To do this you will need either an impact drill or a hammer drill. You can, of course, get by with a regular drill with a drill bit with a Pobedit tip, but it won’t be easy.

In general, an impact drill is the best option. It costs from 800 rubles in a household version. You will need a concrete drill for it; it costs from 40-50 rubles, depending on the diameter of the drill.

The most popular sizes are 6 mm and 8 mm. Also purchase dowel-nails of the appropriate diameter, for example 6x40mm or 8x60mm (you can choose the depth and diameter based on the load). The dowel-nail consists of a glass and a threaded nail, so that it can be dismantled, if not needed, by unscrewing. Also you need to know in advance which type of dowel-nail to take, with a hidden glass or a fungus; it is also important how you will use this fastener, hang it or fix it.

Before you are going to drill a hole, prepare a container of water so as not to burn the drill, cool it periodically. Although brick and “soft” material can fall into burnt brick, it is extremely difficult to drill. Yes, and remember, if you drill too deep, the glass will fall through when you hammer in the nail, and this is fraught with alterations. Use a stopper, it comes with almost every drill, or simply wrap electrical tape around the drill, marking the length you need.

After you have drilled the hole, insert the glass into it and hammer in the nail. That's all.

There is another way, the “old-fashioned” one: drill a hole, hammer a wooden “chopik” or a plug into it, after dipping it in PVA glue. You cut it flush, then screw in the self-tapping screw, but to be honest, such a fastening is not only obsolete, it is also short-lived.

First things first, first things tools

nails, screws, rivets, anchors

Reliable fastening of the structure is a guarantee that it will last a long time without requiring additional repairs. In this regard, it is very important to choose reliable tools and fastening elements. And this choice must be approached with all responsibility.

You will need special tools . An impact drill is best.

You can also choose a regular drill, to which a pobedit tip is selected. But in this case the work will be more complicated. In terms of cost, this will result in approximately the following figures: from 800 rubles for the tool itself and from 40 to 50 rubles in addition for the drill. Running sizes are considered to be 6 and 8 mm diameters.

The list of materials that such tools can work with is extensive. Their choice will depend on the future load of the suspended structure. The most popular are the following:

- self-tapping screws for bricks;

- dowels (will help withstand heavy loads);

- anchors (capable of holding very heavy things);

- rivets (for delicate glass shelves);

- corners (for small cabinets and shelves);

- regular nails combined with all the others.

It is also important to consider what kind of product is used for laying the surface - it can be either solid or hollow. The types and grades of this product will also tell you how reliable the self-tapping screws used for bricks are.

Main rules of fastening

correct fastening of screws

Before starting work, you need to understand some rules. They will help not to spoil the surface and carry out the correct fasteners:

- The most basic requirement that must be met when attaching something to a wall made of such material is not to spoil the mortar that holds the blocks together.

- It would be best to use a drill. It will help to avoid cracks that may appear if, for example, you try to “drive” self-tapping screws into a brick with a hammer drill.

- Drilling should be unhurried and gradual. This approach will help to secure any element to such a wall.

Working methods

working with self-tapping screws

There are several ways to make it easier to place fasteners on such a wall. Some of them are quite interesting:

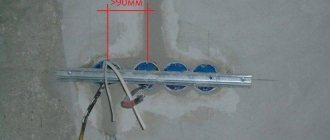

- If we are working with dowel nails, it is important to prepare a container with water - in it we will periodically cool the drill. You can wrap electrical tape around the drill itself, which will serve as a limiter. After the hole is ready, insert the dowel glass and hammer in the nail.

- In order to facilitate the process that self-tapping screws go through when driven into a brick, you can use the “old” method. The dowel inserted into the drilled hole is strengthened with a wooden peg.

- Another “old-fashioned” method would be to drill a hole and screw a plug or cap into it, previously soaked in PVA glue. Then the “excess” peeking out from the wall is cut off and a self-tapping screw is screwed in. But such fastening is considered short-lived.

- It is best to use dowels designed specifically for brick walls. They have projections that will not allow it to turn, even if a screw or nail is screwed in. This rule applies even to hollow bricks, in which they will roll up into a knot and occupy the entire required volume.

- When you need to decorate an external wall (for example, the entrance of a house), you can use corners along with dowels and screws. They will not only connect the structure and the wall, but will even become supporting elements.

We recommend watching a video on attaching drywall to a brick wall:

How to screw a self-tapping screw into a brick?

To do this you will need either an impact drill or a hammer drill. You can, of course, get by with a regular drill with a drill bit with a Pobedit tip, but it won’t be easy.

In general, an impact drill is the best option. It costs from 800 rubles in a household version. You will need a concrete drill for it; it costs from 40-50 rubles, depending on the diameter of the drill.

The most popular sizes are 6 mm and 8 mm. Also purchase dowel-nails of the appropriate diameter, for example 6x40mm or 8x60mm (you can choose the depth and diameter based on the load). The dowel-nail consists of a glass and a threaded nail, so that it can be dismantled, if not needed, by unscrewing. Also you need to know in advance which type of dowel-nail to take, with a hidden glass or a fungus; it is also important how you will use this fastener, hang it or fix it.

Before you are going to drill a hole, prepare a container of water so as not to burn the drill, cool it periodically. Although brick and “soft” material can fall into burnt brick, it is extremely difficult to drill. Yes, and remember, if you drill too deep, the glass will fall through when you hammer in the nail, and this is fraught with alterations. Use a stopper, it comes with almost every drill, or simply wrap electrical tape around the drill, marking the length you need.

After you have drilled the hole, insert the glass into it and hammer in the nail. That's all.

There is another way, the “old-fashioned” one: drill a hole, hammer a wooden “chopik” or a plug into it, after dipping it in PVA glue. You cut it flush, then screw in the self-tapping screw, but to be honest, such a fastening is not only obsolete, it is also short-lived.

Fasteners

One of the most common elements for fastening brick to concrete are dowels. How to use them correctly? A hole is drilled in the wall. Its diameter should be 8 mm. This hole is filled with a dowel. It must be inserted very carefully so that it does not break and part of it remains in the wall. You need to hammer in the dowel with a hammer until it stops.

After fixing the dowels, screws are inserted into them.

The screws must be screwed in all the way and tightened tightly.

How to properly fix a self-tapping screw in a concrete wall

Concrete structures are considered one of the hardest surfaces. Therefore, making a hole, screwing in a self-tapping screw or driving a nail is quite difficult. Nails often bend, screws often break. But, following my advice, this can be done with minimal loss of time and fasteners (in this case, a self-tapping screw):

• Try to drill a hole perpendicular to the plane of the concrete wall, which will allow you to screw in the mounting screw extremely vertically and accurately. As soon as the right angle loses its direction, the diameter of the hole will increase to an uncalculated size, which will lead to loosening of the fastener. The depth of the hole should not be shorter than the length of the helical bolt so that the bolt does not rest against the concrete wall.

• The drilled socket must be cleared of dust and debris by moving the drill back and forth. The debris collected in it will not allow the fastener to properly enter its entire length.

• Then insert a tenon into the prepared hole and drive it in with a hammer.

• Screw in the self-tapping screw with a Phillips screwdriver or a screwdriver at low power. To ensure its strong installation, it is advisable to place a thin splinter in the form of a toothpick into the plastic dowel, which will more reliably fix the fastening in the concrete surface.

• If the dowel does not take its proper place easily and goes in with force, you should not injure it or torment yourself, just pull out the product and drill the hole a little larger so that you can insert it with the least amount of difficulty.

If you use self-tapping screws with curls, like Christmas trees, you can drive them into the concrete with a hammer without using a special screwdriver. This fixation method saves time and does not complicate the work process. It will just be difficult to free it from the fastening if necessary. The quick installation method is best used when there are no plans to rebuild the structure in the future.

Types of self-tapping screws for concrete:

1. Universal. The diameter of the metal products is 3 mm and 6 mm, length from 12 mm to 220 mm.

They are used for any type of fastening, and not only in concrete surfaces, but also in brick ones.

2. Pins. The length varies from 70 to 200 mm, the diameter size remains unchanged - 7.5 mm.

You need to pre-drill a groove for the dowel. Such self-tapping screws do not require a dowel. The presence of serrated threads allows the screw to easily enter the concrete. The hole must be made with a concrete drill with a diameter of 6 mm. The length should be 10 mm deeper than the length of the screw itself.

3. Herringbone carving. The diameters of the metal products are 3 – 8 mm, their length varies from 12 mm to 220 mm.

It is permissible to use self-tapping screws for concrete only in combination with a dowel. It usually comes with a dowel. If there is a void in the concrete base, it is better to use an impact dowel in the installation. In this case, the length of the screw and dowel are the same size.

It is necessary to make a hole for the self-tapping screw longer than the product itself by 4 mm. While observing safety precautions, you should use special glasses to protect your eyes, since when using the hammer drill there will be a lot of cement dust. Wear fabric gloves on your hands. Rubber – promote sliding on steel materials.

You must be careful when drilling into any surfaces so as not to come into contact with electrical wires.

Self-tapping screw into brick without dowel. How to screw in a self-tapping screw without a dowel

Sometimes it becomes necessary to fix a dowel in the wall, but halfway it breaks. Or you don’t have the plastic part of the dowel, and finding it at the right time is problematic. In such situations, when you need to secure a self-tapping screw without a dowel, you can use a simple but effective method, which you will read about below.

To screw a self-tapping screw into a brick or concrete wall without a dowel, you need some tools. However, you don’t need anything rare or hard to find. It is necessary to prepare in advance a drill, a drill (preferably a high-quality universal one or for concrete) with a diameter slightly smaller than the self-tapping screw or screw that needs to be screwed in, and even a screwdriver.

First, mark the point where this screw or self-tapping screw should be located. Then, take a blade, cut the wallpaper at a point with intersecting lines. Bend the resulting wallpaper petals. This must be done in order not to damage the wallpaper. Subsequently, if it becomes necessary to remove the self-tapping screw, this place can be discreetly sealed again.

Next, you need to drill a hole with a thin drill, which is slightly thinner than the self-tapping screw. Try to drill efficiently and evenly. The hole must not be allowed to be larger than the required size, otherwise the self-tapping screw will not hold well in place.

Insert a match into the hole, which is best first dipped in PVA glue. Now you can screw in the screw with a screwdriver. Just don't use a screwdriver. Or use it carefully, at the lowest speeds. The fact is that if you screw in such a screw at high speeds, it will very quickly enter the wall and may spin several times, thereby destroying the walls of the hole. Accordingly, the fastening in this case will be appropriate.

Now you can hang a picture, hanging furniture and even some kind of hanging equipment on the wall. By the way, this method works best when the walls are strong enough, for example, made of high-quality brick or reinforced concrete slabs. If the wall crumbles easily, it is better to use another method.

Cut the wallpaper with a blade and bend the petals. Drill a hole slightly deeper and larger in diameter than the screw you want to screw into the wall. Cut a wooden chip according to the size of the resulting hole, which should fit tightly into the hole and not stick out from the outside. Before inserting the chop into the drilled hole, dip it in PVA. Hammer into the hole. This method is perfect for fragile walls that crumble for some reason. As a result, you will get a wooden section in the wall into which you can screw anything, and then hang what you really need on a self-tapping screw or screw.

How to fix it in a loose wall?

Tell me how best to securely fasten it in a loose slag wall (house built in 1964, slag walls plastered with sand-cement.) We need to fix shelves, mirrors and a wall cabinet. I don't know how to solve the problem. A regular d/g does not hold, it turns along with the dowel. You need something with a very wide thread.

In order to give a definite answer, you need to have a complete understanding of your wall. There are many fastenings for different materials and loads. Fastener stores will help you find what you need. Options are possible: both screw and opening according to the “butterfly” principle. If you plan to store heavy items in cabinets, it is better to provide longer anchor bolts. There is also a liquid anchor. - Fill the hole with it, screw in the bolts and wait until it dries. You can combine all this, I repeat, it depends on the looseness of the wall and the load.

The simplest option is to screw in a 150-180mm wood screw carefully until it stops without turning (it may turn out to be unreliable). The most reliable, but expensive, chemical anchor (it will only come out with a bite of the wall). Something in between - butterflies. Try it, experience it.

There is such a thing - mounting rail https://www. Its purpose is to redistribute the point load. And if it doesn’t stay in the wall, use an expansion anchor.

First things first, first things tools

nails, screws, rivets, anchors

Reliable fastening of the structure is a guarantee that it will last a long time without requiring additional repairs. In this regard, it is very important to choose reliable tools and fastening elements. And this choice must be approached with all responsibility.

You will need special tools . An impact drill is best.

You can also choose a regular drill, to which a pobedit tip is selected. But in this case the work will be more complicated. In terms of cost, this will result in approximately the following figures: from 800 rubles for the tool itself and from 40 to 50 rubles in addition for the drill. Running sizes are considered to be 6 and 8 mm diameters.

The list of materials that such tools can work with is extensive. Their choice will depend on the future load of the suspended structure. The most popular are the following:

- self-tapping screws for bricks;

- dowels (will help withstand heavy loads);

- anchors (capable of holding very heavy things);

- rivets (for delicate glass shelves);

- corners (for small cabinets and shelves);

- regular nails combined with all the others.

It is also important to consider what kind of product is used for laying the surface - it can be either solid or hollow. The types and grades of this product will also tell you how reliable the self-tapping screws used for bricks are.

Into drywall

When finishing the ceiling and walls, plasterboard is often used. And given that this material is relatively fragile, it is important to be careful when screwing a screw into it. So, to screw a self-tapping screw into drywall, you will need a screwdriver with an attachment or a Phillips screwdriver.

Mounting diagram

Much depends on the purpose for which the self-tapping screw will be screwed into the drywall. For example, if you need to hang a small object, you must first insert a special dowel, which, when screwed in, forms a reliable fastening. If you need to screw a self-tapping screw directly into drywall, for example, attaching it to a profile, then the technology is as follows:

- Make markings on the drywall. Depending on the possible load, the step between fasteners can be from 20 to 70 cm.

- Next, put the self-tapping screw on a screwdriver or screwdriver attachment and place it on the point.

- Then you start screwing it in. If you use a screwdriver, you should not turn on high speeds. Otherwise, there is a risk of turning the screw and it will not hold anything. This also applies to doing work with a screwdriver. Don't put pressure on her. The self-tapping screw has a thread that will allow you to screw it into drywall without much effort.

- It is very important to tighten the screw so as not to break through the top layer of cardboard. For example, if you attach gypsum board to a profile, then with great effort the self-tapping screw may simply fall into the cardboard. So, the head of the screw should lightly press the top layer of cardboard. But don’t leave it untwisted. Otherwise, you will have difficulties when puttingtying.

Scheme of correct and incorrect screwing in of a self-tapping screw

After tightening, the head of the fastener should be 1 mm below the general surface level. This will ensure sufficient tension.

We invite you to familiarize yourself with Shpornik - this is... What is Shpornik?

As for the type of self-tapping screw, its choice depends on the material used for the sheathing, whether it is wood or metal. As for the length, it is enough for it to fit into the profile up to 10 mm.

Choosing a self-tapping screw for fastening drywall

Main rules of fastening

correct fastening of screws

Before starting work, you need to understand some rules. They will help not to spoil the surface and carry out the correct fasteners:

- The most basic requirement that must be met when attaching something to a wall made of such material is not to spoil the mortar that holds the blocks together.

- It would be best to use a drill. It will help to avoid cracks that may appear if, for example, you try to “drive” self-tapping screws into a brick with a hammer drill.

- Drilling should be unhurried and gradual. This approach will help to secure any element to such a wall.

Working methods

working with self-tapping screws

There are several ways to make it easier to place fasteners on such a wall. Some of them are quite interesting:

- If we are working with dowel nails, it is important to prepare a container with water - in it we will periodically cool the drill. You can wrap electrical tape around the drill itself, which will serve as a limiter. After the hole is ready, insert the dowel glass and hammer in the nail.

- In order to facilitate the process that self-tapping screws go through when driven into a brick, you can use the “old” method. The dowel inserted into the drilled hole is strengthened with a wooden peg.

- Another “old-fashioned” method would be to drill a hole and screw a plug or cap into it, previously soaked in PVA glue. Then the “excess” peeking out from the wall is cut off and a self-tapping screw is screwed in. But such fastening is considered short-lived.

- It is best to use dowels designed specifically for brick walls. They have projections that will not allow it to turn, even if a screw or nail is screwed in. This rule applies even to hollow bricks, in which they will roll up into a knot and occupy the entire required volume.

- When you need to decorate an external wall (for example, the entrance of a house), you can use corners along with dowels and screws. They will not only connect the structure and the wall, but will even become supporting elements.

We recommend watching a video on attaching drywall to a brick wall:

Into metal

As for screwing the self-tapping screw into metal, only metal fasteners are used here. The twisting method depends on the thickness of the workpiece. If it is thin sheet metal, then you can often tighten it without much effort using a screwdriver or screwdriver. Moreover, there are different types of screws. Some have a small drill with sharpened teeth on the tip, as shown in the picture.

Self-tapping screw with drill with sharpened teeth

But as practice shows, not all such screws can be screwed into metal, this is explained by the weak sharpening of the drill. So, a screwdriver is used to tighten them. You should not gain high speed, otherwise the screw may overheat and quickly become dull. Such fasteners can be used for metal up to 7 mm thick.

We invite you to familiarize yourself with Autumn crafts from wood cuts

When making a hole, remember that its diameter should be smaller than that of a self-tapping screw. When the hole is ready, it can be lubricated with machine oil. This will allow you to tighten the screw without much difficulty.

What do self-tapping screws for aerated concrete look like?

Self-tapping screws mean fasteners that are made in the form of rods with heads. They have a special external thread with which they are screwed into the surface. That is, self-tapping screws are rod screws that have been threaded using a special variable method. This method helps to ensure fixation and good adhesion to concrete structures. The shape of the screws resembles a long rod with a pointed end on one side and a round cross-shaped head on the other.

Concrete structures require special hardware products. Manufacturers have taken this fact into account, and on store shelves you can always see self-tapping screws for aerated concrete and ordinary concrete. To screw in any other hardware, you first need to drill a hole of the required diameter; in concrete structures this can only be done using a hammer drill or impact drill. Then dowels, for example made of plastic, are driven in to the appropriate sizes, and only then can the screws be screwed in. This path must be taken, otherwise the fastener will not adhere firmly to the surface, but there are also other ways!

Self-tapping screws for concrete - dimensions and other parameters

Since these hardware must be firmly held in such a hard material as concrete, they must be made of durable metal. It is important that the material is also moisture resistant. Therefore, they are often made of stainless and carbon steel, or brass. For greater strength, self-tapping screws are covered with protective layers, so they can be of the following types:

- silver color, galvanized, good for all types of work;

- yellow, galvanized, suitable for interior work, quite suitable for external fastenings, serve well as decorative hardware;

- black with oxidized coating, used only for rooms with normal humidity levels.

In order to fasten self-tapping screws in different bases, they are specially made with certain thread pitches. Typically, for these hardware, medium pitch and variable pitch, with notches, are used. The main characteristics that can describe self-tapping screws for concrete: head dimensions, length, thread pitch. Let us give an approximate classification according to this list of parameters.

- Self-tapping screws with a medium thread pitch and a universal profile; with their help, you can make different types of fastenings. Their diameter will be 3-6 mm, and their length will be from 12 to 220 mm. This type of self-tapping screws is the most popular.

- Self-tapping screws also have a medium thread pitch, but with a different profile - herringbone. They need to be used with dowels; they will have a diameter of 3-8 mm and a length of 12 to 200 mm.

- The third type is self-tapping screws with a variable notch (dowel). Such hardware is used for fastening to concrete walls without dowels; they come with a diameter of 7.5 mm and a length of 70-200 mm.

For the last type of self-tapping screws, holes must be drilled with special drills for concrete, the diameter of which is about 6 mm, and the depth must be 10-15 mm greater than the selected length of the fastener.

Self-tapping screws for bricks without drilling a hole

If it is changing, then such a self-tapping screw cannot be combined with a dowel. Attaching screws to walls is not difficult once you understand the algorithm of operation. Before starting manipulations, you should prepare the tools. Without them, it is unlikely that anything will work out.

List of what you will need:. The surface is thoroughly cleaned and, if necessary, leveled. Mark the places where the holes will be located. After making the marks, they begin to drill holes of the appropriate length.

Since the drill gets very hot during operation, from time to time it is dipped in oil or cold water to cool the metal. If the drill length is not sufficient, insert a pin and turn it until a hole of the required length is obtained. If you are completely sure that your plastic product is not one of them, then in this case you should use the technology that was described above for soft metals, using self-tapping screws for wood. Naturally, in this case, you should again use self-tapping screws for wood.

If they are screwed into thin boards or slabs, as well as into hard wood, a thin receiving hole must first be drilled. The easiest way to work is with thick boards made of soft wood: no special tricks are required for this. Drywall is a material in which screwing screws into which involves the largest number of different nuances. The main ones include:. When working with drywall, the type of self-tapping screw is selected based on the material of the supporting sheathing.

If it is wooden, then self-tapping screws with wood threads are used; if it is metal, then universal ones are used. So, we have introduced you to the basic rules that allow you to screw a self-tapping screw into any metal in such a way as to ensure maximum reliability of the structures you create.

We hope that our recommendations will allow you to eliminate any defects and make any repairs the way you originally intended. I put all my soul and all my knowledge into the materials I write in the hope that it will be useful to visitors to our site. I would be very grateful to everyone who decides to write their opinion about my work, their comments and suggestions in the comment form available after each of my published articles.

The first screws for concrete appeared at the time when wooden houses were built. They were also made from natural material. Today, a dowel or concrete screw is used when working to strengthen window frames or wooden structures. This fastener is easy to use, but at the same time very reliable and therefore has found wide application among consumers.

It is made of durable steel and coated with zinc, which is intended for a protective function. Passivation is carried out with white or yellow metal, and we note that there is no difference between their properties.

The head of the screw is flat and can be easily hidden in the structure. And from below it has the shape of a cone and a notch, all this prevents the dowel from jumping out, and the surface does not crack. To make it easy to screw in the screw with a screwdriver or electric tool, this fastener is equipped with a cross-shaped slot. If we look at the thread, it becomes clear that it is characterized by unevenness and notches located along the entire length of the rod.

Due to the presence of these features, the dowel has high adhesion to the concrete surface, which makes it possible to produce high-quality fastening in a porous base. It follows from this that the screw for concrete dowel has a thread with a frequent pitch and therefore it is reliably strengthened and held in the wall. The dowel is used when installing PVC windows, wooden structures, aluminum profiles, door frames to concrete, brick, foam blocks, etc.

Before screwing in the screw, drill a hole in the brick or concrete using a special drill. After marking the holes, they begin to screw in the dowel, while carefully securing it. If the base is made of porous or hollow material - aerated concrete, hollow block, then the fastening process is carried out without pressure, that is, only screwing movements are made. Let's consider the required anchoring and drilling depths for various walls, depending on what material was used during their construction:

Structurally, a dowel or screw, used for fastening to concrete and other surfaces, is a rod with a thread that is alternately high or not.

It also has a countersunk head, with special notches on the inside. If we consider the use of this fastener, we can say that it is used for screwing a plastic or wooden window, door frame to any solid base. When working, first drill a hole to the required depth, and then screw in a dowel, which is tightly placed in the part. The fastenings are made independently.

The first concrete screws, also called dowels, appeared at a time when only wooden structures were built. Today, dowels are often used to fasten window frames or other wooden structures to massive concrete structures. This fastening element is very easy to use, but very reliable, and therefore it is widely used in construction circles.

If you need to attach some kind of structure to concrete, you must use just such hardware. It has great strength, reliability and durability, and therefore builders love to use it.

How to screw a self-tapping screw into concrete - preparing the hole

Self-tapping screws for working with concrete must not only withstand heavy loads, but also provide reliable and durable fastening. Therefore, materials and design are chosen taking into account these properties. Before screwing a self-tapping screw into concrete or aerated concrete, you must additionally use dowels. Thanks to these auxiliary elements, a strong and reliable fastening to load-bearing bases is ensured. Auxiliary elements are made of nylon, polyethylene and polypropylene.

These elements consist of two parts: cylindrical and spacer. The purpose of the cylindrical part is to adjust the fixation in the plaster so that the layer is not destroyed. The spacer part helps to firmly secure the entire structure in the holes. The most basic task of these devices is to ensure easy screwing of fasteners, while at the same time they must be securely fastened to the wall. We will tell you right now how to provide additional strength and reliability to the fasteners, so that in the future you can screw in a self-tapping screw into concrete without any problems.

For example, in order to drill holes, you need to use concrete drills whose diameter is equal to the diameter of the dowels. All holes must be made 3 or 5 mm larger than the length of the dowel. And you need to select self-tapping screws of the same length as the length of the dowels, or a little longer. It is important that the dowels fit into the finished holes easily and without additional effort. To install them in concrete or aerated concrete, you only need to lightly level them with light taps with a hammer. The screws are tightened using either a screwdriver or a screwdriver.

If it is important for you to make fastenings without dowels, then such a method exists, but experienced craftsmen use it very rarely. In this case, the screws will need to be screwed directly into the prepared holes. If the surface itself is made of porous materials, then drilling with a hammer drill is impossible. To facilitate the work associated with screwing, you must use any machine oil. You need to drip it or lubricate the holes. Only this method allows you to screw in the screws forever. In the future it will be impossible to unscrew them.

Self-tapping screws for concrete with a herringbone profile can be driven into the surface with a hammer. This method is also considered “eternal”, and it is not possible to unscrew the hardware back . Self-tapping screws must be driven into the prepared holes together with dowels with a hammer. The main advantage of this method is speed. In this case, no additional time is needed to install and secure auxiliary elements.

How to screw a self-tapping screw into metal – Metalist's Handbook

No matter what construction or finishing work you encounter, in 9 cases out of 10 you will have to deal with metal screws.

This publication is a kind of “mixture” of reference materials and some of the author’s own thoughts. Here you will find size charts and tips for using these products.

Self-tapping screws for fastening “seed” profiles

These products are better known under the popular name “seeds” because of their external similarity to sunflower seeds. There are both black, phosphate coated, and galvanized. Due to the very sharp tip and small size, they are ideal for fastening profiles up to 0.9 mm thick.

These self-tapping screws are much more effective when installing profiles for gypsum boards compared to “bugs” (which were discussed above). The sharp tip allows you not to crawl along the profile and accurately screw the fastener into the intended place.

These hardware are available in a version with a drill - for screwing into metal up to 2mm thick. All self-tapping screws have slots for the PH2 bit.

Table of sizes of self-tapping screws for fastening metal profilesSizeLlength, mmHead diameter, mmHhead height, mmD1outer diameter, mmD2inner diameter, mmWeight 1000 pcs, kg

| Sharp tip3.5×11 | 10,45-11,55 | 7,39-8,00 | 2,45-2,92 | 3,42-3,58 | 2,76-2,92 | 1,13 |

| Drill 3.8×11 | 10,20-11,80 | 7,60-8,00 | 2,70-3,00 | 3,75-3,95 | 2,76-2,92 | 1,13 |

To display the table, use a screen resolution of at least 601 pixels in width!

Choosing self-tapping screws for concrete - what are the criteria?

The main purpose of these hardware is to be in the wall and carry some kind of load. In order for them to last long enough, they must be selected correctly, taking into account the main design features and characteristics. Not only their service life, that is, the ability to withstand a certain load for a long time, but also their appearance will depend on their length. Today you can purchase self-tapping screws for concrete from different manufacturers. When purchasing, you need to pay attention to the thickness, the material from which they are made, and the presence of protective coatings.

It is also possible to select screws that match the color of the room design. Often decorative elements are attached to these hardware, and therefore it is possible to purchase them with colored heads.

There are also special fittings for masking on the surface of the heads. Self-tapping screws for working with concrete are particularly durable. The head is often cross-shaped for ease of use. It is important to choose the right screwdriver. Also, this type of hardware is additionally treated with an anti-corrosion layer. If, using a method such as driving, the screws remain in the wall forever, it is important that the integrity of the metal is not compromised.

Classification

This fastener is made from different materials such as brass, stainless steel and carbon steel. Also, self-tapping screws have different coatings, such as:

- galvanized (available in yellow);

- oxidized black;

- phosphated black;

- without cover.

Differ by head type:

- semi-cylindrical;

- secret;

- hexagonal;

- hemispherical.

Black screws

The use of one or another self-tapping screw depends on the density of the material that you plan to attach. Therefore, before purchasing this product, you need to decide on the following:

- Connection operating conditions.

- Is it necessary to drill a hole before screwing?

- What material should it be screwed into?

- What material will be attached.

Based on this, you make the appropriate choice, whether it will be a self-tapping screw for metal, wood or concrete.

On wood

The main difference between self-tapping screws for wood is the rare thread, unlike their counterparts intended for metal. Such fasteners can be black, gold and white. So, if it is necessary to screw a golden hinge on a door, then a golden self-tapping screw is selected accordingly. In most cases, the choice falls on a black self-tapping screw.

For metal

As already mentioned, the thread on such a self-tapping screw has a frequent pitch. This is due to the fact that metal is a fairly hard material, so the adhesion must be made strong. Moreover, some metals should not be pre-drilled, such as tin. For thicker metals, you will need to make a hole.

Roofing

Such self-tapping screws are used for fastening roofing sheet material. It must be equipped with a rubber seal. As a result, the connection, in addition to strength, becomes airtight.

This type of self-tapping screw requires pre-drilling a hole in the furniture piece. A hex wrench is used to tighten it.

These are perhaps the most common types of self-tapping screws that are used in various fields of construction. Let's look at the details of how to screw this or that self-tapping screw into different surfaces.

We invite you to familiarize yourself with the beneficial properties of hazelnuts for the human body.