The primary function of the chimney is to remove combustion products from the firebox to the outside, but its role in the process of fuel combustion and draft formation should not be underestimated. Experts say that with the right choice of material for the chimney pipe and its proper installation, the heat transfer of a stove or boiler can be increased by up to 10-15%. However, for a gas or solid fuel boiler, fireplace and stove, you will need a chimney not only of different heights and diameters, but also of different materials. If previously the choice was only between brick and non-galvanized metal, today the range of suitable options is much wider. Let's figure out what materials for a chimney, or rather chimney pipes, exist, for what conditions they are intended, and which chimney to choose depending on the type of fuel used.

What to consider when choosing a material for a chimney?

A chimney is a complex structure consisting of a vertical pipe, an umbrella for protection from precipitation, an inspection window for maintenance, a tray for collecting condensate and other elements. The vertical pipe is considered the main part of the chimney, and the safety and efficiency of the stove or boiler depends on it.

To choose the right chimney material, you need to clearly understand what fuel will be used : natural gas, diesel fuel, coal, firewood, peat or sawdust. Each of them has a different combustion temperature, temperature and composition of the exhaust gases. Therefore, when selecting material for a chimney, the following parameters are taken into account :

- flue gas temperature .

Naturally, the material must withstand slightly higher temperatures than those characteristic of the exhaust gases; Approximate flue gas temperature (*high sulfur fuel) - corrosion resistance . When some types of fuel burn, vapors of sulfuric and hydrochloric acid are formed, which not every material can withstand. The more sulfur in the fuel, the more resistant to the effects of sulfur compounds the material must be. According to this parameter, chimneys are divided into three classes : the first - for removing gas combustion products, the second - firewood and liquid fuel with a sulfur content of up to 0.2%, the third - for coal, peat, diesel fuel;

- presence of condensate in the chimney;

- gas pressure in the chimney . There are designs designed to work with natural draft, and there are those that are designed to work with pressurized boilers;

- resistance to soot fire . The temperature in the chimney when soot ignites, if present, can briefly rise to 10,000C - not every material can withstand this.

From all this it follows that:

- for wood stoves, solid fuel boilers, sauna stoves and fireplaces, it is necessary to choose a material that can withstand operating temperatures of about 7000C and a short-term increase to 10000C. These are brick and less often ceramic chimneys;

- gas boilers require a chimney that can withstand temperatures of 2000C with a short-term increase to 4000C. Typically, metal pipes are used for these purposes;

- For boilers using liquid fuel and sawdust, a material for the chimney pipe is needed that can easily withstand temperatures up to 2500C with an increase to 4000C, and if we are talking about diesel fuel, then resistant to the aggressive environment of exhaust gases.

Now let's look at the properties of the most popular materials that are used to construct a chimney pipe.

Chimney made of expanded clay concrete blocks

Question

Hello, Gennady Andreevich! Please tell me! I am building a cottage from expanded clay concrete blocks with an area of 140 sq.m. Is it possible to lay out chimney ducts from expanded clay concrete blocks and then sleeve it?

I plan to install a gas boiler in those. indoors and a fireplace in the living room. What is the best way to sleeve? If you take metal, does it have to be a sandwich or is it sufficiently single-walled?

Andrey.

Answer

Hello Andrei!

You are right, in practice there are cases of creating chimneys from expanded clay concrete blocks. The use of a sandwich can be considered mandatory.

Lining is usually done with a stainless steel pipe filled with vermiculite or mineral wool. However, the service life of this chimney is unlikely to exceed 10 years due to oxidation of the stainless steel.

The chimney will last much longer if a pipe made of acid-resistant steel grade AICI304 (in our country this grade corresponds to steel 08×18H10), AICI316 or AICI321 is used for lining.

Interesting too

Technical characteristics of expanded clay concrete blocks

Expanded clay concrete is an excellent wall material. Inexpensive, with good thermal characteristics. Half, if not two thirds of the country's housing stock was built using it.

Wall blocks made of cellular concrete are not so clear

Cellular concrete is a popular and quite good alternative to traditional brick in the construction of walls or partitions inside a building. Cellular concrete blocks are a building material with a porous structure.

How to make a chimney for a gas boiler

The chimney for the boiler is an essential component of the heating system, which must be calculated at the stage of designing the house. At this point you need to know exactly which boiler will be installed

Add a comment

Fields marked * are required. HTML tags are disabled.

gennadiy.info

No. 1. Brick chimney pipe

Brick has been used for chimney construction for a long time, and it has already become a traditional material. Today it cannot be called universal, which, however, does not reduce its popularity. A brick chimney is installed inside the walls of the building; those sections of it that pass through unheated rooms or outside the building are carefully insulated so that the flue gases inside do not cool. For the construction of such a chimney, red solid brick of a grade no lower than M150 is suitable; lime or lime-cement mortar is used for its laying.

The main advantages of brick chimney pipes include their durability and excellent heat resistance (ceramic brick can withstand temperatures up to 8000C), and they look great in appearance, and in terms of fire safety they have practically no equal. A brick chimney is suitable for wood-burning stoves and fireplaces , and when working with liquid fuel, gas, pellet and solid fuel pyrolysis boilers, it is quickly destroyed. The thing is that such boilers are designed in such a way that the exhaust gases have a low temperature. They quickly condense and settle on the pipe walls, due to which the latter are constantly moistened. Considering the fact that the exhaust gases contain aggressive chemicals, including sulfuric acid, the brick quickly deteriorates. The results of such exposure appear as wet spots on the outer surface of the pipe.

True, there is always a way out of the situation. To connect a modern gas or liquid fuel boiler to a brick chimney pipe, a steel or ceramic pipe , which has slightly different performance qualities, is built into the brick channel.

Since the surface of the brick is rough, soot settles well on it, which gradually leads to a decrease in traction. Cleaning and repairing a brick chimney is not an easy task. In addition, the large weight of the structure will necessarily require a foundation. On the other hand, it is difficult to find a worthy analogue for arranging the chimney of a stove or fireplace.

Passage of a brick pipe through the ceiling

A brick chimney is usually designed to protect the surrounding combustible materials from overheating. The section of the pipe that is laid out as it passes through the ceiling is itself a cutting and is called “fluff”.

This chimney design is traditional, long tested, and most often chosen by stove makers.

The “fluff” begins right at the ceiling in the living room (three to four rows of bricks before it) and passes through the entire thickness of the attic floor. Sometimes the fluff is raised to the clean floor of the attic, in other cases it is made flush with the subfloor. Both options can cause quibbles from inspectors - let’s remember the notorious “70 millimeters” already discussed above.

This structural element acts as the necessary thickening of the pipe walls, protecting the flammable materials of the ceiling from overheating.

In fact, the design of the “fluff” is directly influenced by precisely those SNiP requirements that were discussed in the first section of the publication. In order not to repeat ourselves, we can provide a diagram that clearly shows what dimensions must be observed and where:

The diagram graphically displays the basic requirements of SNiP for the location of the stove and chimney, to ensure the safe passage of the pipe through the ceiling

Arranging the passage of a brick pipe through the attic floor without laying out the “fluff”

The hole in the ceiling can be covered with a metal sheet or a fiber cement slab. In the middle of the thermal insulation panel, a window is marked through which the chimney will pass. The length and width of this opening should exceed the similar parameters of the pipe by literally 3–5 mm.

When laying a chimney, approximately three or four rows up to the ceiling, a sheet with a prepared opening is placed on it, and then the laying is carried out further up to the height of the finished attic floor.

The next step is to lift the sheet placed on the pipe, press it and fix it to the ceiling in a way convenient for a particular case - with self-tapping screws or dowels.

Further, the work is carried out from the attic or second floor. Along the walls of the opening cut out for excavation, strips of basalt wool, pieces of asbestos or fiber cement boards are laid. This “frame” should cover the entire thickness of the attic floor. If necessary, the material can be fixed to the floor beams.

Thanks to these operations, a kind of box is created around the neck of the pipe, which will be filled with heat-resistant material. You can use basalt wool as it, which tightly fills the entire volume. If cotton wool with a foil layer is used, then it is turned towards the walls of the oven.

It is quite possible to perform similar thermal insulation of a pipe with expanded clay or vermiculite, but before backfilling it is necessary to seal the remaining gaps between the pipe and the edges of the opening, especially if fine-grained material is used.

Of course, you can do exactly the same as with a metal pipe, by putting a ready-made penetration made from a steel sheet onto a brick chimney. This option will probably be more reliable and convenient both in terms of its installation and reliable fixation, and when filling the box with thermal insulation material. True, such a box will cost significantly more. Whether it makes sense - decide for yourself.

Having filled the penetration with insulation, it is also covered with a metal or fiber cement sheet on top.

At this point, work on arranging a safe passage of the chimney through the ceiling can be considered completed.

Having familiarized yourself with the details of the arrangement of this area of the chimney pipe, you can come to the following conclusion:

No. 2. Chimney made of steel pipe

For gas and solid fuel boilers , steel pipes are best suited, but at the same time it must be stainless, heat-resistant and acid-resistant , since sulfur particles, which are found in almost every type of fuel in one quantity or another, when combined with moisture and coal particles form aggressive environment. Stainless steel can withstand temperatures up to 5000C ; pipes with a wall thickness of 0.6 mm are used to construct chimneys, but for solid fuel boilers it is better to use steel with a thickness of 1 mm. Steel pipes are a whole system of straight sections and various shaped elements, incl. adapters, bends, tees, etc. Such a system can be installed independently or built into an existing brick channel.

The main advantages of steel pipes:

- simplicity and high speed of installation, because the weight of the structure is small, there is no need for a foundation, and even not the greatest professional can assemble the entire system from ready-made elements without any problems;

- repair work is easy to carry out;

- soot particles do not accumulate on smooth walls, their surface is easy to clean, so we can talk about consistently high aerodynamic characteristics for the passage of exhaust gases;

- high corrosion resistance;

- the ability to create complex structures;

- high tightness, due to which you can create forced exhaust.

Among the disadvantages is the high cost, especially when compared with a brick or ceramic analogue, but if simplicity and speed of installation, light weight and resistance to aggressive environments are important, then it is better to choose a steel chimney. Disadvantages sometimes include low heat resistance, but for modern boilers with a slow combustion system, greater heat resistance is unnecessary.

Depending on the characteristics of the room, boiler and climate, one of the following types of steel chimneys is used:

- single wall steel pipe , consisting of one layer of stainless steel. This is the simplest and cheapest option; such a chimney is laid in a specially laid vertical channel. Often such chimneys are installed in a bathhouse, and the heat released from the steel pipe is used to heat water;

- Single-wall steel pipes for reconstruction of a brick chimney can be oval in shape. Such a restoration process and adaptation of an existing chimney to work with a gas boiler is called “linering”;

- double-walled sandwich panelsconsisting of two steel pipes, in the space between which a layer of insulation (basalt wool) is placed. Using the latter allows you to prevent the formation of condensation inside the pipe, while its outer surface hardly heats up. Ease of assembly and excellent performance allow such systems to be used both indoors and outdoors on the wall;

- coaxial chimneys made of steel also consist of two pipes placed one inside the other, only there is no insulation between them, and the resulting space is intended to supply air to the boiler to support combustion. Combustion products are discharged through the inner pipe. Such chimneys do not behave very well in harsh domestic winters. Cold outside air passing through the outer pipe can sometimes greatly cool the inner pipe and the gases flowing through it. This leads to a sudden drop of condensate and its freezing on the surface of the pipe. The chimney gradually becomes clogged, and the automation, reacting to this, turns off the boiler, so in this case it is better to equip chimneys with two separate pipes.

It is worth noting that sometimes thick pipes made of low-alloy steel are used to construct a chimney - this option is usually found in sauna stoves. Also, craftsmen sometimes use cast iron sewer pipes for the same purposes.

Chimney installation

Once the owner has decided on the choice of chimney model, installation work can begin. Of course, this is a complex repair process that requires at least minimal knowledge in this area. First of all, for work you need to stock up on construction tools. Only after this can you begin. Below are step-by-step instructions that, if followed, will make the process easier.

Step 1. Pre-install the stove at the future installation location. This is done in order to determine the location and height of the chimney passage through the wall of the house.

The boiler must be placed at the installation site

Step 2. After installing all the connecting pipes, make marks on the wall using a simple pencil.

Marks are made on the wall

Step 3. Prepare a special device for diamond cutting. This is a noisy, but practically dust-free process.

Preparing a special device

Step 4. Drill a through hole in the wall at the previously marked location.

A hole is drilled in the wall

Step 5. Prepare all chimney elements for assembly.

Preparation of chimney elements

Step 6: Assemble the wall stand, inspection compartment, stash and meter pipe. The finished structure can be installed.

Chimney installation process

Step 7. Be sure to use a building level during installation. It is advisable to do this when installing each individual element.

A building level is used

Step 8. When installing a chimney, a ladder alone is not enough; scaffolding will be required. Therefore, as soon as the work process moves to a higher level, it is necessary to take care of the construction of scaffolding.

It will be necessary to build scaffoldingWear and long-term use of stairs

Step 9. Everything turned out quite quickly. The last meter of pipe remains.

Assembling the last meter of the chimney

Step 10. Now assemble all the elements of the oven. As with the chimney, when installing the stove you must use a building level.

Boiler elements are assembled

Step 11: Done! The chimney and solid fuel boiler are fully installed and ready for use.

Everything is ready for use

Video - Chimney diagrams for a boiler

No. 3. Ceramic chimney pipe

Ceramic chimney pipes are considered the most versatile, and among their main advantages:

- durability;

- resistance to aggressive environments and corrosion;

- soot does not linger on the smooth inner surface, making pipe maintenance easier;

- high heat-absorbing characteristics;

- resistance to high temperatures. For solid fuel boilers, ceramic pipes are used, which can withstand up to 6500C and are resistant to a sharp increase in temperature when soot ignites. For gas boilers, you can use pipes that can withstand up to 4500C, are designed to operate in a wet state and have condensate drains.

To install a ceramic chimney pipe, a separate channel is required. The shell is constructed from special concrete blocks with voids. A layer of mineral wool insulation is placed around the pipe to protect adjacent structures from excess heat and reduce the formation of condensation. Both the pipe and the insulation are capable of absorbing water, so they need to be provided with normal ventilation. It is created due to the presence of vertical air channels between the insulation and concrete blocks. By the way, concrete blocks also contain channels for placing reinforcement in them. Be sure to reinforce the part of the chimney that faces the street.

To expand the scope of use of ceramic chimneys, they are produced in a steel casing , as well as in the form of rectangular elements . The former do not require the construction of a foundation or the creation of special channels, the latter can be used for the reconstruction of brick chimneys.

Features of installing a smoke exhaust pipe for long-burning chimneys

One of the disadvantages of convection ovens is their susceptibility to the formation of condensation with a pronounced tar smell and flammable properties, which can greatly spoil the appearance of the chimney and increase the risk of fire. The chimney should minimize the formation of condensation as much as possible.

When installing a sandwich, this point should be taken into account and installation should be carried out “by condensation”, when the lower link is put on the upper one. The seams should be carefully sealed.

To increase the heat transfer of a convection oven, an economizer can be additionally included in the chimney circuit. This element ensures that part of the thermal energy of the exhaust gases is used to heat the air inside the room.

Chimney calculation

In order for the heating system to function with maximum efficiency, it is important to correctly calculate all the parameters of the smoke exhaust duct

- Chimney length. Regardless of the location, the total height of the structure must be at least 3 meters. The height provides draft in the firebox, while taking into account the location of the chimney relative to the roof ridge.

- Pipe diameter. There is an unspoken rule here that the cross-section of the pipe should be 10 times smaller than the combustion chamber.

Also, Buleryan's performance is taken into account. For example, a heat transfer rate of 300 Gcal/hour will best correspond to a chimney with a diameter of 14 cm

Installation methods

There are two options for laying a chimney: external and internal. Both provide the required functionality, and the choice in favor of one method or another depends on the conditions of a particular project

The complexity of passage through the roof, walls and ceilings, climatic conditions, aesthetic appeal of the structure, costs of project implementation, etc. are taken into account.

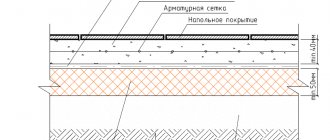

Laying inside the house (CHIMNEY No. 1). It is mandatory to provide passage through the ceiling and roof. Since the chimney can heat up to 50-300°C (the variation is determined by the pipe material and the presence of thermal insulation), the passage opening must provide fire protection. For these purposes, a gap of 20-25 cm is left, which is filled with non-flammable material - expanded clay, asbestos, etc. A long horizontal section of the chimney will negatively affect the draft level. Its length should not exceed 3 meters.

58d9d363771891d8798fa0f17f75badd.jpe

ed442a8ed6f56d419d7e1b69e597c5f7.jpeExternal chimney laying (CHIMNEY No. 2). In this case, the pipe is brought out to the street through the wall. For wooden buildings, the conclusion is made according to the same rules as for passage through the ceiling or roof. For brick walls, additional gaps will not be needed. Some people prefer to install the chimney outlet to the street through a window opening. Fastening to the wall is done using clamps. If the pipe is significantly elevated above the roof level, it is worth adding guy wires. A heavy ceramic chimney will require a separate foundation.

No. 4. Chimney made of asbestos-cement pipe

A couple of decades ago, asbestos-cement pipes were widely used to construct chimneys. Actually, they were not originally intended for such purposes, which is easy to see by studying their performance characteristics. The only advantage of the material is its low price , but there are disadvantages :

- the material can withstand temperatures up to 3000C, and often this is not enough. Such a pipe can only be used at the maximum distance from the firebox, where the smoke passes through already cooled;

- Soot quickly accumulates on a rough surface, which tends to catch fire. But if a brick chimney can easily cope with this, then a chimney made from an asbestos-cement pipe can simply explode;

- instability to condensate, which contains aggressive chemicals. Moreover, condensate can be absorbed into the pipe, destroying it and worsening its appearance;

- heavy weight and difficult installation;

- leaking joints.

You can use an asbestos-cement pipe for a chimney only if you are sure that the installation will be done correctly, as well as if the chimney is regularly cleaned, but it is better to pay attention to other options.

Chimney blocks: types, application, installation

Good traction is the key to good heating. Fuel consumption, the efficiency of its combustion, the amount of waste and the associated need to clean the chimney and stove - all these factors are determined by the presence or absence of draft. The latter depends on the quality of the chimney.

Type of block chimney

Block or brick?

Not so long ago, the issue was resolved exclusively in favor of a brick chimney, since no other options were provided. And, in fact, the quality of a brick chimney depends not so much on the materials as on the quality of installation. A significant disadvantage of such a chimney is its considerable weight and the high complexity of the installation process. The ability to use a hollow brick to lay a chimney does not bring much relief.

Block sizes

Today, such an option as making a chimney from special chimney blocks, both industrial and self-produced, is possible. The block material is concrete with appropriate characteristics, characterized by low weight and high mechanical strength. The dimensions of the blocks are determined by the dimensions of the internal channels and the thickness of the walls, but in general, they allow installation even by one person.

Materials

- Industrial block - for the chimney you should choose blocks made of concrete. It is better to avoid chimney blocks made of baked clay: the raw materials are not durable, and the product becomes covered with cracks even during manufacture.

Installation

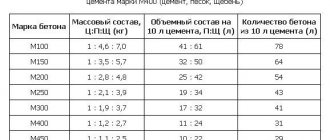

- Self-produced block - if you are not satisfied with industrial blocks, then after spending some time, you can make your own. For preparation, it is recommended to choose lightweight slag concrete - it has good thermal insulation properties. On average, for a chimney 10 m high, 32 blocks are required.

- Pipes - it is recommended to use metal pipes, since ceramic ones have lower heat transfer rates.

- Fastening - blocks are installed either with cement mortar or with special glue. The cement must be at least grade M50-M75, and the glue must be designed for use at high temperatures.

- Thermal insulation – for thermal insulation it is recommended to use mineral wool. This is a heat-resistant, fireproof material with low thermal conductivity.

Installation of chimney blocks

- Foundation - since a fairly light material is used for the chimney, a lightweight foundation will be needed: just lay a cement pad up to 25 cm high on the floor and waterproof it. Please note that the edges of the slab on each side of the block must protrude by at least 15 cm.

- Laying blocks - blocks are laid on cement or glue and carefully leveled using a level. The holes for the ventilation grille, chimney door, and smoke duct are made in advance with an angle grinder. The fittings are attached only by inserting into the body of the block.

- Pipe installation - pipes, one or two, depending on the design of the chimney, are installed together with the chimney, ahead of it by no more than one meter. Pipes for the chimney are cut in advance into fragments convenient for installation, and fastened with a mixture for sealing joints, if we are talking about ceramic pipes. Excess mixture is removed with a damp sponge. During installation, you should carefully align the seams and be sure to remove any remaining mixture: the inner surface of the pipe should be completely smooth, and the seams should be filled. To connect pipes to blocks, embedded brackets are used. They are laid directly into the seams, otherwise the fastening will not be strong enough.

- Thermal insulation is done last, but before lining the chimney. Insulation is required in order to extend the “life” of the chimney pipe: thermal insulation protects the chimney walls from condensation and reduces the impact of temperature changes.

You can install a chimney, and even make blocks for it, on your own. The only and most important rule is strict adherence to the manufacturer’s instructions.

kamingid.ru

No. 5. Vermiculite chimney pipes

Not so long ago, vermiculite chimney pipes appeared on sale. These are stainless steel pipes coated inside with a 5 cm thick layer of the mineral vermiculite. This mineral has low thermal conductivity, therefore, in fact, it is a natural heat insulator. Moreover, vermiculite is absolutely inert to aggressive combustion products.

Other advantages of vermiculite pipes include high durability, relative ease of installation, and no need for chimney insulation. The main disadvantage is the ability to accumulate soot, so you will have to clean the chimney often.

Other options

At the moment, there are other ways to arrange a chimney:

- Glass pipes would have raised eyebrows just a few years ago, but today their advantages are undeniable. Glass does not accumulate soot and soot, is easy to clean, is inert to aggressive environments and can withstand high temperatures. But a glass chimney will be expensive, it is difficult to install, additional thermal insulation will be required, and sealing joints is complicated, so such an extravagant method has not yet become widespread;

- polymer pipes are another new product. They are made from a composite, which, according to the declared qualities, has a long service life, but can only be used at an exhaust gas temperature of no more than 2500C, i.e. its scope of application is limited to geysers and boilers;

- Concrete blocks and chimneys poured from concrete with your own hands are called in some sources an alternative to brick pipes. Professionals strongly criticize this option and recommend not playing with fire: concrete will not withstand severe temperature loads, and it is impossible to make a heat-resistant composition at home.

Finally, we note that before choosing a material for the chimney, you need to select a boiler or decide on the design of the stove. In addition, it is worth taking into account the design features of the building, and it is best to think through all the nuances of its future heating before starting construction of the house. For your safety, it is better to entrust calculations of the chimney duct to a specialist.

Where are they used?

Chimney made of expanded clay concrete.

The use of ventilation expanded clay concrete is relevant for:

chimney; fence posts; for ventilation of public buildings; ventilation ducts; sanitary facilities and kitchens; permanent formwork.

As an example, expanded clay concrete chimneys, which have the following advantages:

ease and speed of installation of the chimney; reduced loads on the base of the chimney; the presence of an additional unit for a large amount of ventilation; the chimney can be installed in walls, which allows you to save the area of the room.

Expanded clay blocks use a process of sintering the solution under high pressure. This technology provides chimney blocks with strength characteristics and a long service life.

Currently reading: Crushed (crushed) concrete

Return to contents