During construction, it is very important to correctly calculate how much load the floor slab can withstand. The fact is that it is precisely this that ensures the rigidity of the structure, so in this case we are talking, first of all, about the safety of the entire construction and the people carrying it out.

Floors consist of upper, lower and structural parts. The latter transfers its weight to the supports. Thus, a factor such as calculating the permissible load is very important.

In the construction of private houses and multi-storey buildings, floor slabs are often used.

As for the lower part of the ceiling, it is made of plaster, tile materials or various types of cladding. The upper part consists of floor structures and leveling screeds. They provide sound insulation and thermal insulation. Monolithic and prefabricated slabs are used to assemble the structural part of the floor. Basically, such slabs are made of reinforced concrete, however, in addition, prestressed concrete can be used, and the use of ceramic liners is acceptable.

You can make a monolithic ceiling with your own hands.

Calculations for any building structures are made, first of all, to ensure that the structures do not subsequently collapse. If the calculation turns out to be incorrect, then very soon cracks will creep along the walls. And there is no need to explain how this may end in the very near future.

Loads on the slab are calculated in two categories: dynamic and static. The latter includes all those objects that lie, hang or are nailed to the slab. And those objects that can run, fall and jump are already dynamic loads.

In order to calculate everything accurately, you will need:

- calculator;

- long ruler;

- building level;

- roulette.

Considering the fact that dynamic loads can be distributed evenly and unevenly, they are not taken into account for an ordinary residential building.

Main Factors

Plate parameters: L – length; B – width; H – height.

If we are talking about calculating the loads on a hollow-core floor slab, then everything depends on its size. On average, it can withstand from 800 to 1450 kg per square cm. A standard hollow-core slab has a thickness of 200 mm, but it should be taken into account that there are slabs 150 mm thick. In addition, it must be taken into account that such slabs are quite fragile and it is not worth conducting experiments to see how much weight they can withstand.

Soil characteristics important for slab foundations

The calculation of a concrete structure, such as the foundation, takes into account.

Therefore, it is necessary to understand the total number of symbols for all quantities that may be required.

From the variety of soil characteristics, we will indicate their types and some features that are important to calculate the slab option:

- Clay soil. This is a cohesive soil.

- Sand. Non-cohesive soil in which more than 50% of the particles have sizes not exceeding 2 mm.

- Coarse soil. Cohesive soil in which more than 50% of the particles are larger than 2 mm.

- Silt and sapropel. Water-saturated sediment with a particle content of less than 0.01 mm.

- The soil is peat. Sandy and clayey, containing up to 50% or more (by weight) of peat.

- Swellable soil is a soil that, under conditions of free swelling when soaked in water, increases in volume and has a relative deformation of more than 0.04.

- In some types of soil, when soaked with water, even its own weight can give a relative vertical subsidence of more than 0.01.

- Heaving dispersed soil. Due to the formation of ice crystals, it has a relative deformation of more than 0.01.

Return to contents

Concrete requirements for slab foundations

Concrete is an ideal material for building concrete structures as it can withstand compressive loads well. But it works very poorly in tension. They try to compensate for this drawback by placing it inside with a metal frame. Based on compressive strength, concrete is divided into classes (B3-B80) and grades M50-M1000.

For foundations, grades no lower than M200 are suitable. This means that the compressive strength will be at least 200 kgf/cm². Concrete reaches normal strength in approximately 28 days. Over time, strength tends to increase.

The slab requires as much concrete as possible for one-time pouring, so the manual method of preparation will not work. You need a solution prepared at a concrete plant that is well mixed, which is very important for its strength.

Based on frost resistance, concrete is divided into grades F50-F1000, where the number indicates the number of freeze-thaw cycles that a structure made from it must withstand.

A very important characteristic is the water resistance of concrete. According to this indicator, it is divided into grades W2-W20, where the number determines the water pressure (in MPa) that a sample of the established size can withstand. For foundations, concrete grade W6 is recommended. It should be noted that for any brand of concrete, waterproofing will not hurt. This is especially true for such a slab structure.

The strength of the foundation depends on compliance. The slab should be poured onto a well-cleaned surface in layers. For a strip base, the thickness of the next layer should not exceed 40 cm. It is enough to fill the slab in one layer. After hardening, there should be no voids in it, so concrete must be poured from a height not exceeding 1.5 m, and it should be compacted well.

Return to contents

Advantages of a monolithic foundation

- Slab foundations are used on heaving, clayey and soils with high groundwater levels.

Considering that all soils containing clay are classified as clayey, it turns out that there is no need to carry out any engineering-geological studies within the construction site. - Saving on earthworks. To be convincing, let’s compare it with a strip foundation, which must be buried below the freezing level of the soil.

For example, in the Moscow region this level is approximately 1.35 m. The foundation must be buried 20 cm below this level, that is, the depth of the trench will be approximately 1.6 m.

For a house measuring 10 × 10 m with two internal load-bearing partitions, the total length of the strip base will be 55.5 m. If you dig a trench 0.5 m wide, then the total volume of excavated soil will be approximately 44 m³, not counting the fertile layer (soil), which usually removed.

In accordance with the indicated scheme, the total deformation is determined by summing the settlement of individual layers according to the formula:

s=0.8·SUM(σ zp.i ·hi)/E i , (2)

where σ zp. σ zp.с – average value of additional stress (vertically) in the i-th layer; is defined as half the sum of the stresses at the boundaries of this layer; hi – thickness of the i-th layer; E i – deformation modulus of the i-th layer kPa (kgf/cm²).

The value of additional stress in the center of the foundation is determined by the formula:

- σ zp. = а·р 0 , (3)

and at the corner points of the foundation according to the formula:

- σ zp s. = a·p 0 /4. (4)

Coefficient a is determined depending on the shape of the foundation (along the base) and on the aspect ratio (if the shape is rectangular), or on the diameter (if the shape is circular) and on the relative depth x = 2z/b (z is the depth of the layer, b is the width of the foundation ).

A slab foundation is a solid reinforced concrete structure placed under the entire area of the building and evenly supporting all possible weight loads. The standard scheme includes drainage from compacted sand and crushed stone, a slab of high-quality mortar with volumetric reinforcement and waterproofing; in particularly difficult conditions, the base is insulated. The main requirement of the laying technology is the selection of the correct thickness of these layers; the exact value is determined by the calculation. The initial data are soil parameters, type and weight of the building; during calculations it is important to comply with all design standards.

Additional data

When calculating floors, you need to determine the class of concrete and reinforcement.

However, if you know all the technical characteristics of the ceiling and at least the approximate weight that will load them, then making calculations does not seem to be a very difficult task. It should be taken into account that there are several load classifications.

So, the first type depends on the duration of the load. That is, we must proceed from the fact that they can be permanent and temporary. Constants include: the weight of furniture, people, household appliances and other items that are constantly in the apartment. This should also include the weight of the supporting structure, soil and rock pressure. As for temporary loads, these include those that arise during the construction of a building, storage and transportation of various structures.

Which base design to choose?

In the construction of wooden houses I use the following structures:

- Tiled.

- Tape.

- Columnar.

- Pile.

There are areas where it is rational to use a mixed type platform, for example, a strip-pile platform. This is a modification of one of the main types. But this is a complex structure and builders are trying to change the composition of the soil to suit one of the main types. This is how the swampy area is drained and sand washed in, or part of the soil is simply removed and covered with slag, which, when compacted, turns into concrete.

The foundation is chosen depending on the house being built. The heavier the structure, the more massive the foundation. To build a house from profiled timber or rounded logs, strip or columnar types are used. Moreover, the tape type is made shallowly recessed.

The depth of occurrence is calculated based on two main factors:

- Depth of groundwater.

- Soil freezing in the area of future construction.

There are average standards for the depth of the sole on various soils:

- Sandy loam - 125cm

- Clay and loams - 150 cm

- Sand and gravel - 100 cm

This is the maximum occurrence of the foundation of the house according to the construction GOST, but it also indicates the maximum occurrence indicators:

- For dry soil - 70 cm,

- For wet areas with close groundwater - 120 cm.

If the house according to the plan has basements, then the base of the structure should be at least 40 cm below the floor level.

Each type of foundation has its pros and cons. So, for example, a columnar one is erected in a short time, a strip one is considered one of the most durable due to the rigid connection of the structure both across and along. Monolithic is expensive, it is built in rare cases when the soil is very mobile.

Useful tips

To increase the load-bearing capacity of the floor, reinforcement is used.

When calculating the load on slabs of various production equipment, it is necessary to take into account what the standard load is (here it is worth taking into account, among other things, the weight of the pipelines). If we are talking about non-standard equipment, then you should be guided by the passport data from the manufacturing plants of such equipment. When making calculations, it is necessary to take into account the weight of conveyors, insulation, and devices. In most cases, the manufacturer indicates how much load the floor slab can withstand.

In conclusion, it should be said about snow loads, which are of great importance. There is a standard formula for this: S=SgxU. In this formula, Sg is the approximate weight of snow per square meter, and U is the snow load factor on the pavement relative to the weight of the snow cover on the ground.

During construction, it is necessary to take into account the fact that the floor slab cannot be overloaded; it will only support the weight that was obtained in the calculations. There are builders who neglect the results of such calculations, loading the slab beyond the norm. As a result of this, unpleasant and often tragic incidents occur, so the saying “Measure twice, cut once” in this regard could not be more relevant.

What affects the thickness of the screed

The main criterion for the design height of the screed is its purpose. This design is necessary in the following cases:

- creating slopes for draining liquids in bathroom stalls and bathhouse washrooms;

Beacons for creating a slope with concrete.

Floor slabs cannot be laid perfectly evenly.

Raising the floor level on the balcony.

Communications running along the floor are masked with a layer of concrete.

It is quite natural that to solve such dissimilar problems, the default minimum thickness of the screed cannot be the same.

Recommendations SP 29.13330

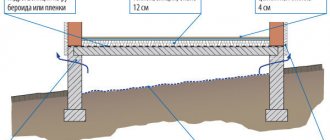

According to building regulations, the thickness of the floor screed must be as follows:

- 20 mm is the minimum for sand concrete, ensuring operation without destruction of the layer;

- 40 mm - if acoustic and heat-insulating materials are used in the screed cake, the height is measured from their surface, in fact it reaches 140 - 190 mm (if counted together with materials);

- Dt + 45 mm - the concrete layer above the heated floor contours laid inside it must correspond to this value.

Screed with heated floor.

Important! The specified values are valid only for concrete screeds made from CFRP.

Not only the height of the screed is standardized, but also the strength grade of the mixtures used:

- B12.5 – for monolithic concrete structures;

- B15 – for sand concrete;

- 20 MPa - since dry mixtures do not have an indicator of brand strength, the permissible strength limit of the hardened mortar is used for them.

When using concrete, self-leveling floors and other ready-made packaged mixtures, it is necessary to take into account the following nuances:

- the design rigidity/hardness is given to them by filler (sand, crushed stone, polymer additives);

- therefore, the screed layer should be 1.5 times larger than the fraction of this filler.

Important! For the convenience of the developer, manufacturers indicate the necessary information on the packaging of their products. If concrete is mixed on site from imported crushed stone and sand, or delivered by mixer, the developer must additionally control this characteristic.

In contrast to the permissible minimum leveling layer, the maximum thickness of the screed is limited by the design solutions of specific projects:

- level of finishing flooring in individual rooms;

- the number of insulating materials inside the screed and the thickness of each of them;

- availability of communications, underfloor heating circuits;

- economic efficiency to save construction/finishing budget;

There are no strict restrictions here, however, it should be noted that at a height of 10 cm or more, floor screeds automatically become reinforced concrete slabs. They must be reinforced with wire or reinforcing mesh:

- in the lower level - to absorb operational loads, distribute them evenly and transfer them to the lower structures (soil, floor slab, footing);

Reinforcement of the leveling layer.

Important! The basic principle for floor structures is that the bottom layer should be stronger than the top. That is, the screed must be laid on solid foundations and ensure absolute immobility of the floor covering on top of it.

Therefore, the floor slab is first visually inspected, cracks are sealed, loose areas are removed or strengthened with special compounds.

Screed materials and technologies

The height of the structure is influenced by the material from which it is made. Even when using a cement-sand mixture of DSP for mixing sand concrete, the proportions of the components may change. This applies mainly to the water-cement ratio (W/C):

- reaches 0.75 in ready-mixed concrete;

- does not exceed 0.45 units in mixtures for semi-dry cement screed.

A mixture with a minimum VC ratio for semi-dry technology.

Therefore, the following thickness values for structures manufactured using these technologies are accepted:

- 3 cm minimum for wet screed;

- 4 cm for semi-dry screed.

Important! These design characteristics are valid only in the absence of insulating layers and engineering systems that need to be laid inside it. When using a heated floor, sound-absorbing material, the thickness automatically increases.

Self-leveling flooring is a universal material; it is used both for rough screeds and for finishing floor coverings. It costs much more than DSP, so it is usually used in combination with DSP:

- sand concrete is used to level out significant irregularities of 3 cm or more, achieve the design level of the structure, cover engineering systems, reinforcing mesh and acoustic materials;

- a 5-10 mm layer of self-leveling floor is poured on top, which has self-leveling properties;

Combined leveling with different materials.

This allows you to quickly complete large volumes of work without carefully leveling the not very plastic sand concrete. Then it is ideal to level the floor plane with expensive material with minimal expense.

How to calculate the load?

As you know, concrete panels, additionally reinforced with strong metal rods, are most often used as floors in private houses. The panels have cavities that allow them to evenly distribute loads and protect the floors from damage.

When making calculations, it is necessary to multiply the length of the panels by their width. This will allow you to get an accurate indicator of the area of the floor slab. After this, you need to determine the maximum loading capacity of the ceiling. To do this, the area indicator (in square meters) must be multiplied by 0.8. The resulting value is calculated in tons. In the future, you need to subtract the weight of the slab from it.

The complexity of the calculations lies in the need to find out the exact weight and size of the floor slab. For this reason, when carrying out work, there is often a need to turn to professional builders who have special machinery and equipment.