Home / Installation, repair, maintenance / Installation of interfloor floors using wooden beams

When building their own home, many people prefer to use lighter wooden structures instead of heavy reinforced concrete floors. This reduces the cost of constructing a building and, on top of that, the interfloor flooring on wooden beams can be installed without the use of expensive heavy equipment.

Structural options for flooring on metal beams

Based on a steel profile, you can make a durable floor using various options:

- The ceiling is monolithic on metal beams. It is formed by pouring concrete into the formwork, and is additionally reinforced with reinforcing mesh. This is a practice-tested option with a range of advantages. The main advantages that attract developers are the increased strength of the seamless surface and the absence of irregularities;

- monolithic prefabricated structure. For its arrangement, blocks of cellular concrete manufactured at industrial enterprises are used. They are laid with their edges on the surface of the steel profile. Thermally insulated formwork is constructed, reinforcement is made and the joint areas are filled with concrete mortar;

- composite structure made of various materials. Standard panels, wooden boards, and slabs can be used. The base elements are installed on load-bearing steel beams. To ensure comfortable operating conditions, it is important to insulate and soundproof the formed surface, as well as seal the gaps between the elements.

Depending on financial capabilities and availability of materials, developers equally use these options.

Particularly stringent requirements are imposed on the quality and strength of floors in a building of any design.

Materials and equipment used

Various types of rolled metal are used as load-bearing beams:

- I-beam number 16 or 20;

- channel up to 20 cm high;

- corner welded into a load-bearing frame.

To form the selected design option, in addition to load-bearing elements, the following materials will be required:

- concrete mixture to form a solid base;

- standard blocks made of cellular concrete for a prefabricated monolithic version;

- planed boards or ready-made concrete panels for a composite structure.

For reinforcement, reinforcing bars are used, the diameter of which corresponds to the results of the calculations performed.

The construction of formwork will require the use of the following building materials:

- wooden panels or moisture-resistant plywood with a thickness of 2 cm or more;

- polyethylene film for waterproofing concrete mass;

- supports made of metal or wood to ensure the stability of the formwork.

For different types of houses, they use both metal and wooden beams, as well as reinforced concrete

You should also prepare the equipment:

- concrete mixer, which speeds up the process of preparing the working mixture;

- a welding machine designed for welding reinforcement cages.

No special tools are required for construction activities. A set of tools available in the arsenal of every home craftsman is used.

Advantages and disadvantages of flooring on metal beams

The design with load-bearing elements made of rolled steel has a number of advantages:

- increased reliability;

- high safety margin;

- long service life;

- increased load-bearing capacity.

By using metal structures made from steel profiles, it is possible to cover spans of increased dimensions by correctly selecting the number of rolled products used.

Expert opinion: Floors on metal beams

In the construction of a private house, the most common use is a monolithic floor on metal beams, since a prefabricated base requires the use of a heavy crane, and wooden floors are the least durable. In any case, the involvement of specialists will be required, since when assembling a mono-floor, the most important thing is to correctly calculate and design all structural components.

Along with the advantages, there are also weaknesses:

- the complexity of installation work associated with the increased weight of metal structures and the need to transport them using special devices;

- the need to perform complex engineering calculations confirming the load capacity of foundations being constructed based on steel profiles.

Disadvantages also include the metal's susceptibility to corrosion processes, which reduce the strength of structures. However, with the help of special coatings it is possible to reliably protect the metal and ensure the durability of metal structures throughout the entire period of operation of the building.

Metal beam ceilings are very durable and reliable

Advantages

The design of floors is most often used in individual construction, since it provides excellent thermal insulation of the room. This technology is suitable for one-story houses and premises with. The maximum width of the span that needs to be covered should be 5 m. It is possible to install floors using the technology for installing wooden beams without experiencing any particular difficulties; the main goal is to install beams supported by load-bearing walls.

Wooden beam floors are used for span widths of no more than 5 meters.

Install interfloor, attic, basement and basement floors. The purpose of installing an attic floor is to separate the living floor from the attic space. It is necessary to use a protective layer of vapor barrier. separate the floors of the room, which requires sound insulation to a greater extent than thermal insulation. Basement floors should separate the residential floor from the basement. Basements should separate the living floor from the underground. For the attic floor, as for the basement, a high level of thermal insulation is required.

Despite the fact that the use of wooden beams is associated with a fire hazard, the presence of a number of advantages in wooden floors suggests the following main advantages of the structure:

- Availability of acoustic capabilities.

- A light weight.

- Low cost of construction and installation of floors.

- Thermal insulation qualities.

- Simple and convenient assembly technology.

- High installation speed.

- Performing installation of floors at low temperatures.

- Various ways to use ceilings, from basement to attic.

- Assembly does not require the use of special equipment.

Calculation of floors using metal beams

It is necessary to take a responsible approach to performing calculations when deciding to make a floor or ceiling based on steel profiles.

In this case, it is necessary to take into account a number of factors:

- total weight;

- load capacity;

- area of the formed surface;

- distance between beams;

- span width.

The selection of a suitable number of rolled metal products corresponding to the profile height is carried out taking into account the perceived load.

Load bearing capacity is:

- 0.075 t/m2 – for attic floors;

- 0.150 t/m2 – for the basement base and interfloor foundations.

As the span width increases, the height of the steel beams increases:

- strength over a six-meter span is provided by I-beam No. 20 with a profile height of 200 mm;

- when the distance between the walls is reduced to 4 m, I-beam No. 16 with a height of 160 mm can be used.

Knowing the area of the monolithic surface, it is easy to calculate the need for concrete. To do this, multiply the area by the height of the concrete mass. Having a drawing of the reinforcing lattice, you can calculate the need for steel rods to strengthen the base. All calculations are made on the basis of pre-developed design documentation or a working sketch.

However, they also have a drawback - they are susceptible to corrosion.

Flooring on I-beams - preparatory work

At the preparatory stage, perform the following activities:

- Decide on the material that is supposed to be used to make the ceiling of the room, and also study the sequence of actions.

- Develop a working drawing that provides complete information about the design features of the ceiling and the range of materials used.

- Perform calculations confirming the strength characteristics of the building structure and the safety margin necessary for long-term operation.

- Calculate the need for building materials, estimate the amount of expenses, and prepare tools.

- Mount the I-beams, maintaining an interval between the supporting elements of 1–2 m and check the correct installation using a level.

- Assemble panel collapsible formwork along the lower level of the I-beam using laminated plywood or planed boards, provide a flange 15–20 cm high.

- Anchor wooden beams or steel spacers to ensure the formwork structure remains stationary and must support the mass of concrete.

When installing supports, install one wooden beam for each square meter of area, and metal elements 2 times less often. The use of telescopic racks will significantly facilitate the work of fixing the formwork structure. Having completed the preparatory activities, proceed to the main work.

Correct calculation of flooring on metal beams is very important

Types of floors for aerated concrete

- monolithic;

- reinforced concrete slabs;

- aerated concrete slabs;

- wooden or metal beams.

Slab floors

Floor slabs can be reinforced concrete or aerated concrete. Aerated concrete floors are lighter than reinforced concrete; aerated concrete slabs are assembled into a monolithic sheet thanks to a tongue-and-groove system. If slabs without grooves and ridges are used, then reinforcement is placed in the gap between the slabs and sand-cement mortar is poured. Aerated concrete floor slabs are reinforced with mesh; they can withstand a load of 600 kg per 1 square meter, which is quite enough for an individual residential building.

Diagram of aerated concrete slab floor installation

Aerated concrete slabs for floors can be of different sizes. The slab floor should be 20 centimeters longer than the span, so that it extends 10 centimeters onto the wall on each side.

Reinforced concrete slabs are similar to aerated concrete slabs, but they are much heavier, so when using them it is necessary to accurately calculate the load.

The advantages of slab floors include:

- quick installation;

- good noise and heat insulation;

- high load-bearing capacity;

- affordable price.

Monolithic floors

For a monolithic floor, a reinforcement frame is made, which is filled with concrete. The thickness of the monolithic floor can reach 300 mm. A monolithic floor can be of any shape - this is the main difference from a slab floor, which can only be rectangular. Monolithic flooring has a high load-bearing capacity - up to 800 kg per square meter, but it is quite time-consuming and expensive to make.

Monolithic ceiling device

Ceilings on beams

For this option, metal or wooden beams are used, on which plywood or boards are laid, and the space between the beams is filled with expanded clay, mineral wool, polystyrene foam or other insulation materials. This is a proven and inexpensive way to make interfloor slabs.

An example of a wooden floor in a house made of aerated blocks

We install a monolithic ceiling on metal beams

Developers are attracted by the solid structure, made of concrete reinforced with reinforcing lattice.

After installing the metal beams, constructing the formwork and ensuring its stability, carry out work on forming a monolithic reinforced concrete slab according to the following algorithm:

- Check for any gaps in the wooden formwork and, if necessary, seal them.

- Assemble the reinforcement frame using metal rods with a section size of 10–12 mm.

- Place the frame in the formwork, ensuring a constant interval of 4–5 cm to the surface of the future concrete slab.

- Pour the concrete mixture into the formwork and thoroughly compact the concrete mass using a vibrator.

- Do not expose the hardening mortar to loads for 4 weeks and then dismantle the formwork.

Pay attention to the size of the supporting surface around the perimeter of the slab, which should be more than 150 mm.

Installation of reinforced concrete interfloor covering on metal beams in the old building

| Naboka Alexander Andreevich St. Petersburg Polytechnic University of Peter the Great (St. Petersburg, Politekhnicheskaya street, 29), [email protected] |

| Key words: reinforced concrete flooring on metal beams reconstruction replacement of flooring units of the floor structure flooring on a profile sheet major repairs | Abstract: Reconstruction and major repairs of buildings have been gaining momentum in recent years. For the central regions of large Russian cities, the problem of eliminating the accident rate of building structures is very relevant. There are a number of regional programs for carrying out major repairs in multi-apartment residential buildings. The article provides design solutions and recommendations for the installation of reinforced concrete floors on metal beams in the old housing stock. |

Main text

In [1] they refer to UNESCO statistics, according to which more than 50% of all European residential buildings were built in the period before the 50s of the last century. The need to repair or reconstruct a large number of residential buildings is now beyond doubt. Thus, in St. Petersburg there is a regional program for the overhaul of common property in apartment buildings in St. Petersburg, for which it is planned to allocate about 32 billion rubles from 2020 to 2020 [2].

Carrying out such a volume of work requires the involvement of a large number of specialists in the field of design. The work contains design solutions for the installation of a new interfloor ceiling in order to facilitate, reduce labor costs and optimize the design process. It is worth noting that the design solutions given are not binding and, in the opinion of the author, are purely advisory in nature and may contain errors and inaccuracies. The application of a particular solution must comply with existing standards and be confirmed by calculations.

The building structures of the old housing stock are not only outdated - the layouts are outdated and the quality of engineering equipment does not meet modern standards, but also physically - individual structures outlive their operational period and are not able to meet the strength and reliability requirements imposed on them at the time of construction. The main causes of physical wear and tear [3] are both time, a long period of use, and operating conditions - untimely and improper care and repairs.

Defects and damage, as well as the causes of their occurrence characteristic of a particular type of structure, can be found in [4].

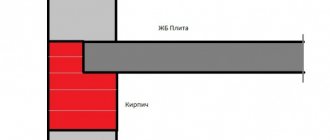

We are interested in overlaps. The most common types of floors in old apartment buildings are floors on metal and wooden beams. Floor structures are shown in Figures 1 and 2.

Figure 1. The most common design of interfloor ceilings on wooden beams in the old foundation

Figure 2. The most common design of interfloor ceilings on metal beams in the old foundation

When carrying out a major overhaul, it may be discovered that the existing load-bearing beams are in poor condition and require replacement. Then there is a need to install a new floor. The simplest design is a reinforced concrete floor on metal beams using a profile sheet as permanent formwork. Further solutions for the arrangement of this floor will be considered.

First of all, you need to install the metal beams. It is better to use rolled profiles as load-bearing beams. Figure 3 shows a node for supporting a metal beam on a load-bearing brick wall of a house.

Figure 3(a). Beam support unit on brickwork

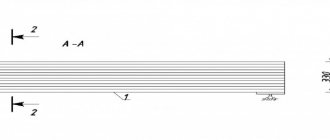

Figure 3 (B). Supporting unit for a beam on brickwork. Section A-A

Figure 3 (B). Supporting unit for a beam on brickwork. Section B-B.

Where, 1 – stiffener; 2 – support sheet.

The stiffener is installed to ensure the stability of the beam and prevent bending of the I-beam flange. The support sheet is necessary to distribute the load on the brickwork.

Other design options for the support unit can be found in [5].

The span between load-bearing walls sometimes reaches 6 m or more, and it is not possible to deliver a metal beam to the mounting mark in one piece due to its large weight. Narrow entrances, the impossibility of installing lifting mechanisms and equipment for lifting beams - all these are the difficulties that builders encounter. Then it becomes necessary to make an equal-strength installation joint, shown in Figure No. 4.

Figure 4. Equal-strength assembly joint of beams.

The most popular is the assembly joint, in which the top and bottom plates are the same in width and wider than the I-beam flanges. But in construction conditions, for the convenience of welding work, the upper plate can be made narrower than the I-beam shelf, then the lower one should be enlarged. (This is exactly the joint shown in Figure 4).

All metal elements must be protected from corrosion. A typical solution is a layer of GF-021 primer and 2 layers of PF-115 enamel. Fire protection measures for metal structures should also be taken into account.

After installing the beams, they begin to install a reinforced concrete slab along the top flange of the I-beam and inter-beam filling.

The predominant way to install reinforced concrete slabs in the old foundation is to use corrugated sheets as permanent formwork. (If the designer decides to use a profiled sheet also as working external reinforcement, the requirements specified in [6] should be taken into account).

Profiled sheets should be joined together along the longitudinal edges with an overlap using self-drilling screws or rivets with a pitch of no more than 500 mm. They should be attached to load-bearing metal beams using metal screws in each corrugation on the outer supports and through the corrugation in the intermediate ones.

The profile flooring should be selected depending on the pitch of the beams so that it can withstand the load from the weight of the slab until it gains strength.

Figure 5 shows a possible floor reinforcement scheme.

Figure 5. Scheme of reinforcement of a floor slab using a profiled sheet.

The reinforcement consists of longitudinal rods laid in each corrugation of the corrugated sheet and upper reinforcing mesh with a pitch of 150-200 mm. The frame elements are connected either by welding or using steel wire.

Figure 6. Flooring on metal beams using profiled sheets as permanent formwork

The sound attenuation in a reinforced concrete floor slab is too low, so additional sound insulation is necessary to ensure comfortable living conditions and reduce noise levels. There is a wide selection of heat and sound insulating materials on the market, and depending on your budget, you can select the required material. To fix the material on the bottom shelf, use a profile sheet or separate profiles. As a finishing touch, you can use plasterboard facing panels.

At the end the overlap pie will look like shown in Figure 7

Figure 7. Final overlap pie

This overlap will allow you to implement any layout; however, the partitions should be made of lightweight materials, for example, gypsum plasterboard. Possible options for partitions can be found in [7].

It is worth noting that the installation of such an overlap may be accompanied (depending on the type of initial overlap) by an increase in loads on the walls and foundation. When replacing floors on more than just one floor, an inspection should be carried out to ensure that the walls, foundation and base are able to withstand the design loads.

Conclusion.

A sharp increase in the volume of major repairs and reconstruction work carried out in the old building indicates the need to develop standard solutions.

The article contains design solutions and recommendations for the construction of a new floor, which are widely used in rear reconstruction. All accepted materials must be certified and comply with current regulatory documents.

Bibliography

1. Savyovsky, V.V. Repair and reconstruction of civil buildings / V.V. Savyovsky, O.N. Bolotskikh. – Kharkov: Publishing House “Vaterpas” 1999. – 287 p.

2. Decree of the Government of St. Petersburg dated December 8, 2016 No. 1127 (short-term plan for the implementation of the regional program for capital repairs of common property in apartment buildings in St. Petersburg in 2020, 2020 and 2020)

3. Rabinovich G.M. Twice born / G.M. Rabinovich. – Leningrad: Stroyizdat, (Leningrad branch Leningrad, Ostrovsky Square, 6) 1971. – 112 p.

4. Fizdel, I.A. Defects and methods for their elimination in structures and structures (2nd edition, supplemented and corrected) / I.A. Fizdel. – M.: Stroyizdat. 1970. – 175 p.

5. TsNIIproektstalkonstruktsiya. Series 2.440-1 Issue 1. Frame and hinge units of beam cages and connections of crossbars to columns / TsNIIproektstalkonstruktsiya, VNIKTIstalkonstruktsiya Ministry of Montazhspetsstroy of the USSR, VNIPI Promstalkonstruktsiya - approved 12/15/1981 Gosstroy USSR (State Committee of the Council of Ministers of the USSR for Construction Affairs)

6. JSC "TSNIIPSK im. Melnikov." STO 0047-2005 Steel-reinforced concrete floors with a monolithic slab on a steel profiled flooring. Calculation and design / JSC TsNIIPSK im. Melnikov", CJSC "Hilti Distribution Ltd" - M. 2005 - 63 p.

Stages of construction of a wooden floor between floors

The advantage of a multi-storey building is obvious - a large living area with the same external dimensions. Figuratively speaking, by placing floors on floors, you can double the usable space.

This is actually not difficult, the only thing that needs to be thought through in advance is the design of the floors. Concrete creates excess load on the walls, steel is difficult to process.

Wooden floors between floors are the best choice for a country house. It is only important to accurately calculate its parameters and choose high-quality materials.

Interfloor ceiling on metal beams

The task of floors in a building is to perform load-bearing and enclosing functions, to ensure the spatial rigidity of the structure, its stability, to separate floors, to connect walls to each other, transferring the load to them. In low-rise construction there are several options for arranging interfloor floors. One of them is flooring using metal beams. They can also be used for attic and basement floors.

Advantages of metal floors

Metal structures, unlike wooden beams, are more reliable in terms of fire safety and resistance to biological hazards (mold, mildew). They:

- much stronger than wooden beams, with a smaller thickness they can withstand heavy loads. Their use allows you to save space and provide more usable space;

- can be laid on spans up to 24 meters. The I-beam (channel) section of rolled metal remains static, is resistant to changes in the amplitude of the floors, and is not subject to deflection.

The disadvantages of metal floors include low thermal insulation and sound insulation parameters, as well as the likelihood of corrosion. The latter can be prevented by thorough anti-corrosion treatment of the metal before installation. To eliminate shortcomings in sound insulation, the ends of the I-beams are wrapped in felt, tightly sealed into brick walls with cement mortar, and fixed with anchor bolts.

The large weight of the metal may require the use of a crane when installing the structure. It will be very difficult to change the size of beams, cut or extend them using a welding machine. As a result, it is necessary to very accurately measure the dimensions of the spans before ordering rolled metal from the enterprise.

The only restrictions in the use of floors on metal beams are the financial side, as well as the size and type of structure. The load-bearing part of the building, the walls of the building, must withstand the weight of rolled metal, so before purchasing materials, you need to calculate the loads on the beam floors.

Calculation of beam floors

When choosing the section of I-beams, channel or angle, take into account the installation pitch (no more than one meter), the width of the span, the total load from the roof and roll-up. For the attic floor, the calculated value is 75 kg/sq.m. m. When installing interfloor and basement floors, the working load almost doubles (150 kg/sq. m), so the section of the long products is also increased. It must have sufficient load-bearing capacity.

Types of interfloor ceilings on metal beams

During the construction of private houses and cottages, rolls onto the floors using metal beams are done:

- wooden, when the openings between the channels are filled with boards. This is a combustible fill option;

- using a lightweight reinforced concrete slab (fireproof filling);

- monolithic;

- monolithic on the load-bearing corrugated sheet, the latter has a high profile and additional stiffening ribs.

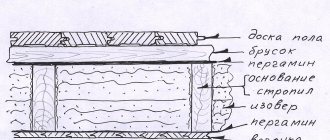

When arranging wooden flooring over metal beams, wooden panels are laid between the I-beams. Shingles are nailed to them from below and the ceiling of the lower floor is plastered. To arrange the floor of the upper floor, wooden joists are placed on steel beams, and the floor is placed on them. In the space between the floor and the panels, waterproofing of the corresponding elements is arranged, and sound-proofing material is poured.

When using prefabricated reinforced concrete slabs, they are laid on the upper and lower flanges of the I-beam, caulking the lower reinforced concrete slabs with cement mortar and pouring sound insulation on them. A mesh is welded to the beams below, on which the ceiling is plastered. You can put OSB on top, and then the floor.

Reinforced concrete monolith has better characteristics in comparison with reinforced concrete slabs. Thanks to its monolithic structure, it has better thermal insulation and noise absorption parameters. When starting to calculate a monolithic floor using metal beams, take the outer perimeter of the load-bearing wall as a basis. To create the formwork, use waterproof plywood and support it with temporary supports. To independently calculate the thickness of the slab, select the range of reinforcement or mesh for reinforcement, use the relevant reference books and manuals on the design and reinforcement of reinforced concrete structures, SNIPs.

Manufacturing a monolithic floor using a profiled sheet is a relatively new technology. Corrugated sheeting (fixed formwork) is fastened on top of the steel beams with self-tapping screws, and the sheets are also fastened with them. To eliminate subsidence of the profiled sheets, temporary supports are placed under them. To increase the strength of the structure, reinforcing rods are placed in the grooves of the corrugated sheet.

Correct calculations, adherence to installation technology and quality of materials - all this determines the quality of the interfloor covering.

Material selection

First of all, this design is functional, therefore, the interfloor ceiling on wooden beams must be reliable. It is important to understand that it must not only withstand its own weight, but also the weight of the furniture located on the top floor, and the weight of the people there. Consequently, high quality requirements are placed on the material used, especially for beams.

As already mentioned, the best material for beams is coniferous wood. The choice of wood should be taken with all possible responsibility. Basic requirements for the material:

- minimum humidity, its value should not exceed 14%;

- minimum knots per unit length;

- there should be no pronounced cross-layer;

- absence of cracks, rot, darkening, traces of pest activity.

To ensure the durability of the ceiling, all wooden surfaces are pre-treated with an antiseptic and impregnated with special compounds that reduce the flammability of the material. This guarantees the durability of the structure and protects against fire.

Monolithic ceiling on metal beams

Sometimes in private housing construction this type of flooring is used - monolithic reinforced concrete, supported by metal beams (paired channels, I-beams, square pipe, etc.).

The advantage of such an overlap is that due to the fairly frequently spaced beams (from 1 m to 2.5 m on average), the overlap itself can be made quite thin (but not less than 50 mm). Such an overlap is reinforced in one layer, which also provides considerable savings.

The main disadvantage is that, according to fire safety requirements, metal structures must be coated with a special fire retardant compound, and this is not a cheap pleasure.

In this article we will consider two questions: how to make a reinforced concrete floor and how to select metal beams.

Where should I start? From the analysis of the floor plan. Let's say we have a floor measuring 4x8 m. It is more rational to place the beams along the short side of the slab, i.e. the length of the beams will be 4 meters (not counting the depth of support on the walls). The shorter the beam, the less metal we will spend on it, and the less frequently these beams can be spaced. Of course, this is not a hard and fast rule, but simply rational advice.

Next, you need to collect loads per 1 m2 of flooring. How to collect loads is described in detail in the article “Collecting loads on the strip foundation of a house.” This takes into account:

– temporary load on the floor,

– load from the weight of the partitions (it is advisable to place the beams under the partitions to avoid excessive load on the lightweight floor),

– load from the weight of the floors,

– own weight of the floor.

Then you need to set the pitch of the metal beams. Here the monolithic ceiling comes to the fore. If we make the beam spacing too frequent, we risk causing waste of both metal and reinforced concrete. If the distance between the beams, on the contrary, is too large, this will cause an increase in the reinforcement in the slab, an increase in the thickness of this slab (at the same time, the load on the beams will significantly increase), and therefore the cross-section of the beams will increase. Therefore, before starting the calculation, you always need to analyze and select the optimal distance between the floor beams. The calculations outlined below are applicable under the following conditions: there must be the same distance between all beams; the condition L 1/ L 2 > 2 must be met, where L 1 is the length of the beam, L 2 is the distance between adjacent beams.

In principle, there are several ways to calculate this type of overlap.

The first way (more labor-intensive, especially without sufficient experience, but sometimes necessary). You can specify the profile of metal beams (let’s say you already have metal of a specific profile); then, having specified the thickness of the floor and the spacing of the beams, you can collect the loads and perform the calculation of the beam. At the same time, when performing calculations, in several approaches you can determine the maximum permissible distance between beams at which the conditions of strength and deformability are met. After this, you can proceed to the calculation of the floor and determine its thickness and reinforcement. If everything goes well, good. If the thickness turns out to be greater than you specified, the calculation will need to be repeated from the beginning - until all parts of the problem come together.

Second way. The calculation begins with a reinforced concrete floor. We set the pitch of the beams and the thickness of the slab, collect the loads and perform the calculation of the slab. If necessary, we adjust the pitch of the beams and the thickness of the slab to the most economical results. We collect the load on the beam from the resulting span and select the cross-section of the beams.

We will look at the second way using an example.

The calculation is carried out for a conventionally selected slab strip 1 m wide.

It is necessary to cover a room with a plan size of 6x10 m. There will be living rooms above the ceiling - a temporary load of 150 kg/m2. Slab materials: concrete class B15, design resistance of concrete Rb = 7.7 MPa, hot-rolled reinforcement of periodic profile class A400C, design resistance of reinforcement Rs = 365 MPa.

The minimum thickness of the floor must be greater than L /35, where L is the distance between the beams.

We set the pitch of the beams - 2.5 m, the direction of the beams - along the short side of the room, the thickness of the reinforced concrete. overlap - 80 mm (which is more than 2.5/35 = 0.071 m = 71 mm), the distance from the bottom edge of the slab to the working reinforcement is 35 mm.

Fastening the timber to the wall

The most common material used for installation of interfloor, roofing and floor coverings is wood.

Especially in private buildings, since this material is easy to process, environmentally friendly, and easy and quick to install. Restrictions on the span length of wooden floors are eight meters. The main load-bearing elements are beams with cross-sectional dimensions of 5x15 cm (minimum) and 14x240 (maximum). Sometimes sanded logs of suitable diameters are used to make beams. The varieties of coniferous trees used for the ceiling are the most durable. Before installation, wooden structures must be thoroughly dried.

The quality of drying can be determined by tapping an ax on the products; the ringing and clear sound will confirm this.

The advantages of wooden floors include lightness, the ability to impart proper thermal and acoustic properties to the structure

Other structural elements are also used in floors to strengthen the beams, connect them firmly and create a reliable frame for the house. When constructing them, the following are used:

- Skull block is a 5x5cm wooden block, which, as a rule, is attached to the bottom of the beam, for hemming the ceilings below the located room.

- Subfloor boards. Even low-quality boards - unedged and unplaned - are suitable for the device.

- Floorboards are specially made, well-planed boards with tongue and groove.

- Insulation material - it can be ecowool, polystyrene foam (penoplex), rolled material for thermal insulation.

- Waterproofing and vapor barrier films that serve to prevent moisture from entering and remove condensation.

- Antiseptic impregnations, bitumen, paint, roofing felt.

- Decorative finishing materials.

Vapor barrier device in the interfloor ceiling

As mentioned above, the structure of the floors consists mainly of wooden elements, but the technology for finishing the floor and ceiling can use any modern material. Correctly installing various parts into a single floor structure is an important task; in this case, the beams will be reliable and will last a long time.

In particular, one of the important functions of floors is sound insulation. The advantage of wooden floors is that any insulating materials can be easily attached to them. The installation of decorative finishes is also good to give a modern design to the room.

Another difference between wooden floors is that they do not provide additional load. Therefore, by choosing wooden structures, it is possible to save on the construction of a reinforced foundation for the house. Proper installation of floors between the levels of the house allows the rooms to “breathe”, maintain the desired temperature and have good sound insulation. Wooden beams are very reliable and durable.

Proper installation of wooden floors between floors will eliminate noise and create a comfortable atmosphere in the house

The distance between the beams is calculated depending on the number of storeys of the building, its area and floor loads. Varies from 60 centimeters to 1 meter.

The length of the beams is selected taking into account their strong support on the walls of the building in special nests.

Attaching timber to a wall is not a simple matter. Timber has always been popular in the construction of private houses. Currently, building materials with new properties are increasingly appearing and technologies are developing. The combination of timber with new building materials and installation systems sometimes raises questions - how will it be technically correct to attach timber to different surfaces?

Fastening material is required for fastening. Today there are many types of fasteners for any connection of elements. Their differences are the scope of application and technical characteristics, which regulate the permissible load on the fastening element and fastening technology.

Corner fasteners made of metal have holes for fastening with screws, nails or dowels. Metals for corners are used that are not subject to oxidation and are quite durable. The safety margin of the corner must be taken to be at least 2, that is, the corner must withstand a weight twice as large as the weight of the element that will rest on it. At the same time, you also need to take into account and calculate which structures will rest on this beam.

Wooden beams are attached to walls for different purposes - to strengthen hanging furniture, bookshelves or decorative interior elements, as well as household appliances on these walls. When installing door frames, for cladding outside and inside, for installing a canopy over the front door or a canopy for a veranda, you also need to attach the timber to the walls.

The choice of fastening method depends on the wall material and the features of the structure being created. Of course, in the context of aerated concrete, we are not talking about attaching purlins made of timber to walls made of cellular concrete or ceramic blocks; this is impossible without installing an armored belt or structures that reinforce the support, but only about attaching bars, for example, for sheathing under plasterboard.

Also, we are not talking about attaching timber to brick and concrete walls for the construction of floors or floors with logs made of timber, since in these structures the timber and its fastening must bear significant loads. The design of fastening the timber in this case is installation into the wall during the process of laying or concreting, or resting on an armored belt.

The end of the beam is additionally impregnated with a fire-biozacite composition before embedding or laying in the wall and protected with a layer of waterproofing material. Oil-based antiseptics are not recommended because they make it difficult for moisture to evaporate. The ends of wooden beams are cut at 70 degrees so that moisture evaporates better. The gap between the niche wall and the beam is required; thermal insulation is placed in it, since the beam rests on the outer wall.

When laying timber beams on an armored belt, they are secured with special anchor plates coated with an anti-corrosion compound.

Angle fasteners are used to fasten timber to concrete and brick structures. A reliable and durable connection is possible when using high-quality metal corners that can withstand the load.

- Before installing the corner elements, mark the position and contours of the beam on the surface using measuring tools. You can use a regular plumb line and a building level, but a laser level will allow you to quickly make markings both vertically and horizontally at the same time.

- Then the corner elements are fixed with dowels, self-tapping screws, and nails are used for lighter structures. The screws are not fully tightened so that the position of the element can be slightly adjusted.

- The timber is inserted into the corners and attached to them with self-tapping screws, then the fastenings of the corners to the wall are tightened completely. The corner is clamped with fasteners, if necessary, adjusting its position exactly according to the markings.

We suggest that you familiarize yourself with the Chimney with an exit into the wall.

Drill the brick carefully, strictly at a right angle, without “losing” the drill, so as not to split the brick. Splitting can cause the brick to fall off. if a brick gets into the cavity, you will have to use an anchor-type dowel, which, when screwed into the wall, forms a knot, or a spacer dowel.

For concrete, you need a drill with a hammer drill function and durable plastic dowels for self-tapping screws; sometimes, before driving a plastic dowel into the wall, it is additionally lubricated with glue.

Perforated fasteners of angle type or flat are used. Fasteners vary in size, metal thickness and coating. Nails, self-tapping screws and screws are used. For larger nails, pre-drill holes, especially when working with seasoned wood.

Logs made of timber are secured with a locking connection and brackets, but for a roof such a connection is unacceptable, since the roof is used in completely different conditions. All elements of the roof (rafter system) are installed according to the design and calculations, and they are secured with special elements and bolt systems, sometimes additionally reinforced with brackets.

In interiors, decorative elements are sometimes used that require the beam to be fixed to the ceiling on a free suspension or to imitate such a suspension. Sometimes beam suspension is needed for structural reasons. This type of fastening is performed using a special suspension designed for a certain load. A suspension system of this type may have the additional ability to adjust the height of the beam suspension.

The suspensions are attached to the ceiling with dowels, and the second part of the fastening is installed on the beam, then the elements are connected. Practice shows that such fastenings, contrary to expectations, can withstand considerable loads. But it’s still better not to have such a risk factor over your head, and for the design, imitate a suspension, and attach the beam securely to the wall. In this case, the suspension system is installed to strengthen the fastening, and for design purposes, “for beauty.”

Errors when creating a rafter system can lead to roof collapse and leaks. At the design stage, it is important to correctly set the angle of the roof so that it can withstand the load from snow and other precipitation. In addition, you need to consider the distance between the elements so that the roof has an optimal weight.

When preparing your project, pay attention to the following points:

- roof shape;

- roofing material used;

- locations of internal supports;

- rafter system;

- at what angle the roof slope will be located;

- distance between walls.

The appearance of the future roof will depend on these points. The use of such a structural element as a Mauerlat depends on the material of the walls of the house and the distance between them. If it is less than six meters, then this beam does not need to be laid.

In the construction of light frame structures, rafters can be attached directly to the floor beams without a Mauerlat. Step-by-step instructions for carrying out this work are as follows:

- When you start working with the rafter system, you must have walls and a rough ceiling erected. Install additional supports during the work.

- Connect the ceiling beams and the top trim. Secure them.

- Install the rafters. To strengthen their block, you can use double vertical posts.

- Using racks, attach the rafter legs to the walls. After this part of the work, you can begin lathing and installing the roof.

Metal floors: production and installation

The technology of monolithic formwork manufacturing has a number of advantages compared to prefabricated formwork. Such structures are 15-20% stronger and lighter than prefabricated analogues, which increases seismic resistance, reduces the cost of the foundation and reduces the overall construction time.

When constructing buildings from monolithic formwork, designers get rid of multiple sizes and restrictions on the shape of surfaces, and receive additional opportunities for creativity. High quality materials make it possible to obtain walls and ceilings that are almost ready for finishing.

In the practice of manufacturing panel building formwork, this method is in many cases the only effective one. For example, the construction of tunnels and various hydraulic structures.

An important advantage is the transfer of the main production process to the construction site. The main elements in this case are the production of concrete mixtures and the installation of monolithic, panel formwork for walls and ceilings.

Metal floors are used as building elements for the construction of buildings of various types, including multi-level apartments and private multi-storey buildings. Using various types of metal floor beams, you can achieve significant savings on construction costs, without compromising the overall strength of the structure. In addition, such steel products weigh much less than their analogues, and their installation is carried out very quickly - this reduces the price of the product and significantly reduces the project implementation time.

Overlapping of the second level in an apartment + installation price from 112,000 rub./t

Ceiling beams in an apartment (with installation) price from RUB 89,400/t

Ceiling from metal structures in the showroom (with installation) price from 105,000 rub./t

Flooring in a private house (with installation) price from RUB 91,100/t

School floor beams (manufacturing only) price from RUB 62,000/t

Ceiling covering for a building price from RUB 81,500/t

Types and features of metal floors

Metal structures for floors are manufactured in several types, depending on their purpose of use. The choice depends, first of all, on the purpose of the building - a large industrial premises, a multi-level apartment, a house, or just a temporary structure.

1. Floors made of rolled metal

Although such metal floors are considered universal, they are most often used in the construction of large objects, usually for industrial purposes. The I-section ensures uniform load distribution and high rigidity, so the design of floors for industrial facilities can be carried out with allowances for increased pressure on the floors of the upper floors.

Such options are universal in that there is a wide selection of rental types, depending on the intended purpose of use. The varieties most often used are cold- or hot-rolled steel or expanded metal sheets.

2. Floors with load-bearing steel beams

Such metal floors are quite simple both in manufacturing and installation. Strength is ensured by adhering to existing standards for material rigidity, as well as the rules for load distribution. Any type of flooring can be easily laid on these metal floor structures, and the structures themselves can be welded or rolled, depending on the application.

Steel beams are widely used in the construction of high-rise buildings with large areas. The use of such material increases the efficiency of creating a building and makes it possible to widely use opportunities for the implementation of non-standard projects, since beams, unlike, for example, reinforced concrete slabs, are more convenient for work.

3. Monolithic metal floor beams

This option is a set of beams on top of which sheets of a certain profile are laid. The use of various options for lattice trusses instead of beams allows you to reduce the overall weight of the structure, which is very suitable for building houses or remodeling apartments. When installing floors in an apartment, you can count on overall savings in building materials and, first of all, concrete and reinforcing material without saving on strength.

The production of floor beams in the form of monolithic structures makes it possible to achieve a high degree of rigidity with low weight, and this technology allows you to operate with many types of profile shapes. Considering that the ceiling design in an apartment may imply different degrees of load on the floors of the upper floors, this option is very popular for residential premises.

Advantages and disadvantages of metal floors

Metal floors, which have recently been manufactured using modern technologies, are distinguished by their high strength and ease of installation. Unlike classic concrete or wooden ones, such options allow you to reduce the cost of building materials, since with increased technical characteristics they are much smaller in volume and easier to manufacture.

It is especially worth highlighting metal floors, which are installed in residential buildings or multi-level apartments. As a rule, such premises have a non-standard layout, especially if we talk about such a popular project as the construction of lofts. Wooden options may be unacceptable for one reason or another, and reinforced concrete ones are not at all convenient to install for rooms with an unusual design and layout. That is why metal floors have gained great popularity in this area of use.

Among the shortcomings, one can single out almost the only one - building codes require fire protection for such elements. However, this requirement is not a particular problem and all manufacturers can not only coat products with fire-resistant alloys, but also provide anti-corrosion protection, which will significantly increase the service life of building structure elements.

Factors taken into account

The frame of any house begins to be assembled with the construction of the floor.

The cross-section is determined by calculation and depends on the magnitude of the expected load and the span width of the building.

The main parts that make up the ceiling are:

- support beam;

- floor frame;

- flooring or paneling.

Section selection table

Floors are made by processing wood, which is dried for 3-4 months. Before installing the structure, in the process of preparing materials for laying or when installing floors, the following is taken into account:

- Possible load to which the structure will be subjected.

- Method of room ventilation.

- Humidity level.

- Location of heating devices.

- The structure has a roll of prefabricated boards (boards) for waterproofing and sound muffling.

- The presence of a chimney at a distance of 40 cm to wooden beams.

The presence of cracks and rot is unacceptable. Before installing the ceiling, the products should be cleaned of bast and bark and treated with an antiseptic, which will protect them from fungal damage. Cleaning should reveal oblique layers and various knots that may interfere with the installation of floors.