Composition of the mixture for the screening block

The following ingredients are used to make products:

- high-quality cement screenings;

- coarse sand;

- cleaned stone chips;

- plasticizers;

- additives that accelerate the hardening of blocks;

- dyes;

- pure water.

The technical characteristics of screening blocks and their quality directly depend on the quantity and ratio of components included in the concrete mixture.

The composition of the screening block must be selected carefully. The technical characteristics and quality of the product depend on the quantity and ratio of components. Only Portland cement M500-DO is used as a binder.

Standard dimensions of the screening block in mm:

- length - 390;

- width - 190;

- height - 188.

The volume of one block is equivalent to 8 standard bricks.

Main advantages and disadvantages of the material

- High strength and durability with full preservation of quality characteristics during the entire operational period.

- Good sound insulation.

- The fire resistance limit is 90 minutes.

- The low thermal conductivity of the screening block, due to the optimal shape, geometry and arrangement of voids, provides excellent thermal insulation and performance characteristics.

- Eco-friendly and safe for humans and the environment, due to the use of natural ingredients that do not release harmful substances over time.

- Frost resistance ≥ 50 cycles.

- The screening block is characterized by an affordable price, and the saving of mortar reaches 50%.

- Low weight (a block weighs about 16 kg) with the presence of voids creates small loads on the foundations, allowing the construction of buildings of several floors even on weak soil foundations.

- The speed of masonry is 5 times higher than with traditional bricks.

- The possibility of installing thinner walls increases the usable area of the premises.

- Easy to perform work that does not require qualifications.

- No need to use heavy lifting equipment.

- Versatility of use.

Disadvantages of the ejection block

- the material allows the construction of a wide variety of structures from multi-storey buildings to cottages, outbuildings and fences, but has an unsightly appearance when dyes are not used;

- violation of manufacturing technology leads to loss of strength; during transportation and storage, cracks and breaks appear in the blocks.

- the cost is slightly higher than similar block products.

Aerated concrete wall block "GRAS" D400 B2.5 600*300*200

The composition of aerated concrete wall blocks includes sand, Portland cement, water and lime; aluminum paste or powder is also added during the production process, which promotes the formation of a cellular structure. Thanks to this structure, the material is endowed with excellent thermal insulation characteristics.

Application of GRAS wall blocks

- For external load-bearing and internal load-bearing walls in low-rise construction

- For filling external self-supporting walls in multi-storey frame-monolithic housing construction

Advantages of Grasse blocks

Environmental friendliness . The blocks are made from safe and clean materials: cement, sand, water, lime - only traditional raw materials. The blocks do not release toxins over time and do not absorb harmful substances.

Durability . The GRAS block production technology uses the optimal ratio of structure density and strength. The blocks are porous, resulting in lower weight. Excellent for the construction of high-rise buildings and for the installation of load-bearing structures.

Frost resistance . Thanks to their porous structure, GRAS aerated concrete blocks cope well with many freezing and defrosting cycles. No changes are observed in the blocks even in buildings that have been in operation for 35-40 years.

Fire safety . Aerated concrete does not contain materials susceptible to combustion. That is why GRAS blocks are excellent for ventilation shafts and firewalls.

Energy efficiency . Allows you to save on heating costs. The porous structure helps retain heat 6-10 times more efficiently than classic concrete or brick. A house made of aerated concrete is cool in summer, warm in winter.

Seismic resistance . Aerated concrete blocks are actively used in areas with increased seismic activity due to their combination with reinforced elements.

Dimensional accuracy. The aerated concrete manufacturing process guarantees consistently accurate dimensions. The deviations are so minimal that after laying the wall the surface is ready for applying plaster. Often readiness is achieved by applying thin putty to the interior walls, as a base for painting or wallpaper.

Good sound insulation . Sound insulation is achieved thanks to the porous structure of the blocks. Speed of installation and ease of processing Construction of buildings from aerated concrete blocks reduces time costs by 2.5 times compared to brickwork. Aerated concrete is easily processed with standard tools (drill, saw, milling cutter). For laying cables and channels, ordinary power tools are used.

Economical . The price of GRAS aerated concrete is from 2800 rubles. per cubic meter, which is 2-3 times lower than brick. Plus savings on construction time. Plus savings on transportation. Plus minimum costs for external finishing. All this will reduce the price of construction by 20% compared to a brick one.

Do-it-yourself screening blocks

It is almost impossible to achieve decent quality products at home without special equipment. Without renting large areas, it is recommended to purchase a low-power mini-line with a capacity of 100 blocks per hour.

The minimum kit includes:

- equipment for making blocks;

- dispenser of incoming components;

- mixer, which is used to sort and mix components;

- drying chamber, without it drying will last about a month;

- brick making press with a set of special dies;

- storage of pallets with finished products;

- roller conveyors for delivering finished blocks to a temporary warehouse.

The cost of such a line is about 1,000,000 rubles, the payback period is about 6 months. Required area - 50 square meters. m. The workshop must be supplied with electrical energy, water supply and sewerage. In the future, production can be easily expanded.

How to make a screening block

The process is not particularly complicated, but requires adherence to technology.

Work order:

- Purchase and selection of quality raw materials.

- Selection of the required proportions of concrete mixtures. To obtain products of the desired brand, it is necessary to select the correct ratio of all components. The correct proportions of concrete for screening blocks are determined by subtracting one part of crushed stone and sand from the basic proportions of concrete of the required class and replacing them with a plumb line. For example, take one part of cement, 2 parts of sand, 3 parts of crushed stone and 2 parts of screenings. Screening will give the structure additional strength.

- Mixing the components to produce a rigid concrete solution. Concrete preparation must be carried out at temperatures ≥ +10 degrees, and humidity from 40 to 60%.

- Loading concrete into molds and subsequent compaction.

- Removing blocks from molds and creating conditions for storage until they gain strength.

- In the absence of drying chambers, the storage temperature should be 20 degrees with the need to regularly moisten the products.

A house made from a screening block, made using innovative technology, is distinguished by its reliability and durability, natural environmental friendliness and ease of use, and its affordable price and reduced construction time have made it especially attractive for Russian individual developers.

- Wall kit

Screening block

Wall block made from screenings is a modern, highly efficient building material that has a number of significant advantages compared to traditional building materials. A huge advantage of the screening block is that its use can significantly reduce construction costs, which means that now many more people will be able to finally make the dream of owning a private home come true.

What is important is that the screening block is recognized throughout the world as an environmentally friendly building material, since it is made from natural raw materials. To produce screening blocks, high-quality cement, stone chips (sand from crushing screenings), and especially coarse-grained sand 2.5-2.8 microns are used. etc. The material itself used to make a wall block from screenings, the optimal shape, geometry and arrangement of voids in the screening block provide it with excellent thermal insulation and performance properties.

Screening blocks are successfully used in high-rise housing construction, in the construction of cottages, garages, outbuildings, fences, for the construction of interior and inter-apartment partitions, etc.

Screening blocks have been and remain one of the most popular materials for building walls in any type of construction. They are durable, easy to use, and not only a professional mason, but also any private developer can lay a wall from them.

The use of wall blocks in construction allows:

- increase the usable area of the premises by reducing the thickness of the walls (the load-bearing capacity of masonry made from screening block is 20% higher than that provided for by SNiP “Stone and reinforced masonry structures. Design standards” for masonry made of ceramic bricks of the same thickness);

- dramatically increase the productivity of the construction process (the installation speed of a screening block is 4-5 times higher than the installation speed of bricks for the same volume being built);

- save up to 50% of the solution on the construction of a structural element. At the same time, the total mass of 1 m³ of masonry from the screening block will decrease by 1.3 times, which in turn will reduce the load on the foundation;

- reduce the cost of general construction work on laying screening blocks, compared to using conventional bricks, by 30-40%.

Thus, the high productivity of construction from screening blocks, the absence of the need to use complex lifting mechanisms and the reduction of the building area leads to a sharp reduction in the unit cost of 1 m² of wall block.

Characteristics of screening blocks

| Size (Width x Height x Length), mm | (400 x 200 x 200) |

| Block weight, kg | 16 |

| Number of pieces in 1m3 | 63 |

| Equivalent of one block (in size) to a brick, pcs. | 8 |

| Product brand by compressive strength | M100 |

| Block density including voids kg/m3 in dry condition | 1650 |

| Airborne noise insulation index for a single unit, dB | 45 |

| Fire resistance limit, min | 90 |

| Water absorption | 8 — 9 % |

| Thermal resistance coefficient | 0,46 |

| Frost resistance indicator | 50 |

| Number of products on a pallet, pcs | 60 |

| Weight of packed pallet, kg | |

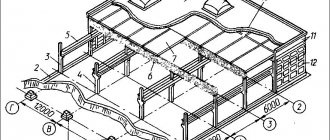

Aerated concrete block plant

The GreenBlok aerated concrete products plant produces building wall and partition blocks from aerated concrete.

The products have impeccable quality and technology. GreenBlok LLC is equipped with new modern certified equipment, its own warehouses for raw materials and finished products. The company operates successfully, providing the supply of high-quality building wall materials, which are in high demand in modern construction. Using modern technologies and strict regulations, the company produces wall blocks from cellular concrete-aerated concrete, the most popular and in demand in the modern building materials market.

The modernization and automation policy is aimed at achieving high standards of productivity and quality of products. The professionalism of the team and the quality control system at all stages of production guarantee our customers the quality, reliability and durability of the finished product.

In 2013, the first ASM-40K conveyor-type line for the production of wall blocks made of cellular concrete (aerated concrete blocks) with a capacity of 40 cubic meters was put into operation. m of aerated concrete per day. This equipment allows us to produce a product that meets all the requirements of the modern construction market and ensures compliance with all GOST, sanitary, hygienic and environmental standards. In 2020, it is planned to launch a second line with an increased capacity of 100 cubic meters. m. per day.

Compositions and proportions of mixtures for making cinder blocks

A cinder block is a building product that is manufactured industrially or by handicraft. The production uses the method of vibration pressing of concrete in special forms.

Cinder block is one of the most popular building materials due to its low cost composition and low manufacturing cost.

What makes the product popular is the abundance of materials in the working solution—what the cinder block is made of.

Materials for making cinder block

The standard solution for the production of wall stone includes mixtures, materials and substances such as slag, coal ash, combustion waste from blast furnaces and open-hearth furnaces. But in practice, the presence of just such components is not necessary - most often the filler that is most common in the region is used. For example: perlite, gravel, crushed stone, limestone, expanded clay, sawdust, sand and gravel mixture.

If you maintain the correct proportions when adding non-traditional building materials, you can not only increase the strength of the building stone, but also reduce its cost. Reinforced cinder block is produced in accordance with the requirements of GOST 6133-99.

Only a few points are mandatory for compliance with GOST, namely:

- Compliance with the color of the mixture according to the sample.

- Compliance with the rectangular shape according to GOST.

- The amount of voids or fullness.

- The thickness of the walls and partitions of hollow wall cinder blocks is not less than 20 mm.

- The symbol of the product must contain the abbreviated designation of the stone - K, the area of use and construction purpose (S - masonry walls or P - partitions, L - front block or R - row block), type of block for laying (PR - row block, UG - corner , PZ - dressing block), with voids (PS - hollow product), length in cm, frost resistance grade, strength grade, average density coefficient and GOST.

An example of designation of a product with a length of 410 mm, strength grade 50, frost resistance grade F75, average density 1800 kg/m3: KRL-PZ-PS-41-50-F75-1800 GOST 6133-99.

The composition of the mortar for the production of cinder blocks according to GOST 6665-91 “Concrete wall stones. Technical specifications":

- Cement M-400 class D 20.

- Purified and sifted quartz sand for the mixture.

- Screening is a material that is obtained by crushing rocks, gravel or crushed stone.

- Water.

The mixture for preparing blocks is prepared in the following proportion: sand, cement and slag in a ratio of 3:1:5. Adding water is 0.5% of the amount of cement. If the cinder block is pressed without the use of sand, then the following proportions must be observed: 1:9 with the same water consumption.

It is recommended to dry the product until the product is completely hardened for 20–30 days at high air humidity and a temperature of 20 °C (requirements of GOST 6133-99). To speed up the hardening of concrete, plasticizers can be added to the solution. The blocks can be placed on a pallet 4 days after complete drying. In winter, hollow wall stone should be laid with the voids facing down to avoid cracks.

Note to the table:

- Hollow wall block, size 188x190x390 mm.

- The total volume of one wall stone is 0.0139 m3.

- The volume of solution per block is 0.01 m3.

- The number of blocks in 1 m3 is 72 pcs.

- Strength grade: M75.

- The cost of materials depends on your region and may vary.

Cinder block refers to wall stones, which are made from materials mixed in different proportions according to the standard regulated by OKP 57 4130, which gives an idea of the use of materials for the production of wall stone groups that differ in the content of substances.

The dimensions of cinder blocks can vary within +/- 2–10%, since this parameter is not strictly defined by GOST 6133-99 (deviations in size are allowed), but the operational, physical and technical characteristics of the wall block must comply with the standards. Pigmentation of a cinder block is also regulated by GOST 13015.0-83 and GOST 6133-99, which state that the color of the front surface of a cinder block must correspond to duly approved samples.

Concrete blocks: types, characteristics and process of self-production

One of the most common materials for the construction of load-bearing walls and partitions of residential buildings, as well as small industrial buildings, are concrete blocks. Their popularity is due to their low cost, excellent performance characteristics and a large number of varieties, which allows you to choose the right block for almost any task.

The instructions given in this article will help you learn how to make concrete blocks yourself, and will also introduce you to their existing types.

Concrete blocks for walls

Types of artificial stones made of concrete

Let's look at the main types + characteristics of concrete building blocks, which are most common in modern construction.

cinder block

These wall stones are made using the method of vibrocompression of concrete mortar on special platforms.

The composition of the mixture from which the cinder block is made may include:

- crushed stone for concrete products;

- brick fight;

- sawdust;

- expanded clay

The technical characteristics of concrete blocks with slag leave much to be desired, but due to the fact that their price is one of the lowest on the market, cinder blocks are widely used in private construction.

But cost is almost the only advantage, since they lag far behind other materials in the following parameters:

- durability;

- heat-saving parameters;

- strength.

The main area of application for blocks is small buildings that will not be subject to heavy loads:

- sheds;

- garages;

- summer kitchens;

- workshops and so on.

Photo of cinder block

Arbolit

A less common material that is made from the following components:

- organic matter (mainly wood);

- binding element (powder);

- hardener.

Essentially, this artificial stone consists of sawdust encased in a concrete shell.

The advantages of the material are obvious:

- light weight of the concrete block;

- high thermal insulation properties;

- good sound insulation;

- efficient air exchange.

To protect the blocks from the negative effects of the environment, the stones are treated with a special solution. This prevents mold from forming and prevents rotting.

Wood concrete is perfect for the construction of small houses that are suitable for year-round living without the use of additional thermal insulation.

Arbolite block

Gas blocks and foam blocks

Cellular concrete blocks, according to GOST, which determines their technical characteristics, must consist of 70-85% artificially created pores (cells) filled with air. The most common are foam and gas blocks.

These materials have the following advantages:

- They are light in weight, as a result of which transportation of concrete blocks and their installation in private construction does not require the use of special equipment;

- easy to process - you can give the cellular block the required shape using an ordinary hacksaw for wood;

- walls made of cellular concrete blocks retain heat well and have excellent sound insulation properties.

Cellular concrete blocks are made from a solution containing sand, cement and aggregate. To form foam, lime, aluminum powder or another foaming agent are added.

Note! Unlike foam concrete, aerated concrete undergoes additional processing in an autoclave oven, where it is exposed to high temperature under high pressure (10-12 MPa). As a result, this material acquires increased strength: it is almost impossible to crumble or break it.

Cellular concrete block

Self-production of blocks

The technology for producing artificial stone from cement mortar with filler is relatively simple, which allows you to make concrete blocks yourself.

Preparatory work

At the initial stage, the dimensions of the future block should be determined. In the case of self-production, the parameters of each individual element are taken based on the required wall width.

The thickness of the bottom of the block should not be less than 2 cm, and the walls of the voids should not be less than 4 cm. In this case, a standard stone measuring 20x20x40 cm with voids inside weighs about 40 kg, which makes it convenient for laying walls.

For production you will need any flat area covered with plastic film and special molds without a bottom.

The materials for the forms will be:

- boards;

- chipboard;

- plywood.

To protect the wood from damage, the inside of the mold is lined with sheet metal. Inserts are made in a similar way, thanks to which voids are formed in the finished block. They improve the thermal insulation properties of the material and make it lighter.

Molds for making concrete blocks

You can produce concrete blocks with your own hands faster if you make several forms at once in one block. To do this, you need plywood or a board with a width equal to the height of the future block. The material is sawn into pieces and fastened with self-tapping screws. Next, internal partitions are made.

Advice! In order for the frozen block to be easily separated from the mold, all its parts must be lubricated with kerosene, machine oil or antifreeze.

Manufacturing process

To cast concrete blocks, you will need the following materials:

- fine gravel;

- cement;

- sand;

- water;

- lime;

- wire for reinforcement.

The quantity of each component is determined based on your needs for artificial stone. The proportions of cement, sand and gravel are taken in the ratio 1:3:5.

It is better to use a concrete mixer to mix the concrete solution.

For ease of presentation, we will divide the entire subsequent process into several stages.

- Gravel, sand and cement should be placed in the concrete mixer . Then, while stirring, add lime in small portions. At the last stage of kneading, water is added. The finished solution should not be too liquid so as not to leak out of the mold. As a result, you will get concrete grade M135 with fine gravel aggregate.

- The mixture is poured from a concrete mixer into the molds in a layer 2 cm thick . After this, the liners are fixed, which are necessary to form voids inside the artificial stone. The inserts can be fixed using transverse slats, which are removed after filling one third of the form with concrete.

- It is advisable to cover the bottom of the mold with newspapers or paper . This will prevent the concrete from setting to the base. The mixture with which the mold is filled must be semi-dry. This is checked this way: taking a little solution, crush it and place it on a flat surface. The lump should retain its shape and not spread.

- After filling the form up to half the height, reinforcement should be laid, which will make the future stone more durable.

- Instead of liners, empty bottles can be used to form voids inside a concrete block . It is closed with a cork and walled up inside the stone.

- After the final filling of the form, the solution must be compacted and leveled using a trowel..

- You can remove the blocks from the molds on the 4-5th day, but you can use them in work only after 2-3 weeks, as soon as the solution has completely hardened.

Self-made concrete block

Conclusion

The technology described above allows you to make concrete blocks with your own hands without using much effort. The technical characteristics of the finished products will be almost in no way inferior to analogues sold in construction supermarkets, and the size will ideally match your needs. In addition, this can significantly reduce the cost of purchasing building materials and their delivery.

The video in this article will help you get acquainted with the material in more detail.

Composition by type of filler

Cinder block is produced in the form of a solid or hollow parallelepiped with right angles. The following compositions of building stone are distinguished depending on the filler:

- SCC - with the addition of cement as a binder.

- SKI - with the addition of lime as a binder.

- SKSH - with the addition of slags of various origins.

- SKG - with the addition of gypsum or alabaster.

- Depending on the filler introduced, a solid block has an average weight of 25-28 kg, a hollow block - 18-23 kg, and a half-slag block - 10-13 kg. The thermal conductivity coefficient of a cinder block also depends on the composition of the solution and occupies the range of 0.27–0.65 W/m*K.

- The compressive density is allowed in the range of 750–1455 kg/m3. When the density changes, the thermal conductivity and strength of the wall stone changes. Also, the density characteristics, weight of the blocks and thermal conductivity depend on the composition of the mixture and the number of voids in the product - they can be oval, round, rectangular or square.

- The percentage of voids to filler is 28–40%.

- The texture of the blocks is divided into smooth (without visible surface defects), polished (1 grinding cycle), corrugated (repeating irregularities) and chipped (the surface is leveled by chipping off the protrusions). For different slag concrete fillers, their own, most optimal, stone texture is determined.

Table of composition of fillers for wall blocks

| Type of filler | Cement kg/m3 | Brand/class of concrete | Density kg/m3 |

| Blast furnace, coal, wood, open hearth ash and sand | 120–160 | 75/5 | 1800 |

| Fly and waste ash | 100–150 | 50/3,5 | 1550 |

| All types of ash and sawdust (shavings) | 220–290 | 35/2,5 | 950 |

| All types of ash and expanded clay | 120–160 | 75/5 | 1300 |

| Quartz sand and expanded clay | 170–200 | 75/– | 1400 |

| Quartz sand and sawdust (shavings) | 300–340 | 50/3,5 | 1200 |

| Quartz sand and polystyrene foam | 320–400 | 35/2,5 | 800 |

| All types of ash polystyrene foam | 300–380 | 35/2,5 | 750 |

| Quartz sand and crushed brick | 100–150 | 75/5 | 1900 |

| Slag and all types of ash | 120–180 | 75/5 | 1800 |

| Arbolit | 280–320 | 25/2 | 700 |

| Soil concrete | 220–300 | 15/1 | 1900 |

What is a screening block?

Many people who want to buy an apartment in a low-rise residential complex in Khabarovsk are wondering: what are modern apartment buildings made of? Why are they being built so quickly? Are such buildings reliable? We have no secrets! And we proudly answer: “Svoy Dom” uses the most popular and environmentally friendly material today in the construction of apartment buildings – screening block.

What is a screening block? This is a modern building wall block made from screening out fine fractions of high-quality cement, coarse sand and stone chips.

The latest technology for the production of screening blocks allows us to quickly obtain high-quality building material, without causing harm to the environment.

Special equipment for vibrating compaction of the mixture allows the use of stone chips and cement screenings, which makes it possible to profitably use valuable high-quality building material, as they say, down to the last crumb. This, in turn, saves natural resources and financial costs for construction.

Most people confuse screening block with cinder block, considering it not an environmentally friendly and durable waste material. Despite the similar name of these materials, they are completely different in essence:

A cinder block consists of many different wastes: gravel, sawdust, coal combustion waste, chemical slags - clearly not a very environmentally friendly list.

A screening block, on the contrary, differs from a cinder block precisely in its environmental friendliness and durability - as mentioned above, the screening block is based on high-quality cement and stone chips.

The environmental friendliness and safety of the screening unit are not all the advantages. High strength and sound-thermal insulation make it possible to reduce the thickness of walls during the construction of houses and, thereby, increase the usable area in apartments.

Building houses from screening blocks is five times faster than brick buildings; during construction, half the working solution is used; it is not only economical, but also very reliable, because the overall load on the foundation is reduced.

Everyone should have their own home! That is why we build affordable and high-quality housing for you!

Replacing sand with screenings in wall blocks

When constructing buildings and other construction projects, wall blocks are often used. Unlike the mediocre cinder blocks of past decades, the current ones have already received excellent recommendations from users. The wall block is a parallelepiped cast from a special building mixture. Standard blocks are larger than ordinary bricks, their sizes range from 10-20-40 or 20-20-40, but at the same time it is much more convenient and faster to work with them when constructing wall masonry. Wall blocks are solid, hollow and slotted and are used in accordance with their intended purpose. The presence of cavities and through gaps provides good noise and heat insulation and, importantly, makes them lighter, significantly reducing the load on the foundation during construction. Partitions and internal walls are built from hollow (hollow) and slotted blocks, while monolithic (solid) blocks are used for external wall masonry. The growing range of wall blocks on the construction market is due to the variety of mixtures for their manufacture. The standard composition of components includes filler, binder, water and improving additives. Sand concrete blocks consisting of one part water-cement mortar and three parts coarse sand have become widespread. Instead of sand, you can use AGS (sand-gravel mixture) or granite screenings - such a replacement will help reduce the amount of concrete mortar due to large gravel grains or screening grains forming a strong bond with cement. Blocks in which granite screenings (0-5 mm) or washed granite chips (2-5 mm) are used as filler instead of sand to facilitate identification are called screening blocks. In addition to these components, Portland cement is sometimes added to the mixture, making the finished blocks more dense, frost-resistant and less susceptible to corrosion. It is not necessary to completely replace the sand by screening; the quality of the mixture will be better if both components are left. Brand-compliant screening blocks must meet compressive strength requirements. The higher the grade, the stronger the material of the wall block. For example, M50 - 5 MPa, M75 - 7.5 MPa, M100 - 10 MPa. A durable and high-quality screening block M75 will be obtained if one part of sand and one part of crushed stone from a standard sand-crushed stone mixture is replaced with two parts of granots screening, so that the resulting ratio is: one part cement, two and a half parts sand, five parts crushed stone, two parts screening .