construction stage.

Thermal insulation of the floor in a wooden house

Choosing material for floor insulation

The selection of thermal insulation materials should be treated with maximum responsibility. In many ways, the choice will depend on the financial well-being of the home owner, but you should not save on insulation. Remember that heat loss is the consumption of excess electricity to heat your home, and this means additional financial expenses.

What is the best insulation for floors in a wooden house? You can find out by considering the advantages and disadvantages of each type of thermal insulation material.

Laying sheets of plywood on the joists and filling the voids with stone wool.

The most common materials for floor insulation today are:

- mineral wool;

- ecowool;

- wood sawdust;

- polyurethane foam;

- penofol;

- Styrofoam;

- expanded clay

The insulation is cut according to the size between the joists.

Each of these materials has its own characteristics, as well as installation nuances.

In order to choose the best way to insulate the floor in a wooden house, you should consider the following parameters:

- indoor conditions - average humidity and air temperature, extreme values of these indicators and the frequency of their changes;

- expected thickness of the thermal insulation layer;

- expected loads on the floor and general operating conditions;

- calculated weight of the entire floor structure.

Floor insulation scheme

Insulation of the floor in a wooden house is carried out by creating a double structure, which in the standard version consists of rough flooring, insulation, vapor barrier and finishing flooring. This layered system can withstand significant loads and prevent heat loss.

Double flooring is installed during the renovation of an old house or new construction. This technology is called “insulation of a wooden floor using joists.” It is efficient and easy to implement. Ideal for thermal insulation of floors on the first and basement floors located in close proximity to the ground, as it can significantly reduce heat loss.

Guide to floor insulation

Insulating the floor in a wooden house is a simple process; it can be done with your own hands. The main thing is to take into account such important parameters as the purpose of the room, the average temperature and humidity inside it, the load on the floor, the minimum thickness of the thermal insulation layer, choose a good insulation and follow the technology for its installation.

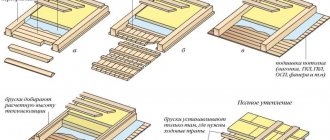

Stage 1 – laying the subfloor along the joists. This simple and versatile design is most often used in renovations and new construction. Its main advantage is that the insulation is not affected by mechanical loads, so any heat-insulating material can be used.

This floor is made of wooden panels or rough boards measuring approximately 25x150 mm. You can also use boards left over from the foundation formwork for these purposes, provided they are in good condition. In any case, it is recommended to pre-treat the wood with an antiseptic composition.

First, wooden logs are laid, not reaching the walls by about 2-3 cm. They are either installed using the T-shaped cut into the log house, or laid on a foundation, brick pillars or wooden pad at a distance of 0.6-1.0 m from each other . A cranial beam with a cross-section of no more than 50x50 mm is attached to the logs using screws, then shields or rough boards are nailed to it from below, making sure that there are no large gaps left between them.

Stage 2 – laying insulation. Sheet, slab or roll thermal insulation material (foam plastic, glass, eco-, mineral wool, etc.) is placed tightly on a wooden base between the joists, and the remaining gaps are filled with polyurethane foam. Sometimes such insulation is laid under the subfloor.

Sprayed insulation is fixed using special equipment. These materials have good adhesion, follow the contours of the surface and do not form joints.

Stage 3 – laying vapor barrier (waterproofing) material. Waterproofing of the subfloor is mandatory when insulating wet rooms in a wooden house, as well as in the case of using hygroscopic heat insulators. In particular, it is necessary when using fiberglass, ecowool or mineral wool as insulation. At the same time, you can do without it if you use sprayed insulation.

Waterproofing is divided into impregnation, painting and pasting. Pasting materials include polyethylene films, PVC membranes, glassine, roofing felt, isoplast, etc. Film waterproofing materials perfectly protect fiber insulation from condensation and moisture penetration.

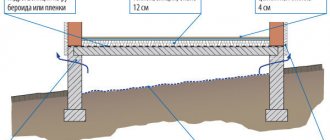

Sheets of vapor barrier film are laid over the thermal insulation layer with an overlap of approximately 15 cm, and the edges are folded by approximately 10 cm and attached to the joists. The joints and resulting gaps are glued with metallized tape. Sometimes two layers of moisture-resistant film are laid: a waterproofing layer on the subfloor, a vapor barrier on the insulation.

Stage 4 – laying the finished floor and finishing it. The finished floor is laid on top of the vapor barrier layer at a distance of 3-4 cm from the auxiliary base (subfloor). For its construction, specially treated boards with a width of 9.8-14.5 cm and a thickness of 3.0-4.4 cm are used, which have longitudinal grooves on the bottom side to ensure natural ventilation.

Video guide for floor insulation in a wooden house

It is not recommended to use unedged boards for laying the finished floor, because before laying they will need to be prepared: cut off the wane with an ax, plan the front side. This is a rather labor-intensive process that takes energy and time. Sometimes fibreboard (fibreboard) and a soundproofing coating are placed on top of the boards.

To enlarge, click on the picture

Paint and varnish, or slabs, linoleum, and carpet are used as finishing materials for a finished insulated floor in a wooden house. They are laid according to generally accepted rules governing the installation of these materials, and then skirting boards or profiled slats are installed along the joints with the walls. On straight sections they are connected at an angle of 90 degrees, and in corners - at an angle of 45 degrees.

The profiled slats are pressed tightly against the floor and walls and secured with 75 mm nails, keeping a distance of 60-70 cm between them. Also, nails must be driven into the joints of the baseboards.

How to properly insulate the floor in a wooden house with sawdust

Using ordinary wood sawdust to insulate a floor is one of the easiest ways to increase the level of thermal insulation.

Sawdust has a number of advantages:

- relatively low cost of the material - sawdust will cost less than mineral wool or expanded clay;

- environmental friendliness - wooden sawdust is absolutely safe for human life and health, does not cause allergies;

- ease of installation - in order to insulate the floor using sawdust, you just need to pour it in an even layer under the floor covering;

- easily poured into hard-to-reach places - sawdust can be used to insulate cracks, gaps and other places where it is impossible to install other types of insulation.

You can also use various building materials that contain sawdust in their composition. This includes sawdust concrete, wood concrete, wood blocks and sawdust pellets. But most often sawdust is used in its pure form.

On a note! When choosing insulation for the floor in a wooden house, you should use sawdust only if you are not afraid of an increased fire hazard. Otherwise, it is better to opt for a less flammable material.

Wooden floor construction with insulation.

Why do you need waterproofing of a wooden floor?

A wooden floor is a multi-layer structure of joists, subflooring and floorboards, which are affected by moisture in two ways:

- coming from below, from the basement or ground (private house) or breaking through the concrete floor from lower neighbors (remember that concrete perfectly allows steam molecules to pass through);

- from waterlogged indoor air - appears there as a result of human activity (from indoor plants, washing, breathing of humans and animals, cooking, bathing, etc.).

There are many nuances regarding waterproofing; we’ll talk about them in the following articles. So let's continue

"Dry screed"

An excellent option for floor insulation in a wooden house. It can only be used after the wood has gone through the shrinkage process. The screed is made on the basis of gypsum fiber.

Key benefits:

- high thermal insulation performance;

- resistance to fire;

- ease of installation;

- Possibility of use in combination with any finishing floor coverings;

- small thickness;

- good noise insulation performance.

The main disadvantage is the relatively high cost. A twenty-kilogram bag of mixture is enough to insulate no more than 1 m2 of surface.

The material also does not tolerate moisture well. Because of it, it is deformed. Such deformation does not affect the thermal insulation properties of the material in any way, but the finishing floor covering may deteriorate.

Glass wool.

Popular material for floor insulation. The advantages are as follows:

- non-flammability;

- ease of arrangement;

- environmental Safety.

Main disadvantage

– significant shrinkage. In just a year of service, a meter strip of glass wool can decrease by 10-15 cm. As a result, the integrity of the thermal insulation layer is compromised. Disadvantages also include poor resistance to water and not the best thermal insulation properties.

Expanded polystyrene

This insulation has many advantages, including:

- resistance to fire, moisture and temperature changes;

- incredibly low thermal conductivity;

- high noise insulation properties;

- excellent strength.

The main disadvantage is the relatively high cost.

Subtleties of using mineral wool

If the question arises about what is the best insulation for the floor in a wooden house, then mineral wool is one of the most popular options today. Firstly, mineral wool represents the optimal combination in terms of price and quality. Secondly, it has a lot of advantages:

- low level of thermal conductivity, due to which heat loss in the house during the cold period is minimized;

- high water repellency, that is, mineral wool does not allow moisture to pass through, so this type of insulation can be installed in houses with high humidity;

- non-flammability of the material, which greatly reduces the risk of fire in a wooden house;

Laying a thermal insulation layer.

- durability - insulating floors in a wooden house from below using mineral wool guarantees you a long service life of the insulation, much longer than sawdust or other similar materials;

- environmental safety – mineral wool is absolutely safe for human health and does not cause allergies;

- high level of resistance to rotting - this type of insulation withstands the effects of aggressive chemical environments, tolerates temperature changes and other adverse effects;

A combination of penofol and mineral wool for better thermal insulation.

- affordable price - mineral wool is more expensive than sawdust, but cheaper than many other insulation materials;

- high level of sound insulation. By insulating your home with mineral wool, you not only reduce heat loss, but also minimize the noise level entering the house from the street.

A number of disadvantages of the material arise from its advantages. One of the main ones is low vapor permeability, which is why water condensation can accumulate on the insulation. If you plan to insulate the floor using mineral wool, then you should take care of a good vapor barrier.

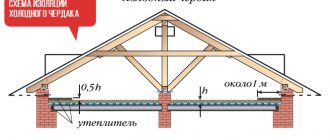

Thermal insulation of the floor is carried out using mineral wool between the beams.

In addition, mineral wool cakes over time, and thermal insulation is reduced. Therefore, when insulating a wooden floor from below in a private house using mineral wool, several overlapping layers should be installed.

Mineral wool is installed without gaps, and a vapor barrier layer is laid on top of the insulation layer, with the seams being taped. This will protect the insulation itself from moisture condensation on it from warm air from the house.

Correct installation of penofol under wooden logs.

Material selection

There are several main criteria by which you should choose insulation. These include:

Materials for floor insulation in the house

- resistance to rodents and high humidity;

- durability of the material;

- complexity of installation;

- financial capabilities of the home owner (some materials are not cheap).

Floor insulation with foam plastic

Note! When insulating the floor in a country house, where the owners rarely visit, it is important to choose materials that are resistant to different types of rodents. It is mice, combined with high humidity, that are the main reasons for the destruction of wooden floors.

What is the best way to insulate the floor in a wooden house?

Table. Overview of wooden floor insulation.

| Name of material, photo | Description |

| Expanded clay | It is a small granule with a porous structure. Expanded clay retains heat well, and small rodents and harmful insects do not live in it. The optimal thickness of the expanded clay layer is 20-30 cm. |

| Styrofoam | A fairly lightweight and easy-to-install material used for insulating houses and apartments. The foam is moisture resistant, but is afraid of rodents, which quickly destroy it. |

| Wood shavings | One of the cheapest insulation materials, which can be purchased without any problems at your nearest wood processing plant. Wood shavings actively retain heat, but are not moisture resistant. |

| Slag | An excellent material for insulating houses. The slag needs waterproofing, which significantly complicates the installation process. But slag is a durable material. |

| Glass wool | An inexpensive heat-insulating material that not only retains heat in the house, but also muffles sounds. Among the disadvantages of glass wool, it is worth highlighting the material’s tendency to shrink over time. |

| Ecowool | Another type of insulation with low thermal conductivity. To install ecowool, a special installation is required, since it is quite difficult to manually blow it into the underground space. |

Thermal insulation materials for floors

Expanded vermiculite can also be used as crumbly floor insulation. This is a natural material with a granular structure. Vermiculite is lightweight and has high heat and sound insulation properties. In addition to construction, vermiculite is actively used in dacha farming.

Vermiculite expanded

Features of using penofol

Penofol has been used for floor insulation relatively recently, and is not yet very popular. It is a roll of material that consists of several layers: insulation and reflective aluminum foil.

When insulating the floor with penofol in a wooden house, you get the following advantages:

- Simplicity and ease of installation - penofol can be installed even without special skills in the field of construction.

- High resistance to mechanical loads - the material can withstand high pressure, shock and much more.

- The high density of the material allows it to be installed in a not too thick layer.

- When insulating the floor with penofol, you do not have to additionally install a vapor barrier, since condensation does not concentrate on this insulation.

Options for installing floors in a frame house.

On a note! When buying penofol for floor insulation in your home, do not be alarmed by its relatively high price: the excellent performance characteristics of the material more than compensate for it.

How to properly insulate floors in a wooden house using penofol? To do this you need to do the following:

- First, the waterproofing layer is installed. This could be a special film or just an additional layer of penofol.

- Then the insulation itself is laid, all seams and joints are filled with polyurethane foam.

- Wooden logs are mounted on top of the foam foam layer. The distance between them should be at least 50 cm.

- Penofol is again laid between the lags, and all seams and cracks are filled with polyurethane foam.

- Wooden boards or chipboard sheets are laid on top.

Penofol has vapor barrier properties, which simplifies the work on floor insulation.

Possible materials for insulation

There is an incredible amount of insulation on the domestic market. But not all of them are suitable for thermal insulation of the floor in a low-rise building made of logs or timber.

On the one hand, one should take into account the compatibility of the selected thermal insulation material and the wood from which the residential building is constructed. On the other hand, we should not forget about the environmental friendliness of all building materials used.

When choosing thermal insulation for the floor in a country wooden house, it is recommended to focus on natural, environmentally friendly materials

The main advantage of a wooden cottage is its environmental friendliness. The floor should be insulated with synthetics only as a last resort.

Among the variety of insulation materials for a wooden house, the following are recommended:

- stone wool;

- ecowool based on cellulose;

- expanded clay;

- sawdust;

- fiberboard

Also in some situations you can use extruded polystyrene foam. But it is best to do without this material, giving preference to more environmentally friendly insulation from the list above.

Stone mineral wool

Mineral wool is made from fiberglass, blast furnace slag and rocks. In wooden houses, it is worth using the last of these types - cotton insulation made from basalt fibers. It is the safest for humans and environmentally friendly - it contains virtually no synthetic binders.

Stone wool has:

- low thermal conductivity 0.034–0.04 W/(m*K);

- excellent vapor permeability;

- good noise absorption.

Basalt insulation is not subject to rotting, does not burn and can easily withstand heating up to 700 °C without loss of characteristics.

A residential cottage should be insulated with glass wool exclusively from the outside. This type of mineral wool is characterized by the fragility of glass fibers, which cause irritation when falling on the skin and mucous membranes

Ecowool from cellulose

This material is environmentally friendly, mold resistant and non-flammable. When producing ecowool, cellulose (paper production waste) is impregnated with antiseptics and fire retardants.

Fire and fungi are not afraid of her. At the same time, this heat-insulating material is capable of absorbing moisture up to 15% of its own weight.

Also, ecowool cannot be installed near the bases of main chimneys, foundations of stoves and fireplaces. When exposed to high temperatures, cellulose will smolder. Due to the abundance of fire retardants, it will not catch fire. But the gradual smoldering of the paper will inevitably thin the insulation layer and lead to an increase in heat loss.

The main disadvantage of ecowool is its high moisture absorption - if such insulation is not dried by ventilation, it will quickly lose its thermal insulation properties

Sawdust

If you want to get a home that is as clean as possible from an environmental point of view, then you can insulate the floor in a wooden cottage with sawdust. They are poured in a compacted layer 10–40 cm thick between the joists, which provides fairly high-quality insulation without any chemicals.

Sawdust is the cheapest existing insulation material. They are tested by time and long-term practice. However, this material, like any wood, is flammable. Whether it is worth adding highly flammable fuel to a potential fire in a wooden house is an open question.

To prevent mice from getting into the sawdust, it is recommended to sprinkle it with slaked lime. And impregnation in the form of copper sulfate is ideal against fungus

Styrofoam

It is no secret that polystyrene foam is extremely popular during the construction of absolutely any structure. It is lightweight, affordable and very durable. But many people consciously refuse to use it for insulation work, doubting its safety for human health. Many years of scientific research have proven that no toxic substances are released during the direct use of the material as the main insulation, so if you are considering polystyrene foam as one of the options, then take a closer look at it. It will provide excellent protection for the concrete floor of the first floor, but in no case is it recommended to use it for insulating logs, because due to the lack of gaps, moisture will accumulate under the sheets of material, as a result of which the likelihood of fungal formations will increase.

Of course, the insulation layer must be placed on the outer sides of the enclosed elements. Thus, for the floor of the first floor it is from below. It is not recommended to use foam plastic in any other insulation work, because it will not be able to maintain the temperature level at the proper level.

Foam insulation of the subfloor

Polystyrene foam is a budget-friendly and very popular building material, especially in the field of private housing construction. The most suitable thickness of insulation for the floor is 200-300 mm.

Expanded clay

Expanded clay can deservedly take second place in cheapness after sawdust. This insulation is made from baked clay. It has the form of granules with many air-filled voids inside.

Of the minuses of expanded clay, only its high hygroscopicity is worth mentioning. If the expanded clay granule is split, it will absorb water like a sponge. Without underlying waterproofing in the form of a thick polyethylene film, such insulation cannot be poured.

Expanded clay is ideal for thermal insulation of floors on the ground. It is also often used when constructing insulated concrete screeds, poured from below or used as a filler for mortar.

Expanded polystyrene

This material is presented on the market as polystyrene foam and slab Penoplex (EPS). If we take it, then for floor insulation only the second option is extruded polystyrene foam. It is denser and absorbs moisture much less.

Expanded polystyrene and wood are often called antagonists. The first does not allow moisture to pass through, while the second, on the contrary, absorbs it well and then releases it to the air.

However, with proper installation, EPS and polystyrene foam can be combined with wooden structures. You just need to leave a gap for ventilation between the polystyrene foam insulation and the wood so that condensation does not accumulate there.

The main disadvantages of EPS are flammability with the release of harmful gases and low vapor permeability. Even the presence of additives does not save this insulation from open fire, and the impermeability of water vapor does not allow the wooden floor to breathe

Foam glass

Foam glass is obtained by foaming quartz sand. This is a durable slab or granular material with high vapor barrier and noise insulation characteristics that can withstand the weight of a truck.

Fiberboard slabs are used for insulating floors on a flat base, and granules are used for backfilling between joists on subfloors. The thickness of the insulation layer is 18 cm for the first floor and 15 cm for the second.

Cork material

The main advantage of natural cork insulation is the extremely high sound insulation of the coating. The high price of the material is compensated by the fact that you simultaneously solve the problem of heat and sound insulation. In addition, cork insulation almost does not burn, is not afraid of moisture, is resistant to rotting and is extremely durable, which allows it to be used as insulation under self-leveling floors.

Cork insulation

Due to its rather beautiful texture, cork insulation is sometimes left even as a finishing coating. In this case, the top layer is covered with a special varnish, which protects it and at the same time emphasizes the design.

Cork insulation is available in rolls and sheets with thicknesses from 3 mm to 200 mm. Sheets of maximum thickness allow you to insulate floors above the ground in just one layer, but at the same time they are very expensive. The cost per square meter of thick cork insulation can reach up to 5,000 rubles. For this reason, cork insulation on the first floors of buildings is rarely used.

Cork thermocork insulation

The thickness of cork insulation on the ground floor of a private house with concrete floors should be at least 100 mm; in floors between floors with concrete floors, a layer of 50 mm is sufficient; if the floors are wooden, then the layer should be increased to 70 mm. In an apartment building, cork insulation is laid in a layer of 10 mm to 30 mm; this is quite enough for effective thermal insulation and complete sound insulation from neighbors below.

Fibrolite

Fiberboards are made from wood chips and cement. This is an excellent insulation material, which is not yet very widespread in Russia.

Fibrolite is characterized by quite high hygroscopicity. It dries quickly, which, however, is only possible under conditions of good ventilation. It is a non-flammable, harmless to humans, non-rotting and breathable heat insulator. Just don’t let it get wet or freeze.

Fiberboard has excellent heat and sound insulation characteristics. This is a high-quality and durable insulation that cannot be used only when laying the floor directly on the ground

Floor insulation with foam plastic

Polystyrene foam is another type of insulation, which in popularity is almost on the same level as mineral wool. It differs favorably from the latter in that it does not absorb moisture, does not cake and, accordingly, does not lose its thermal insulation properties over time.

Insulation with foil: use of foil penofol (read more)

In addition, when insulating the floor in a wooden house from below using polystyrene foam, you get the following advantages:

- The material has a high level of strength and withstands mechanical stress well.

- Low level of thermal conductivity, that is, even a relatively small layer of foam will prevent heat loss in your home.

- Fire resistance.

- Resistance to various types of negative environmental influences. Foam plastic successfully resists aggressive chemical environments and temperature changes.

- Polystyrene foam is not afraid of rodents, so if you need a type of floor insulation in a wooden house against mice, then it will be an excellent option.

- Does not rot or mold.

When replacing the floor, the insulation can be reused if its condition allows this.

Insulation thickness

Let's consider how to correctly calculate such an important indicator responsible for maintaining heat in a house as the thickness of the insulation.

It should be noted that for each specific house this indicator is calculated individually - and the thickness of the material that is suitable for a house in southern latitudes may differ radically from the thickness of the material for a northern cottage. This calculation also includes other features.

To calculate the optimal insulation thickness suitable for your home, you need to use the formula prescribed in SNiP “Thermal protection of buildings”. The formula is: insulation thickness = R x A.

On the video, the thickness of the insulation for the floor in a wooden house:

What do these mysterious letters mean:

- R is the level of thermal resistance of the structure. This level is different for each climate zone. You can find it out from the application map that is attached to the SNiP.

- A is the coefficient of thermal conductivity of the insulation. Each type of insulating material has its own. You can see it on the packaging of the material. Some coefficients are also indicated in SNiP.

Using this formula, you can accurately determine what thickness of insulation is suitable for you, so that you are guaranteed not to freeze and achieve the optimal temperature in the house.

Attention: if according to the formula it turns out that the insulation layer in your house should be thin, then experts recommend in this case using expanded polystyrene or rolled materials. Such insulation can best protect the house, even if the layer is not too thick.

Ecowool floor insulation

When insulating the floor in a private house with your own hands using ecowool, it is worth considering that this will be less effective and will take more time than installing the same insulation using special blowing machines. Nevertheless, it is possible to insulate a floor with ecowool without using specialized equipment. To do this, sheets of material are laid between pre-assembled wooden joists.

The advantages of ecowool are a high level of thermal insulation, impressive durability and resistance to adverse environmental influences. The disadvantage of the material is its high cost and the need to use specialized equipment for high-quality installation. A video of insulating a floor in a wooden house using mineral wool with your own hands greatly simplifies the process, so don’t be lazy to watch it before starting work.

Ecowool is resistant to fire due to non-volatile flame retardants in the composition.

Floor insulation with penoplex

If you are insulating a wooden floor at home with penoplex, then the installation scheme is the same as in the case of mineral wool. First, a layer of insulation is laid, then the seams are filled with polyurethane foam. If necessary, penoplex can be laid in several layers.

The advantages of the material are as follows:

- When insulating with penoplex, a vapor barrier is not needed, since condensation does not accumulate on it.

- Penoplex is not afraid of rodents and insects; it does not need to be additionally protected from moisture or mechanical damage.

- The material boasts a solid service life, while its thermal insulation properties do not change over time.

Penoplex is used as a thermal insulation material for floor insulation.

The only significant disadvantage of penoplex is the fairly high price of the material. It costs more than mineral wool or polystyrene foam, but has better performance characteristics.

Using the "warm floor" system

If you want to use the most advanced technologies, then the “warm floor” system comes to the rescue. This can be a network of pipelines with hot water, which is installed under a layer of insulation or a flooded floor.

Installation of water heated floors on polystyrene foam mats.

However, a much simpler option to install and operate is electric heated floors. You can purchase such a system at any specialized store and install it without having specialized skills in the field of construction. The price of floor insulation in a wooden house based on such a system will be quite high, but its effectiveness is worth it.

Tips for caring for insulated floors

After completing the installation of insulation, you should regularly take measures to care for the floor. This will help extend its service life and maintain high thermal insulation properties.

Attaching water floor pipes to reinforced mesh.

To do this, you need to follow the following recommendations:

- do not walk on the insulated floor in street shoes - small pebbles, dirt and solid particles act on the floor like sandpaper;

- For cleaning, it is best to use a powerful vacuum cleaner; it will effectively remove all dust even in the most difficult to reach places;

- direct sunlight has a bad effect on wooden floors, so it is worth protecting it from their influence;

- where the maximum level of load on the floor is expected, it is better to protect it with mats.

On a note! The biggest enemy of a wooden floor is moisture. Therefore, great attention should be paid to waterproofing. To do this, you can lay a moisture-resistant coating in places where water is expected to be exposed.

Electric heated floor on a wooden surface.

It doesn’t matter whether you use expanded clay, mineral wool, polystyrene or a “warm floor” system to insulate floors in a wooden house, following these recommendations will allow you to significantly extend the life of the insulation and prevent loss of thermal insulation properties.

Floor insulation: which is the best manufacturer and how much does the material cost?

In the modern market of manufacturers of floor insulation materials, there are several popular brands that are most often used for thermal insulation of private houses:

Cable system for heated floors.

- Rockwool is one of the most popular brands, producing basalt insulation for walls, roofs and floors, characterized by high quality, density, and non-flammability. Available in slabs. The price per square meter of insulation can vary from 135 to 200-250 rubles, depending on the brand.

- Euroizol is a mineral wool-based insulation material, non-flammable, with high compressive strength and low water absorption. The price per cubic meter is about 4,000 rubles.

- Linerock is a ventilated non-flammable insulation material, sold in slabs and used for insulating facades and floors. Price - from 140 to 170 rubles per square meter.

- Isover is a glass wool-based insulation material characterized by high tear density, strength and resistance to physical influences. The cost is about 150 rubles per square meter.

Expanded clay is used for insulation and soundproofing of floors.

In addition, brands such as Ecover, Ragos, Techno, Knauf and many others are used for insulation. In order to learn how to insulate the floor in a private house with your own hands using each of them, it is recommended to watch video instructions on the Internet or read advice from experienced builders.