The strength of a concrete balcony slab determines the safety (and sometimes even the life) of not only the apartment occupants themselves, but also people passing by the building. Therefore, it is necessary to monitor the condition of this base and promptly eliminate any damage that has appeared on it over time. In addition, repaired chips and cracks will extend the “life” of the balcony and protect you from many undesirable consequences.

Negative factors affecting the service life of a balcony slab

Over time, a balcony slab loses its structural strength due to natural “aging”, as well as all those factors that have a negative destructive effect on it. This is, first of all:

- Water penetrating into the structure when the outer waterproofing layer is damaged. It causes corrosive “corrosion” of the reinforcing frame, and numerous cycles of freezing/thawing also contribute to the process of destruction of the concrete base.

- Ice and snow (if not regularly removed from the surface of the slab) increase the weight load, which negatively affects the service life.

- Sudden changes in ambient temperatures.

Important! Glazing balconies does not solve the problem, but only aggravates it, since the use of heavy metal structures significantly increases the load on the slab and can lead to its premature failure.

Reinforced concrete floor slabs

The use of reinforced concrete slabs in the floors of residential buildings and other structures not only reduces the cost, but also speeds up the process of assembling the building frame.

Reinforced concrete products can be classified on different grounds. This includes both the type of concrete and the thickness of the finished structure. In this case, the determining factor most often becomes the division according to the presence/absence of voids in the body of the slab. For example, class 10.5 slabs do not have them, so they are suitable for installation as floors.

Modern industry produces the following types of slabs:

- solid – “classic” reinforced concrete; able to withstand significant loads;

- hollow – perform the function of interfloor ceilings; the presence of voids increases the thermal and sound insulation of the material by an order of magnitude compared to the previous category;

- ribbed - the optimal choice for installing roofs of workshops and hangars; any large unheated buildings;

- monolithic - solid, but using metal reinforcement; due to the ability to withstand increased loads, they are ideal for multi-story monolithic buildings;

- lightweight - having a multi-hollow structure and characterized by minimal weight; Suitable for buildings with weak foundations.

Supply of reinforced concrete floor slabs is one of the priorities of Zhelezobeton Resurs LLC. The company has a wide range of products of all sizes.

All supplied products are distinguished by high performance characteristics. Reinforced concrete floor slabs and channel bottoms combine the advantages of prestressed steel reinforcement and heavy concrete. It is from these materials that reinforced concrete products are produced in accordance with GOST. Such reinforced concrete products are universal, suitable for both above-ground and underground methods of laying channels, and perfectly adapt to the peculiarities of the construction of objects for various purposes. This can be confirmed by the P10.5 slab, which was originally developed for the construction of tunnels for heating mains and heat pipelines. Due to its versatility, this brand of slabs has become widely used in construction.

The “advantages” of floor slabs include: low cost; sufficient heat and sound insulation; simple and quick installation; long and reliable service.

There are also features with a minus sign: the need for lifting equipment for delivery and installation; restriction on use in wooden houses.

Obviously, there are fewer disadvantages, which is why reinforced concrete slabs are a popular material today in the construction of multi-story buildings.

"Reinforced Concrete Resource" supplies floor slabs in any batches. It is possible to deliver concrete products directly to the construction site.

- By choosing our company, you find a reliable supplier for whom reputation is on the list of priority qualities.

- All manufactured products comply with all modern quality standards today.

- The efficiency of product delivery meets customer requirements as much as possible.

The cost of floor slabs 10.5 and the terms of sale and delivery can be clarified by calling the telephone numbers listed on the website or through the online application form. The sales manager will answer all your questions and advise on all the nuances. We make cooperation with us as convenient as possible for our clients. Call us!

- By choosing our company, you find a reliable supplier for whom reputation is on the list of priority qualities.

- All manufactured products comply with all modern quality standards today.

- The efficiency of product delivery meets the Customer’s requirements as much as possible.

You can discuss the cost of the necessary products and conditions with the sales manager by calling or sending a request from the website.

Checkout

| Brand | Size | Weight 1 piece/t. | volume, m3 | price, rub. |

| PT 300-90-10 | 2990*880*100 | 0,66 | 0,27 | 3400 |

| PT 300-120-12 | 2990*1180*120 | 1.05 | 0,104 | 1300 |

| PT 300-150-12 | 2990*1480*120 | 1,33 | 0,132 | 1500 |

| PT 300-180-14 | 2990*1780*140 | 1,88 | 0,186 | 2200 |

| PT 300-210-14 | 2990*2080*140 | 2,18 | 0,87 | 11200 |

| PT 300-240-14 | 2990*2380*140 | 2,5 | * | 14200 |

| PT 300-240-20 | 2990*2380*200 | 3,55 | * | 18400 |

| PT 300-240-25 | 2990*2380*250 | 4,45 | 1,78 | 21612 |

| PB 108-10-4.5 | 10780*995*220 | 4,12 | 1,65 | 32900 |

| PC 19-12-8 | 1880*1190*220 | 0,72 | 0,49 | 3700 |

| PC 19-15-8 | 1880*1490*220 | 0,95 | 0,62 | 4500 |

| PC 20-12-8 | 1980*1190*220 | 0,76 | 0,52 | 3700 |

| PC 20-15-8 | 1980*1490*220 | 1 | 0,65 | 4500 |

| PC 21-12-8 | 2080*1190*220 | 0,80 | 0,54 | 3700 |

| PC 21-15-8 | 2080*1490*220 | 1,05 | 0,68 | 4500 |

| PC 22-12-8 | 2180*1190*220 | 0,83 | 0,57 | 3700 |

| PC 22-15-8 | 2180*1490*220 | 1,10 | 0,71 | 4500 |

| PC 23-12-8 | 2280*1190*220 | 0,87 | 0,60 | 3700 |

| PC 23-15-8 | 2280*1490*220 | 1,15 | 0,75 | 4500 |

| PC 24-12-8 | 2380*1190*220 | 0,91 | 0,62 | 3700 |

| PC 24-15-8 | 2380*1490*220 | 1,20 | 0,78 | 4500 |

| PC 24-18-8 | 2380*1790*220 | 1,32 | 0,94 | 4500 |

| PC 25-12-8 | 2480*1190*220 | 0,94 | 0,65 | 3900 |

| PC 25-15-8 | 2480*1490*220 | 1,23 | 0,81 | 4900 |

| PC 25-18-8 | 2480*1790*220 | 1,38 | 0,98 | 7900 |

| PC 26-12-8 | 2580*1190*220 | 0,97 | 0,68 | 3900 |

| PC 26-15-8 | 2580*1490*220 | 0,97 | 0,68 | 3900 |

| PC 26-18-8 | 2480*1790*220 | 1,43 | 1,02 | 7800 |

| PC 27-12-8 | 2680*1190*220 | 1,01 | 0,70 | 3900 |

| PC 27-15-8 | 2680*1490*220 | 1,33 | 0,88 | 4900 |

| PC 27-18-8 | 2680*1790*220 | 1,49 | 1,06 | 7700 |

| PC 28-12-8 | 2780*1190*220 | 1,02 | 0,73 | 4200 |

| PC 28-15-8 | 2780*1490*220 | 1,34 | 0,91 | 5300 |

| PC 28-18-8 | 2780*1790*220 | 1,54 | 1,09 | 7800 |

| PC 29-12-8 | 2880*1190*220 | 1,05 | 0,75 | 4200 |

| PC 29-15-8 | 2880*1490*220 | 1,39 | 0,94 | 5300 |

| PC 29-18-8 | 2880*1790*220 | 1,60 | 1,13 | 7800 |

| PC 30-10-8 | 2980*990*220 | 0,90 | 0,65 | 4200 |

| PC 30-12-8 | 2980*1190*220 | 1,09 | 0,78 | 4300 |

| PC 30-15-8 | 2380*1490*220 | 1,44 | 0,98 | 5300 |

| PC 30-18-8 | 2980*1790*220 | 1,65 | 1,17 | 7800 |

| PC 31-10-8 | 3080*990*220 | 0,93 | 0,67 | 4300 |

| PC 31-12-8 | 3080*1190*220 | 1,13 | 0,81 | 4300 |

| PC 31-15-8 | 3080*1490*220 | 1,45 | 1,01 | 5700 |

| PC 31-18-8 | 3080*1790*220 | 1,71 | 1,21 | 7800 |

| PC 32-10-8 | 3180*990*220 | 0,96 | 0,69 | 4300 |

| PC 32-12-8 | 3180*1190*220 | 1,16 | 0,82 | 4500 |

| PC 32-15-8 | 3180*1490*220 | 1,53 | 1,04 | 5700 |

| PC 32-18-8 | 3180*1790*220 | 1,76 | 1,25 | 7800 |

| PC 33-10-8 | 3280*990*220 | 0,99 | 0,71 | 4300 |

| PC 33-12-8 | 3280*1190*220 | 1,20 | 0,86 | 4500 |

| PC 33-15-8 | 3280*1490*220 | 1,58 | 1,08 | 5700 |

| PC 33-18-8 | 3280*1790*220 | 1,82 | 1,29 | 7800 |

| PC 34-10-8 | 3380*990*220 | 1,02 | 0,74 | 4500 |

| PC 34-12-8 | 3380*1190*220 | 1,26 | 0,88 | 4800 |

| PC 34-15-8 | 3380*1490*220 | 1,65 | 1,11 | 6200 |

| PC 34-18-8 | 3380*1790*220 | 1,87 | 1,33 | 7800 |

| PC 35-10-8 | 3480*990*220 | 1,05 | 0,76 | 4500 |

| PC 35-12-8 | 3480*1190*220 | 1,29 | 0,91 | 4800 |

| PC 35-15-8 | 3480*1490*220 | 1,70 | 1,14 | 6200 |

| PC 35-18-8 | 3480*1790*220 | 1,93 | 1,37 | 7900 |

| PC 36-10-8 | 3580*990*220 | 1,08 | 0,78 | 4500 |

| PC 36-12-8 | 3580*1190*220 | 1,33 | 0,94 | 4800 |

| PC 36-15-8 | 3580*1490*220 | 1,75 | 1,17 | 6200 |

| PC 36-18-8 | 3580*1790*220 | 1,98 | 1,41 | 7800 |

| PC 37-10-8 | 3680*990*220 | 1,11 | 0,80 | 4800 |

| PC 37-12-8 | 3680*1190*220 | 1,35 | 0,96 | 5100 |

| PC 37-15-8 | 3680*1490*220 | 1,78 | 1,21 | 7200 |

| PC 37-18-8 | 3680*1790*220 | 2,02 | 1,45 | 8000 |

| PC 38-10-8 | 3780*990*220 | 1,14 | 0,82 | 4800 |

| PC 38-12-8 | 3780*1190*220 | 1,38 | 0,99 | 5100 |

| PC 38-15-8 | 3780*1490*220 | 1,83 | 1,24 | 7100 |

| PC 38-18-8 | 3780*1790*220 | 2,07 | 1,49 | 7900 |

| PC 39-10-8 | 3880*990*220 | 1,17 | 0,88 | 4800 |

| PC 39-12-8 | 3880*1190*220 | 1,42 | 1,02 | 5100 |

| PC 39-15-8 | 3880*1490*220 | 1,88 | 1,27 | 7100 |

| PC 39-18-8 | 3880*1790*220 | 2,13 | 1,53 | 7900 |

| PC 40-10-8 | 3980*990*220 | 1,20 | 0,87 | 4800 |

| PC 40-12-8 | 3980*1190*220 | 1,46 | 1,04 | 5100 |

| PC 40-15-8 | 3980*1490*220 | 1,92 | 1,30 | 7100 |

| PC 40-18-8 | 3980*1790*220 | 2,18 | 1,57 | 7900 |

| PC 41-10-8 | 4080*990*220 | 1,23 | 0,89 | 4800 |

| PC 41-12-8 | 4080*1190*220 | 1,49 | 1,07 | 5100 |

| PC 41-15-8 | 4080*1490*220 | 1,97 | 1,34 | 7100 |

| PC 41-18-8 | 4080*1790*220 | 2,24 | 1,61 | 7900 |

| PC 42-10-8 | 4180*990*220 | 1,26 | 0,91 | 4800 |

| PC 42-12-8 | 4180*1190*220 | 1,53 | 1,09 | 5100 |

| PC 42-15-8 | 4180*1490*220 | 2,02 | 1,37 | 7100 |

| PC 42-18-8 | 4180*1790*220 | 2,29 | 1,65 | 7900 |

| PC 43-10-8 | 4280*990*220 | 1,24 | 0,93 | 5100 |

| PC 43-12-8 | 4280*1190*220 | 1,53 | 1,12 | 5400 |

| PC 43-15-8 | 4280*1490*220 | 2,01 | 1,40 | 7200 |

| PC 43-18-8 | 4280*1790*220 | 2,29 | 1,69 | 8500 |

| PC 44-10-8 | 4330*990*220 | 1,27 | 0,95 | 5100 |

| PC 44-12-8 | 4380*1190*220 | 1,56 | 1,15 | 5400 |

| PC 44-15-8 | 4380*1490*220 | 2,05 | 1,44 | 7200 |

| PC 44-18-8 | 4380*1790*220 | 2,35 | 1,72 | 8500 |

| PC 45-10-8 | 4480*990*220 | 1,30 | 0,98 | 5100 |

| PC 45-12-8 | 4480*1190*220 | 1,60 | 1,17 | 5400 |

| PC 45-15-8 | 4480*1490*220 | 2,10 | 1,47 | 7200 |

| PC 45-18-8 | 4480*1790*220 | 2,40 | 1,76 | 8500 |

| PC 46-10-8 | 4580*990*220 | 1,37 | 1,00 | 5500 |

| PC 46-12-8 | 4580*1190*220 | 1,66 | 1,20 | 5900 |

| PC 46-15-8 | 4580*1490*220 | 2,20 | 1,50 | 7500 |

| PC 46-18-8 | 4580*1790*220 | 2,49 | 1,80 | 9000 |

| PC 47-10-8 | 4680*990*220 | 1,40 | 1,02 | 5500 |

| PC 47-12-8 | 4680*1190*220 | 1,69 | 1,23 | 5900 |

| PC 47-15-8 | 4680*1490*220 | 2,25 | 1,53 | 7500 |

| PC 47-18-8 | 4680*1790*220 | 2,55 | 1,84 | 9000 |

| PC 48-10-8 | 4780*990*220 | 1,43 | 1,04 | 5500 |

| PC 48-12-8 | 4780*1190*220 | 1,73 | 1,25 | 5900 |

| PC 48-15-8 | 4780*1490*220 | 2,30 | 1,57 | 7500 |

| PC 48-18-8 | 4780*1790*220 | 2,60 | 1,88 | 9000 |

| PC 49-10-8 | 4880*990*220 | 1,47 | 1,06 | 5800 |

| PC 49-12-8 | 4880*1190*220 | 1,87 | 1,28 | 6100 |

| PC 49-15-8 | 4880*1490*220 | 2,33 | 1,60 | 7800 |

| PC 49-18-8 | 4880*1790*220 | 2,67 | 1,92 | 9600 |

| PC 50-10-8 | 4980*990*220 | 1,50 | 1,09 | 5800 |

| PC 50-12-8 | 4980*1190*220 | 1,91 | 1,30 | 6100 |

| PC 50-15-8 | 4980*1490*220 | 2,38 | 1,63 | 7800 |

| PC 50-18-8 | 4980*1790*220 | 2,73 | 1,96 | 9700 |

| PC 51-10-8 | 5080*990*220 | 1,53 | 1,11 | 5800 |

| PC 51-12-8 | 5080*1190*220 | 1,95 | 1,33 | 6100 |

| PC 51-15-8 | 5080*1490*220 | 2,43 | 1,67 | 7800 |

| PC 51-18-8 | 5080*1790*220 | 2,78 | 2,00 | 9800 |

| PC 52-10-8 | 5180*990*220 | 1,54 | 1,13 | 6000 |

| PC 52-12-8 | 5180*1190*220 | 1,88 | 1,36 | 6200 |

| PC 52-15-8 | 5180*1490*220 | 2,48 | 1,70 | 8000 |

| PC 52-18-8 | 5180*1790*220 | 2,82 | 2,04 | 10200 |

| PC 53-10-8 | 5280*990*220 | 1,57 | 1,15 | 6000 |

| PC 53-12-8 | 5280*1190*220 | 1,91 | 1,38 | 6200 |

| PC 53-15-8 | 5280*1490*220 | 2,53 | 1,73 | 8000 |

| PC 53-18-8 | 5280*1790*220 | 2,88 | 2,08 | 10100 |

| PC 54-10-8 | 5380*990*220 | 1,60 | 1,17 | 6000 |

| PC 54-12-8 | 5380*1190*220 | 1,95 | 1,41 | 6200 |

| PC 54-15-8 | 5380*1490*220 | 2,58 | 1,76 | 8000 |

| PC 54-18-8 | 5380*1790*220 | 2,93 | 2,12 | 10100 |

| PC 55-10-8 | 5480*990*220 | 1,62 | 1,20 | 6300 |

| PC 55-12-8 | 5480*1190*220 | 1,98 | 1,42 | 6500 |

| PC 55-15-8 | 5480*1490*220 | 2,61 | 1,80 | 8300 |

| PC 55-18-8 | 5480*1790*220 | 2,97 | 2,16 | 10700 |

| PC 56-10-8 | 5580*990*220 | 1,65 | 1,22 | 6300 |

| PC 56-12-8 | 5580*1190*220 | 2,01 | 1,46 | 6590 |

| PC 56-15-8 | 5580*1490*220 | 2,65 | 1,83 | 8300 |

| PC 56-18-8 | 5580*1790*220 | 3,03 | 2,20 | 10700 |

| PC 57-10-8 | 5680*990*220 | 1,68 | 1,24 | 6400 |

| PC 57-12-8 | 5680*1190*220 | 2,05 | 1,49 | 6500 |

| PC 57-15-8 | 5680*1490*220 | 2,70 | 1,86 | 8300 |

| PC 57-18-8 | 5680*1790*220 | 3,08 | 2,24 | 10700 |

| PC 58-10-8 | 5780*990*220 | 1,72 | 1,26 | 6500 |

| PC 58-12-8 | 5780*1190*220 | 2,08 | 1,51 | 6800 |

| PC 58-15-8 | 5780*1490*220 | 2,76 | 1,9 | 8500 |

| PC 58-18-8 | 5780*1790*220 | 3,09 | 2,28 | 10800 |

| PC 59-10-8 | 5880*990*220 | 1,75 | 1,28 | 6500 |

| PC 59-12-8 | 5880*1190*220 | 2,11 | 1,54 | 6800 |

| PC 59-15-8 | 5880*1490*220 | 2,80 | 1,93 | 8500 |

| PC 59-18-8 | 5880*1790*220 | 3,20 | 2,32 | 10800 |

| PC 60-10-8 | 5980*990*220 | 1,78 | 1,30 | 6500 |

| PC 60-12-8 | 5980*1190*220 | 2,15 | 1,57 | 6800 |

| PC 60-15-8 | 5980*1490*220 | 2,85 | 1,96 | 8500 |

| PC 60-18-8 | 5980*1790*220 | 3,25 | 2,35 | 10800 |

| PC 61-10-8 | 6080*990*220 | 1,77 | 1,32 | 6700 |

| PC 61-12-8 | 6080*1190*220 | 2,13 | 1,59 | 7000 |

| PC 61-15-8 | 5600*1490*220 | 2,88 | 1,99 | 8800 |

| PC 61-18-8 | 6080*1790*220 | 3,29 | 2,39 | 10900 |

| PC 62-10-8 | 6180*990*220 | 1,80 | 1,35 | 6700 |

| PC 62-12-8 | 6180*1190*220 | 2,21 | 1,62 | 7000 |

| PC 62-15-8 | 5610*1490*220 | 2,93 | 2,03 | 8800 |

| PC 62-18-8 | 6180*1790*220 | 3,35 | 2,43 | 10900 |

| PC 63-10-8 | 6280*990*220 | 1,83 | 1,35 | 6700 |

| PC 63-12-8 | 6280*1190*220 | 2,25 | 1,64 | 7000 |

| PC 63-15-8 | 5620*1490*220 | 2,98 | 2,06 | 8800 |

| PC 63-18-8 | 6280*1790*220 | 3,40 | 2,47 | 10900 |

| PC 65-12-8 | 6480*1190*220 | 2,43 | 1,70 | 10200 |

| PC 65-15-8 | 6480*1490*220 | 3,30 | 2,12 | 12400 |

| PC 68-15-8 | 6780*1490*220 | 3,40 | 2,22 | 13300 |

| PC 69-15-8 | 6880*1490*220 | 3,45 | 2,25 | 13300 |

| PC 70-12-8 | 6980*1190*220 | 2,62 | 1,83 | 11000 |

Checkout

External signs indicating the need for repair work

The main signs that a concrete balcony slab needs immediate repair and restoration work are:

- rust stains appearing on the surface of concrete;

- cracks and chips;

- fallen pieces of concrete from the internal or external surface;

- exposed elements of the reinforcement frame;

- a gap formed between the balcony slab and the wall of the building.

Other types of concrete slabs

As the construction industry is constantly evolving, a large number of new materials have appeared on the market. Many of them are a combination of familiar products with each other. The most interesting types of concrete slabs, in addition to traditional ones, are:

- Concrete mosaic . It is created from marble chips and concrete using the dry pressing method. Inside there is a 4 mm reinforced mesh. The front surface of the slab is polished and smooth. and the inner one is embossed. This is necessary so that it can be glued comfortably. The product is well suited for finishing rooms and areas with high traffic. Say, clinics, shops, warehouses, etc.

- Concrete particle board. It is a mixture of wood, cement, plasticizer and mineral additives. The main application is insulation, construction of formwork, partitions and interior decorative finishing.

- Facade slabs . Produced for cladding plinths and walls. Can be single or double layer. With and without reinforcement. Can be made by molding or sawing.

- Concrete and decorative. They are mostly used to create site boundaries, instead of fences. They can have different colors and textures. At the same time they have an excellent appearance.

Types of balcony slab repairs

Depending on the extent of damage to the balcony slab, one of four main types of repairs will be required to restore its strength:

- Small. In case of shallow cracks or small chips appearing on the surface.

- Average. It will have to be done if the reinforced concrete product has significant potholes and exposed elements of the reinforcing frame are visible (but they themselves have minor corrosion damage).

- Capital. The slab has significant damage, but it is possible to restore it by installing special reinforcing elements (metal channels, profile pipes or angles) and installing a new reinforcement frame.

- Emergency. It is performed when it is necessary to completely dismantle the slab from the load-bearing wall of the building and install a new reinforced concrete product.

The first two types of restoration and repair work can be completely carried out independently. But for the rest, the involvement of qualified specialists and the use of special equipment (crane, high-rise cradle and welding equipment) will be required.

Areas of application of concrete slabs

The use of such products largely depends on their type. Typical slab sizes are 2 by 2, 4 by 4, 6 by 6. You can find other options, but these are more common than others.

Fundamental

Such slabs may differ in size and strength parameters, in accordance with the design documentation. The main purpose of the products is to create a strong and stable foundation for future construction. It is important that the material from which they are made has frost resistance, hydrophobicity and fire resistance. It is also important that the slabs are not exposed to microorganisms and small vegetation.

Installation of foundation slabs requires good surface preparation. You will first need to dig trenches or completely clear the area where you plan to make the foundation from the top layer of soil. It depends on the type of foundation.

Floors

Such products are used to create floors for multi-story buildings. They experience a lot of stress and therefore must be very reliable. Monolithic and hollow slabs are used for floors. The slabs have a flat surface and can be installed quickly and easily, even without the use of special equipment.

Coating slabs

Used to create roofs. Can be laid on beams, trusses and semi-trusses. The slabs can be monolithic or prefabricated. Such products are made of concrete with prestressed reinforcement.

Road

Slabs of this type are made specifically to make roads out of them. They are characterized by increased wear resistance. They can serve for several decades. When used in the production of reinforced reinforcement, the slabs are used for the construction of runways. They can withstand temperatures from -55°C to 40°C.

The shape of road slabs can be different:

- rectangular;

- trapezoidal;

- hexagonal;

- semi-hexagonal.

When installing road slabs, the top layer of soil is removed. The site must be completely leveled and compacted. After this, you need to create a cushion of wet sand compacted with a roller. Then the slabs are laid. Their loops are welded together, and the gaps are filled with concrete.

Sidewalk

Such slabs have a reinforced frame. They are used to create pedestrian zones in parks, squares, highways and city roads.

Wall internal

Products can be one-piece or composite. As a rule, they are made of expanded clay-aggloporite concrete. Wall ceilings can be installed in buildings of any number of floors. The slabs can be used both in construction from scratch and in the reconstruction of buildings. The voids inside the slabs can be used for communications. For the most part, they are used in industrial, office or warehouse buildings. The outer surface of the slabs is easy to finish.

External wall

The products are made in three layers. The outer layer is concrete C25/30, the middle layer is thermal insulation, the inner layer is C12/15.

Among other things, slabs can be used to create floors in industrial and residential premises. You can use both monolithic and prefabricated products. At the same time, the quality and service life of such floors will be very long.

The main mistake when repairing a balcony slab yourself

Installing a conventional sand-cement screed (using reinforcing mesh) on top of a concrete balcony base that has significant damage is a major mistake. Such “restoration” only adds excess weight, increases the load on the foundation (which already has defects) and in no way strengthens the reinforced concrete structure. Experts consider this measure purely cosmetic.

What can be done in this situation to make the slab more durable:

- We install a temporary support structure that will support the outer edge of your concrete slab. Naturally, this can only be done with the permission of the owners of the balcony located below, and only if it is in good condition and can withstand the additional load during the repair work.

- Using a hammer and chisel, remove loose parts of concrete from the surface of the slab.

- Along the entire length of the junction of the base of the balcony with the load-bearing wall, we hollow out a narrow recess.

- We attach the formwork around the perimeter of the slab.

- We install a reinforcement frame over the entire surface, which fits into the equipped gap.

- We clean the surface of the stove from dirt and dust.

- We apply a special composition (concrete contact) to it, which increases adhesion.

- We construct the screed from a mortar prepared from a special frost-resistant repair composition.

- After it has completely dried and gained the necessary strength (the time is indicated by the manufacturer on the packaging), we dismantle the formwork and temporary supporting structure.

- We apply a layer of waterproofing to the surface.

Characteristic

The reliability and durability of a well floor slab are determined by its quality characteristics. The basic rule in the production of the structure is to ensure strict compliance of the floor slab of wells with GOST requirements and technical documentation .

According to GOST 8020-90, the floor slab of a sewer well is made of heavy concrete , with a water resistance class of W, and a compressive strength class of over B22.5 (M300). The reinforcement used in the manufacture of concrete for floor slabs must be class A-I, A-III, Bp-I. The frost resistance class must be over F-100, that is, the structure must withstand more than 100 freeze-thaw cycles.

The floor slab of a sewer well, which can be ordered directly from the factory or from a construction company, can be of different shapes: round, oval, square, rectangular. The standard shape of the well is considered to be round. According to GOST, it is important to take into account that when manufacturing a well slab, its size corresponds to the diameter of the ring or the diagonal of the square. According to the standard, the diameter of well slabs can be 1.5 - 2.2 m, and their weight usually reaches 1280 kg.

Compliance of the quality of the appearance and surface of the floor slab of wells with GOST standards is also a necessary condition. Thus, slabs that have a joint on their surface are defined as category A6, and slabs without a joint are defined as category A7.

Minor repair of concrete balcony slab

If cracks have formed in the balcony slab, and you paid attention to them in a timely manner, then the repair can be successfully carried out independently. First, you need to make sure that the damage is not end-to-end. To do this, take a narrow, flat and flexible metal probe and forcefully push it into the resulting gap. If it enters the crack only to a depth of 20–30 mm, then most likely the damage to the slab is superficial, and you can easily get rid of it. What to do:

- Using improvised means (wire, thin brush, awl, etc.) and a vacuum cleaner, we clean the gap from dirt and dust.

- We treat it with a special compound (for better adhesion).

- Fill the gap with a special non-shrinking repair compound. Ready-made mixtures (one- or two-component) for its preparation are produced by both Russian (Lakhta, Vai, Consolit, SpetsRemSmes) and foreign (Basf, Mapei, Sika) manufacturers.

- After complete drying, treat the surface with waterproofing.

On a note! If you doubt the results of your own inspection of slab damage, it is better to pay for an expert assessment, which is carried out by qualified specialists using special equipment. Based on the results of the inspection, they will tell you what type of repair work needs to be carried out based on the identified defects in the concrete balcony slab.

Medium repair of a balcony slab with your own hands

If the concrete base of the balcony has potholes that have exposed the reinforcement frame (but the metal elements themselves are still in good condition), then the slab can still be “saved” from further destruction on its own. For this:

- Mechanically remove all loose concrete (down to a layer with normal strength).

- We clean the exposed parts of the reinforcement frame from rust. To do this, we first use a metal brush and then apply an anti-corrosion compound.

- We remove dirt and dust from the surface of the stove.

- We apply an adhesion-increasing compound (for example, Ceresit CD30) to areas to be repaired and exposed reinforcing bars.

- We fill potholes with a special non-shrinking repair mortar designed for structural restoration of the strength of concrete and reinforced concrete products (for example, MasterEmaco T 1100 TIX).

- After complete drying, we waterproof the entire surface of the repaired balcony slab (preferably using liquid penetrating agents).

Restoring the edges of a balcony slab

It is the edges of the concrete balcony slab that, as a rule, begin to collapse first. If they are repaired in a timely manner, further destruction of the base can be prevented and the reinforcing frame can be prevented from being exposed (with all the ensuing negative consequences). You can do this yourself, even if your balcony is at a very high altitude. The work algorithm is as follows:

- we make formwork, which consists of two boards fastened at an angle of 90ᵒ;

- we clean the damaged parts of the edges from dirt and dust;

- we treat them with concrete contact;

- using clamps we fasten the manufactured formwork to the balcony slab;

- pour sand-cement or special repair mortar into it;

- after complete hardening, remove the formwork;

- We treat the surfaces with a waterproofing compound.

Major renovation

This type of restoration of the strength characteristics of a concrete slab is practically impossible to produce independently. Therefore, in case of significant damage to the base of the balcony, you should first write a statement addressed to the chief engineer of the management company, since it is she who is responsible for the technical condition of such structures. After an expert examination (if the structure is found unsuitable for further safe use), you will receive a certificate of the appropriate form and will wait for the necessary work to overhaul the concrete slab.

Technology.

The technology for the production of reinforced concrete slabs consists of the following stages:

- The frame made of reinforcement is placed in formwork - a special form. If necessary, the rods are tensioned;

- Reinforcing bars are placed on the side rigging;

- Concrete is poured into the mold, blanks are formed;

- The resulting product is sent to a special thermal chamber, where it quickly gains design strength;

- Forms and fastenings are removed from the products, and the rods are compressed.

If technological processes were not disrupted during the production process, then the reinforced concrete slabs will be of high quality.

Arrangement of a new balcony slab “on site”

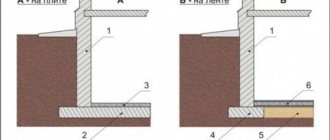

Major repairs are carried out by organizations specializing in such work. One of its options is to make a new concrete base, which is equipped as follows:

- dismantle the remains of the old balcony slab;

- load-bearing structural elements (metal consoles) are made and installed in the wall, followed by concreting;

- a channel is welded around the perimeter;

- permanent formwork made of profiled sheets is attached to the lower part of the manufactured metal structure;

- install fittings throughout the entire internal area;

- the slab is concreted with a frost-resistant solution of increased strength (based on concrete grade M500).

Emergency repairs

This type of repair involves replacing the balcony slab with a new concrete base. In theory everything is fine. In practice, it is simply impossible to carry out such work. Why? Firstly, when completely dismantling the old slab, the strength of the load-bearing wall may be compromised; and secondly, installing a new concrete base in compliance with all technological requirements (which were followed during the construction of the building) is not an easy task, and sometimes completely impossible.

Related publications: