Each M 50 solution has its own characteristics. Some of them are used to create brickwork, others - for stone. Cement-lime mortars grade 50 are used for brick throughout Russia, and Nizhny Novgorod is no exception. Theoretically, every builder can make such a solution on his own, but in practice, maintaining the proportions is very important. Therefore, to obtain high-quality M 50, it is better to purchase it ready-made from a specialized enterprise in Nizhny Novgorod.

Composition M 50

The M50 solution is classified as complex because a filler is used in its manufacture. Typically, the filler is grains of washed river sand. Finding it on your own is quite difficult. In addition to sand, the solution includes water and lime. In order for the solution to meet its intended purpose, all available proportions must be strictly observed.

The correct composition will be as follows:

- cement - 1 share;

- lime - 0.7 shares;

- sand - 6 shares.

Dry mixture or homemade composition?

The undeniable advantage of this material is its cost. It is significantly cheaper than a similar cement-sand mortar. The benefit is determined by the economical consumption when applied to various surfaces in comparison with the analogue. Sand mortar is less plastic due to the scattered sand fraction and the absence of a plasticizer. It has less adhesion and is less well distributed over the surface.

Cement-lime mortar can be purchased as a dry mixture

from various manufacturers, or you can make it yourself. Nowadays there is a wide choice of manufacturers of ready-mixes with their own characteristics and areas of application.

You should pay special attention to the labeling on the packaging in order to choose the optimal mixture suitable for the type of work you need.

To use this mixture, add water according to the instructions on the package and mix thoroughly to achieve a uniform texture. For these purposes, you can use a construction mixer or mix the composition the old fashioned way using a trowel and shovel.

If you decide to make the mixture yourself, it is not difficult to do. It is enough to purchase all the necessary ingredients (cement, lime, sand) and mix them in the proportion of the appropriate brand that you want to obtain.

When making cement-lime mortar, you need to add slaked lime, but if you only have quicklime, you can slak it yourself.

Cement is an artificial inorganic binding material, which, when water, saline aqueous solutions, and other liquids are added, forms a plastic mass, which subsequently hardens, turning into a stone-like body.

Used for the production of concrete and mortars. Now the most popular brands are M (PC) 400 and M500.

Where to buy M 50?

JSC ZHELEZOBETONSTROY No. 5 in Nizhny Novgorod sells a variety of concrete products and cement mortars, including M50 cement mortar at a low price. The products meet all existing quality standards. The client has the opportunity to order delivery of goods. Payment is accepted both in cash and by bank transfer.

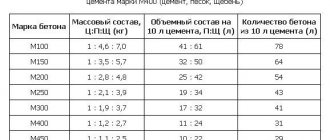

Here you can make the necessary calculations for preparing the masonry mortar with your own hands. Enter the required number in the “Volume of solution” column, select a brand and you will receive the exact proportions of cement, sand and water. Mortars are prepared for different purposes, for example, for laying the walls of a house and laying the walls of a furnace; the preparation recipe is slightly different. Be careful when making calculations.

Brand of ready-made masonry cement mortar

Basically, mortars are classified by composition: mixed, lime, clay, cement (that is, what is added in addition to cement, water and sand to the mortar) and by brand.

According to SNiP, solutions are marked with the letter “M” and then with numbers (50, 75, 100, 150, 200, and so on)

These names differ from each other in terms of compression, strength and other parameters.

The marking is quite simple and indicates the proportion of cement and sand.

Proportions of masonry mortars by composition:

Cement-clay mortar

Dependence of the brand of mortar on the brand of cement and sand (cement, clay, sand)

Cement-lime mortar (cement, lime, sand)

Cement-sand mortar (cement, sand)

Also, certain additives are often added to solutions to give them special properties, such as:

- Great plasticity;

- Frost resistance;

- Great adhesion;

- Great strength;

- Less porosity;

- And much more.

Mortar for laying bricks

For many years, brick was used to build walls, but the development of construction technologies has led to the appearance of new materials on the market - blocks made of aerated or foam concrete, ceramic blocks, and blocks of foamed polystyrene. To ensure that the walls of the building are strong and resistant to various atmospheric influences, different solutions are prepared for laying different types of building materials. For this purpose, building mixtures with a cement, cement-lime or lime base are used.

Cement mortar is used to build walls made of concrete blocks, ordinary or clinker bricks. It must be taken into account that the brand of such masonry mortar should not be higher than the strength class of the material used to build the walls. The solution should be plastic, easy to apply and not run off the wall. To ensure these qualities, plasticizers are added to the mixture, and in order for the solution to maintain the waterproofness of the seams, sealing additives are added to it. It is especially good to use cement mortar for walls that are exposed to precipitation or are in a humid environment. These can be the walls of the foundation or facade of a building, basement, or chimney walls.

What is used for laying blocks?

When purchasing blocks made from ceramic composites, developers are wondering which masonry mortars are best to use? The following options are possible:

- use warm mortar produced in production conditions for the construction of block walls. It is made on the basis of expanded clay or perlite filler and is supplied in sealed packaging. It is characterized by the presence of modified components and special plasticizers that reduce consumption, are resistant to negative temperatures and affect plasticity;

- Prepare your own perlite-cement mixture using crushed perlite. Perlite is popular among developers who individually prepare the composition for laying ceramic blocks. It is mixed with cement in a ratio of 1:3 with the addition of a special plasticizer, which increases the plasticity of the building mixture. Mixing is carried out in a concrete mixer for a limited time, which is due to the ability of perlite to granulate and form dense lumps;

- use traditional sand-cement mortar, the only advantage of which, compared to the above options, is its low cost. Ensuring plasticity is achieved by introducing plasticizers for dry mixtures. But this does not solve the problem of heat loss due to the formation of cold bridges.

Let's look at how warm mixtures differ from those traditionally used based on cement and sand.

For laying external single-layer walls made of blocks, heat-insulating lightweight warm mortars should be used

How to prepare the solution yourself?

To obtain a solution, cement is mixed with sand having a medium fraction. To prepare the simplest mixture, add 3-4 parts of clean sifted river sand of medium fraction to 1 part of cement. The dry composition is mixed well, and then water is gradually poured in until the solution turns into a homogeneous mass with the required level of mobility. However, this composition quickly hardens during laying, so clay or plasticizers are added to it to increase plasticity and astringent qualities. This solution is easier to level on the wall surface, it will provide better compaction, and the masonry will look neat. A small amount of soap, detergent or washing powder can be added to the mixture as astringents.

Characteristics of masonry mixtures

The choice of a specific material depends on where the resulting mixture will be used.

Based on density, they are divided into fatty and skinny. In mixtures of the first type, quartz sand is used, and in lean mixtures, porous components are used. During creation, it is worth remembering that it must have the following characteristics:

- Adhesion. This property is characterized by the ability to resist tearing or shearing. It is worth remembering that the weakest point in the structure is the masonry, so it is important to make the material better.

- Waterproof. If the composition does not have this characteristic, moisture will penetrate into the wall when precipitation occurs.

- Water retention. This property refers to the ability of a mixture to retain water in a layer when water-retaining components are added.

- Impact on building materials. The solution created or purchased should not negatively affect the structure being created.

- Low temperature resistance. It is important that the composition is able to withstand a large number of freeze-thaw cycles. This characteristic, according to GOST, ranges from 50 to 1000.

- Plasticity of the mixture. This characteristic is necessary so that during work it is possible to correct the position of already installed building elements.

- Composition mobility. This property is the ability to spread across the surface of a building material and fill empty spaces.

- Strength. This characteristic is the main indicator. The quality of the composition depends on it. This indicator is measured in kilogram-force per square meter.

Increasingly, when creating a building, colored masonry mixtures are used, which makes the house more beautiful.

Brands of masonry mortars

Solution M25.

This is a cement mortar for laying bricks or laying other types of stones. The brand of mortar M25, is its official and correct name, is used both in specialized literature and in the practice of construction work. Mortar M25 refers to mixed (complex) mortars for masonry. Cement mortar M25 consists of mortar filler, binder and water. The role of filler for M25 solution is usually played by ordinary sand. Moreover, the cleaner the sand, the higher the strength of the solution.

M50 solution.

It is one of the most popular. It is a mixed, complex mortar for laying brick and other types of stone, and mesh floor screed. M50 consists of a binder, water and filler. The filler is sand well cleared of clay, which improves the strength of the cement mortar. The binding element is cement, water is used, of course, also purified.

Solution M-75.

The strength of M75 cement mortar depends on the proportions in which sand is mixed with cement, as a binder, and water. M75 is a high grade mortar, its proportions are 1 part cement to 3 parts sand and a little less than one part water. Therefore, it is plastic and durable, which makes it convenient to use. Cement mortar M75 is indispensable when installing precast reinforced concrete structures, pouring leveling screeds, and brickwork.

Solution M-100.

Cement mortar brand M100 is used mainly for masonry and plastering work, as well as for the production of cement floor screeds. The main difference between the m 100 solution and concrete of a similar brand is the absence of coarse aggregate (crushed stone) in the mixture. Naturally, the composition itself is also different. Significantly higher content of cement and sand than in concrete of a similar brand. M-100 mortar can also be called: cement, construction, masonry, plaster mortar.

What is needed for the solution to harden quickly?

To increase the hardening time of the composition, a cement-lime mortar is prepared during laying. To do this, lime paste is added to the cement-sand mixture. First, pour 2/3 of water into the preparation container, then pour in 1 part of cement and lime, mix well for at least 15 minutes, then add the remaining water and 3-4 parts of sand. This solution is also used for the construction of walls made of foam and aerated concrete, after adding special foam additives to it, which will increase the thermal insulation of the joints.

Lime mortar is used when constructing internal walls or interior partitions. It is characterized by high plasticity, so the walls will look neat. To prepare the solution, mix 1 part of quicklime with 3 - 5 parts of clean sifted sand, mix until a homogeneous dry mass is obtained, and then add the required amount of water. The solution should be homogeneous and free of lumps.

In the case of preparing a mortar for masonry, its composition depends on the quality of the components used, weather conditions, temperature fluctuations and is determined experimentally in each specific case.

One of the most popular mortars based on cement, additives and sand is M50. It is used in almost all construction work related to the construction of walls, the preparation of horizontal foundations (screeds), and the repair of cracks, irregularities and other defects. It is produced in accordance with GOST 28013-98 and delivered to consumers completely ready for use in special machines (automatic mixers).

Consumption of mortar for laying blocks

For laying 1 m 2 single-layer wall

from smooth blocks 30 - 40 cm thick. Approximately

20 - 30 liters of mortar are needed

with a joint thickness of 10-12 mm.

For buildings with a height of 1-2 floors, it is possible to further reduce heat loss through the mortar joint, as well as reduce its consumption.

To do this, when laying the mortar, apply it in two stripes along the outer and inner surfaces of the wall, leaving in the middle of the wall an air gap in the seam 1/3 - 1/4 wide of the width of the block. This measure reduces the thermal conductivity of the seam, but at the same time reduces the load-bearing capacity of the masonry - therefore it is used only for buildings of small height.

A smaller amount of mortar will be needed if you use blocks with a tongue-and-groove connection of vertical joints for masonry. In this case, vertical seams are not filled with mortar.

The use of warm, lightweight masonry mortar can significantly improve the thermal conductivity of the wall compared to conventional mortar, but not so much as to be on par with an adhesive joint. In addition, the consumption of glue is several times less than that of a light solution, and the price of ready-made dry mixtures of glue and solution is almost the same.

Warm light masonry mortar is not recommended for laying walls that can be intensively moistened - foundation, basement, basement.

For information on laying gas silicate and aerated concrete blocks with glue, read the article Laying gas silicate and aerated concrete blocks with glue.

Interior finishing of aerated concrete walls

Laying walls from aerated concrete blocks - video tutorial

More articles on this topic

Dear reader!

Warm lightweight masonry mortar for laying block walls: 2 comments

There is nothing here about vermiculite, but it will give a head start to both foam plastic and mineral wool. Especially when insulating flat roofs, attics, basements, walls, including frame house construction. It can also be used in the production of warm plasters and masonry mortars with low thermal conductivity. More detailed information about vermiculite can be found here ZTVERM.RU technical. characteristics, comparison with other materials, recipes.

“When constructing the walls of buildings made of cellular concrete, there is a problem of different thermal conductivity of the walls themselves and the adhesive mortar. Significant losses of thermal energy occur through masonry seams (up to 10% when using thin-layer adhesives, up to 30% when using cement-sand mortars), which leads to increased heating costs.” One of the solutions to improve the thermal insulation properties of masonry made from aerated concrete blocks is the use of adhesive for cellular concrete thermal insulating brand Gemisch. The main difference between the adhesive for cellular concrete heat-insulating brand Gemisch and traditionally used adhesives is its high thermal efficiency, the thermal conductivity coefficient of Gemisch adhesive is only 0.202 W/(m*K), which practically corresponds to the thermal conductivity of the blocks themselves, i.e., as a result of using Gemisch adhesive we we get an almost monolithic wall, and the absence of “cold bridges”. Along with excellent thermal insulation characteristics, Gemisch adhesive has a number of advantages compared to traditionally used adhesives: - Lightweight. The bulk density of Gemisch glue is only 1000 kg/m3, which is more than 30% less than the bulk density of traditional adhesives, as a result of which the costs of delivering Gemisch glue to construction sites are significantly reduced, and the masonry process is also simplified; - Economical. 1 bag of Gemisch glue 18 kg, replaces 25 kg of traditional glue, thanks to the finely dispersed composition of Gemisch glue, it has become possible to lay blocks with a seam thickness of only 1 mm. - Minimum consumption. Thanks to the finely dispersed composition of Gemisch adhesive, it became possible to lay blocks with a joint thickness of only 1 mm. - Durable. High adhesion to the base (at least 0.6 MPa) and strength grade M100 guarantee reliable adhesion of materials. - Universal. Gemisch adhesive is suitable for laying blocks made of cellular concrete, polystyrene concrete, as well as ceramic blocks and bricks.

The use of ceramic blocks, characterized by a porous structure, is common in the construction of various objects. The products are in demand in the construction of private buildings, as they are durable, have high performance characteristics, and retain the heat of the room well.

For laying ceramic blocks, it is advisable to use special solutions to prevent the formation of cold bridges. To ensure reliability, quality and comfortable operation of the building under construction, masonry mortars must have a low thermal conductivity coefficient. This is achieved by introducing special fillers characterized by low density.

Warm masonry mortar significantly reduces heat loss, reduces the weight of the structure being built, and reduces the need for binding materials used for laying blocks. Let us dwell in detail on the types, characteristics, advantages, preparation features, and consumption of compositions for laying blocks of porous composites.

Thermal insulating masonry mortar LM is specially designed for porous bricks and blocks, which significantly reduces heat loss through mortar joints

Technical characteristics of the M50 solution

The M50 solution has the following average characteristics:

- strength M50;

- frost resistance F50;

- workability PC4;

- density up to 1500 kg/m3.

Depending on the conditions of use and purpose, its characteristics may change in the direction of improving all or some parameters by adding various additives, plasticizers and other components to the composition. Changes in the composition of the solution are made in agreement with the customer.

Cement-lime mortar M50 is produced based on cements M300 or M400, additives and washed river sand without inclusions of clay substances, gravel or pebbles. The size of sand fractions is up to 2 – 2.5 mm.

The ratio of components by weight in the solution is standardized and depends on the brand of cement.

| Cement (grade) | cement | lime | sand |

| M300 | 1 | 0,6 | 6 |

| M400 | 1 | 0,9 | 8 |

For external masonry, in places of high humidity or in structures located below ground level, cement-sand mortar M50 can be produced without adding additives. It consists only of sand and cement in specified proportions.

| Cement (grade) | cement | sand |

| M200 | 1 | 3,5 |

| M300 | 1 | 5 |

| M400 | 1 | 6 |

Ready-made masonry cement mortar grade 50, as well as cement-lime mortar, can be purchased in any volume with delivery, both on the day of order and at any required time. The plant serves customers in St. Petersburg and the Leningrad region, regardless of distance from the plant.

Our own fleet of special vehicles allows us to deliver the solution to the site in working condition. According to the technical characteristics, it is advisable to use the ready-mixed construction mixture M50 within 1.5 hours after unloading. The peculiarities of the company's vehicle fleet make it possible to deliver 7 or 10 m 3 of solution in one trip. For larger orders, the quantity of solution must be a multiple of these figures.

You can order M50 solution in several ways:

- adding the required product on the website and using the “Cart” button to order online;

- write by email;

- make a phone call;

- order a call back.

All details regarding price, payment, delivery conditions and solution formulation are agreed upon in a working manner. The company office is open from 10.00 to 18.00. The plant's mortar-concrete units make it possible to fulfill orders of any volume. They work under automatic control and all products comply with the specified parameters. We work with enterprises of all forms of ownership and individuals.

The group offers the M50 solution to everyone in Moscow and localities in the Moscow region. Understanding that the material is in demand at almost every stage of construction, we carry out its uninterrupted production and supply.

Working without intermediaries, we are ready to offer an affordable price for M50 cement mortar. We have our own laboratory, so the high quality of our products is confirmed by research.

TECHNICAL DATA:

Cement-sand mixture M 50 produced by Magma LLC has the following certification test results for

TU 5745-00186214064-2008

| The name of indicators | Normative value | Actual value |

| 1. Average density of the mortar mixture, kg/m 3 | Not less than 1500 | 2140 |

| 2. Mobility of the mortar mixture, P k (cm) | Not less than P to 2 (4-8) | P to 2(4.6) |

| 3. Water holding capacity, % | Not less than 90.0 | 95,6 |

| 4. Delamination of the mortar mixture, % | No more than 10 | 7,5 |

| 5. Average density of the hardened mixture, kg/m3 | Not less than 1500 | 1980 |

| 6. Compressive strength, MPa (kgf/cm2) | Not less than 5.0 (50.0) | 7,5 (75,0) |

| 7. Frost resistance | Not less than F 10 | F 35 |

| 8. Water consumption per 1 kg of dry mixture | 0.13-0.14 l. | |

| 9. Vitality | 2 hours. | |

| 10. Consumption of dry mixture per 1m2 with an application thickness of 1mm. | 1.9 kg | |

| 11. Layer thickness | 5 – 20 mm. | |

| 12. Work temperature | Not lower than +5°C not higher than + 30°C. | |

| 13. Guaranteed shelf life in original packaging and in a dry place, month | 6 months | |

| 14. Bag weight | 30 kg; 50kg |

Where can I buy M50 masonry mortar at a competitive price?

Concrete mortar is used as a binder when performing:

- bricklaying;

- laying other types of stones.

It belongs to the group of complex solutions, but is less durable. The material is rarely used in other types of construction, since products made from it have low compressive strength.

The group sells cement-sand mortar M50 at a favorable price. Placing an order with us means getting a material with the necessary strength and mobility, which is resistant to climatic factors, versatile and practical. Place your order by phone or online from our website.

Proportions of masonry mortar

In order to choose the correct ratio of masonry mixture components, you need to know what brand of mortar is needed for laying a particular structure.

The most popular brands are M25, M50 and M75. The ratio of the components of the solution depends on the brand of cement used for its preparation. Typically, cement grades 300, 400 and 500 are used to prepare masonry mixtures.

For cement-sand mortars, the ratio of components is approximately as follows:

| Cement brand | Brand of solution | Cement to sand ratio |

| 300 | 25 | 1:9,5 |

| 50 | 1:5,8 | |

| 75 | 1:4,2 | |

| 100 | 1:3,4 | |

| 150 | 1:2,6 | |

| 400 | 50 | 1:7,4 |

| 75 | 1:5,4 | |

| 100 | 1:4,3 | |

| 150 | 1:3,25 | |

| 500 | 75 | 1:6,7 |

| 100 | 1:5,3 | |

| 150 | 1:3,9 |

To put it in a simplified way, the grade of the mixture is approximately equal to the quotient of the grade of cement divided by the number of volumetric parts of sand.

To prepare solutions, only volumetric parts of the components are always used. You can't rely on weight. The volume of water in the masonry mixture can vary between 0.6 - 0.8 of the volume of cement. Most often it is determined by eye, based on the quality of the solution.

If you need to lay out a durable structure, then use a cement-sand mortar. But you need to remember that it sets quickly, so its use time does not exceed 2 - 2.5 hours. Therefore, it is necessary to carefully calculate the amount of prepared mixture in order to have time to produce it during this period of time.

If it is necessary to extend the life of the masonry mixture, lime is added to it. This allows you to double the shelf life of the solution.

To obtain high-quality masonry, it is important to carefully prepare the components of the solution:

- It is best to purchase cement immediately before starting. You should not use “old stocks”; such material has already lost its strength.

- It is better to buy river sand. It must be clean and free of debris. Good river sand has a gray color; particles of clay give it yellowness, which in this case are completely undesirable. For masonry, sand of medium fraction is used - at least 2 mm.

- should be cold and clean (ideally 15 - 20 degrees). The presence of acid and oil impurities in it is unacceptable.

In order to properly prepare the solution, you will need:

- a large container - this can be a mortar mixer or a tub (if the mixture is supposed to be mixed manually);

- buckets with a volume of 10 - 12 l;

- shovel.

If the amount of work is small, then you can measure the components with a shovel, but if there is a lot of work to be done and a lot of solution is needed, then it is better to use buckets.

- First, sand and cement are poured into the container alternately in layers in measured quantities.

- Then the dry mass is thoroughly mixed and sifted through a sieve.

- Next, you need to add water little by little and constantly stir the mixture. At the same time, you need to be careful not to add too much water - this will negatively affect the quality of the masonry mortar.

You can often find a recommendation to moisten all containers with water before starting to prepare the solution - this reduces the amount of waste during mixing. Stir the mixture for 3 - 5 minutes, and then you need to let it stand for a while to achieve the correct consistency.

During masonry work, the mixture must be constantly stirred, as it tends to separate.

If you need to get a plastic solution, you will have to add lime to the mixture.

It can be used in two ways:

- in the form of dry ground slaked lime;

- in the form of prepared lime milk.

Lime milk is prepared as follows: slaked lime is diluted with water to the consistency of thick milk and filtered through a sieve. Then the solution is closed with this silence.

By following the technology and the ratio of components, it is not difficult to obtain a high-quality masonry mixture.

Masonry mortar is used to secure the bricks together. When such a solution hardens, a strong, durable structure is obtained.

But the strength of the structure itself depends on the brand of the solution - the higher it is (that is, the solution can withstand a higher compressive load) - the stronger and more durable the resulting structure.

Preface

Preface

1 DEVELOPED by the State Central Research and Design Institute for Complex Problems of Building Structures and Structures named after V.A. Kucherenko (TsNIISK named after V.A. Kucherenko), Research, Design and Technological Institute of Concrete and Reinforced Concrete ( NIIZHB), with the participation of JSC "Experienced Rosconitstroy" of the Russian Federation

INTRODUCED by the State Construction Committee of Russia

2 ADOPTED by the Interstate Scientific and Technical Commission for Standardization, Technical Regulation and Certification in Construction (MNTKS) on November 12, 1998.

Voted for acceptance

| State name | Name of the state construction management body |

| Republic of Armenia | Ministry of Urban Development of the Republic of Armenia |

| The Republic of Kazakhstan | Committee on Housing and Construction Policy under the Ministry of Energy, Industry and Trade of the Republic of Kazakhstan |

| Republic of Kyrgyzstan | State Inspectorate for Architecture and Construction under the Government of the Kyrgyz Republic |

| The Republic of Moldova | Ministry of Territorial Development, Construction and Communal Services of the Republic of Moldova |

| Russian Federation | Gosstroy of Russia |

| The Republic of Tajikistan | State Construction Committee of the Republic of Tajikistan |

| The Republic of Uzbekistan | State Committee for Architecture and Construction of the Republic of Uzbekistan |

3 INSTEAD GOST 28013-89

4 ENTERED INTO EFFECT on July 1, 1999 as a state standard of the Russian Federation by Decree of the State Construction Committee of Russia dated November 29, 1998 N 30

5 EDITION (July 2020), with Amendment No. 1 (IUS 11-2002)

Information about changes to this standard is published in the annual information index “National Standards”, and the text of changes and amendments is published in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly information index “National Standards”. Relevant information, notices and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet (www.gost.ru)

Cost of mixtures

The total price of factory mixtures depends on:

- the name of the manufacturer;

- the presence of expensive additives;

- strength grades;

- degree of sand purification;

- size of wholesale purchase;

- region and delivery distance from the warehouse.

Price of the most popular ready-made cement-sand mixtures on the Russian market in Moscow and the Moscow region

| Blend name | Bag weight, kg | Price per bag, rubles |

| Polygran M150 | 25 | 70 |

| BAG M150 universal | 50 | 160 |

| Magma M150 universal | 30 | 140 |

| Putty Classic cement plaster | 25 | 170 |

| Knauf Sockelputz | 25 | 240 |

| Knauf Grünband | 25 | 280 |

| Betonite M150 | 50 | 160 |

| EK TT 30 | 25 | 220 |

| Quartz M200 dry masonry | 50 | 170 |

| Petrolit M300 | 25 | 90 |

| Real TsPS M100 | 25 | 65 |

At large construction sites, mixtures are often ordered in bulk form or in the form of solutions. The cost of a dry CSP ordered in this way will be 2500-3000 rubles per ton, a ready-made solution - 3500-4500 per cubic meter.

The cheapest and most labor-intensive option would be to make it yourself. For example, for 1 m3 of M150 masonry mortar you will need 8 bags of M400 cement, 50 kg each, costing 200 rubles and at least 1.1 m3 of river or washed quarry sand costing 1000 per cubic meter. The total consumption is 2700 rubles per 1 m3 of the finished composition or 2000-2200 kg of dry mixture.

Scope of application

Cement-sand mixtures are used for many different jobs, the main ones being plastering, laying bricks or cinder blocks, and screeding floors. The ratio of components in a particular material greatly depends on the permissible scope of its application indicated on the packaging and the strength grade:

1. Cement-sand plaster mixtures for interior work usually contain a small amount of cement, lime additives and are graded no higher than M100. Especially fine and homogeneous sand is selected for them.

2. Universal mixtures are suitable for masonry, internal and external plaster, and to a limited extent for screed. The cement content in them is average; various plasticizers are often added. A typical brand is M150.

3. Masonry mixtures are suitable for the construction of mid-rise brick buildings, floor screeds for covering, and external plastering for protection against high humidity. They may have a high cement content, hydrophobic, anti-shrink, frost-resistant additives, and plasticizers. A popular brand on sale is M200.

4. M300 and M400 are used mainly in the construction of multi-storey buildings, and also as DSP for high-strength floor screed without subsequent coating. They contain a high amount of M500 or M600 cement, plasticizers and reinforcing fiber. Limited use of such materials instead of concrete is acceptable.

This Personal Data Privacy Policy (hereinafter referred to as the Privacy Policy) applies to all information that the Internet site located on the domain name www.site can receive about the User while using the site.

1. DEFINITION OF TERMS

1.1 The following terms are used in this Privacy Policy:

1.1.1. “Site Administration website (hereinafter referred to as the Site Administration)”, authorized employees acting on behalf of TechnoTorg-Beton LLC, who organize and (or) carry out the processing of personal data, and also determine the purposes of processing personal data, the composition of personal data to be processed , actions (operations) performed with personal data.

1.1.2. “Personal data” - any information relating to a directly or indirectly identified or identifiable individual (subject of personal data).

1.1.3. “Processing of personal data” - any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data.

1.1.4. “Confidentiality of personal data” is a requirement for the Site Administration to comply with to prevent their dissemination without the consent of the subject of personal data or the presence of another legal basis.

1.1.5. “User of the site site (hereinafter referred to as the User)” is a person who has access to the Site via the Internet and uses the site site.

1.1.6. “Cookies” are a small piece of data sent by a web server and stored on the user’s computer, which a web client or web browser sends to the web server each time in an HTTP request when an attempt is made to open a page on the corresponding site.

1.1.7. “IP address” is a unique network address of a node in a computer network built using the IP protocol.

2. GENERAL PROVISIONS

2.1. The User's use of the site means acceptance of this Privacy Policy and the terms of processing of the User's personal data.

2.2. In case of disagreement with the terms of the Privacy Policy, the User must stop using the site.

2.3. This Privacy Policy applies only to the website. The website does not control and is not responsible for third party websites that the User can access via links available on the website.

2.4. The site administration does not verify the accuracy of the personal data provided by the Site User.

3. SCOPE OF THE PRIVACY POLICY

3.1. This Privacy Policy establishes the obligations of the Site Administration to non-disclose and ensure a regime for protecting the confidentiality of personal data that the User provides at the request of the Site Administration when filling out feedback forms, applications on the site, as well as generating reviews on the quality of services.

3.2. Personal data permitted for processing under this Privacy Policy is provided by the User by filling out forms on the website and includes the following information:

3.2.1. last name, first name, patronymic of the User;

3.2.2. User's contact phone number;

3.2.3. email address (e-mail);

3.2.4. city and country of residence;

3.2.5. Website address.

3.3 The website collects statistics about the IP addresses of its visitors. This information is used to identify and resolve technical problems, as well as to monitor the legality of use of the site content.

3.4. Any other personal information not specified above (history of navigation on site pages, browsers and operating systems used, etc.) is subject to secure storage and non-distribution, except for the cases provided for in paragraphs. 5.2. and 5.3. of this Privacy Policy.

4. PURPOSES OF COLLECTING USER’S PERSONAL INFORMATION

4.1. The User’s personal data may be used by the Site Administration for the purposes of:

4.1.1. Providing consultations;

4.1.2. Establishing feedback with the User, including sending notifications, requests regarding the use of the site, provision of services, processing requests and applications from the User;

4.1.3. Determining the location of the User to ensure security and prevent fraud;

4.1.4. Providing the User with effective customer and technical support if problems arise related to the use of previously developed sites;

4.1.5. Providing the User, with his consent, with service updates, special offers, pricing information, newsletters and other information on behalf of the site or on behalf of the site’s partners;

5. METHODS AND TERMS OF PROCESSING PERSONAL INFORMATION

5.1. The processing of the User's personal data is carried out without a time limit, in any legal way, including in personal data information systems using automation tools or without the use of such tools.

5.2. The User agrees that the Site Administration has the right to transfer personal data to third parties solely for the purpose of fulfilling the User’s request made on the site.

5.3. The User's personal data may be transferred to authorized government bodies of the Russian Federation only on the grounds and in the manner established by the legislation of the Russian Federation.

5.4. In case of loss or disclosure of personal data, the Site Administration informs the User about the loss or disclosure of personal data.

5.5. The site administration takes the necessary organizational and technical measures to protect the User’s personal information from unauthorized or accidental access, destruction, modification, blocking, copying, distribution, as well as from other unlawful actions of third parties.

5.6. The site administration, together with the User, takes all necessary measures to prevent losses or other negative consequences caused by the loss or disclosure of the User’s personal data.

6. OBLIGATIONS OF THE PARTIES

6.1. The user is obliged:

6.1.1. Provide information about personal data necessary to use the site;

6.1.2. Update, supplement the provided information about personal data if this information changes.

6.2. The site administration is obliged to:

6.2.1. Use the information received solely for the purposes specified in clause 4 of this Privacy Policy.

6.2.2. Ensure that confidential information is kept secret, not disclosed without the prior written permission of the User, and also not sell, exchange, publish, or disclose in other possible ways the transferred personal data of the User, with the exception of paragraphs. 5.2. and 5.3. of this Privacy Policy.

6.2.3. Take precautions to protect the confidentiality of the User's personal data in accordance with the procedure usually used to protect this type of information in existing business transactions.

6.2.4. Block personal data relating to the relevant User from the moment of application or request from the User or his legal representative or the authorized body for the protection of the rights of personal data subjects for the period of verification, in the event of detection of unreliable personal data or unlawful actions.

7. RESPONSIBILITY OF THE PARTIES

7.1. The site administration, which has not fulfilled its obligations, bears responsibility in connection with the unlawful use of personal data, in accordance with the legislation of the Russian Federation, except for the cases provided for in paragraphs. 5.2., 5.3. and 7.2. of this Privacy Policy.

7.2. In case of loss or disclosure of Confidential Information, the Site Administration is not responsible if this confidential information: 8.2. The recipient of the claim within 30 calendar days from the date of receipt of the claim notifies the claimant in writing of the results of consideration of the claim.

8.3. If a general agreement is not reached, the dispute will be referred to a judicial authority in accordance with the current legislation of the Russian Federation.

8.4. The current legislation of the Russian Federation applies to this Privacy Policy and the relationship between the User and the Site Administration.

9. ADDITIONAL TERMS

9.1. The site administration has the right to make changes to this Privacy Policy without the consent of the User.

9.2. The new Privacy Policy comes into force from the moment it is posted on the website, unless otherwise provided by the new edition of the Privacy Policy.

9.3. All suggestions or questions regarding this Privacy Policy should be reported through the "" section.

Each M 50 solution has its own characteristics. Some of them are used to create brickwork, others - for stone. Cement-lime mortars grade 50 are used for brick throughout Russia, and Nizhny Novgorod is no exception. Theoretically, every builder can make such a solution on his own, but in practice, maintaining the proportions is very important. Therefore, to obtain high-quality M 50, it is better to purchase it ready-made from a specialized enterprise in Nizhny Novgorod.

APPENDIX A (for reference). List of regulatory documents

APPENDIX A (for reference)

GOST 4.233-86 SPKP. Construction. Construction solutions. Nomenclature of indicators

GOST 125-79 Gypsum binders. Specifications

GOST 2226-2013 Bags made of paper and combined materials. General technical conditions

GOST 2642.5-2016 Refractories and refractory raw materials. Methods for determining iron (III) oxide

GOST 2642.11-97 Refractories and refractory raw materials. Methods for determining potassium and sodium oxides

GOST 3594.4-77 Molding clays. Methods for determining sulfur content

GOST 5578-94 Crushed stone and sand from ferrous and non-ferrous metallurgy slags for concrete. Specifications

GOST 5802-86 Construction mortars. Test methods

GOST 8735-88 Sand for construction work. Test methods

GOST 8736-2014 Sand for construction work. Specifications

GOST 9179-77 Construction lime. Specifications

GOST 10178-85 Portland cement and Portland slag cement. Specifications

GOST 10181-2014 Concrete mixtures. Test methods

GOST 10354-82 Polyethylene film. Specifications

GOST 18481-81 Hydrometers and glass cylinders. Specifications

GOST 21216-2014

GOST 21216-2014 Clay raw materials. Test methods

GOST 22266-2013 Sulfate-resistant cements. Specifications

GOST 23732-2011 Water for concrete and mortars. Specifications

GOST 24211-2008 Additives for concrete and mortars. General technical conditions

GOST 25328-82 Cement for mortars. Specifications

GOST 25592-91 Ash and slag mixtures from thermal power plants for concrete. Specifications

GOST 25818-2017 Fly ash from thermal power plants for concrete. Specifications

GOST 25820-2000 Lightweight concrete. Specifications

GOST 26633-2015 Heavy and fine-grained concrete. Specifications

GOST 26644-85 Crushed stone and sand from thermal power plant slag for concrete. Specifications

GOST 30108-94 Construction materials and products. Determination of specific effective activity of natural radionuclides

GOST 30459-2008 Additives for concrete. Methods for determining effectiveness

SNiP II-3-79* Construction heating engineering

APPENDIX B (mandatory). Clay for mortars. Technical requirements

APPENDIX B (required)

These technical requirements apply to clay intended for the preparation of mortars.

B.1 Technical requirements for clay

B.1.3 The content of chemical components by weight of dry clay should not be more than %:

- sulfates and sulfides in terms of - 1;

- sulfide sulfur in terms of - 0.3;

- mica - 3;

- soluble salts (causing efflorescence and efflorescence):

total iron oxides - 14;

the sum of potassium and sodium oxides is 7.

B.1.4 Clay should not contain organic impurities in quantities that impart a dark color.

Proportions for preparing mortars

Many people think that the M400 or M500 brand is an indication of what proportion should be followed to prepare the mixture. This is wrong. The number indicates that the cement can withstand a load of 400 or 500 kg/cm2, respectively. How to dilute cement?

The tables of the Instructions for the preparation and use of mortars CH 290-74 indicate strictly regulated proportions.

So solutions are divided into:

- Plaster mortars: grades M10, M25, M50;

- Masonry mortars: grades M50, M75, M100, M125, M150, M200;

- for screed: grades M150, M200.

- Mix water with binder to obtain cement laitance, to which sand is added.

- The second option is preferable: first mix cement with sand, and then add water. This guarantees the homogeneity of the resulting cement mass and the quality of construction work.

When preparing a cement-lime or cement-clay mortar, first the lime (clay) dough is diluted with water to the consistency of milk and passed through a sieve with 10x10 mm cells. Then add it to the already mixed mixture of sand and binder.

For plastering work, clean river sand is used; quarry sand can also be used for masonry. Before use, the sand is sifted through a sieve with 10x10 mm cells. Often in individual construction, old armored mesh from a bed is used for these purposes.

The amount of water is determined during the production of the mixture, judging by the consistency of the mixture.

To mix the solutions manually, use a shovel or a construction mixer. But it is still better to purchase an electric concrete mixer for large volumes of construction work. To deliver the solution, use ordinary buckets, stretchers or a wheelbarrow. Don't forget about gloves and safety glasses.

One of the most popular mortars based on cement, additives and sand is M50. It is used in almost all construction work related to the construction of walls, the preparation of horizontal foundations (screeds), and the repair of cracks, irregularities and other defects. It is produced in accordance with GOST 28013-98 and delivered to consumers completely ready for use in special machines (automatic mixers).