How to hang a cabinet or shelf on a wall made of aerated concrete blocks

How to fix wall cabinets on a wall made of aerated concrete?

How to properly fix kitchen cabinets on a wall made of aerated concrete blocks?

Aerated concrete is currently the most common material for building houses using frame-monolithic technology. Aerated concrete is a building material that is light enough and very durable to be used to build reliable and durable permanent buildings from aerated concrete blocks. At the same time, aerated concrete has good thermal insulation characteristics, which is due to the porous structure of the blocks. The porosity of aerated concrete blocks, however, can also have negative sides when it comes to installation - hanging a wall cabinet on an aerated concrete wall . How to hang furniture in a wall made of aerated concrete blocks in such a way that heavy hanging furniture does not fall out of the aerated concrete wall and fall on the floor?

Even the highest quality kitchens and wall cabinets can cause a lot of trouble with installation on an aerated concrete wall if you do not know and do not follow the rules for securely attaching wall cabinets to an aerated concrete wall

. Specialists in the production and installation of kitchen furniture know that to reliably hang kitchen cabinets on a wall made of aerated concrete blocks, it is necessary to use special fasteners. When working with porous materials, which include aerated concrete blocks, furniture makers use elongated dowels with an increased cross-sectional diameter. They provide more reliable fastening of wall cabinets, allowing customers to rest assured about their safety, as well as the safety of the kitchen throughout its entire lifespan.

In addition to the correct choice of fasteners, when working with aerated concrete, it is also necessary to use special techniques for attaching wall cabinets to a wall made of aerated concrete blocks. There is one way to achieve reliable fixation of fasteners in a wall made of aerated concrete. First, a wooden sleeve with a diameter of 2-3 cm is driven into the aerated concrete wall, and then the fastener itself is installed into it. In this case, the fasteners can be mounted on glue or any sealant - this will improve the adhesion of the fasteners to the wall material and increase the reliability of fastening wall cabinets. The use of technology for installing wall cabinets using a sleeve and sealant allows you to mount wall cabinets on a wall made of porous and bulk material as reliably as on a monolithic stone slab.

Basic fastening methods

There are two ways to securely attach wall-mounted cabinets:

- using special furniture hooks and loops;

- using mounting tape.

Related article: What kind of garden is located within the walls of the Moscow Kremlin

The first option is not used so widely. It is suitable if the walls were not leveled during the renovation. This is a very painstaking process that requires some experience. If there is the slightest error in the calculations, everything has to be redone.

Working with a mounting rail also requires following certain rules, but this method has a number of advantages:

- It is much easier to mark under the mounting rail.

- Installation and dismantling of furniture is quite easy, while the accuracy of installation of kitchen cabinets is higher due to the presence of adjustment on hangers.

- All cabinets are placed in one tight row, without gaps.

Attention! Before working with the mounting strip, you need to take into account that after installation there will be a small gap between the wall and the cabinets. To level it over its entire height, you need to either attach the same rail to the bottom of the furniture, or select the installation height taking into account the overlap of the cabinets from below onto the kitchen apron.

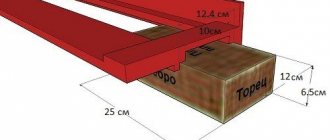

Rules for mounting cabinets on a rail:

- The first thing you need to do is attach the hangers to the side walls. At the same time, their hooks should protrude beyond the side sheet so that they can catch on the bar.

- After this, you need to measure the distance from the hook to the top sheet of the cabinet.

- Taking into account the data obtained and the height of the cabinet, markings are made according to the level of the space for the holes.

- Dowels are installed and the rail is screwed to the wall.

- The cabinets are hung and their level is precisely adjusted using screws in the hangers.

- If several elements are installed, they are fastened with an intersectional tie, after which the doors are aligned on adjacent cabinets.

Fastening furniture and equipment to aerated concrete walls

Aerated concrete is a lightweight building material with a cellular structure that is very popular. Porosity improves its thermal insulation properties. It also leads to rapid loosening of blocks when trying to hammer a nail into them or drill a hole. For this reason, hanging a shelf, TV, sink or other object on a wall made of aerated concrete using conventional methods is quite problematic: under mechanical stress, the material begins to crumble, and the fastenings become unreliable. How to fix the situation? This will be discussed further.

Fasteners for aerated concrete

+

requirements for fasteners for aerated concrete

Fastening light objects to a wall made of aerated concrete blocks - photo frames / lamps / decor - can be done using universal self-tapping screws or nails driven at an angle. If you need to fasten heavy objects - a bookshelf on an aerated concrete wall / a TV on a wall made of aerated concrete / a cabinet weighing more than 5 kg on a wall made of aerated concrete blocks - it’s not worth the risk. It is better to use fasteners specifically designed for aerated concrete foundations.

Steel dowels for mounting on aerated concrete walls

Steel dowels are made in the form of a galvanized tube with load-bearing blades. The studded structure of the latter creates good adhesion to the porous block. There are also more advanced solutions from global manufacturers that modify traditional types of fasteners to improve their properties. An example is the fischer FPX – I anchor:

NEMA nails for fastening to aerated concrete walls

?

HEMA nails are designed with a special sleeve. Thanks to this sleeve, when entering the wall, the nail bends at an angle, which increases its tensile strength. Nema nails are equipped with a special sleeve, due to which the nail, when driven into the wall, bends inside it, providing itself with increased adhesion to the wall made of aerated concrete.

Spiral nails for fastening to aerated concrete walls

When driving, spiral nails are screwed into aerated concrete without destroying the structure of aerated concrete. The adhesive strength of spiral nails is 4 times stronger than with regular nails. Spiral nails have a twisted surface, due to which the nails, when driven, are screwed into aerated concrete without damaging the surface of the aerated concrete wall.

Nylon anchors for mounting on aerated concrete walls

The wide thread of the nylon anchors allows for a secure fastening. Various screws are also used along with the anchor.

Chemical anchors for fastening to aerated concrete walls

Chemical anchors are a tube that is filled with adhesive made from organic polymers and synthetic resins. The mixture penetrates deep into the pores of the material. After hardening, it, together with the hardware, forms a monolithic structure of high strength. Chemical anchors are installed using polymer adhesives, which ensure their reliable fastening to the wall.

Fasteners are more durable the larger their length and diameter. The material from which the fasteners are made is also important. Hot-dip galvanized and stainless steel fasteners, as well as those with anti-corrosion protection, are best suited for aerated concrete. It is imperative to pay attention to this property if the use of screws and nails is intended in damp, unheated rooms or on the outside of buildings. Otherwise, the metal will rust over time and will not withstand the load, and the object hanging on the wall will fall to the floor.

To avoid the risk of bending or breaking fasteners, when choosing, you should inquire about their load-bearing capacity. But information about the density of aerated concrete will help eliminate the possibility of tearing out these elements. It is designated by the letter “D” and subsequent numbers. The higher the indicators, the stronger the wall. Ideally, be guided by the data on the packaging and in the certificates, which indicate the maximum permissible loads for fasteners depending on the density of aerated concrete.

How to hang a TV on a wall made of aerated concrete?

Mounting a TV on an aerated concrete wall

must be reliable. Technology is expensive; In addition, falling the TV is quite capable of causing a fire. Therefore, it is better not to take risks, but to secure such items correctly.

Mounting a TV on a wall made of aerated concrete

To mount a TV on a wall made of aerated concrete, you need to proceed as follows: 1. Make a hole in the wall using a hammerless hand drill or a hammer. 2. Drive a wooden bushing with a diameter of 2–3 cm into the hole in the wall. 3. Mount metal fasteners into the bushing.

To increase adhesion, the dowel can be placed on a special glue or any sealant. The fastening will be reliable and durable. It can also be used when you need to hang a cabinet on a wall made of aerated concrete. The main thing is to choose fasteners that are proportional to the weight and dimensions of the furniture. It is also worth thinking about before hanging something heavy not on a load-bearing wall, but on a partition made of aerated concrete.

How to hang a kitchen on aerated concrete?

To secure very heavy furniture structures or household appliances to an aerated concrete wall, screws, nails, self-tapping screws and similar devices are often not enough. To hang kitchenware cabinets on aerated concrete walls, it is highly recommended to use chemical anchors.

Metal

Such dowels are made of galvanized steel, they are for fastening to materials with voids, including foam blocks:

- wall office cabinets and shelves;

- kitchen cabinets and rails;

- cornices and structures for drying clothes;

- chandeliers and sconces;

- paintings and mirrors.

The dowel consists of a galvanized screw, a ring or half-ring, as well as a hollow collet, which has a non-expandable part, the length of which is selected equal to the thickness of the supporting base, and four fixation segments. The screws have a spherical or countersunk head.

Another important detail in the structure of the dowel is the side, which protects it from falling into the drilled hole. And the sharp teeth located around the circumference of the locking edge create a reliable obstacle to turning it around its axis.

Important: The structure of the dowel allows it to be dismantled by unscrewing the fastening screw, and makes it possible to reuse it without reducing the reliability of the fastener.

Frame

They are used for through fastening of slats, window frames, door frames to hollow bricks, foam blocks and gas blocks. Moreover, the frames themselves, which need to be fixed, can be made of wood, metal, or plastic.

The structure of such a dowel:

- a hollow sleeve having a conical spacer zone and a three-sided spacer part;

- screw with metric thread;

- cone-shaped bushing.

Related article: How to make an opening in a load-bearing brick wall

This fastener allows you to withstand very high loads, which is important when installing window and door structures.

Fastening furniture and equipment to a wall made of aerated concrete blocks

Aerated concrete is a lightweight building material with a cellular structure that is very popular. Porosity improves its thermal insulation properties. It also leads to rapid loosening of blocks when trying to hammer a nail into them or drill a hole. For this reason, hanging a shelf, TV, sink or other object on a wall made of aerated concrete using conventional methods is quite problematic: under mechanical stress, the material begins to crumble, and the fastenings become unreliable. How to fix the situation? This will be discussed further.

Fasteners for aerated concrete and requirements for them

Fastening lightweight objects (photo frames, small lamps, decorative elements) to a wall made of aerated concrete can be done using universal screws or nails driven at an angle. If it comes to bookshelves, a TV, or a cabinet weighing 5 kg or more, then it’s not worth the risk. It is better to use fasteners specifically designed for aerated concrete foundations.

Steel dowels

They are made in the form of a galvanized tube with load-bearing blades. The studded structure of the latter creates good adhesion to the porous block.

There are also more advanced solutions from global manufacturers that modify traditional types of fasteners to improve their properties. An example is the fischer FPX – I anchor:

NEMA nails

Their design includes a special sleeve. Thanks to it, when entering the wall, the nail bends at an angle, which increases its tensile strength.

Frame dowels.

Used for through installation. Their load-bearing capacity is increased by wedging spiral outer ribs.

Spiral nails

When hammered, they are screwed into aerated concrete without destroying its structure. The adhesion strength with these nails is 4 times stronger than with conventional ones.

Nylon anchors

Their wide thread allows for a secure fastening. Various screws are also used along with the anchor.

Chemical anchors

They are a tube that is filled with glue made from organic polymers and synthetic resins. The mixture penetrates deep into the pores of the material. After hardening, it, together with the hardware, forms a monolithic structure of high strength.

Fasteners are more durable the larger their length and diameter. The material from which they are made is also important. Hot-dip galvanized and stainless steel fasteners, as well as those with anti-corrosion protection, are best suited for aerated concrete. It is imperative to pay attention to this property if the use of screws and nails is intended in damp, unheated rooms or on the outside of buildings. Otherwise, the metal will rust over time and will not withstand the load, and the hanging object will fall.

To avoid the risk of bending or breaking fasteners, when choosing, you should inquire about their load-bearing capacity. But information about the density of aerated concrete will help eliminate the possibility of tearing out these elements. It is designated by the letter “D” and subsequent numbers. The higher the indicators, the stronger the wall. Ideally, be guided by the data on the packaging and in the certificates, which indicate the maximum permissible loads for fasteners depending on the density of aerated concrete.

Dowel for aerated concrete - design features

The soft and friable materials from which walls are built have always been problematic when it comes to attaching various household products to them. As a result, not a single manufacturer of fastening structures gave a guarantee that their anchor or self-tapping screw would adhere well to such a surface. In practice, this was very often confirmed; the soft base simply crumbled, and the fasteners lost their holding properties.

But a solution was found, it was the dowel for aerated concrete that solved the problems of installation in soft materials. The immediate solution to this issue was the specific design of such fasteners. Externally, this is a sleeve on which there are ribs made in the form of a spiral; when installing a self-tapping screw, it expands the sleeve, which, with spiral-shaped ribs, seems to cut into the soft surface of aerated concrete. As a result, we get a strong mount that holds a certain load.

Fasteners of this category are available in two versions, plastic and metal. As for the metal version, its design can also be of two types. The first design sample has the same wide spirals on its base as the plastic one, and the method of its fastening is completely identical to its plastic counterpart.

The second type of such dowel has a completely different design. It is made in the form of a bushing, which has teeth along its entire length, and the main feature is its cone-shaped shape, increasing from the bottom edge to the base. On the working surface with teeth, the metal has technical slots, which expand when the bolt or screw is tightened, and the teeth also bite tightly into the soft material.

How to hang a TV on a wall made of aerated concrete?

Mounting even a light TV on the wall must be reliable. The equipment is not cheap, so that if it falls, it can be immediately replaced. In addition, damage to the TV can cause a fire. Therefore, it is better not to take risks, but to secure such items correctly.

You need to proceed as follows:

- Make a hole in the wall using a hammerless hand drill or a hammer.

- Drive a wooden bushing with a diameter of 2–3 cm into it.

- Install metal fasteners into it.

To increase adhesion, the dowel can be placed on a special glue or any sealant. The fastening will be reliable and durable. It can also be used when you need to hang a cabinet on a wall made of aerated concrete. The main thing is to choose fasteners that are proportional to the weight and dimensions of the furniture. And, of course, you should think twice before hanging something heavy not on a load-bearing wall, but on a partition made of aerated concrete.

How to hang a kitchen on aerated concrete?

To secure very heavy furniture structures or household appliances, screws, nails, self-tapping screws and similar devices are sometimes not enough. To hang kitchen cabinets on aerated concrete walls, it is advisable to use chemical anchors.

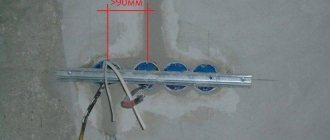

They need to be installed in this order:

- Make markings, since it will be almost impossible to correct inaccuracies in the placement of the fastener.

- Make a hole. Expand its bottom slightly with oscillating movements of the drill.

- Blow construction dust out of the recess. Insert the bushing into the neck.

- Fill the hole with adhesive mixture using a mounting gun.

- Immediately insert the anchor rod into the cavity and be sure to allow the solution to harden.

Hang a kitchen cabinet on a foam block wall

There is a wall between the bathroom and the kitchen made of 10ka foam blocks. On one side there is tile (in the bathroom). With another centimeter plaster. So the question is, is it possible to hang a kitchen cabinet from the kitchen side? If so, is it possible to load it (with dishes, for example)?

Is any additional reinforcement needed? Are special anchors needed for this?

ylgo wrote: Is any additional reinforcement needed? Are special anchors needed for this?

Need to. Anchors won't save you - you need a supporting frame.

Can you be more detailed, at least a schematic description? Is a frame necessary if there are only cabinets without heavy objects in them? (that is, put only something light there)

Yes, everything is possible. The sports corner will be difficult to secure, but will withstand static. It’s not so important what, but how and who will do it. Foam concrete is soft, i.e. It must be done carefully, but tightly and with full expansion. For example, black self-tapping screws up to 65 in 6 will not roll dowels - softly, and anchors will not bite either - they are for concrete. I use either long dowel nails or long bugs with long 6 dowels. Another question is the ears (hooks) on the furniture.

There are special dowels for foam concrete. A cabinet without heavy loads can be hung by two “ears”. If with a load, then it’s better to use a rail with 4 dowels.

Does anyone know what is stronger: plaster or foam concrete? On which wall will the shelf rest more securely?

About the same, plaster is less impact resistant and heavier. And so - the characteristics are similar. You can screw 75mm wood screws into aerated concrete without dowels, it holds quite a lot of weight. I think the locker will hold up too. My neighbor's plasma panel hangs on one of these.

Vladimir_Vas wrote: Are special anchors needed for this? Need to. Anchors won't save you - you need a supporting frame.

For several years now, kitchen cabinets have been hanging on such a wall, simply on self-tapping screws. Self-tapping screws are needed long, with a fine thread pitch. How long depends on the foam concrete. The length of the screws should be such that it is strong enough to tighten with a simple hand screwdriver, and also so that they do not go through.

As already said, either a long dowel-nail or a special one. an iron plug that can be painted with a screw, or one with a thread. Look for “foam concrete dowel”.

I don't think it's worth it with small steps. Better on wood, they hold tighter.

In this case, the cabinets need to be hung on a rail, and not by hinges at two points. We fasten the rail with 3-4 fasteners per cabinet. There are special fasteners for gas silicate, they look like a brush (metal). If you don’t find pipe cleaners, you can fasten nails onto the dowel, but first we drill the plaster with a drill equal to the diameter of the dowel, then with a drill with a diameter 1 mm less than the diameter of the dowel, we drill (without hitting) the gas silicate itself, trying not to “irritate” the hole. We hammer the plastic dowel into the hole with a light hammer and screw in the “nail”. I hung an LCD TV on a gas silicate wall like this, everything holds perfectly on 4 points, I first tried to tear it off with my own weight.

2ylgo How much does your shelf weigh? Very heavy?

The weight of the shelf/or cabinet will depend on the capabilities of the wall..i.e. it’s possible – we’ll hang a cabinet (probably 20-30 kg with a load); it’s not possible – a shelf without a load – no more than 10 kg..

Gray wrote: Kitchen cabinets have been hanging on this wall for several years now, simply with self-tapping screws.

No question - they will hang. But whether it will fall or not is the question. The trouble is that porous concrete does not support concentrated loads. When overloaded, even a long self-tapping screw does not pull out, but crushes the foam block material in the transverse direction and the cabinet lowers. The most reliable frameless solutions are screw-in plastic dowels special for aerated concrete. They have a large diameter - 10-12 mm. They do not hammer into the hole, but are screwed in, cutting a thread for themselves in the body of the foam block. But they are also suitable for relatively small loads. Frame structures allow you to make a large number of dowels with an equal load, because the frame distributes the load from the cabinet evenly over 10 or 15 dowels.

Vladimir_Vas wrote: it crushes the foam block material in the transverse direction and the cabinet lowers.

I agree, but in this case the plaster will not allow this to be done. Maybe

Vidis I don’t know about you, but our official plaster is made 90% of sand, almost without a binder and, in terms of its load-bearing capacity, only reliably holds a cockroach. If it weren’t for the soil with the wallpaper, it would have fallen off on its own.

Chip and Dale wrote: There are special dowels for foam concrete.

They don't hold. In addition, we usually save on building materials and the brand strength of foam concrete is significantly less than required. The dowels fly out with a whistle.

In this case, a chemical anchor will probably help. It's expensive - but it's most likely the only option. There is a capsule that breaks and it hardens. For foam concrete this should be suitable because... the chemical composition will still have time to be absorbed and “will reinforce a significantly larger area. Otherwise, just a frame.

Vladimir_Vas wrote: It’s not a question - they will hang. But whether it will fall or not is the question.

Perhaps I should have added “and nothing fell down”? Let me clarify. Six years ago I hung kitchen cabinets on Sibit aerated concrete (Siberian Itong). I simply screwed in 2 long self-tapping screws with a regular screwdriver onto each cabinet and hung it up. Cupboards filled to the brim with dishes hang neatly to this day. I wasn’t too lazy to get up and look - nothing had crumpled, fallen, chipped or bent. The paint wasn't even cracked (the wall had been painted before). If someone believes that 6 years is not a long time, and is looking forward to a cataclysm, well, remind me from time to time about this topic. As soon as any of the cabinets are even slightly askew, I will immediately report it.

I saw special screws for foam concrete in the store. Maybe try them?

Here someone advised to additionally lubricate the dowels with liquid nails. Will help? Oh! How about lubricating the outside of the dowel?

Is it possible to hang a wall-hung sink with a cabinet on a wall made of foam blocks?

On the Internet (I previously read everything that was said on this topic) there are very diverse solutions to this question: from “you can’t” to “everything is possible.” You can all mean either longer anchors or additional horizontal linings (reinforcements). In my blog there is a bathroom plan, the sink still looks better opposite the door. On the wall made of foam blocks. I don’t want to make a protruding part of the wall with a built-in installation. I like wall-hung cabinets. The main question is: can all this wealth be hung on a foam block wall? And how? The second question (if you don’t mind coming to my blog) is it possible, as an option, to mount a double installation on the wall (double in the sense of a sink and a toilet), then will it be normal there with the pipes for the toilet at an angle to the sewer? Or clog for all the trendy aesthetics of wall-hung sinks and choose a regular floor-standing cabinet?

Experts answered the question

Dowels for foam blocks: features of metal and plastic products

Did you like the article? Follow our channel for new ideas of useful car tips. Subscribe to us in Yandex.Zen. Subscribe.

Very often you hear that walls made of foam blocks are inconvenient, since it is impossible to hang anything on them. They say that it is necessary to arrange special mortgages during the laying of the masonry, to which it will then be possible to screw fasteners for various accessories, from paintings to shelves.

This involves not only additional costs, but also the need to plan the entire design of the premises in advance, down to the smallest detail. And, if you want to hang a picture on the wall later, you will not be able to do this.