A cellar under the garage is convenient because it does not take up much space on the site. In winter, the garage basement is not covered with snow, and you can get into it at any time. This cellar does not require additional thermal insulation, since it is already located inside the garage, and if necessary, it can be equipped with an inspection hole for self-repair of the car.

Before starting construction work, you need to take into account a number of important nuances, such as: length, depth, width.

In addition, constructing such a basement requires much less money than building other types of cellars.

The nuances of building a basement under the garage

When building such a cellar, many important conditions must be observed, the main ones being effective ventilation and complete waterproofness. It is best to build a basement at the same time as building a garage.

The cellar is convenient because it can also be used as a viewing hole. To make this possible, a staircase with a slight slope is made, running along the entire length of the cellar. Thanks to the small angle of inclination, standing on the steps of the stairs, you can service the car. This option allows you to save a lot of money.

One of the most serious aspects is the construction of the cellar walls.

They are an integral element of the garage foundation, so it is better not to skimp on their thickness. In addition, the thicker the walls in the garage basement, the easier it will be to insulate it. Typically, stone or brick is used to construct basement walls. Red brick is more preferable. However, if the groundwater level is high or your region has a humid climate, it is better to use monolithic reinforced concrete for wall construction.

The floor in the cellar requires high-quality waterproofing, since it is through it that the greatest amount of moisture leaks. The best option for the base is a cushion of crushed stone about 10-15 cm thick with bitumen impregnation. Garage walls can also be insulated using bitumen, best in combination with burlap. Making such insulation is very simple: the burlap is impregnated with bitumen, and then glued to the walls of the cellar. The walls of the garage basement must be vitriolized and covered with lime whitewash. It is recommended to use this particular mixture for whitewashing, as it absorbs moisture well.

It can be made as an integral part of a general ventilation system or separately. High-quality and proper ventilation will prevent the appearance of fungus. Typically, for this purpose, ventilation windows and other ventilation devices are created in the basement walls.

Wiring in the basement of the garage is carried out by analogy with the arrangement of the rest of the power supply. If you have never worked with wiring before, it is best to have it done by a professional electrician. Due to the high humidity in the basement, special attention must be paid to insulating the contacts.

Return to contents

Construction of a basement under the garage: step-by-step instructions

As already mentioned, it is best to do it simultaneously with the construction of the garage. In this case, construction begins with marking the base, and at the same time marking the place for the inspection hole. However, in cases where a garage is purchased ready-made and without a cellar, you have to make it yourself.

First of all, prepare the tools that you may need for the job:

- hammer;

- nails;

- boards;

- metal tank;

- wooden box;

- metal rods and holders;

- polyethylene film;

- sawdust;

- mineral wool;

- gravel;

- table;

- cement mixture;

- fine mesh;

- entrenching tool;

- level;

- roulette;

- sand;

- water.

Before starting construction work on arranging a cellar, you need to take into account a number of important nuances, such as:

- the length of the inspection hole (usually it is made 0.5 m longer than the car);

- depth - determined individually (depending on the height of the owner);

- width – 700 mm plus the thickness of the pit walls.

In the walls of the pit, it is necessary to provide for the creation of auxiliary niches for placing tools, devices and other needs.

The opportunity under your garage needs to be assessed. This depends most on where it is located. The main obstacle that can negate all plans is the high level of groundwater. , built in such a place, will be flooded in the spring. Check to see if there are utility lines running under your garage. If it is located within the city, this is quite possible. If the listed obstacles are absent, you can begin to build a basement.

Dig a pit. Its dimensions should exceed the dimensions of the future basement by 50 cm on each side. Additional space is necessary for the convenience of concreting and waterproofing work. It is not recommended to expand the hole too much - this will increase the amount of work and complicate filling the sinuses.

The bottom of the dug pit is cleared of any remaining soil and compacted well. A layer of crushed stone, gravel or coarse sand is poured onto the bottom. The thickness of the backfill should be approximately 10 cm. The poured layer is compacted and impregnated with hot bitumen. After the bitumen has hardened, it is necessary to cover the bottom with waterproof materials, for example, plastic film.

The basement floor is created on the prepared base. Monolithic concrete with a thickness of about 30 cm is best suited for this. The walls are made of brick or concrete reinforced with steel rods. Waterproofing the cellar is carried out by coating it with a layer of about 10 cm of crumpled clay. Another available option is to apply an inexpensive waterproofing coating (roofing felt works well). The space between the walls of the pit and the walls of the basement is filled with soil, which is carefully compacted.

The inner surface of the walls is plastered with cement mortar and smoothed with a metal trowel. The thickness of the plaster layer is approximately 1 cm.

The ceiling of the garage basement is made of reinforced concrete slabs. In one of the slabs it is necessary to hollow out a hole measuring 80x80 cm. Instead, you can simply leave a hole of the appropriate size between the slabs, covering it with brick.

Make the entrance to the basement directly from the garage itself or from an extension to it. The manhole door is made double - this way there will be an air gap between the doors.

Since most residents of megacities do not have the opportunity to use an individual basement, you need to learn how to properly build a cellar in a garage

.

Although this event requires certain financial resources and labor costs, the end result fully justifies the expended effort and resources. In addition, the presence of a cellar in the garage

significantly increases the cost of the structure.

The cellar under the garage can be used not only as a storage area for unclaimed items

or

a vegetable pit

, but also as a small

workshop

. In the latter case, the premises must be properly equipped in compliance with all labor safety rules.

Naturally, setting up a cellar in the garage

can be done when the building is already in use, but in order not to violate the integrity of the building, experts recommend building a cellar directly

during the construction of the garage

.

How to build a cellar in the garage with your own hands - instructions:

https://youtu.be/aFwWY6Z2Odk

A cellar under the garage - how justified is it?

If your suburban area has all the buildings necessary for comfortable living, but you forgot about the cellar when designing the house and developing the landscape design, you still have two options. Firstly, you can try to dig an underground storage area under the house with your own hands, but this will mean that the kitchen or hallway (not to make a hole in the living room) will look trashed for some time. After all, you will have to dismantle the floor or break through the foundation. Secondly, if you do not want to destroy, even temporarily, the comfort in your home, you have no choice but to dig a deep cellar in the garage with your own hands.

Underground storage under the house

Of course, you can try to find a place on the site, for example, under a gazebo or right on the slope of a natural hill, and then decorate the hole in some unusual way. But, in fact, this is tantamount to destruction in the house, only on a garden scale, since you will have to either spoil the lawn or invade already landscaped plots with plants. Therefore, in order not to destroy the landscape design with your own hands, the creation of which requires a lot of time and effort, it is best to go to the garage. There, as a rule, part of the work has already been completed - there is a fairly deep inspection hole. Here in it or nearby you can make a fairly convenient entrance to the cellar.

What kind of cellar to build?

Proper arrangement of the basement during the construction of the garage will save the owner from the need for further redevelopment of the structure. Before making a cellar in the garage

with your own hands, you need to decide what exactly it should be.

If it is assumed that the basement will be located directly under the building, then the type of storage is determined by its depth

.

If the project for building a cellar in a garage involves the construction of a semi-buried storage facility

, then it should be arranged according to the principles of arranging

an inspection pit

.

The standard depth is 70–100 centimeters. If you want to decorate the walls of the cellar in the garage, then, as a rule, they are laid out from well-burnt bricks

or poured from

concrete

. Modern coating materials are used for waterproofing.

When is it planned to install a completely buried basement

, the calculation of metric characteristics is carried out taking into account the presence of groundwater on the site.

1.5–3 meters

are the classic parameters for a recess.

Important!

When starting the construction of a garage with a cellar with your own hands, it is imperative to carry out

geological reconnaissance of the area

, determine the type of soil, groundwater level, as well as the presence of economic and industrial communications under the site.

How to make a cellar in the garage

with your own hands - photo:

Cellar project

Before drawing up the drawings, you need to find out whether communications pass under the planned or existing garage. According to civil engineering regulations, the installation of any objects above them is prohibited. The second, no less important point is the study of the soil to determine the depth of groundwater. Often in the spring, during floods, owners discover flooding in their basements. To avoid an unpleasant surprise, it is worth considering a drainage system with a drainage channel.

How to arrange underground storage during the construction of a garage?

Before building a cellar under the garage

with your own hands, you should think through all the nuances of arranging the storage facility in as much detail as possible.

Creating a competent drawing

will allow you to most accurately calculate the dimensions of the basement and determine the amount of building materials needed.

The width of a standard cellar is approximately 2–2.5 m

, and the depth is

170–190 centimeters

.

Experts recommend building a basement with a distance of half a meter from the main walls. Such a gap is necessary for further organization of moisture insulation

.

The main wall will be the plane of the strip foundation

. The floor surface should rise above the foundation by approximately 30 cm.

Foundation

The work of constructing the foundation begins with digging a pit

. Its bottom should be carefully compacted and leveled. After the preparatory work, it is necessary to lay a cushion of brick shavings or crushed stone 3 cm thick on the bottom. This litter is filled with a layer of concrete 7–8 cm thick.

Once the concrete has hardened, you can begin waterproofing

. To do this, several layers of roofing material are laid on the surface of the concrete coating, which are glued together with liquid resin.

In order to protect the structure from flooding with groundwater, it is necessary to install a drainage system

.

The material used for waterproofing should protrude beyond the wall by about 10–15 cm. Once this condition is met, you can begin installing the formwork

and filling it

with concrete

.

Masonry, wall decoration and ceiling arrangement

brick is chosen as a building material for the walls

, then it is most advisable to perform simplified ordinary masonry.

The main thing is to maintain the absolute verticality of the walls. You can control the process using a plumb line and level. It is recommended to grout the seams on both sides, and cover the walls themselves with lime

.

A simpler option for edging an underground storage facility around the perimeter is the construction of monolithic concrete walls

. When constructing the formwork, it is necessary to make shields for the walls from straight wooden boards. The formwork is attached to metal supports, which are placed around the perimeter of the location, after which the structure is filled with concrete.

If you plan to use paint to finish the surfaces of the walls, then before painting it is recommended to apply a special base

.

It will not allow the paint to peel off. A moisture-resistant emulsion can be used as a base. It is best to use silicate paints

, which do not absorb moisture and do not emit toxic substances.

Acrylic paint is considered an excellent material for finishing any surfaces in the cellar.

. Moisture resistance and presentability are the main advantages of this material.

If your budget allows, experts recommend using paints based on liquid glass

. They are characterized by high resistance and durability.

Slaked lime is successfully used to whitewash walls in warehouses with excellent ventilation and low humidity.

. This is an excellent tool for destroying fungi, mold, and pathogens.

Lime is inexpensive

, which allows you to save money on finishing walls and ceilings.

To construct the ceiling as quickly and easily as possible, reinforced concrete slabs

. A hole for entry is created in one of them. The structure is lubricated with resin and then insulated with a mixture of sawdust and cement or glass wool.

The thickness of the insulation should be approximately 15–20 cm. If it is necessary to install an additional ball of insulation, the ceiling surface should be plastered

. Lining and slate are successfully used as finishing materials.

Floor, ventilation and waterproofing

Reinforced concrete is rightly considered the ideal material for flooring.

. After the bottom is leveled and compacted, it is covered with a dense ball of sand and crushed stone 15 cm thick. In order to simplify and speed up the process, a reinforced concrete slab is placed on the bottom of the basement as a floor.

Natural ventilation

- the simplest and most affordable way to organize proper air circulation in an underground storage facility. To set up the system you will need 2 pipes. The supply pipe is led outside the garage.

On top it must be equipped with a metal mesh to prevent rodents from entering and a cap to prevent precipitation. The lower segment of the pipe should be at some distance from the cellar floor (15–20 cm). The exhaust pipe is installed directly under the ceiling.

Forced ventilation

- a more expensive, but at the same time very reliable way to guarantee excellent air circulation in the basement of the garage.

This modular system is equipped with a hood

. It will be relevant for large basements where a fairly large number of products are stored.

Reliable waterproofing

– the key to the durability of the storage facility and the building as a whole. The effectiveness of waterproofing guarantees the safety of products and the reliability of the building.

Before you properly make a cellar in the garage

, find out what kind of soil the garage is on.

If it is dry

, then to ensure waterproofing it will be enough to use hot bitumen coating.

When a large amount of groundwater is detected at the site, waterproofing should be done by gluing the surfaces of the room

.

Rolled roofing felt on bitumen mastic

– an ideal material for high-quality waterproofing of underground premises. If necessary, repairs to such coatings can be carried out fairly quickly on your own.

How to dig a cellar in a garage?

To find out how to dig a cellar in a finished garage

Without violating the stability of the structure, it is necessary to strictly adhere to a certain algorithm of actions.

DIY cellar in the garage step by step:

- Determine and mark the perimeter of the future basement storage.

- Dismantle the floor covering and dig a pit.

- Cover the bottom of the hole with several layers of roofing material.

- Place a concrete screed at the bottom of the pit.

- Lay out the walls of bricks and fill them with concrete mortar.

- Make supports for the floor.

- Construct a frame from boards and reinforcement.

- Fill the formwork plane with a layer of concrete.

- Perform finishing work on the underground storage facility.

So, having understood the basic principles and concepts of arranging a cellar in a garage

, it becomes obvious that every wise and attentive owner can hold this event. So don't waste your precious time. Feel free to start making a cellar in your garage and feel the real benefits after the project is completed.

You can also equip a vegetable pit in the garage with your own hands for long-term food storage.

Watch the video on how to make a cellar in the garage

:

from time immemorial they have been used to store a variety of products. Regardless of the time of year, the optimum temperature was maintained at which vegetables were stored for quite a long time. They are still used now, and not only in rural private sectors. Today we will talk about how to build a basement in a garage, learn about the rules, arrangement, ventilation, and also step-by-step analyze the algorithm of actions for such construction with photographic examples for a more complete understanding of the process.

Before building a cellar in the garage, you should decide what type of storage it will be. There are three of them:

- buried

- depth from 1.6 m to 3 m, depending on the level of occurrence. Ideal for storing preparations and vegetables. This is the most common type of cellar; - semi-buried

- recessed to a depth of no more than a meter; - above-ground

- a caisson is placed in a small recess, which is insulated (today you can purchase ready-made caissons for above-ground cellars with heating).

We offer you to consider several examples of basements built with your own hands.

Photo examples of basements in self-built garages:

Options for building a cellar

There are two types of building a cellar in a garage. Let's look at each one separately. And how to build a cellar under the garage will depend on the stage of construction. Let us now examine in more detail how to make a cellar in a garage.

We immediately decide on the hood

Construction of a garage and cellar from scratch

So, how to build a cellar in a garage at the initial stage of construction. When building a garage with a basement, as a rule, consider the simplest construction technology. But do not forget that some difficulties may always arise. They may force you to change the construction technology a little. It might even lead to a completely different way of working.

We make plans at the initial stage of construction

So:

- Let's look at the example of concrete walls. Here it is not necessary to adhere to the fact that the walls should be made of concrete mixture only. It is quite possible to assume the presence of bricks or ready-made blocks in it. In fact, it all depends on which material is more accessible and easy to use for you.

- It is worth paying attention to the fact that not all bricks can be used in the construction of a basement. Red brick is best in this case, since it retains moisture very well. For a cellar, having this quality is very important. White sand-lime brick is a bad option for such construction.

- Various types of materials can be used in basement construction. Your choice may depend on your financial situation, the chosen construction technology, as well as any personal preferences. The only thing that is important is not to use materials that are absolutely not suitable for this type of construction.

- We've sorted out the choice of materials, now let's move on to the construction of the basement itself. You need to start work by digging a pit. Despite the fact that the basement is most often up to 2.5 meters deep, it is best to do this with the help of an excavator, since manually digging such a hole is very long and painful. Moreover, you will still have to work with a shovel; after the excavator works, you will need to level the walls.

- After the pit is ready, it must be sheathed with film or boards. This is done so that the earth does not crumble when the foundation is poured and the walls are driven out.

- In order to carefully pour the concrete mixture, you will need formwork. It must also be made from boards and leveled along the perimeter of the upper edge.

- Once the formwork is ready, you can safely move on to the next stage of pouring the foundation and walls.

- For a cellar, it is best to make a combined foundation. Take a slab as a base and add tape around the perimeter.

It must be done in the following order:

- To begin with, in a circle around the entire pit, you need to make a small depression, the width of which will be 50 cm and the height of about 40 cm. To make the foundation more durable and withstand the load that will be placed on it during the shrinkage of the building, you need to make the so-called "pillows". They are small square holes that are slightly deeper than the foundation strip itself. Concrete will also be poured into them. Pillows should be located in the corners, as well as every one and a half meters around the entire perimeter.

- At the bottom of the pit, along the entire surface, it is necessary to remove everything unnecessary in order to thoroughly level the surface.

- For some cushioning, there must be sand between the ground and the foundation. To do this, you need to sprinkle it on the entire surface of the bottom around the perimeter, including the tape.

- On top of the laid sand on a plane you need to put a layer of thick film or roofing material. For a belt, roofing felt is not suitable; it is best to cover everything with film, both the bottom and the walls.

- The next layer will be a frame made of reinforcement in the form of a horizontal mesh. The distance between the rods should be 50 cm. The belt itself should have vertical rods, the height of which should be about a meter. They are needed to attach metal to walls.

- Now you can fill the entire bottom of the pit, including the belt, with concrete mixture. The result should be a concrete slab 30 cm thick. To ensure that there are no voids in the slab that would allow water to penetrate into the basement, the concrete mixture must be compacted very well when pouring. When the concrete at the bottom has set a little, you can start pouring the walls.

- After both the walls and the foundation are ready in our cellar, we need to start waterproofing the walls. It must be done from the outside using bitumen mastic or something similar.

- Now you need to fill the remaining space between the soil and the walls with earth, and at the top of the entire perimeter of the walls, avoiding the entrance hatch, a ceiling is made. To accomplish this, you will need to make formwork, attach reinforcement to the vertical bars and fill everything with concrete.

- Once the base of the cellar is ready, you can move on to building the garage, and then just equip the cellar.

In the finished room, a cellar in the garage, we already understand how to do it. Now let's move on to another option.

Basement in finished garage

Making a cellar in a garage with your own hands is much easier at the initial stage. But in a finished room it is more difficult and the approach is somewhat different. In this option, there are already walls and a roof of the room. Our task is to build the basement in such a way as not to violate the integrity of the building. This is quite possible. And there are instructions for this and everything can be seen in the photo.

The technology for building a cellar in a ready-made garage is performed in the following order:

Making a foundation pit

- First we make the markings. At the same time, measure 30 cm from the garage walls on each side. If this is not done, it may well be that the walls of the garage will shrink a little or even crack.

- The next step is digging a pit.

- Several layers of roofing material are laid on the bottom of the finished pit. This is necessary for high-quality waterproofing.

- Now a screed is made at the bottom of the pit.

- Let's move on to building walls. This is done from brick or a concrete mixture that needs to be poured. It is very important to provide a distance for the moisture-proof layer, which should be on the outside of the wall. This must be done using a special mixture, mastic. It is applied using a spatula or roller. If these tools will not fit between walls, then it is quite possible to find something similar with a long handle. For such purposes, materials in rolls are often used.

- In the option with a ready-made garage, the possibility of working with ready-made slabs is excluded, since space is limited. Therefore, the ceiling will need to be poured from concrete. This is done very simply. Take boards and place them horizontally on supports. All this is covered with a thick film, and a mesh of reinforcement is laid on top, thus creating a frame. It is very important to leave an exit hatch.

- A layer of concrete mixture is poured onto the finished formwork, the thickness of which must be at least 30 cm. If the thickness is made less, the concrete floor may not withstand the load from the car that will be parked in the garage.

- We are building a cellar in the garage and the last stage of building the structure is removing the formwork. Next, only finishing work will be needed.

You already have an idea of how to properly build a cellar in a garage. You can also make a wooden cellar in the garage. The truth here is that this material does not tolerate dampness well and will not last long enough. So watch the video and make the right choice.

Arranging a cellar in a garage with your own hands: step-by-step instructions with photo examples

In this section, we will first present photographic examples of the actions performed with descriptions, and then we will analyze them in more detail.

| Illustration | Description of action |

| First you need to dig a pit. This can be done manually, however, if the garage has not yet been built and heavy equipment can freely approach the construction site, it would be more rational to pay for the work of an excavator. One full shift (8 hours) will cost about 18,000 rubles. | |

| In the excavated pit, a strip foundation is installed and a sand cushion is poured, which is best compacted tightly. The foundation can be deepened by 200-300 mm - this will be quite enough for a garage. | |

| After it has dried, we begin to install concrete blocks - the walls of the future cellar. They are laid on cement mortar. If there are gaps between them, it’s not a big deal; they’ll be rubbed in afterwards. If the location of the concrete block is uneven, it is corrected using a crowbar. | |

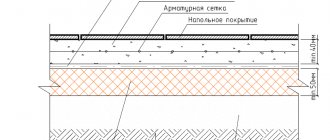

| Between the rows (the optimal choice for a garage would be an FBS block 300×580×2380), a reinforcing mesh must be laid - it will add rigidity to the adhesion of the blocks to each other. | |

| All remaining gaps are carefully filled with cement mortar and rubbed down to avoid damage from the sharp edges of the concrete blocks. | |

| The next step is to install the floor slabs on top. This is much better than covering the cellar in the garage with waterproofing and then filling it with earth. No matter how thick and durable the wood is, over time it will begin to rot. | |

| All walls outside the basement are covered with bitumen mastic. This is done to improve the adhesive ability during subsequent installation of the waterproofing coating. | |

| Bicrost is used as waterproofing, which is heated with a propane burner and glued to the wall. Here you should make sure that there are no air bubbles left. Subsequently, they are damaged by the soil and become useless. | |

| The cellar is also insulated from the outside. For this purpose, durable polystyrene foam (penoplex) is used, which has very good properties. It is attached to a special adhesive foam. It also clogs all the cracks in the corners. | |

| Now the resulting structure can be filled in. It is necessary to thoroughly compact the soil when backfilling to avoid its movement. They can tear off the insulating layer. |

Helpful information!

Setting up a cellar in a garage can be done without using concrete blocks. In this case, formwork is made for the walls (no higher than 50-60 cm), reinforced and filled with concrete. After drying, the next layer is poured, and so on until the top. To cover the cellar in the garage, you assemble a solid formwork with your own hands with an opening for a hatch.

Now let's try to analyze everything in more detail.

Materials and tools needed to build a cellar in the garage

To build such a storage facility, various tools and materials may be required, depending on the method of work and the type of future basement. If all work will be done manually, then you need to prepare:

- shovel, crowbar, pickaxe;

- boards for arranging formwork;

- , nails;

- tape measure, mounting level;

Of course, you should take care of purchasing sand and crushed stone. It will not be possible to mix such an amount of concrete manually, so an electric mixer (barrel-concrete mixer) will not hurt.

Construction of a pit: how to dig it

When starting to dig a hole for a garage basement with your own hands, you should design it in such a way that on all sides it is at least a meter larger than the outer walls of the basement. This will allow you to easily assemble the formwork, and also provide free access to the finished walls for the production of waterproofing and.

How to properly lay the foundation for a garage basement

Before you build a cellar in the garage, you should lay it correctly - a foundation that will take on the entire load. Let's consider the algorithm of actions.

- Having marked the perimeter of the basement using pegs with ropes, we dig a trench 20-30 cm deep (no longer required).

- We assemble the formwork inside so that its height protrudes above the level of the bottom of the pit by 20-30 cm.

- We install a reinforcement cage inside the formwork. The reinforcement on top should stick out a little - this will increase adhesion to the walls.

- We pour concrete into the formwork, wait for it to dry, after which we disassemble the formwork, lay it out and glue it inside the perimeter, pour a sand cushion half the height (10-15 cm) and tamp it.

- The last step is to pour concrete on top of the sand, level with the upper level of the foundation strip.

Stairs to the basement: what it should be like

Most often, if the entrance to the cellar is through a square hatch, a wall hatch is made. In order for it to be reliable, it is better to make it from metal. It is better to think about fastening to the wall in advance, even at the stage of wall construction. To do this, embeds made of T-shaped reinforcement are mounted into the concrete - this will prevent them from becoming loose and falling out of the concrete wall.

How to make cellar walls in a garage with your own hands

After the foundation has completely dried, you can proceed to the walls. Observing the geometry, we assemble formwork around the perimeter with a height of no more than 60 cm. Otherwise, the weight of the concrete will simply tear it apart, resulting in the entire solution ending up on the ground and floor of the basement. Reinforcement is laid inside the formwork and concrete is poured. After drying, you can move on to the next layer.

Important!

The foundation should protrude beyond the outer wall by at least 5 cm. This will prevent concrete corners from crumbling under the influence of moisture over time.

We arrange ventilation in the garage cellar: one of the most important stages of construction

A lot will depend on the correct arrangement of the basement in the garage. In fact, this stage is the most important for storing vegetables. Ventilation is done before the top floor is installed, and is done in two ways: it can be forced or natural.

How to properly make natural ventilation in a garage cellar

For the arrangement you will need two pipes (or asbestos) with a diameter of 100 mm and fastening elements for them. They are located in opposite corners. Where vegetables are planned to be stored, the pipe is lowered almost to the floor, and its upper part is led out into the garage. The lower edge of the second section, located in the opposite corner, is located under the ceiling, and its second side extends onto the roof of the garage. This ensures good air circulation.

How to make forced ventilation in the garage basement

The algorithm of actions is the same. The only difference is that it is installed on the hood (pipe located under the ceiling). It ensures the forced removal of humid air from the storage, instead of which dry air is supplied from the garage through the second ventilation pipe.

How to properly make a ceiling and hatch in a garage cellar

It is better to make the basement at least 50 cm below the level of the garage floor. To equip it you will need boards, although it is quite possible to get by with an edged board, the strips of which will fit tightly to each other. It is necessary to assemble a flat surface, making stops for it inside the cellar.

Important!

Don't forget about the hatch. In the place where you plan to install it, you should leave a space with sides at the height of the planned pouring.

Interesting and sometimes even strange options for installing the ceiling:

Insulating a built basement: some secrets

We figured out penoplex at the stage of step-by-step instructions. The basement ceiling is also insulated in the same way before it is covered with earth. How to make it in the garage cellar? This work must be done from the inside, but the actions performed are the same - bitumen mastic, waterproofing layer, penoplex. The top of this “pie” is covered with plywood, chipboard or OSB.

Ceiling and walls - is additional insulation necessary?

For some regions, additional insulation is simply necessary. For this, the same penoplex is used, which is glued to a surface covered with bitumen mastic, after which it is covered with plywood or OSB. Chipboard is not used here due to its heavy weight. Plywood is bolted to concrete surfaces.

Basement lighting: how to do electrical installation correctly

If electricity is supplied to the garage, it will not be difficult to do. Of course, provided that the home handyman is generally familiar with electrical safety and installation techniques. Otherwise, it is better to seek help from specialists.

Very important!

Remember that any electrical installation work is carried out with the voltage removed. Electric shock is dangerous to life and health.

Finishing touches: doing the finishing touches

The choice of finishing material depends entirely on the wishes of the owner. Anything can be used here - from

Construction Features

The design solution for a cellar in a garage may well look like this

According to statistics, many compatriots build a cellar with their own hands in the garage, and there are reasons for this:

- Firstly, choosing this method of building a basement allows you to save space on your summer cottage.

- Secondly, this method of construction allows you to save money on the purchase of building materials.

- Thirdly, a cellar built in a garage can be used as a viewing hole if necessary..

You can build a cellar under the garage with your own hands, but the finished result must meet two basic requirements:

- the structure must be waterproofed;

- An effective ventilation system must be installed in the room.

The easiest way is to build a garage and a cellar with your own hands at the same time. In this case, the soil is initially examined for excess moisture, a plan for a garage with a cellar is drawn up, and a decision is made on the feasibility of construction on this site.

Scheme where: a – waterproofing, b – hatch, c – stone backfill or crushed stone

If, when starting construction, you find that the soil is wet, it is better to build walls using monolithic concrete.

If the soil is dry, you can build the walls of the cellar using asbestos-cement slate roofing. To do this, the slate is laid in two layers and glued with bitumen mastic. Also, for the construction of walls, you can use ordinary corrugated slate, the sheets of which are attached to the wooden sheathing with screws.

We are building a foundation pit

Considering the weight of the already built garage, the perimeter of the cellar should be slightly smaller to eliminate the possibility of the entire structure collapsing. You will have to dig manually, since the excavator will not fit in the limited space. The depth of the cellar in the garage must be at least 2.5 meters, so we dig the pit 3 meters deep.

Before starting excavation work, we acquire an electric pump for pumping out water. If groundwater is located close to the surface, the pit will have to be drained by pumping water out of it.

Pit waterproofing

Literally stasis, after the hole is dug, you need to start waterproofing it:

- We compact the bottom of the pit until a dense surface is formed.

- Next, sprinkle the bottom of the hole with a layer of clay 5 cm thick.

- We moisten the clay with water and tamp it until a hard crust forms on the surface.

Important: To compact the clay layer, you can use a homemade tamper made from a 1.5 m long log with a handle attached to the end.

Construction of the floor

Smoothing the mixture along the beacons

In order to prevent the formation of excess moisture inside, you will need to concrete the cellar in the garage.

The construction instructions are as follows:

- On the compacted clay base, pour a layer of sand 5 cm thick and tamp it;

- Next, fill in a layer of crushed stone and tamp it again, moistening it with water;

- We make reinforcing strapping from metal rods along the entire floor;

- After this, we prepare concrete at the rate of 3 parts M400 cement, 3 parts sifted river sand and 4 parts expanded clay;

Tip: It is advisable to mix concrete using a concrete mixer; in the absence of one, the solution can be prepared in a metal trough.

- The concrete screed is poured in one go without long breaks. Fill the screed to a minimum height of 15 cm. You should immediately try to smooth the surface as thoroughly as possible, but if small bumps appear, it’s okay, since they can be smoothed out later.

- After the concrete screed has dried, you can begin the final leveling. For these purposes, we prepare a cement-sand mortar at the rate of 3 parts cement to 6 parts sand.

Important: For subsequent convenience of leveling the screed, we use fine-grained and carefully sifted sand.

- Using the already finished screed, we place beacons 1.5 cm high. When installing the beacons, we are guided by the water level readings.

- We lay the solution between the laid beacons and disperse it with wave-like movements of a long rule.

- After finishing the finishing, small blemishes can be rubbed out with a foam float.

Construction of walls

Building a basement before building a garage

After the floor is built, it's time to start building the walls. But, before building, you need to decide on the type of ventilation, taking into account the size of the cellar in the garage.

You can familiarize yourself with the features of calculation and construction of ventilation in the basement in the relevant articles on our portal.

Simple ventilation scheme

For the construction of basement walls, you will need a reinforcing rod with a cross-sectional diameter of 1 cm, boards and laminated plywood for the construction of formwork, as well as concrete mortar with expanded clay backfill.

- At the initial stage, we build formwork for the walls. The thickness of the wall should be 15-20 cm. The structure should be approximately 5 cm away from the slope of the pit. We build the formwork by placing parallel plywood panels, supporting them with boards or beams for greater stability.

In the photo - reinforcing strapping

- Inside the formwork we make reinforcing strapping from metal rods.

- Concrete is made in the same way as in the manufacture of floor screed, but instead of the M400 cement grade, the M300 grade can be used.

Important: Taking into account the large volumes of concrete required to fill the formwork, it is advisable to use a concrete mixer.

- Concrete can be poured using belts. That is, first we fill the formwork by a third, then by two thirds, and then completely.

- It will take up to two weeks for the poured concrete to dry, after which the formwork can be knocked down.

- The gap formed between the walls and the pit slope should be filled with sand and compacted.

Construction of the ceiling

Frame for hatch in ceiling

It must be said that this is the most critical stage of construction, since the car will be located on the floor. Consequently, the total weight load on the floor will be no less than a ton.

When constructing a cellar and garage, factory-made concrete slabs are used. By setting up a basement in a finished garage, we are deprived of this opportunity, and therefore we will have to pour the concrete floor with our own hands.

We make a monolithic concrete floor as follows:

- We cut railway rails or T-rolled metal with similar cross-sectional dimensions into beams and install them into the cellar walls in increments of 0.6-1 m.

- At the bottom we attach the plank base of the formwork.

- Between the metal beams we make a strong strapping of reinforcing bars.

- At the same stage, we install a metal welded frame for installing the hatch.

- We prepare the concrete as for floor screed, only we replace the expanded clay with crushed stone. For maximum strength and durability of the floor, polypropylene fiber can be added to the concrete.

- Concrete is poured into the formwork in one layer, so it will not be possible to do without a concrete mixer. The height of the concrete layer must be at least 20 cm.

- The overlap is suitable for use no earlier than after 2-3 weeks.

Waterproofing and interior finishing

Waterproofing floors and joints

After the cellar is ready, the room is waterproofed from the inside with rolled materials (it is preferable to use roofing felt, the price of which is low).

Before proceeding with the installation of waterproofing, all surfaces should be thoroughly cleaned of dirt and dust. Then, all concrete surfaces are coated with a layer of penetrating primer. After the primer has completely dried, we coat the joints between the walls and ceilings, as well as between the walls and the floor, with mastic.

When the mastic has hardened, we glue the floor and walls with roofing felt. A sheathing is made over the laid waterproofing, into which the insulation is laid. A plastic or wooden lining is mounted on top of the sheathing.

How to build a basement in a garage if the walls and roof are already installed

How to dig a cellar in a finished garage? All actions are performed in exactly the same way, as if there were no walls and roof. There is only one significant difference - digging the pit is done manually; technology will not help here. Although there are cases when a tractor helped in digging, perhaps not the entire pit, but definitely up to half. However, this will require small equipment (like “Belarus”) and a professional tractor-excavator driver. In this case, soil is collected with an almost fully extended boom through the gate.

We are renovating the cellar in the garage: getting rid of dampness and mold

If dampness appears in the cellar, the first thing you should do is check the ventilation - it may be faulty. We empty the cellar of all canned goods and vegetables, after which we thoroughly clean all the places where mold has appeared. This can be done with a wire brush. It is better to disassemble and take it out into the sun. When they dry, they must be treated with an antiseptic composition.

To disinfect the basement, we use a sulfur bomb, which can be purchased at a hardware store. All vents are closed and the sulfur is ignited.

Important!

After you have set the sulfur on fire, leave the basement as quickly as possible. Breathing sulfur vapor is very harmful and dangerous to health.

The next day, when the vapors have disappeared, it is necessary to treat all surfaces with lime. To prevent the recurrence of mold, copper sulfate is added to it. After this, we open the ventilation pipes and wait 1-2 days until the cellar dries thoroughly. Now you can use it.

Summarize

A basement in a garage is a necessity for the majority of the Russian population living in cities. After all, only in it can you preserve fresh and canned vegetables for a long time. And the duration of storage will depend on how well it is built and insulated. Of course, the work is time-consuming and hard, but it is worth it.

If the cellar

made correctly: using heat and waterproofing materials, with forced or natural ventilation installed in it, with the construction of special shelves for storing food, then it can be stored

in good condition

until the end of spring, both canned goods in jars and other containers, and and fresh vegetables: carrots, potatoes, beets, cabbage, etc.

In this case, not only the conditions created in the room are taken into account, but also the requirements for storing products

. The lids should tightly close the jars, the potatoes should be placed in boxes with holes (if they are dry, they rot less), apples and large ranetkas should be wrapped in parchment paper, etc.

What does a cellar look like in a garage

- photo:

Advantages

It makes sense to build a basement if the garage space is owned and expected to be used for many years. What are the benefits

near the cellar in the garage?

in excellent condition until late spring

.

But it is worth paying special attention to ventilation

.

Natural, usually consisting of 2 pipes, one of which is installed above the floor level, and the second above the ceiling, does not always save the situation. It would be better if these were modular systems controlled by a mini-computer. Then the conditions in the basement can be controlled artificially

.

Fresh air for the cellar - we arrange ventilation

The safety of fruits and vegetables in the basement for a long time is ensured by the competent organization of its ventilation system. It can be made natural or forced.

The natural supply of fresh air is simple to arrange:

- One pipe (it is called a supply pipe) is mounted from the cellar floor at a height of about 25 cm and leads out into the street. The outer part of the supply pipe is protected using a metal cap.

- The second pipe (exhaust) is installed 25 cm lower from the ceiling of the cellar, where the most humid and warm air masses are always present, which must constantly be removed to ensure the required microclimate in the basement. It is placed above the garage roof by about 50 cm.

Ventilation arrangement

The efficiency of natural ventilation is low. In summer, it often simply does not function (the air outside and in the basement has the same temperature), and in winter the system can become clogged with frost and snow, from which the ventilation must be constantly cleared.

Forced air exchange systems are many times more modern and efficient. But their installation requires financial costs for the purchase of special fans operating from a household power supply. These devices are mounted in ventilation pipes, which are installed in the same way as when organizing natural ventilation. A scheme using one double-leaf pipe is also possible.

Compulsory systems are almost independent of climatic conditions. They guarantee an optimal microclimate in the cellar. If you want to create the most reliable ventilation in your basement, buy a special monoblock controlled by a mini-computer. This technique will itself calculate the required amount of fresh air supplied to the cellar, as well as draw out the required volume of moist and warm flows from it.

And don't forget to build a staircase to your garage cellar. It can be the simplest - attached, or stationary, made of metal, durable wood or concrete.

Source

(Visited 1,097 times, 1 visits today)

Arrangement of the cellar

Shelving

can be located along the entire wall (as a rule, in this case they are not portable) or occupy only part of the space near it (we are talking about non-bulky portable structures).

25-30 cm higher than the bottom of the pit

- this allows you to build a sand “cushion” and cover the base of the floor with waterproofing material (mainly 2 layers of roofing felt are used, the sheets of which are glued together with molten bitumen).

This way, the floor will be protected from underground water entering the cellar

, and the vegetables will remain dry.

Potatoes, carrots and beets can be stored on the floor in boxes. Carrots and beets are perfectly preserved if additionally sprinkled with sand

.

Racks with shelves are made taking into account the height and width of the cellar

, as well as the sizes of the cans. At the same time, the shelves should easily support the weight of the container filled with food. Installation of wooden structures takes little time. This is an economical and labor-intensive option.

But over time, in conditions of high humidity, wood is exposed to fungus and mold

.

To prevent this from happening, wooden shelving is treated with drying oil

.

more durable in this sense

, but the metal is susceptible to

corrosive destruction

.

And the metal lids of the cans will also become rusty. Therefore, steel shelves are covered with special water-repellent materials

.

The racks are made of plastic and are convenient to use, and they are not afraid of moisture, but still their quality characteristics leave much to be desired. They are not capable

hold a lot of weight and are easily damaged by external mechanical influences.

People often opt for wooden structures

, as an option that has fewer disadvantages than others proposed and is the least expensive in terms of money.

Standard cellar dimensions:

The width of the walls is 2-2.5 meters, the height is about 2 meters.

It’s definitely impossible to get lost in such a small space, but no one would want to trip over jars and boxes. In the cellar, shelving is located on the right wall, and boxes with vegetables are located on the left. Between them there should be a free passage approximately 0.9 meters wide. Due to the “scarcity” of space, the staircase can be portable

.

Watch a video about arranging a cellar in a garage

:

What does depth depend on?

The depth of the excavated pit directly depends on the depth at which groundwater flows in this place. If water gets into the cellar, we can assume that all efforts were wasted. Food in a humid environment will spoil very quickly.

In permanent garages with a large area, the depth of the pit can reach up to 3 m, and the width of the walls - 2.5 m. If the garage space is small, the source of groundwater is located shallow - then the depth of the cellar in the garage does not exceed 1 m and is semi-buried

.

Ground view of the cellar

- a shallow pit in which plastic structures are placed (to protect against moisture), and workpieces are stored in them. Even this option for storing food has its advantages: they retain their nutritional value until spring and significantly save free garage space.

When building a cellar, it is necessary to ensure that the floor surfaces are located at least 0.5 meters from the groundwater source.

Optimal sizes

Before you start building a basement, you need to draw up a drawing

, transfer the dimensions to it and act in accordance with the intended scheme.

When arranging a cellar, the structural features of the soil and climatic conditions must be taken into account. The optimal dimensions of a cellar in a garage

are a height of 1.7 meters with a wall width of 2.5 meters.

See another option for a cellar under the garage - photo below:

It will be much easier and faster to carry out work during which the construction of a garage space occurs simultaneously with the basement. With the help of technology, you will be able to achieve your goal much faster. And you shouldn’t refuse the help of your partners. It will take much longer to work alone, when technical devices do not fit in a small area, and a large number of people will only interfere with each other.

Before you start building a cellar

, you need to have some kind of accurate calculations, prepare the necessary tools and materials and, of course, stock up on a certain amount of patience.

A basement built according to all the rules is a very good investment.

Tasty and aromatic preparations will delight household members for many years to come. And for this you don’t need to go far, because the cellar is very close.

Construction of a cellar in a ready-made garage

In this case, we have a ready-made frame of the room - walls and roof. It turns out that everything needs to be done so that all these elements are not damaged. This is quite real.

Built basement in garage

The technology is that the construction of a basement in a garage is carried out in the following sequence:

- The perimeter of the future cellar is marked.

Please note that the indentation from the wall line must be at least 30 centimeters. If this distance is less, then there is a high risk that when constructing a cellar, the garage will shrink and, accordingly, its walls will crack.

- A pit of the required depth is dug.

- Roofing felt spreads along the bottom, overlapping the walls of the pit. You can lay it in several layers - the level of waterproofing will be better.

- A concrete screed is made along the bottom of the pit.

- The walls of the future cellar are built from brick or poured from concrete. In this case, you need to leave space for a moisture-proof layer on the outside of the walls. It is advisable to do such insulation with special mastics, which are usually applied with spatulas or rollers (If the space between the walls and the ground is narrow, then you can use a tool with long handles to reach the lower level). Roll materials are also used.

- Since it is not possible to carry out operations with finished slabs (due to the height and width of the garage itself), you will have to do the ceiling yourself. Boards are placed horizontally on the supports (taking into account the hole for the hatch), a film is placed on top of them and a frame of reinforcement is knitted together - formwork is obtained.

Example of formwork for pouring a floor

- A layer of concrete approximately 30-40 cm thick is poured onto the formwork plane. It is undesirable to do less, since this is after all a garage, not a house. The load from a car is an order of magnitude greater than the weight of a person.

- The concrete dries, the formwork is removed - in general, this completes the construction of the basement in the garage. In fact, next comes the finishing work.

Let's summarize.