The importance and necessity of finishing the base

Painting the base improves its appearance and protects it from external influences.

Painting the base allows you to solve several important issues, but you need to choose the composition taking into account climatic conditions and operating characteristics. It is also important to understand why this procedure is needed:

- Many materials that are used to build a foundation have a porous structure, so moisture can penetrate inside, destroying the structure.

- Concrete or brick is subject to mechanical stress. The paint protects the base from damage.

- The above-ground part of the foundation is subject to rapid contamination, which worsens its appearance. Painting the surface will make it easier to maintain.

A concrete structure without proper finishing does not look very aesthetically pleasing. Paint treatment allows you to achieve a decorative effect: the base will look neater, and minor construction defects will not be visible.

Technology for painting the base of a house

For those who are comfortable with basic painting tools, the process of painting the basement of a house should not cause any difficulties. The following tools may be required for work:

- bayonet shovel;

- a metal or plastic brush with hard bristles;

- brushes;

- rollers;

- electric spray gun;

- putty knife.

The sequence for finishing the base is as follows:

- check the quality of the house's foundation. If painting a new foundation, make sure the concrete is completely dry - some types of paints are not recommended for use on a wet base. When finishing an old basement, before painting the foundation of the house with a stone or other texture, thoroughly clean the lagging areas and fill them with new mortar, troweling them in with a float. If necessary, remove some of the soil from the base of the building and clean the surface.

Advantages and disadvantages of painting the foundation plinth

Before choosing a suitable composition, you should consider the advantages and disadvantages of this finishing method. Base paint has the following advantages:

- decorative: most compositions have improved qualities;

- variety of textures and breadth of colors;

- affordable price for any buyer;

- improving the appearance of the base and extending its service life;

- ease of application (here you can use manual and mechanical methods);

- the ability to work under a wide range of humidity or temperature;

- the presence in paints of components that provide breathability;

- the ability to change the appearance of the structure.

This finish fits into any exterior design style. However, the paint has some disadvantages: not all compositions are vapor-permeable and adhere firmly to the surface. High-quality and durable mixtures are expensive. Their application requires preliminary preparation of the base.

Carrying out preparatory work

Before you begin finishing the outer part of the base, it is necessary to carry out preparatory measures:

- Cleaning the foundation surface from dust and dirt

- Grouting joints and smoothing the surface

- Sealing cracks and cracks

- Conducting a blind area along the entire perimeter of the building

- Applying a layer of waterproofing. The materials used can be roofing felt or bitumen.

- Installation of a thermal insulation layer. Materials – polystyrene foam, polypropylene foam, isover, etc.

- Before covering the foundation, it is necessary to prime its surface, level it and plaster it.

After all the work is completed, you can proceed directly to the procedure for finishing the base with facing materials.

Coatings used

Finishes for concrete, as well as other building materials, must meet certain requirements. A good coating has the following qualities: resistance to abrasion, decorativeness, inertness to the influence of chemicals and precipitation. For external application, silicone, alkyd, polyurethane paints and enamels are used.

Alkyd based

Alkyd compounds are more suitable for working with metal and wood substrates. They protect the surface from moisture and aggressive substances. The layer does not fade for a long time under the influence of ultraviolet radiation, but it will have to be renewed periodically. The composition will reliably protect the base from mechanical damage and is resistant to abrasion. Chemicals can be used to clean the surface.

Since the paint contains a solvent, you need to work with it in protective clothing, gloves and a respirator - the substance has a strong, unpleasant odor. Do not store them near open fires - alkyd mixtures ignite easily.

Polyurethane paints

The main advantage of polyurethane-based paint is durability and decorativeness. The aesthetic qualities of a layer can be improved by changing its texture. The coating reflects the negative effects of ultraviolet radiation, chemicals and precipitation, and also prevents mechanical damage to the base. To achieve this effect, the peculiarity of the material allows it to penetrate into the smallest pores of the structure and clog them.

To achieve maximum effect, the composition is applied in several layers. The layer gains final strength in 1-2 weeks. The only drawback of this foundation paint is the high price, although it quickly pays for itself.

Enamel

The composition of enamel paint contains varnish, resin, and polymer components. Before use, you need to prepare it: mix it with a small amount of solvent. This finish is durable, resistant to moisture, and provides a beautiful glossy shine. The advantage of the product is the variety of color options. However, the mixture does not allow air to pass through well, so indoor humidity problems may arise.

If there is a risk of exposure to high temperatures on the base, it is better to use fire-retardant paint for finishing. It is suitable for metal surfaces. Such material must be stored correctly: in a dark, dry place.

Silicone compounds

To paint the base of a house, it is optimal to use a silicone compound. It is best suited if the surface is finished with plaster. The coating layer is durable, securely fixed to the surface, and resistant to the influence of almost all negative factors. Silicone paint is elastic (does not crack even when the building shrinks) and is capable of allowing air to pass through. The finish retains its decorative effect and color for a long time, as it is resistant to ultraviolet radiation.

Polyvinyl acetate paints

Before painting the foundations with polyvinyl acetate paint, you need to dilute the mixture with water (it has an adhesive base). This composition is cheap, but the coating is not resistant to abrasion and precipitation. This material is used the least often.

Concrete paint manufacturers

The main difference between paints is their chemical composition. All the characteristics of the paint coating depend on it. Nowadays there is a huge selection of paints of all colors and textures on sale.

Mizar Rezolux Profi-52

This enamel is intended for painting concrete floors and stairs. It is characterized by increased frost resistance - the minimum permissible operating temperature reaches -15°C. While similar products (which include, for example, the popular Tikkurila Betolux Aqua) are not recommended for use at temperatures below +5°C.

Mizar Rezolux Profi-52 is suitable for painting concrete surfaces inside residential and non-residential premises (warehouses and garages), as well as interfloor and street stairs. For example, one of the largest housing developers in Russia uses Rezolux Profi-52 to paint public areas and staircases.

Enamel can be used not only for painting concrete, but also furniture, doors, wallpaper for painting and other surfaces. It has excellent wear-resistant, water-repellent and strength properties. The cost of 1 kg of “Mitsar” Rezolux Profi-52 is 220 rubles. And this is four times cheaper compared to the popular Tikkurila Betolux Aqua enamel.

The St. Petersburg manufacturer - the Mizar company - is notable for its vast experience in the development and production of coatings with increased wear and weather resistance (exposure to high/low temperatures, precipitation, etc.).

For example, Mitsar enamels with anti-corrosion and acid-resistant properties were used in the construction of the Leningrad and Kola nuclear power plants. Also, the manufacturer’s materials have the lowest (up to 5 times!) price among competitors with the same or higher parameters.

Therefore, paint and varnish materials of the Mizar company regularly win tenders and are actively supplied to enterprises within the framework of the State Defense Order.

Pre-primer

Before painting the surface of the base, you need to treat it with a primer. After this procedure, the adhesion of the composition to the base will increase and the decorative properties of the finish will improve. This preparation will reduce paint consumption. For apartment buildings located in industrial areas of cities, an acrylic-based mixture is suitable, which provides breathability and reliable protection.

If the structure is built in an environmentally safe region, then you can choose a water-dispersion solution. For porous materials, you need to select a special deep penetration primer. It is better to choose the protective and decorative composition of one manufacturer.

You can make your own primer. To do this, paint or enamel must be diluted with solvent in a ratio of 10:1. This composition is the first layer of finishing. Professional solutions are applied 1-2 times. In this case, the previous layer must dry completely.

Types of paints for concrete

Coloring agents include water-dispersion paints, alkyd substances and polyurethane compounds.

All of them must withstand:

Products used in industrial areas and near roads must be resistant to the activity of chemical compounds. These can be solvent-based paints, before using which an acrylic primer is used.

The choice of paint composition is also influenced by the material of the base, the surface of which can be clean or covered with plaster.

Acrylic paints

A dispersed variety of paints and varnishes based on acrylic dyes, resins and copolymers. When finishing, a durable polymer coating with good adhesion is formed on the concrete surface, which is facilitated by preliminary priming. Such paints are not suitable for surfaces made of silicate and lime plaster due to low vapor permeability. The product consumption is 0.35-0.4 kg/sq.m. m. It is easy to apply and dries quickly.

Silicone paints

The product is used for painting surfaces coated with mineral paints. It can also be applied to fresh concrete, as long as the humidity level is no higher than 50%.

The advantages of silicone paints include:

- frost resistance;

- waterproof;

- self-cleaning ability;

- quick drying within 4 hours;

- efficiency - 1 liter per 8-9 sq. m.

Epoxy paint

The material does not fade and is resistant to water and chemical compounds. It can be used to color newly laid concrete. Esters, alcohols and aromatic hydrocarbons are used as solvents. Before such finishing, it is necessary to prepare the surface. Apply the paint in 2 layers, each of which dries within 24 hours.

Polyurethane paint

A two-component composition resembling epoxy enamel in its characteristics. The hardener here is an aromatic or aliphatic isocyanate. The first of them gives the coating a yellowish tint, as a result of which the paint gradually loses its gloss. An aliphatic chemical compound is more expensive, but allows you to maintain the visual appeal of the finish.

The coloring material is not afraid of low outdoor temperatures and can last up to 15 years without repair. Penetrating into the structure of concrete, the composition strengthens it from the inside, creating a dense polymer film 200 microns thick. To obtain such a coating, 2 layers of paint will be required. Mechanical strength of the coating occurs after a week, chemical strength - after 2 weeks.

Silicate

The basis of the material is liquid potassium glass and coloring pigment. As a result of their connection, a solid adhesion to concrete is formed. This coating is resistant to climate influences, has good strength, but is also breathable. The use of silicate paints requires skill in working with such products. The mixture can be applied to damp and previously painted surfaces. The exception is foundations finished with organic materials. Then modified substances based on synthetic resins are used.

Alkyd

The popularity of alkyd products is explained by their availability. The raw materials for them are resins obtained from vegetable oil processing.

Among the advantages of these dyes:

- quick drying;

- frost resistance;

- waterproof;

- long service life;

- deep penetration into the concrete structure;

- the possibility of changing the composition by including additives;

- rich color palette;

- economical paint consumption -180 g/sq.m. m.

Oily

The dyes contain drying oil and pigment fillers. After drying, they form a dense, durable film. The substance is applied to the surface only after the concrete has completely hardened. The paint itself dries for 24 hours. One of the advantages of the material is its economical consumption - 250 g/sq. m - and a rational ratio of price and quality. However, the product quickly loses its protective properties and shine.

Cement

These compositions include light grades of cement, pigments and polymers. They are used for finishing plastered walls, stone and concrete plinths. The main disadvantage of cement paints is their fragility.

Processing and painting technology

If the surface of the base has a large area, it is better to use a spray gun

Before painting a concrete foundation, you need to select the appropriate tool. The work requires: cement (it is used to seal cracks and recesses), primer, sealant, and also a decorative composition. For application you need a brush or roller (you can use a mechanical device), a paint container, and a stiff brush. You also need a shovel for excavation work and protective clothing.

The work includes the following stages:

- Preparing the base. You need to clean the foundation itself and dig around it. To clean the surface, use a metal brush, after which all cracks and chips are repaired. After the cement has dried, the base must be washed.

- Surface priming.

- Painting. Most often you will have to apply several layers of paint. This will improve the decorative and protective qualities of the coating.

If the outside area of the base is large, it is better to use a spray gun. In this case, material consumption may increase, but the work time will be reduced.

Tools

Painting the base begins with the selection of tools and materials.

For work we will need:

- Brushes of different widths and rollers with a ditch; it is better to choose a pile roller material - it wears less on the concrete surface;

- Stiff brush and hose with water;

- Shovel;

- Gloves, protective equipment.

To prepare a wall for painting, cement is used to seal cracks and a primer is applied before painting.

The use of primer reduces the absorption of concrete and reduces paint consumption. The quantity is calculated based on the characteristics of the paint and its consumption.

Features of restoration work

Natural or artificial stone is often used to cover the base, but such decor is not cheap. If a new building requires little preparation, then the old facade will have to be processed more carefully. Restoration is a labor-intensive process. First you will have to examine the base for the presence of exfoliated fragments. They are removed, and the chips are covered with cement mortar.

The surface is cleaned of dust, dirt, deposits, and the base is primed. After drying, the base is painted with the selected composition. To do this, use a roller or a wide brush.

Modern paints for finishing the outer surface of the foundation have similar properties, but in each specific case it is necessary to select the optimal composition. Before purchasing a material, you should carefully study the instructions for its use and further operation.

Painting the foundation of a house

Painting the foundation yourself is not difficult; follow the recommendations:

- Pre-clean the concrete from contamination with a brush and a stream of water from a hose, and allow it to dry thoroughly;

- Using a shovel, the layer of turf in front of the foundation is removed and the blind area is leveled;

- The chips are carefully processed and puttied with liquid cement mortar, allow it to dry for at least a day so that the next layer can be applied;

- Using a roller, we cover the entire surface with a special primer for concrete bases; it will ensure adhesion to the paint and fill the pores of the concrete;

- Before use, the paint is diluted to the desired consistency with water or solvent, and lumps are removed;

- The paint is applied with a roller, having previously rolled it over the ditch. In narrow places and corners it is more convenient to use a brush. It is convenient to cover large areas using a spray gun.

The coating is left until completely dry and a second layer is applied.

Put the soil back.

Surface finishing with panels

Covering the foundation of a house with siding has the following features:

- Acceptable cost

- High level of durability

- Protection from harmful environmental factors

- Durability

- Moisture protection

We invite you to familiarize yourself with the principles of decorating dry bouquets

This type of cladding is also one of the most popular. Modern technologies make it possible to create panels of various shapes, modifications and colors. All of them have protective properties.

This type of material is also popular in construction. Allows you to obtain structures of various shapes and sizes. Wide range of colors.

Among the main features are an easy installation method and a very reasonable cost.

Finishing with rock stones

This method is the most expensive. This is due to the price of the material and the complexity of working with it.

The following types of stone are used in construction:

- Granite

- Marble

- Porcelain tiles

- Sandstone

To secure it, it is necessary to use a concrete solution as an adhesive material.

Peculiarities:

- Increased level of durability

- Durability

- Frost resistance

- Luxurious appearance

A more affordable type of building materials. In appearance it resembles rocks, although it is made artificially.

Peculiarities:

- Low price category

- Easy to install

- Strength

- Reliability

- Fortress

- Long service life

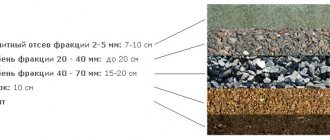

Let's consider the basic composition of artificial stone:

- Concrete

- Sand

- Crushed stone

- Expanded clay

- Various types of fillers

This type of stone can take on almost any color and shape. At the same time, its basic qualities are not lost. Due to the wide variety of modifications, cladding the foundation of a house with artificial stone is the most popular among consumers.

Plaster cladding

Selection of materials for work

The modern construction market offers consumers a wide range of different facing materials. The modern consumer often wonders what to cover the foundation with.

Foundation cladding

Among the most common models for cladding, you can choose the following:

- Finishing using natural rocks

- Installation of artificially made stones

- Plaster

- Siding

- Brick

- Decorative tiles

- Corrugated sheet

- Use of plastic panels

- Profiled sheet

To understand what type of material to use in construction, it is necessary to consider each of them in more detail.

Working with bricks

It should be remembered that in order to cladding a house with bricks, it is necessary to carry out additional calculations of the load level and pressure on the foundation, calculate the type of base, and measure the base area. After completing the preparatory work, you can proceed directly to the finishing procedure.

Brick foundation cladding

Peculiarities:

- Ease of execution

- Fast turnaround time

- Reliability

- Strength

- Long service life

- High level of thermal insulation