Preparing the surface of aerated concrete base

The base surface is leveled or levelness is checked. The first row of AEROC blocks is laid on the laid mortar. Possible differences in the height of the masonry can be easily eliminated using mortar. When laying the first row of AEROC blocks, you must work especially carefully - this row is the “foundation” for all subsequent rows.

After laying the first row of AEROC blocks, it is necessary to remove all uneven areas using a plane, then sweep away dust and small fragments.

Installation of AEROC lighthouse blocks and tensioning of the mooring line

The corners and junctions along the perimeter of the wall are leveled and corner lighthouse blocks are installed. Masons pull a mooring cord at the level of the top of the lighthouse blocks, at a distance of 2-3 mm from the side edge, and secure it. To eliminate sagging of the cord with a significant length of the wall (wall), intermediate lighthouse blocks are installed.

When rearranging the cord, it is tied to nails secured to the seam of the masonry.

Stages of correct reinforcement of a strip foundation

The manufacture of any foundation requires adherence to a certain sequence:

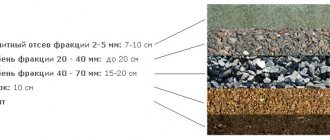

- The first thing to do, after the foundation trench has been dug, is to make a sand and gravel cushion, and then lay down pieces of brick, creating a kind of support for the reinforcement frame. This will allow the reinforcement to be deepened inside the concrete so that it does not deform, while the strength of the foundation will be much higher. In addition, the reinforcement should also retreat 5 cm from each edge of the foundation walls.

- It is important to know that to increase strength, it is better to use whole pieces of reinforcement for longitudinal rods.

- Next, you need to drive vertical rods into the ground along the entire perimeter of the tape so that cells about 20x30 cm in size are subsequently formed.

- Then, after installing all the vertical rods around the perimeter of the foundation, you need to screw the lower tier of reinforcement from the longitudinal rods, and then proceed to the upper tier. It is best to use a crochet wire and a special crochet hook or gun for this. They can be purchased at special construction stores or made independently.

Particular attention must be paid to the corners of the strip foundation, because the load on them is much greater. Most often, the corners of the tape are strengthened using L-shaped reinforcement elements. They must be bent at an angle of 90 degrees in advance, and then connected according to the diagram:

- Having completed the formation of the strip foundation, the result should be a single metal frame that has good stability.

- Finally, the foundation is poured with concrete at once and left covered for 2-3 weeks.

Preparation of AEROC mortar mixture

Before laying AEROC blocks, it is necessary to prepare a composition from a dry mortar mixture. Mixing is recommended to be done mechanically (with a mixer, drill with an attachment, etc.), by gradually adding the dry mortar to a pre-measured amount of water at room temperature, with constant stirring until a homogeneous mass is obtained. .During the work process, it is necessary to stir the prepared solution from time to time to maintain the uniformity of its consistency. Installation of the AEROC block on the applied solution should be carried out in no more than 15 minutes.

In the cold season, masonry mortar with anti-frost additives is used as a leveling layer for laying the first row of AEROC blocks.

Marking and preparation of aerated concrete blocks AEROC

Markings are made along the axis of the wall of the location of the receptions, the junction of the internal walls with the external ones. After this, blocks are taken from the pallet delivered to the laying site (1.8 m3 or 1.92 m3 of blocks on one pallet) and laid out for laying walls of one row along axis of the wall. To bandage the seams of vertical restrictions, junctions and intersections of walls, partitions, incomplete AEROC blocks are required.

Masons prepare such blocks at the workplace using hand tools: a hacksaw (mechanical band saw, electric saw) and a marking square.

Technology of reinforcement and concreting of building structures. 1. Purpose and types of reinforcement

Reinforcement is steel rods, rolled profiles and wire located in concrete to work together with it.

Prefabricated monolithic and monolithic non-tensioned structures are reinforced with enlarged mounting elements in the form of welded meshes, flat and spatial frames, which are manufactured outside the structure being constructed and then installed by assembly cranes. Sometimes complex structures are reinforced directly in the design position from individual rods and connected into a complete reinforcement frame by welding or knitting.

The fittings are divided according to their purpose in the structure into working, distribution and installation (Fig. 8.1).

Working reinforcement absorbs tensile forces arising in reinforced concrete structures from its own mass and external loads.

Distribution fittings serve:

• for uniform distribution of loads between the working rods;

• to ensure their collaboration;

• to connect the working rods with each other, preventing the displacement of the working reinforcement during concreting.

Mounting reinforcement usually does not absorb forces, but ensures the exact position of working rods and flat reinforcing meshes and elements in the formwork.

The main reinforcement in modern construction is periodic profile reinforcement, which has reliable anchoring and increased adhesion to concrete. When using rods made of smooth reinforcement, for better fastening in concrete, the ends of the tensile rods are bent in the form of hooks.

In civil engineering, reinforcing bars with a diameter of 12...30 mm are usually used, in industrial engineering - reinforcement with a diameter of up to 40 mm, in hydraulic engineering - rods with a diameter of 90... 120 mm. Rolled profiles are sometimes used as reinforcement.

Reinforcing products include individual rods (bar reinforcement), reinforcing mesh, flat and spatial reinforcement cages, reinforcing products for prestressed structures, embedded parts, mounting loops and clamps.

Rod reinforcement is made with a smooth profile (due to low efficiency, its output is reduced) and periodic with the projections arranged along a helical line or in a herringbone pattern. The fittings are divided depending on the manufacturing technology into hot-rolled (divided into 5 classes from A-1 to A-VI according to the old designation - according to the new designation A-240 (A-1), A300 (A-III), A400 (A-IV ), A800 (AV), A1000 (AV1)) and hot-rolled with subsequent hardening by stretching in a cold state, it has 2 classes - A-Pv and A-Shv.

Welded reinforcing mesh consists of mutually intersecting rods, connected at the intersection points by welding. They are produced with longitudinal, transverse and mutually perpendicular working reinforcement. In general, the meshes combine working and distribution reinforcement and consist of individual wires with a diameter of 3 to 9 mm inclusive and reinforcing steel rods with a diameter of 10 mm, located

Rice. 8.1. Types of fittings:

a - reinforcing bars; b - flat frame; c - spatial frame; g—reinforcing mesh: 1—flat; II—roll; d - reinforcement block; e — hot-rolled reinforcing steel rod: /—smooth; //—periodic profile; g - column frame made of rod reinforcement; h - the same, from rigid reinforcement; 1 — working rods are straight; 2 — the same, bent; 3 — mounting rods; 4 - clamps; 5 — distribution rods; 6 — grids; 7 — spatial frame; 8 — reinforcement outlet; 9—corner; 10— brace

located in two mutually perpendicular directions and connected at the intersection points by resistance spot welding. These meshes are used when necessary to provide the structure with minimal non-design reinforcement. The distance between individual rods ranges from 50 to 250 mm; the cells formed between the rods and wires usually have a size from 50x100 to 150x250 mm. The total width of the mesh along the axes of the outer rods is set from 900 to 3500 mm (the mesh must be placed between the longitudinal sides of the truck during transportation).

Rice. 18.2. Reinforcement for prestressed structures:

a-seven-wire strand; b- the same, 19-wire; c, d - ordinary wire ropes (strands of 7 and 19 wires); d - the same, three-strand; f, g - beam; h, i - multi-strand ropes; I - working wire; 2, 9 - knitting wire; :spiral; 4- shorty; 5-axis rod; 6, 7 - external protective coating

Flat working meshes are produced up to 2.5 m wide, up to 9.0 m long, sometimes up to 12.0 m in accordance with the order. Longitudinal working rods have a diameter of 12...25 mm with a pitch of 200 mm, mounting fittings are usually with a diameter of 8 to 12 mm with a maximum pitch of up to 600 mm. If necessary, meshes at factories can be subjected to additional processing - cutting holes, welding additional rods and bending.

Meshes in the form of rolls have a wide range of steel used, rod diameters, mesh sizes and mesh widths. The length of the nets is not specified, but the weight of an individual roll should not exceed 1200 kg.

Flat steel frames usually consist of longitudinal reinforcement, forming one or two chords and connecting them with lattices in the form of individual transverse or continuous rods in the form of a snake. A large number of transverse rods in the frames, connected to the working rods by spot welding, creates reliable anchoring of the longitudinal rods in concrete along their entire length and makes it possible to avoid bending the hooks even with smooth reinforcement. Working reinforcement for standardized frames is accepted with a diameter of 10 to 30 mm, and distribution reinforcement is accepted only with a diameter of 10 mm (during welding, rods with a smaller diameter may burn out). Frames are used for reinforcing linear structures - beams, purlins, crossbars, hollow-core floorings.

Spatial reinforcement frames consist of two or four flat frames connected to each other by separate rods or clamps. Such frames are used to reinforce columns, beams, crossbars and foundations.

Sometimes reinforcement load-bearing frames are used, which together with the formwork are called reinforcement-formwork blocks. Typically, such a decision is made when it is necessary to erect a single structure with a span of up to 9 m. In this case, rolled profiles are used for reinforcement, mainly in the form of angles, strip and square steel, which allows, with some overexpenditure on reinforcement, to do without special scaffolding, racks, supporting formwork block, reduce the consumption of timber, significantly reduce labor costs and work time.

Mounting loops , made of reinforcement, are an element of prefabricated reinforced concrete structures and are intended for slinging during lifting and installation.

Embedded parts - metal plates attached to the reinforcement frame of a structure by welding, are necessary for connecting prefabricated elements to each other during the construction of buildings and structures; The joining of elements is carried out by welding embedded parts embedded in the structure during their manufacture.

Clamps are used to connect individual working and mounting rods into a finished spatial frame.

To reinforce prestressed structures, wire reinforcement is most often used (Fig. 8.2).

Wire reinforcement is divided into several types:

• low-carbon reinforcing wire of class B-1 and high-strength carbon reinforcement wire of class V-P;

• wire strands from three-, seven- and multi-wire strands with right-hand lay, and when cutting the strands, the wires do not unwind;

• high-strength wire ropes.

In recent years, non-metallic reinforcement in the form of fiberglass and asbestos has begun to be widely used.

Fiberglass mixed with cement mortar forms glass cement, which has high strength but low water and gas permeability. The strength of cement stone increases when chopped fiberglass is used with its chaotic distribution in the structure. Also, a monolithic structure with a chaotic distribution of scraps of reinforcing bars and wire in it will have high strength characteristics.

Using asbestos fibers, asbestos cement is produced, products from which have high strength and impermeability.

Laying aerated concrete blocks AEROC

The mixed mortar mixture is applied evenly using a toothed comb (trowel) onto the previously laid AEROC blocks. In the case of using rectangular AEROC wall blocks, the mortar is applied to the butt and horizontal seams.

In the case of using tongue-and-groove AEROC wall blocks, the mortar is applied to the horizontal seam and partially to the side zones of the end surface.

After this, the next block is laid and pressed. The size of the comb teeth is 4-5 mm. The thickness of the seam between the blocks should not exceed 3 mm. The blocks are laid with bandaging in the floor of the block.

The mortar protruding from the seam is not rubbed down, but is removed using a trowel.

After laying each row of AEROC blocks, they are leveled using a grater or plane, and then dust and small fragments are swept away with a brush. After laying the blocks of one row, the mooring cord is pulled for the next row of masonry. Junction nodes of external and internal walls, junctions of window and door openings, are carried out according to the working project drawings.

The walls of their AEROC blocks must be waterproofed where they adjoin the plinth, first floor floor and basement.

Punching of blocks and reinforcement with steel and composite rods

Recesses - grooves, are made with a wall chaser, grinder and jigsaw. Depth and width within 25 mm. Any tool that is capable of forming a recess/groove for the reinforcing rod can participate in the process. To enhance the effect, the reinforcement technology provides two recesses no closer than 5 cm to the edge of the block. If the block thickness is more than 500 mm, a third rod will be required. Connections are not allowed at corners. The rod must be curved.

If the reinforcement is made with one rod, then the groove is located in the center. The connection of the reinforcing rod is carried out by any of the acceptable methods (welding, coupling, overlap).

In places of overlap (which is recommended approximately 4 cm), the groove should be much wider. Before laying the reinforcing rod, the recess should be cleaned. For higher adhesion, you can moisten the groove, then fill it with glue used for laying the blocks, and lay the reinforcement, not forgetting about the overlap.

Russian building codes do not include fiberglass reinforcement, but its use is not prohibited. In the West this is an everyday practice. There are certain advantages inherent to composite materials:

- Deformation stability;

- a light weight;

- low thermal conductivity;

- corrosion resistance.

The main disadvantage is that connecting sleeves are required, since welding cannot be used, nor can such a rod be bent before installation.

Reinforcement of aerated concrete masonry

The need for reinforcement and the location of the reinforcement is determined by the designer. The following must be reinforced:

- long walls for which it is necessary to provide resistance to lateral loads (wind); parts of the wall with an increased load; the first row of blocks on the foundation; the bottom seam of window openings (at least 900 mm on both sides of the opening); the supporting surfaces of the lintels (900 mm).

As reinforcement for joints in walls made of AEROC blocks, it is recommended to use A-III reinforcement, with a diameter of 8 mm. To lay the reinforcement, grooves are cut in the blocks, which are filled with block glue before laying the reinforcing bars. After this, the reinforcing bars are pressed into the grooves filled with glue so that they were completely covered with glue.

The distance of the suture reinforcement belt from the outer surface of the AEROC block should be about 60 mm.

Reinforcement of monolithic walls and piers

The percentage of reinforcement from the wall section is about 10%. For this process, steel reinforcing mesh or frame is used (for increased strength).

Strengthening with reinforcement is most often performed horizontally and vertically. For this, rods with a diameter of 6-8 mm are used. They are placed symmetrically near the side walls. Horizontal rods with vertical rods at opposite side walls are connected by transverse links. Such connections are needed in order to prevent buckling of vertical reinforcement. Reinforcement of the corners of a monolithic wall is mandatory. To do this, it is advisable to use U-shaped clamps. They provide the necessary fastening of the ends of the horizontal rods and protect the vertical ones from bulging.

A pier is a part of the wall between two openings (windows, doors). Reinforcement of small partitions in monolithic walls occurs using flat meshes mounted on both sides. If the floors are prefabricated, then a prefabricated frame is used. The flat walls of the first wall need to be combined with spatial frames by connecting the rods.

Checking the correct masonry

After laying each row of AEROC blocks, it is necessary to check the correctness of their installation. The correct laying of the corners of the building is controlled with a wooden corner, horizontality - with a rule and a level. To do this, the rule is placed on the masonry, a level is placed on it and, having leveled it horizontally, the deviation of the masonry from the horizontal is determined. If it does not exceed the established tolerance, the deviation is eliminated when laying subsequent rows. After 2-3 rows in height, the evenness of the masonry is checked with a level. The verticality of the wall surfaces and corners of the masonry is checked with a level and plumb line. Deviations that do not exceed the permissible limits are corrected during the subsequent laying of the floor. Deviations of the structure axes are eliminated in the levels of interfloor floors.

The length of the walls is checked with a meter (tape).

Reinforcement of walls made of aerated concrete blocks is a prerequisite. This rule is dictated by certain operational characteristics of aerated concrete. If the walls made of this material are not reinforced, the service life of the building is significantly reduced.

What determines the need for reinforcement of aerated concrete?

Despite the fact that aerated concrete has a high degree of compressive strength, it has low resistance to tension and bending. After construction, a house is subject to a number of negative factors, such as shrinkage of the building and temperature changes. These factors lead to the risk of shrinkage and temperature deformations.

When a building shrinks, horizontal stress can lead to cracks and breaks in the wall that are incompatible with its further operation. Such violations are called shrinkage deformations.

In addition, temperature deformations occur. Almost all materials have the property of contracting when the temperature decreases and expanding when it increases. Such vibrations can lead to a violation of the structural integrity of the walls.

It is to prevent this kind of problems that reinforcement is made of walls made of aerated concrete blocks.

Reinforced rows protect the entire structure from horizontal loads caused by temperature changes or shrinkage of the building. We are talking about protection from horizontal deformations because vertical loads are absorbed by gravity. However, it also creates additional stress in the area of the openings, so protection against vertical loads is also provided.

Separately, it is worth noting that reinforcement does not increase the load-bearing capacity of the walls.

Nuances of reinforcement

When independently reinforcing monolithic walls, the following factors should be taken into account:

- When creating reinforcement mesh, it is best to use new steel bars because they can withstand heavy loads.

- If rust is found on new rods, do not remove it. This can lead to poor adhesion between concrete and rods.

- To cut the rods, it is best to use a grinder. If the rod needs to be bent, then the bend site is preheated immediately before the manipulation itself. But this is highly not recommended. As with welding, the material loses strength.

- If concrete has already been poured into the formwork, then reinforcement cannot be installed. If the order of work is not followed, then the whole process must be started over.

- It is also not recommended to increase the reinforcing mesh in length or height, since under heavy loads, tears may form in the areas of expansion. If such loads are not expected, then you need to perform this work as efficiently as possible.

There will be a heavy load on the walls of rooms located below ground level. Therefore, to install the mesh, you need to choose high-quality reinforcement of standard sizes, and reinforcement units for monolithic walls should be made of special wire.

Reinforcement materials

Reinforcement of aerated concrete masonry can be carried out in different ways and using different materials. The following materials can be distinguished for strengthening walls:

Fittings. The classic method of reinforcing aerated concrete masonry. It uses reinforcing bars with a diameter of 0.8 to 1.4 centimeters.

The technology of their use involves the formation of gutters in the masonry, corresponding in size to the diameter of the reinforcement and taking into account the fact that the solution will also be poured into them. As a rule, with a standard thickness of an aerated concrete block, two parallel gutters are formed. When reinforcing corners, gutters are made in the shape of an arc.

Reinforcing bars

In the classic case, metal rods are used as reinforcement.

However, there is a more advanced material - fiberglass reinforcement. It is devoid of a number of disadvantages inherent in steel. The following advantages of fiberglass fiber can be highlighted:

This composite material has high chemical resistance and, unlike metal, is not subject to corrosion. It bends quite simply, which greatly simplifies the reinforcement of corners. The tensile strength of fiberglass is many times greater than that of metal.

At an identical load level, the permissible thickness of composite reinforcement is less than that of metal reinforcement. Thanks to this, you can make smaller gutters for laying it and save solution. Fiberglass, unlike metal, practically does not expand when the temperature rises. This helps reduce the mechanical impact on the walls from the inside. Composite reinforcement has low thermal conductivity and does not conduct electricity.

However, this material also has a number of disadvantages, including the impossibility of fastening its pieces using electric welding.

This problem is solved by placing metal tips at the ends of the reinforcing bars, which are subsequently welded. This improvement is made in the factory. In addition, due to its high bending ability, its use in reinforcing floors is not recommended.

Metal network. Reinforcement of masonry with iron mesh is carried out by applying it to a number of aerated concrete blocks without pre-processing the latter.

After this, the network is covered with a solution. The reinforcing mesh, as a rule, has the following characteristics: the side of the square cell is 5 centimeters, the thickness of the wire is from 0.3 to 0.5 centimeters. The mesh for reinforcing openings and the first row of masonry is subject to slightly higher requirements: the mesh size is 7 by 7 centimeters, and the wire thickness is from 0.4 centimeters.

Metal net

Mounting perforated tape. Another option for reinforcing the masonry of aerated concrete blocks. The tape is a long strip of galvanized metal dotted with holes, hence the name perforated.

Reinforcement using this material is carried out similarly to the method using reinforcement. The difference is that there are no gutters in the masonry. The tape is attached using self-tapping screws directly to the gas blocks.

Mounting perforated tape for reinforcing gas blocks

This option is applicable for buildings whose design load is relatively low. Since the cross-section of the tape is much lower than that of the reinforcement, its laying should be carried out in a larger number of parallel rows than laying metal rods. The advantages of using this material include ease of transportation and saving of mortar, due to the absence of gutters in the masonry.

Construction stores sell tape in different sizes. Not every one of them is suitable for reinforcing masonry. It is necessary to use tape at least 1.6 centimeters wide and at least 0.1 centimeters thick.

SNiP requirements for installation of fittings

General schemes and requirements for the construction of structures using concrete (reinforced concrete) are defined in SNiP 52−01−2003. This document contains rules for calculating the susceptibility of reinforced concrete to deformation, its ability to form cracks, strength indicators, requirements for the size and shape of the structure:

- when constructing foundations, you can only use reinforcement that meets the standards , with a quality certificate, defined in the design documentation;

- the rods are interlocked in such a way as to completely eliminate the possibility of their displacement during concrete pouring;

- if welded frames or meshes are used to reinforce a strip foundation, then in their manufacture it is allowed to use a welding method that does not allow deformation;

- the bending radius of the reinforcing bars must correspond to that required in the project;

- mechanical joints of reinforcement should not be inferior in strength to the strength of the base material;

- the distance between the vertical rods depends on their diameter , type of concrete mix aggregate, location in the frame, method of pouring concrete, but a step less than 25 cm is not allowed;

- the distance between the longitudinal rods should not exceed 40 cm;

- the distance between the rods installed transversely should not exceed 30 cm.

For vertical reinforcement, rods with a diameter of 10−12 mm with a ribbed surface are used. For a longitudinal arrangement, the diameter of the reinforcement should not be less than 10 mm and more than 32 mm. For transverse placement, reinforcement with a diameter of 6 to 8 mm is used.

Reinforcement of the top and bottom rows

When reinforcing masonry, there is no need to strengthen each row.

As a rule, the laying of reinforcement, tape or mesh is performed in a certain step, for example, every third row. However, there are a number of elements that are always strengthened without fail. These include the extreme upper and lower rows of the wall.

The upper level of the wall is the basis for the roof structure, which causes the impact of additional loads on it. The total mass of the roof presses unevenly on the top row, so its individual parts are loaded more than others.

The difference in these pressures can cause a violation of the integrity of the wall. For this reason, special attention is paid to the reinforcement of the uppermost row. When the masonry is reinforced with aerated concrete, even the partitions in the top row are reinforced.

The bottom row of masonry is subject to the greatest loads, because the weight of the entire structure presses on it. Therefore, it is more susceptible than others to the risk of shrinkage deformations. Reinforcement of the first row is recommended even for small-sized buildings.

Reinforcement of aerated concrete masonry

Correct reinforcement of the masonry is carried out every four rows with a block height of 250 mm or in increments of three rows if blocks with a height of 300-350 mm are used. That is, a step is maintained, approximately 1 meter. The first row above the foundation must be reinforced. In addition, areas where additional load on the structure is provided are reinforced:

- Above and below the window opening (with an overlap of up to 1 meter on both sides),

- row corresponding to the level of the Mauerlat,

- area (min. 1 meter) where the lintels will be supported.

Types of wall reinforcement

Using division based on the purpose of strengthening the walls, the following types of masonry reinforcement can be distinguished:

To strengthen areas with increased load. These areas include door and window openings provided for by the building design. To prevent the occurrence of cracks and ruptures due to temperature and shrinkage deformations. To protect against destructive natural factors. This type of amplification is relevant for regions where seismic activity or frequent hurricane winds are observed.

Unlike previous methods, in this case vertical reinforcement of the walls is used. This procedure is widely used not only for aerated concrete walls, but also for brickwork. This is a fundamentally different method of strengthening buildings, deserving a separate article.

Construction regulations, state standards for cellular concrete

Recommendations for the construction of houses from aerated concrete, the installation of engineering and communication elements, components, requirements for the production of aerated concrete blocks, hollow-core slabs can be found in the following regulatory documents:

- GOST 9561-91 – standard for reinforced concrete hollow-core slabs for floors;

- GOST 10884-94 - standards for steel for reinforcement of reinforced concrete structures;

- GOST 31359-2007 – for cellular concrete;

- GOST 31360-2007 - standards for wall products made of cellular concrete;

- SP 22.13330.2011 – set of basic rules “Foundation of buildings and structures”.

Here we will consider the general requirements and types of materials used for reinforcement